Prefabricated building steel structure system and installation method

An installation method and technology of building steel, applied in the direction of building structure, construction, etc., can solve problems such as complex structures, and achieve good earthquake resistance, reasonable force, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

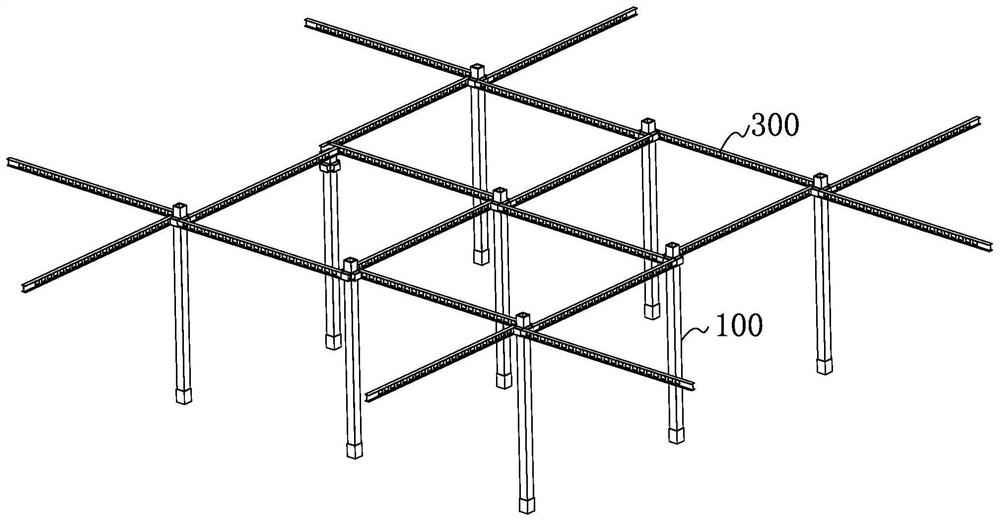

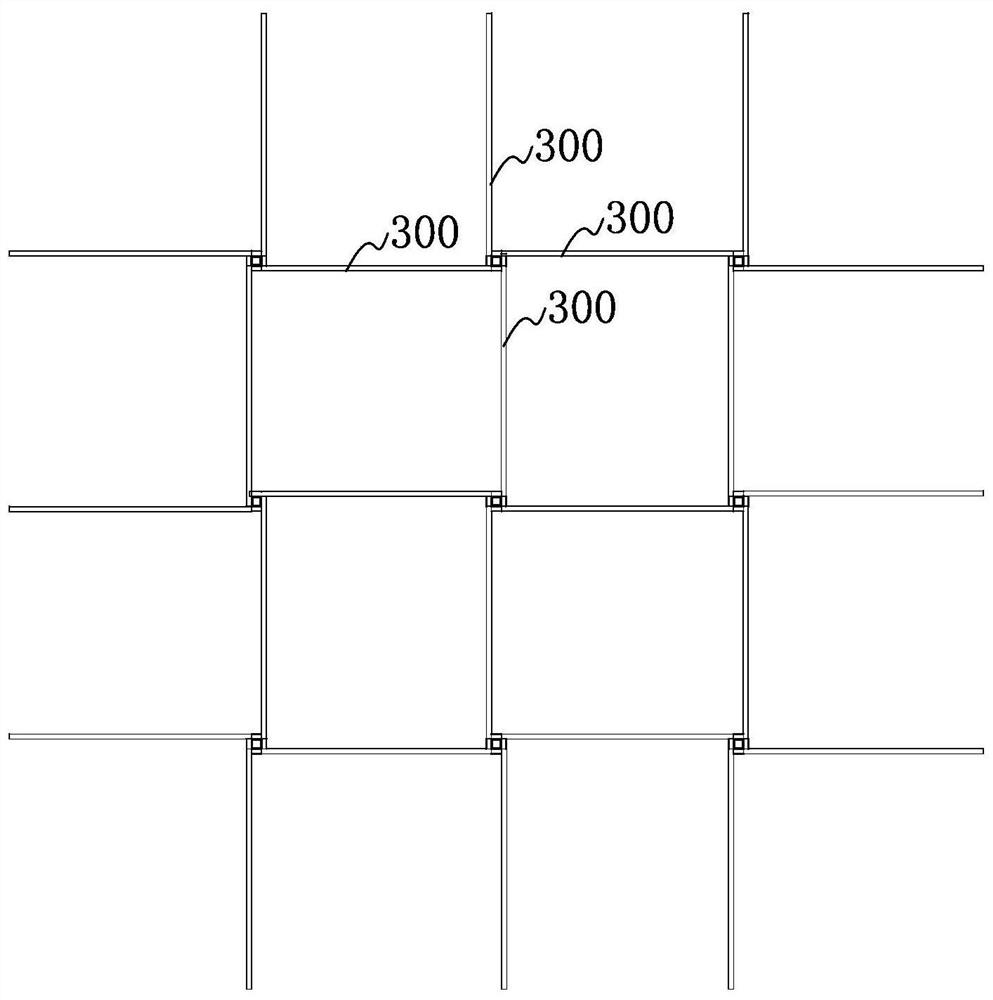

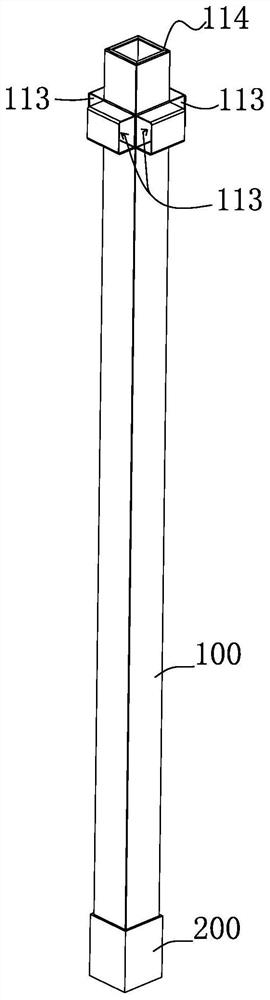

[0073] Taking the connection method of steel pipe columns and steel beams as an example to illustrate one of the implementation methods, for example, in figure 1 , a light steel structure system composed of beams and columns.

[0074] The following is attached with the manual figure 1 to the attached Figure 13 The serial, partial or global structural views in the present invention explain in detail the essence and implementation process of the present invention, and the applicant describes in detail as much as possible, but still does not rule out whether there is a detailed explanation. For this embodiment For the inappropriate and unsatisfactory wording in the document, technical personnel can understand it according to the technical common sense and knowledge in this field.

[0075] The orientation words such as up and down in this embodiment refer to the gravity coordinate system. In this embodiment, the near end and the far end are described with the reference point a...

Embodiment 2

[0097] refer to Figure 14 , in this embodiment, the position and state of the slot 113 are not perpendicular to the length direction of the steel pipe column, and are suitable for special installation positions. For example, this structure is suitable for the installation of beams with a certain slope, such as various roofs and balconies with slopes. That is to say, in the sheet metal fabrication stage of the steel strip 110 , it is enough to design the slot 113 to form a certain angle with the steel pipe column and have a certain slope structure. During the installation process, self-tapping screws can be used for auxiliary fixing to complete the installation of beams and columns.

Embodiment 3

[0099] refer to Figure 15 , for a multi-storey steel structure building, the steel pipe column 100 is pre-set in the form of matryoshka, so that the specific application of the nesting doll technology in the steel structure, specifically, the steel pipe column 100 is processed into different size series, for example In this embodiment, the steel pipe column includes an inner and outer structure, the height of the inner steel pipe column is greater than the height of the outer steel pipe column, and the inner steel pipe column is nested in the outer steel pipe column. Steel pipe column 100, nested, wherein the inner diameter of the outer steel pipe column is equivalent to the outer diameter of the inner steel pipe column, and no patch is provided at the corresponding slot position on the outer steel pipe column, and the inner steel pipe column acts as a patch role, with good compressive strength. Usually, the outer steel pipe column is used to support the floor load of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com