Turnable lightweight steel structure and precast concrete slab structure system and construction method thereof

A technology of concrete and prefabricated slabs, which is applied in the direction of building construction and construction, can solve the problems of ordinary concrete prefabricated panels, such as heavy weight, large deformation of scaffolding frame structure, and failure to meet the needs of multiple turnover, and achieve high long-term use benefits, Significant social benefits, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

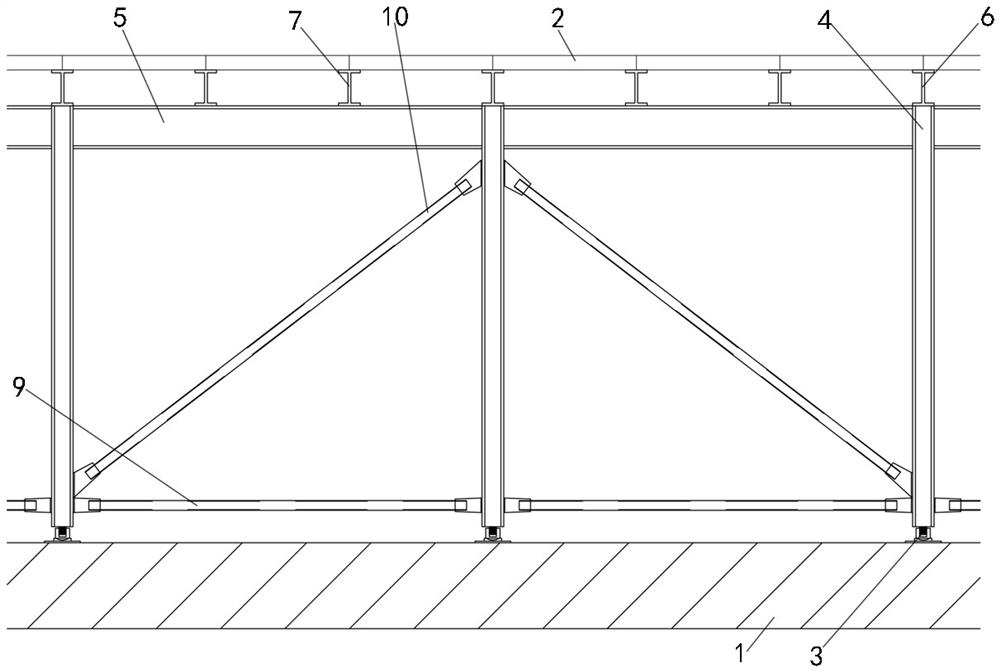

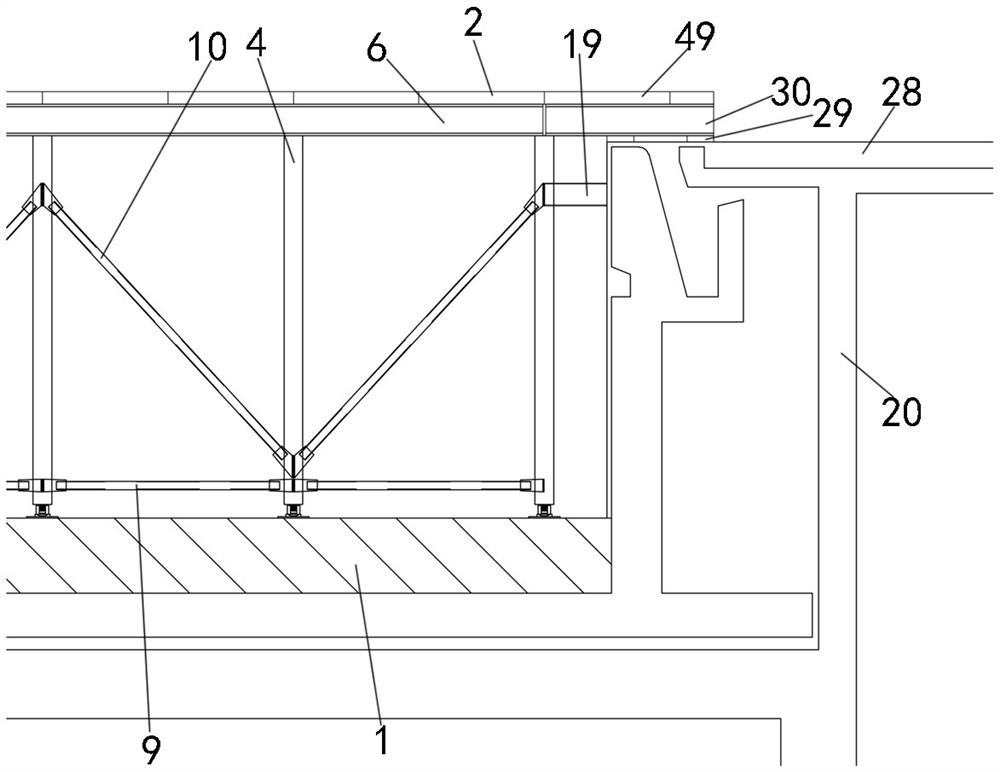

[0086] Examples see Figure 1-7 , Figure 9 As shown, a turnable lightweight steel structure and concrete prefabricated slab structure system includes a light-weight frame body that stands on the pool floor 1 within the pool wall 49 and a light-weight panel that is fixedly connected to the upper side of the light-weight frame body 2. The ground of the pool should be solid and reliable, and meet the load requirements after design calculation.

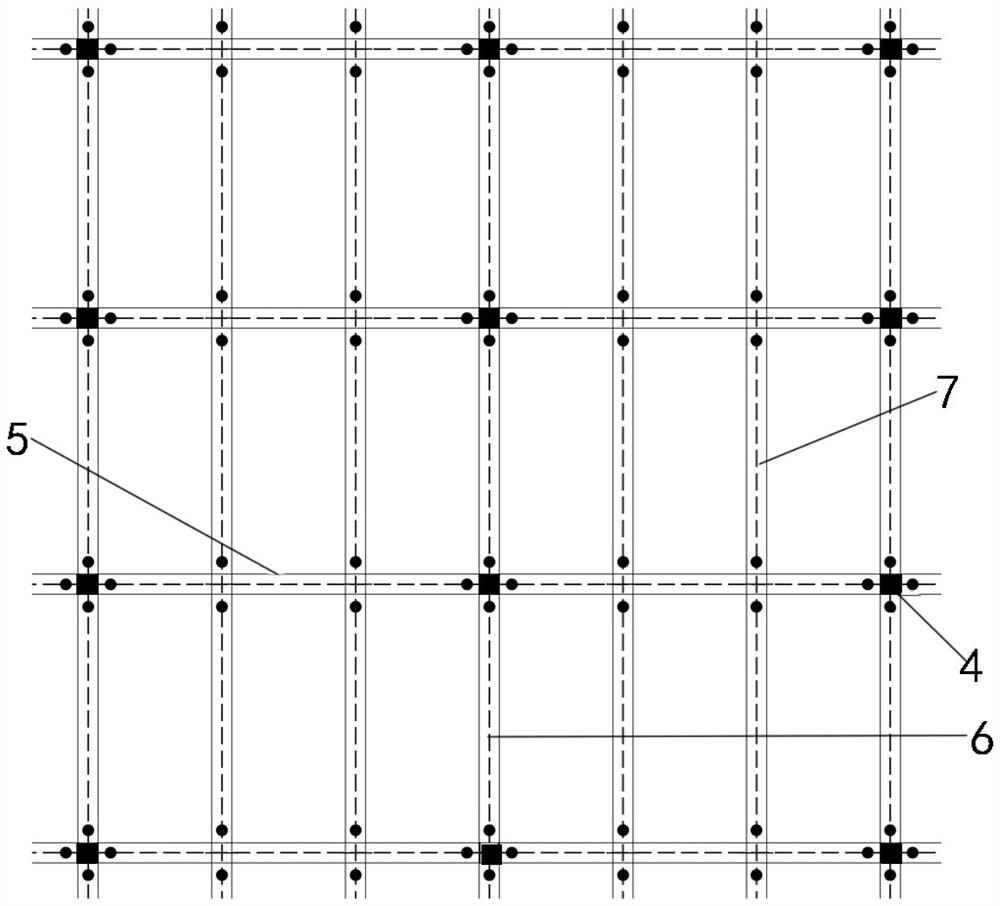

[0087] The lightweight frame body includes a set of adjustable column base structures 3, a set of upright columns 4, a set of main beams 5, a set of secondary beams and a set of inter-column supports.

[0088] The column 4, the main girder 5 and the secondary girder are all high-frequency welded thin-walled H-shaped steel, and the cross-section is H-shaped.

[0089] see Figure 9 , 10 , 11, 14 and 15, the columns 4 are arranged horizontally and vertically to form column nets, and the column nets stand on the pool ground 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com