Double-angle-steel component

A double angle steel and component technology, which is applied to slender elements, building elements, building types, etc., can solve problems such as insufficient support to adapt to transmission towers, etc., to achieve reliable fixation, avoid excessive thickness, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

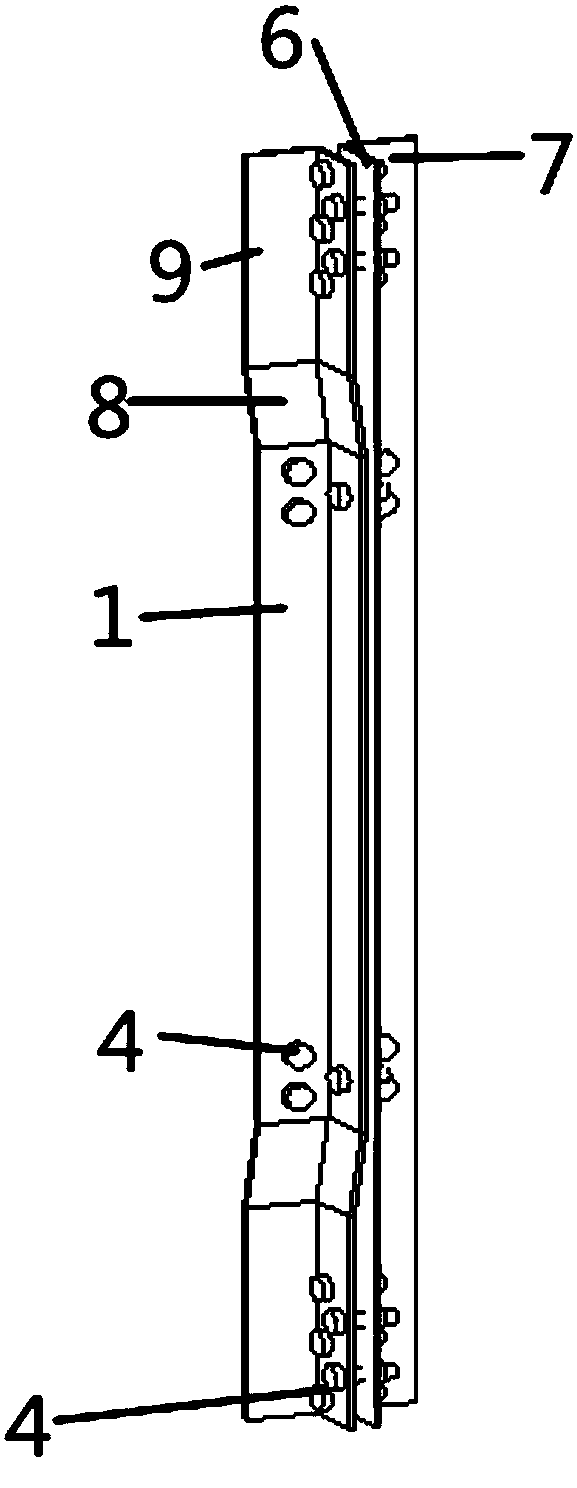

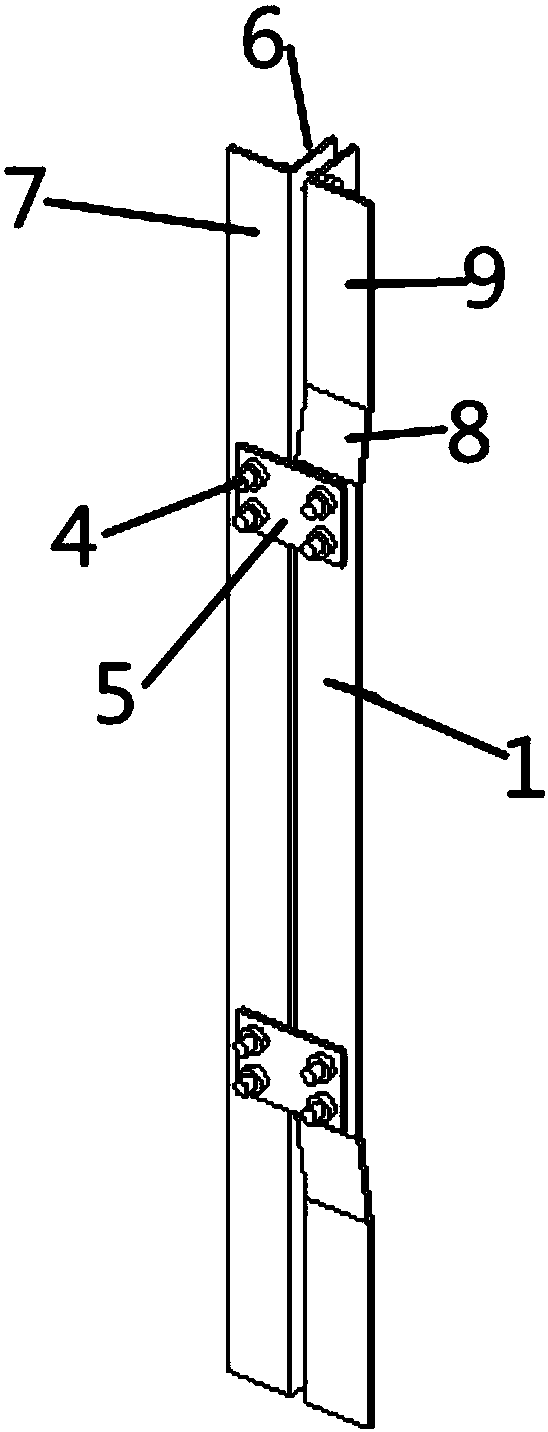

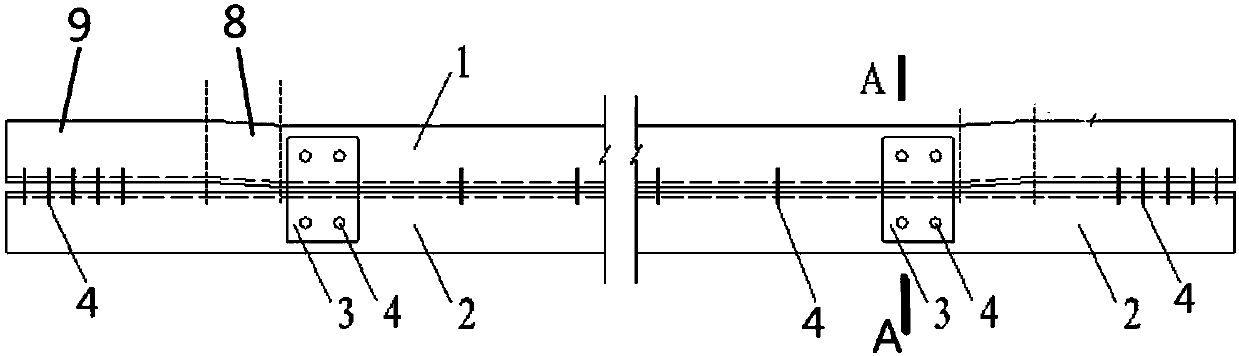

[0043] The length of the double angle steel provided in this example is 1850mm; the slenderness ratio is 60; the cross section of the angle steel and the straight angle steel are both ∟100×7 (mm); the type of bolts used in the end section is 6.8 grade M20×85; the size of the connecting plate is 8× 120×170(mm), the bolts used are grade 6.8 M20×55; the size of the fill plate is 10×60×60(mm), the bolts used are grade 6.8 M20×65; two fill plates are set in the middle section; the length of the section is 310mm .

[0044] The single angle steel comprises the following components by mass fraction:

[0045] C: 0.25, Si: 0.17, Mn: 0.40, Cr: 1.20, Mo: 0.30, and the balance is Fe.

[0046] The connecting plate 3 comprises the following components by mass fraction:

[0047] C: 1; N: 2, In: 0.8; Pd: 0.08; Zr: 0.9; Ir: 1; Rh: 1.5;

[0048] The filler plate 5 comprises the following components by mass fraction:

[0049] C: 0.12, Si: 0.20, Mn: 0.50, P: 0.035, S: 0.050, Cu: 0.20, and the ...

Embodiment 2

[0051] The length of the double angle steel provided in this example is 2500mm; the slenderness ratio is 80; the cross section of the angle steel and the straight angle steel are both ∟100×7 (mm); the type of bolts used in the end section is 6.8 grade M20×85; the size of the connecting plate is 8× 120×170(mm), the bolts used are 6.8 grade M20×55; the filler plate size is 10×60×60(mm), the bolts used are 6.8 grade M20×65; the middle section is equipped with 3 filler plates; the length of the section is 310mm .

[0052]The single angle steel comprises the following components by mass fraction:

[0053] C: 0.55, Si: 0.37, Mn: 1.50, Cr: 0.60, Mo: 0.15, and the balance is Fe.

[0054] The connecting plate 3 comprises the following components by mass fraction:

[0055] C: 1; N: 2; In: 0.8; Pd: 0.08; Zr: 0.9;

[0056] The filler plate 5 comprises the following components by mass fraction:

[0057] C: 0.12, Si: 0.20, Mn: 0.50, P: 0.035, S: 0.050, Cu: 0.20, and the balance is iron....

Embodiment 3

[0059] The length of the double angle steel provided in this example is 3090 mm; the slenderness ratio is 100; the cross-section of the angle steel and the straight angle steel are both ∟100×7 (mm); the type of bolt used in the end section is 6.8 grade M20×85; the size of the connecting plate is 8× 120×170(mm), the bolt used is 6.8 grade M20×55; the size of the filler plate is 10×60×60(mm), the bolt used is 6.8 grade M20×65; the middle section is equipped with 3 filler plates; the length of the section is 230mm .

[0060] The single angle steel comprises the following components by mass fraction:

[0061] C: 0.30, Si: 0.30, Mn: 1.0, Cr: 1.0, Mo: 0.20%, and the balance is Fe.

[0062] The connecting plate 3 comprises the following components by mass fraction:

[0063] C: 1; N: 2; In: 0.8; Pd: 0.08; Zr: 0.9;

[0064] The filler plate 5 comprises the following components by mass fraction:

[0065] C: 0.12, Si: 0.20, Mn: 0.50, P: 0.030, S: 0.045, Cu: 0.20, and the balance is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com