Prefabricated concrete ground beam-frame column connecting joint and construction method thereof

A prefabricated concrete, connecting node technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of lack of fast and efficient detection methods, insufficient tensile and shear resistance, and narrow sleeve operating space. Improve assembly efficiency and connection quality, avoid premature cracking, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

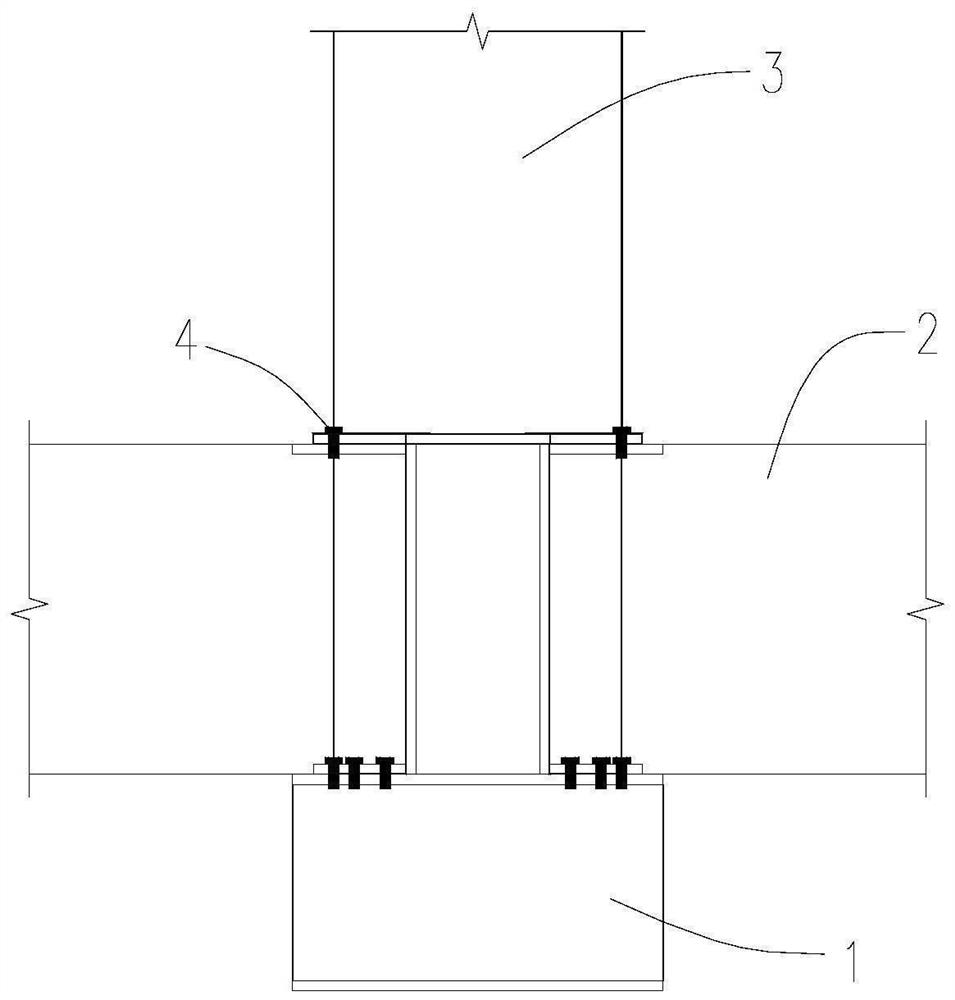

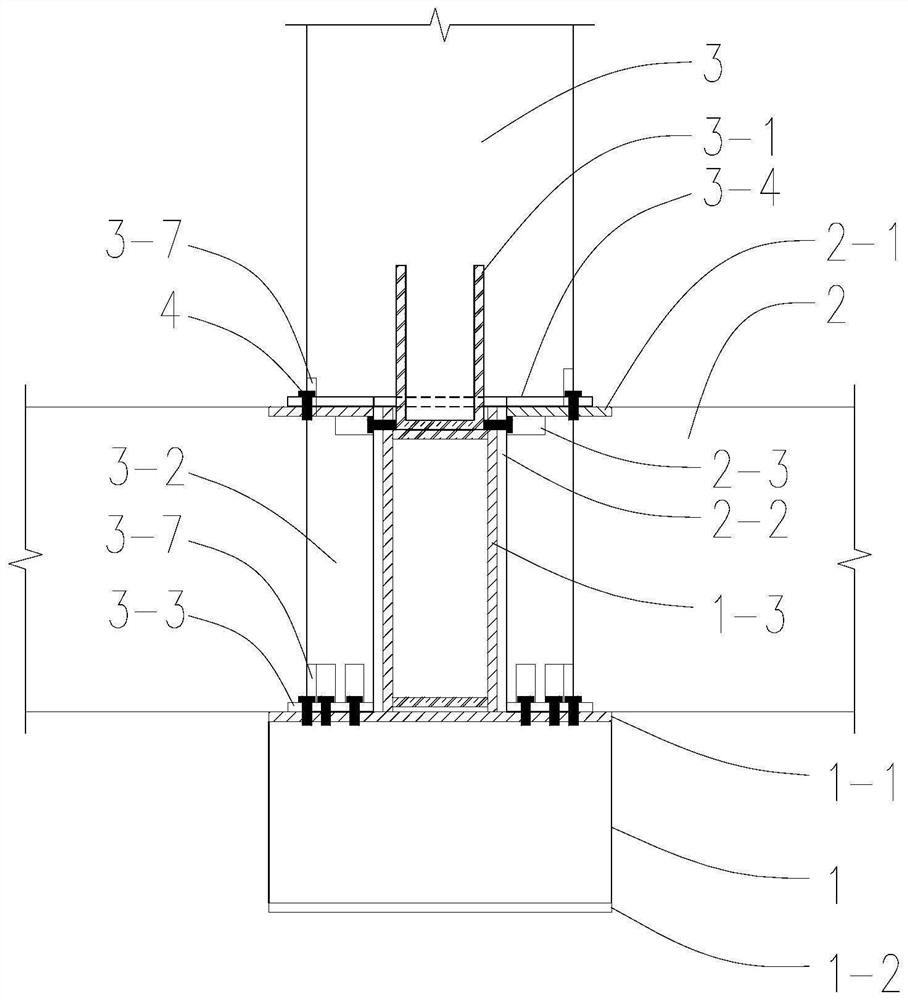

[0029] Such as figure 1 As shown, it is the prefabricated concrete ground beam-frame column connection node according to the present invention, which includes the conversion column 1, the ground beam 2 and the frame column 3 which are sequentially connected from bottom to top.

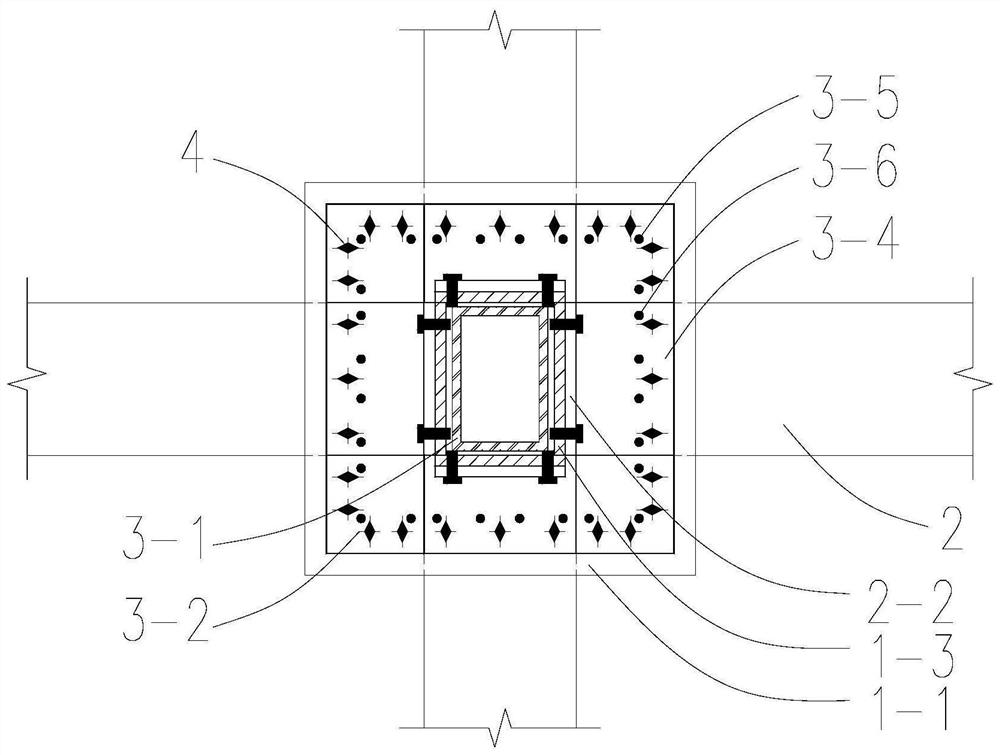

[0030] The number of ground beams 2 is two to four, depending on the top view, the ground beams 2 are connected to the core column 13 in a straight, L-shaped, T-shaped or cross-shaped. In this embodiment, a cross is taken as an example.

[0031] The top steel plate 11 and the bottom steel plate 12 with bolt holes are pre-embedded at the bottom and top of the concrete conversion column 1. There is a core column 13 made of high-strength steel. The core column 13 is made of rectangular steel pipes. Bolt holes are provided on the four wall panels. The height of the core column is the same as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com