Agricultural automatic tumbril

A fertilization vehicle and agricultural technology, which is applied in agriculture, fertilization devices, fertilizer distributors, etc., can solve the problems of laborious fertilization vehicles, waste of workers' physical strength, waste of fertilizers, etc., and achieve the goal of improving fertilization efficiency, good use effect, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

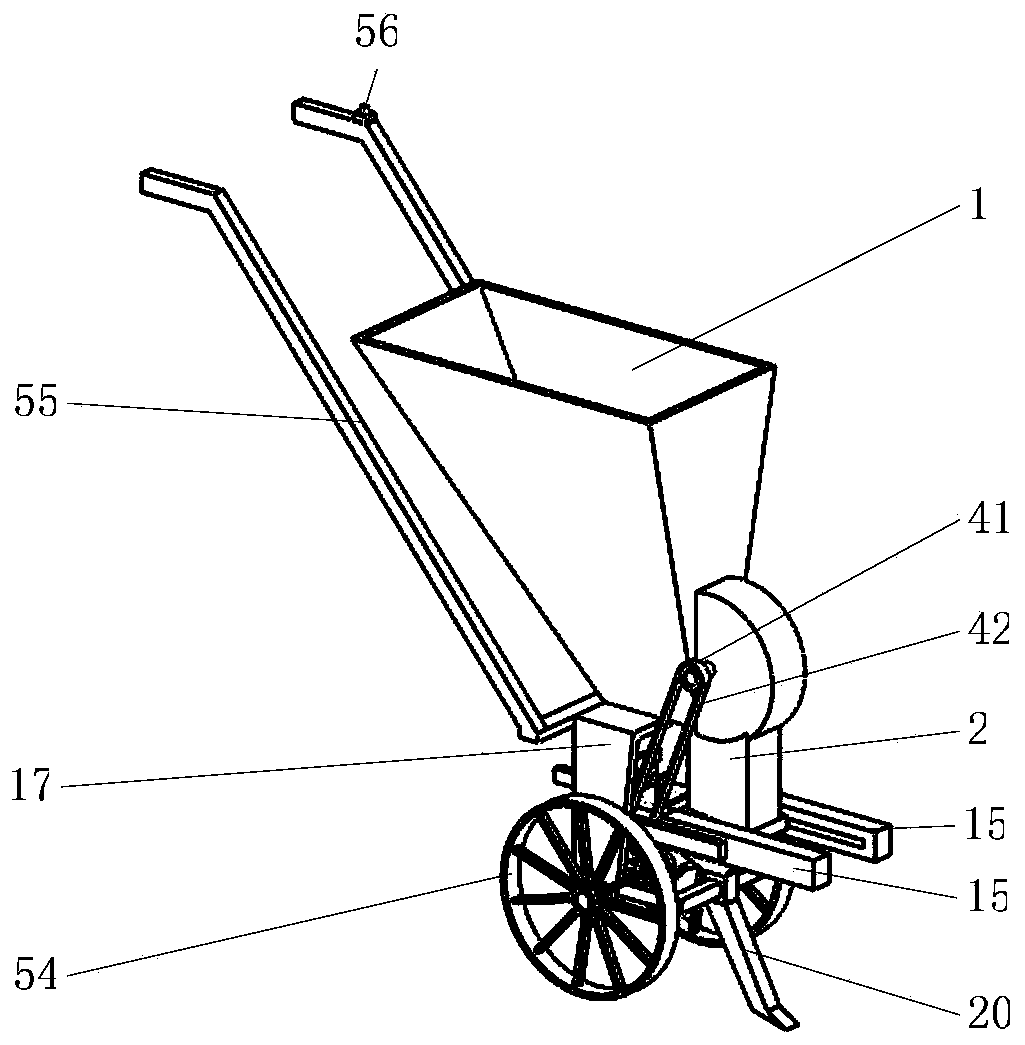

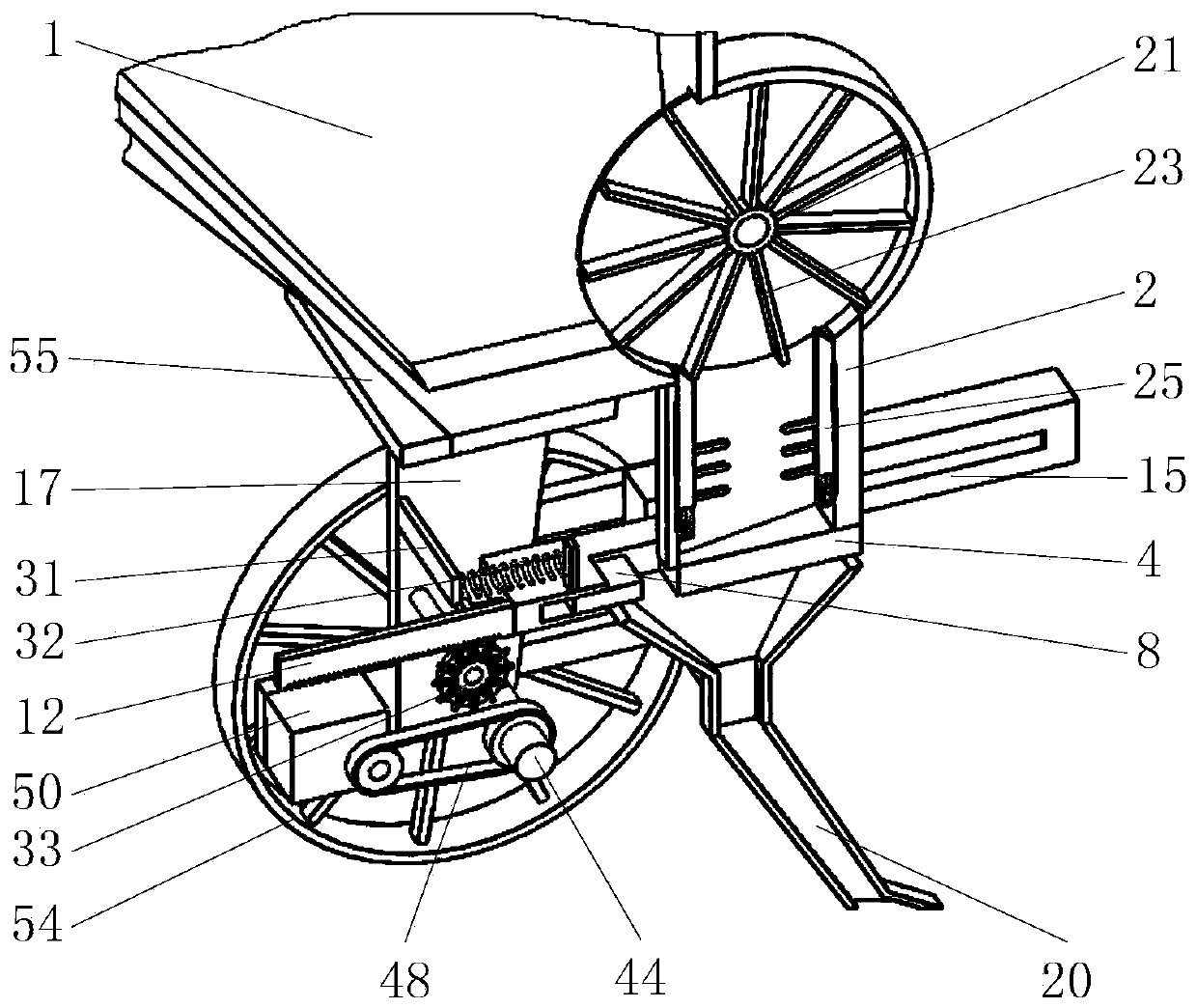

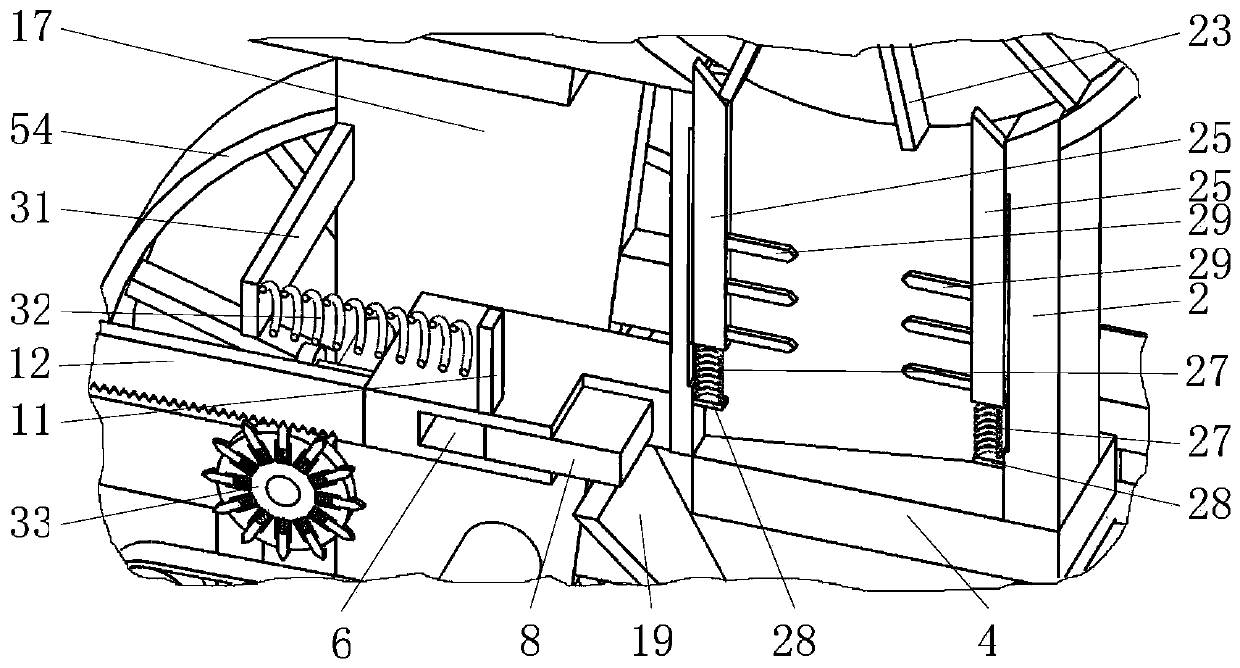

[0041] Such as figure 1 , 2 As shown, it includes a material storage shell A1, a material storage shell B2, a material distribution plate 4, a rack 12, an n-type plate 17, a material receiving funnel 19, a material guide pipe 20, a transfer mechanism 21, a vibrating bar 25, a spring A27, Dial bar 29, spring B32, centrifugal mechanism 33, wherein as figure 1 , 6 As shown, the two ends of the n-type plate 17 cooperate with the axle A44 bearings on which the wheels 54 are installed at both ends; as Figure 7 As shown, the upper end of the n-type plate 17 is equipped with a bucket-shaped storage shell A1; the bottom of the front side of the storage shell A1 has a semicircular shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com