A binding method and binding device for reducing the risk of bracket unloading

A risky, binding machine technology, applied in the field of medical devices, can solve the problems of unloading, loose binding, etc., to achieve the effect of reducing the outer diameter, binding firmly, and strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

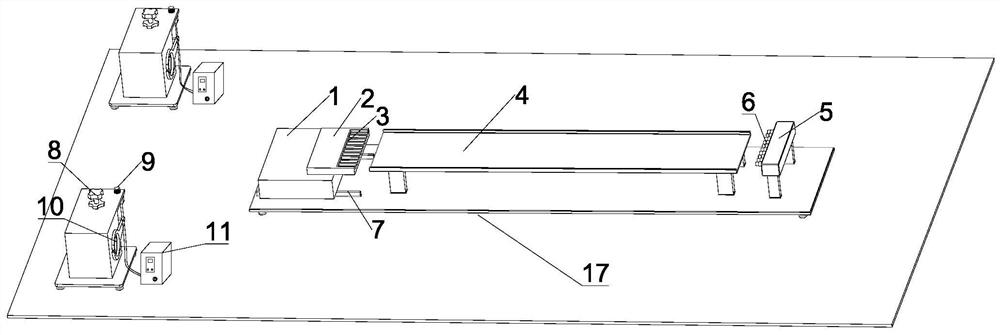

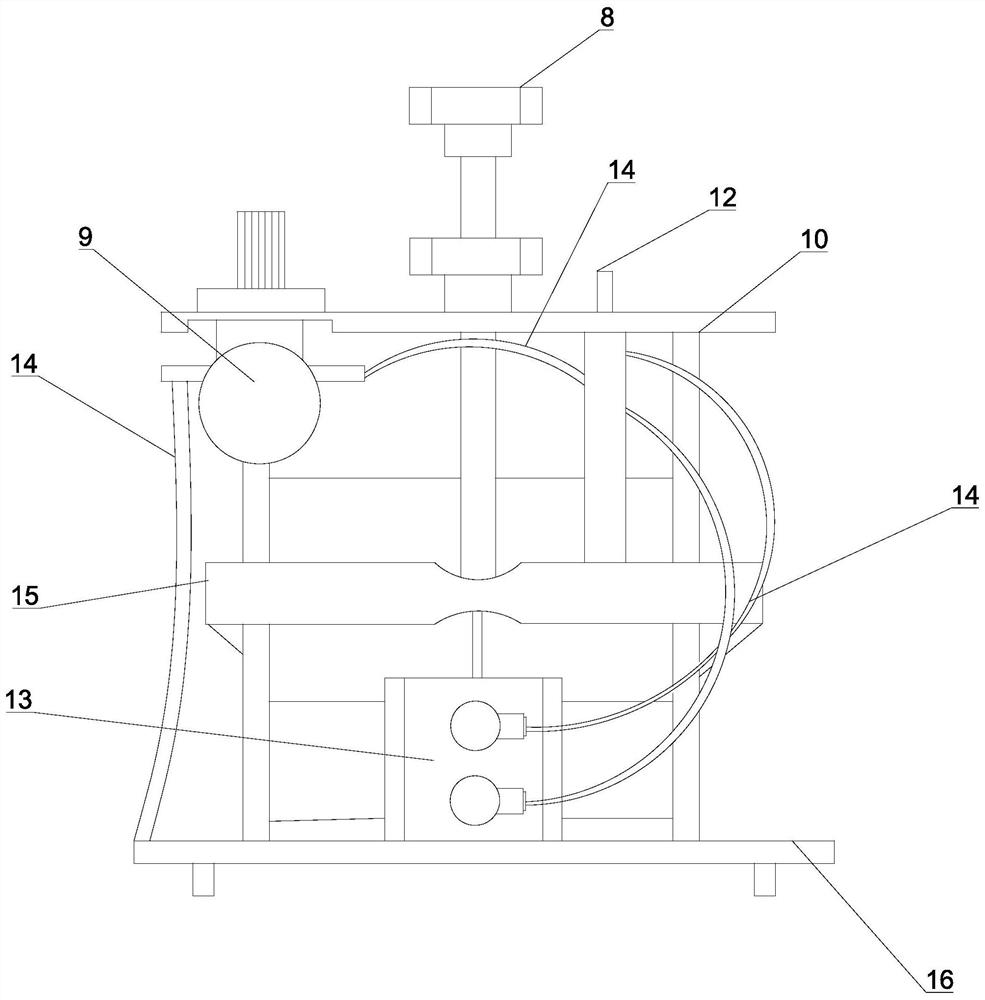

Method used

Image

Examples

Embodiment 1

[0025] (1) Pre-binding: Set the binding pressure of the pre-binding machine to 40psi and the time to 8s, adjust the inner diameter of the binding cavity to 0.035inch, put the stent and the balloon into the binding cavity, perform the first binding, and manually place the stent Rotate 90° with the balloon for the second binding, then remove the stent and the balloon from the binding cavity, and add a heat-set sleeve outside the stent to complete the pre-binding;

[0026] (2) Heat setting: place the bracket and balloon pre-bundled in step (1) on the storage tray, place the end covered with the heat setting sleeve on the guide tray, and set the heat setting temperature to 40 ℃, the time is 550s, the other end is connected to the luer connector, and the pressure is applied to the balloon with nitrogen gas to 70psi, and the heat fixation is started;

[0027] (3) Final binding: Set the binding pressure of the final binding machine to 40psi and the time to 10s, adjust the inner diame...

Embodiment 2

[0029] (1) Pre-binding: Set the binding pressure of the pre-binding machine to 50psi and the time to 7s, adjust the inner diameter of the binding machine to 0.031inch, put the stent and the balloon into the binding cavity, perform the first binding, and manually place the stent and The balloon is rotated 90° for the second bundling, and then the stent and the balloon are taken out of the bundling cavity, and a heat-set sleeve is added outside the stent to complete the pre-bundling;

[0030] (2) Heat setting: Place the pre-bundled bracket and balloon on the storage tray in step (1), place the end covered with the heat setting sleeve on the guide tray, and set the heat setting temperature to 50 ℃, the time is 500s, the other end is connected to the Luer connector, and the pressure is applied to the balloon with nitrogen to 85psi, and the heat fixation is started;

[0031] (3) Final binding: Set the binding pressure of the final binding machine to 50psi and the time to 15s, adjus...

Embodiment 3

[0033] (1) Pre-binding: Set the binding pressure of the pre-binding machine to 60psi and the time to 5s, adjust the inner diameter of the binding machine to 0.033inch, put the bracket and the balloon into the binding cavity for the first binding, and manually place the The stent and the balloon are rotated 90° for the second bundling, and then the stent and the balloon are taken out of the bundling cavity, and a heat-set sleeve is added outside the stent to complete the pre-bundling;

[0034] (2) Heat setting: place the stent and balloon pre-bundled in step (1) on the storage tray, place the end covered with the heat setting sleeve on the guide tray, and set the heat setting temperature to 100 ℃, the time is 600s, the other end is connected to the Luer connector, and the pressure of 60psi is applied to the balloon with nitrogen gas, and the heat fixation is started;

[0035] (3) Final binding: Set the binding pressure of the final binding machine to 60psi and the time to 20s, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com