Coating for coatings and method for preparing matrixes

A coating and coating technology, applied in the field of materials, can solve the problems of increasing product cost, increasing the complexity of components, reducing the range of brackets and balloons, etc., to achieve the effect of increasing the coefficient of friction, reducing the risk of unloading, and increasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

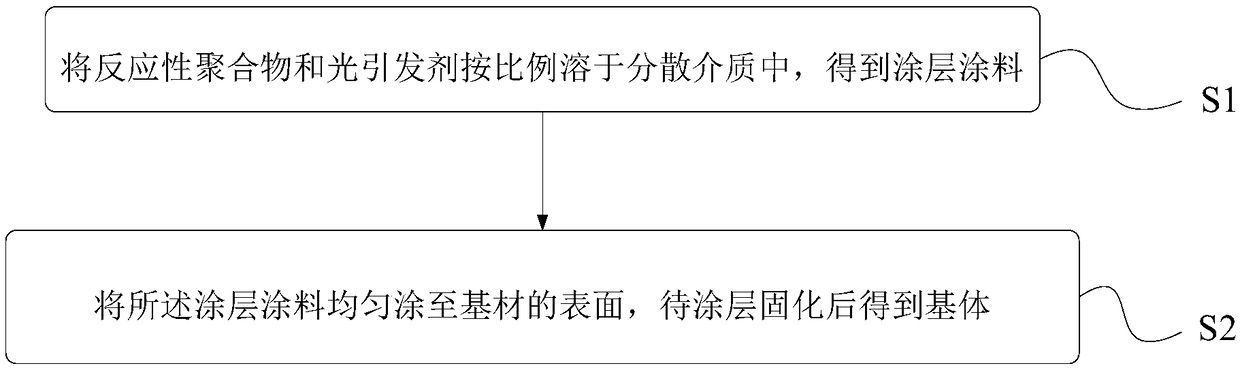

[0044] A method of preparing a matrix, such as figure 1 shown, including the following steps:

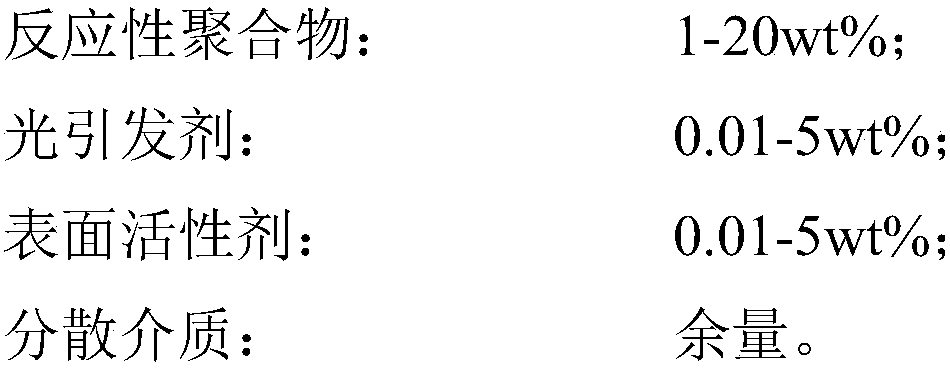

[0045] S1: The reactive polymer and photoinitiator are dissolved in the dispersion medium in proportion to obtain the coating; in addition, when the coating contains surfactant, the reactive polymer, photoinitiator and surfactant are The ratio is dissolved in the dispersion medium to obtain the coating paint. Wherein, the reactive polymer can be any one of the polymers described above or below, and the photoinitiator can also be any one of the photoinitiators described above or below.

[0046] S2: Apply the coating paint evenly to the surface of the substrate by spraying or dipping, and then the coating is cured, and the substrate is obtained after the coating is cured. The irradiation time is more than 1 min, and the thickness of the coating is 0.1-50 μm in the prepared matrix.

[0047]In order to further understand the present invention, the preferred solutions of the present i...

Embodiment 1

[0049] In this embodiment, the coating paint comprises a reactive polymer, a photoinitiator, a surfactant and a dispersion medium, wherein the reactive polymer is selected from polyethylene glycol diacrylate, and the photoinitiator is benzophenone, and the surface The active agent is Tween80, and the dispersant is isopropanol. The specific proportion of the coating paint is shown in Table 1 below.

[0050] Table 1 Components and proportioning of coating paint

[0051] reactive polymer

Norrish-type photoinitiator

Surfactant

dispersion medium

polyethylene glycol diacrylate

Tween80

Isopropanol

3.00wt%

0.1wt%

0.1wt%

96.8wt%

[0052] The matrix provided in this embodiment uses nylon as the base material, and the preparation method of the matrix is as follows:

[0053] The coating paint was prepared according to the ratio in Table 1, and then the coating paint was coated on the surface of the nylon subs...

Embodiment 2

[0058] In this embodiment, the coating paint includes a reactive polymer, a photoinitiator, a surfactant and a dispersion medium, wherein the reactive polymer is selected from unsaturated polyamides, the photoinitiator is a diacylphosphine oxide, and the surfactant is Sodium dodecylbenzenesulfonate, ethyl acetate is used as dispersant. The specific proportion of the coating paint is shown in Table 3 below.

[0059] Table 3 Components and ratios of coatings

[0060] reactive polymer

Norrish-type photoinitiator

Surfactant

dispersion medium

Unsaturated polyamide

Diacylphosphine oxide

SDBS

5.00wt%

0.15wt%

0.15wt%

94.7wt%

[0061] The substrate provided in this embodiment uses 304 stainless steel as the substrate, and the preparation method of the substrate is as follows:

[0062] The coating paint was prepared according to the ratio in Table 3, and then the coating paint was coated on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com