Edge drilling and middle drilling compatible glass drilling machine

A drilling machine and compatible device technology, which is applied in the field of glass drilling machine edge and central drilling compatible devices, can solve the problems of waste and single function, and achieve the effect of reducing investment and realizing flexible switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

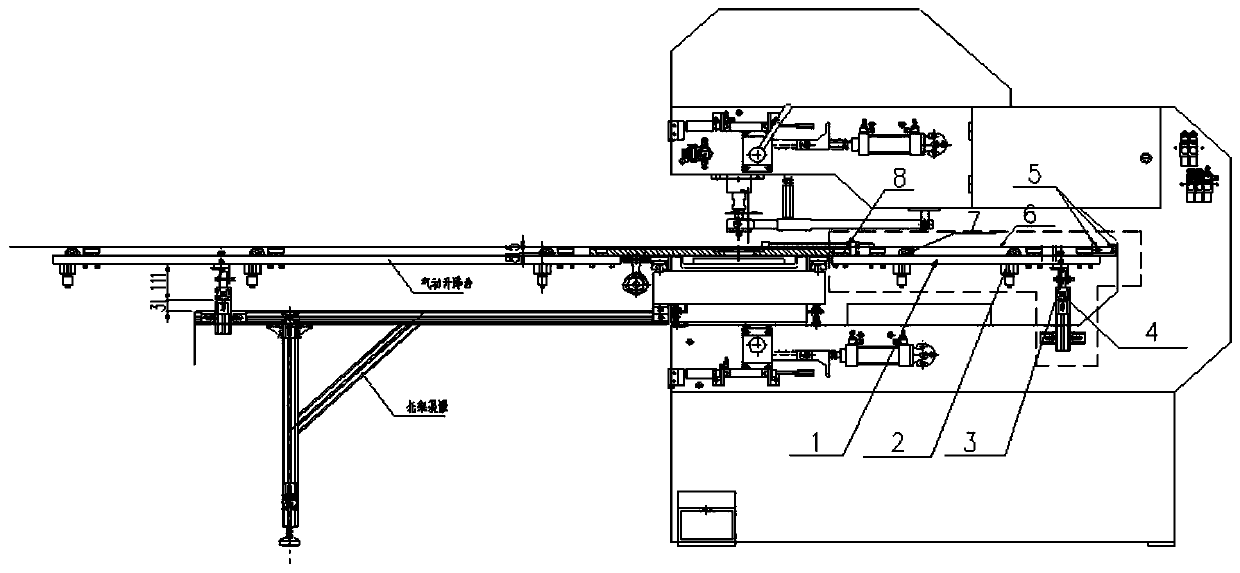

[0013] Such as figure 1 Shown: this positioning device mainly is made up of mobile lifting bracket platform 1, fixed support bracket 4, lifting cylinder 2, roller 3, universal wheel 7, positioning device 5,8 etc. Please refer to the attached drawings for details. The dotted frame in the attached drawings is the compatible device of the present invention.

[0014] Drill and tap at the lower part of the inner side of the mobile platform of the existing edge drilling machine, and fix the mobile lifting bracket platform 1. The mobile lifting bracket table 1 moves with the drilling machine mobile platform, and the lower part of the mobile lifting bracket table 1 is equipped with four lifting cylinders 2. When the glass is on and off, the cylinder 2 lifts the universal wheel 7 and lifts the glass 6 to prevent The glass is scratched. Drilling and tapping on the existing drilling body is provided with a fixed support bracket 4, and two rollers 3 on the mobile lifting bracket platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com