A centering platform of a ceiling automatic production line

An automatic production line and centering table technology, applied in the field of centering table, can solve problems such as deformation of the outer plate, and achieve the effect of preventing deformation of the outer plate, realizing flexible switching, and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

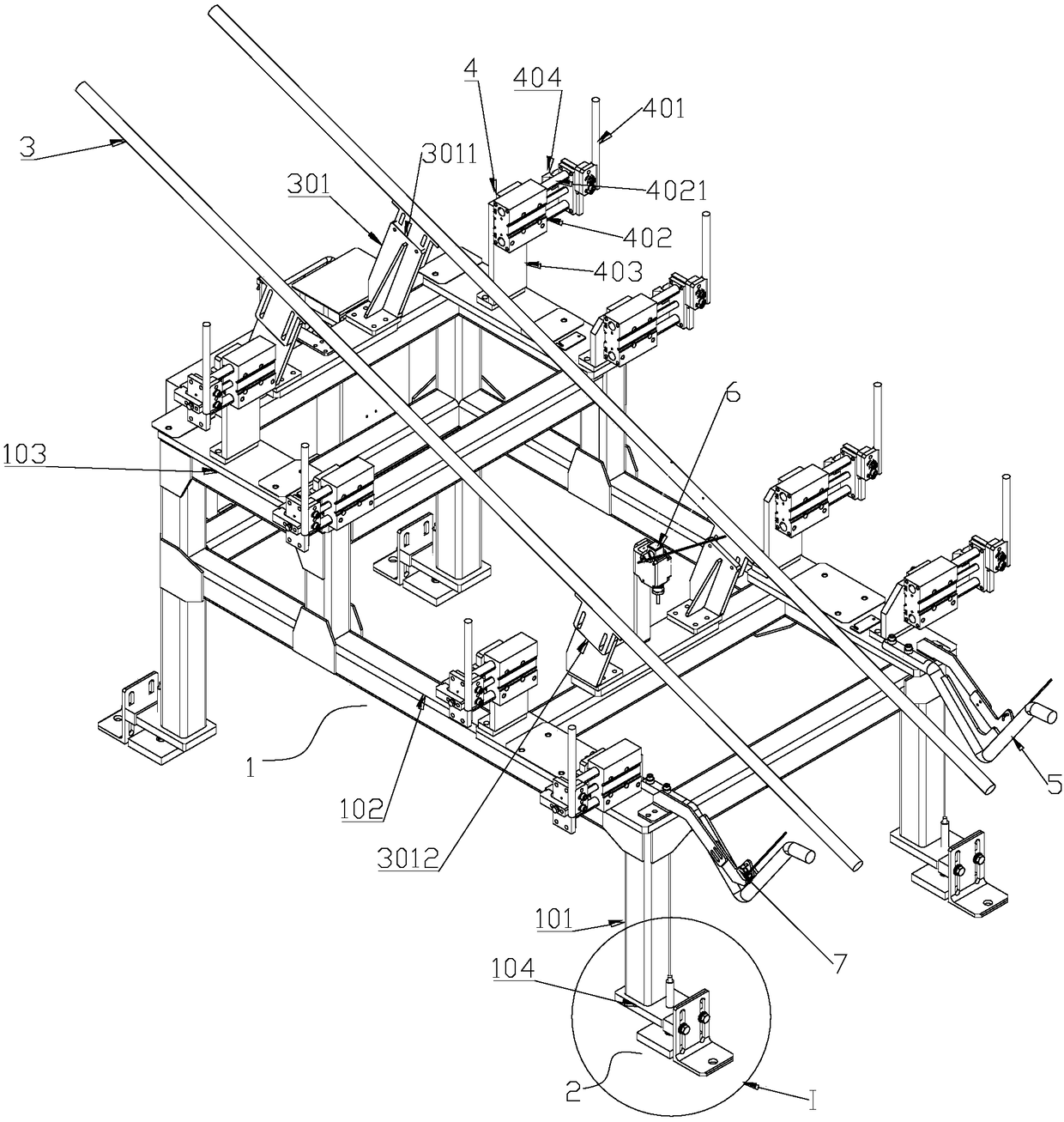

[0017] Such as figure 1 As shown, a centering platform of an automatic ceiling production line includes a stepped platform 1, and the stepped platform 1 includes legs 101 arranged at four corners. The legs 101 support a low platform 102, and a high platform is provided at the rear of the low platform 102. 103 , the bottom end of the leg 101 is provided with a leg bottom plate 104 .

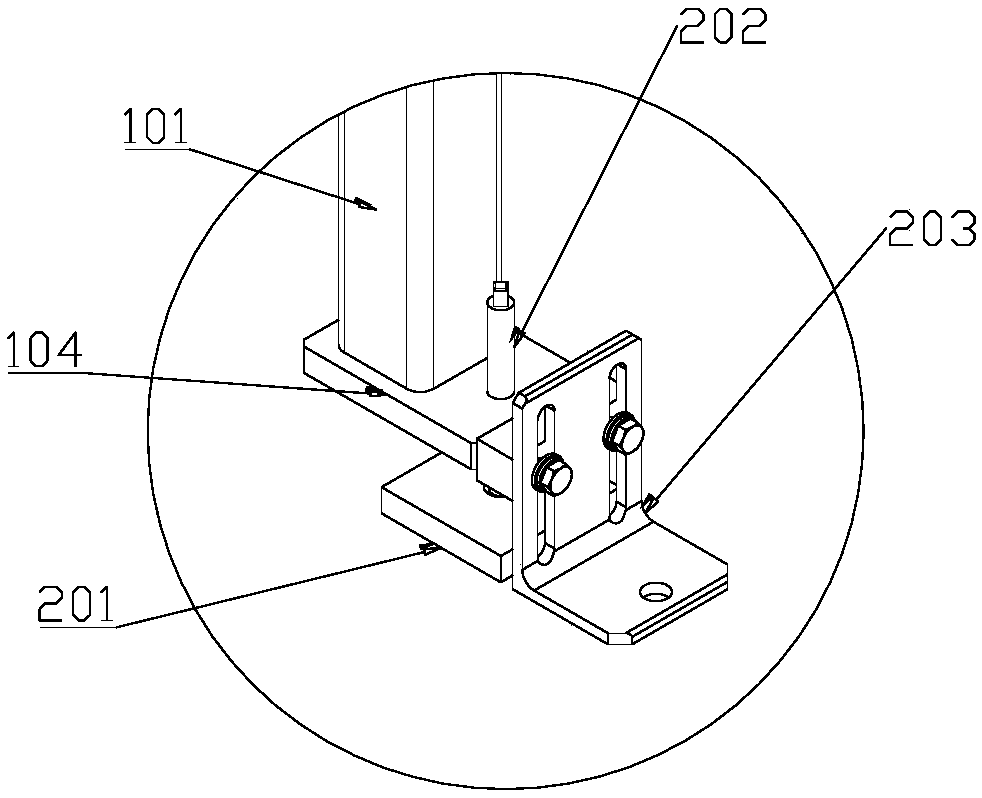

[0018] The bottom end of the ladder stand 1 is fixed by a horizontal adjustment mechanism 2; the horizontal adjustment mechanism 2 includes a base 201, and a vertically arranged spiral support 202 is provided on the base 201, and the leg bottom plate 104 is screwed on the spiral support 202, One side of the base 202 is provided with an L-shaped positioning foot plate 203, one end surface of the positioning foot plate 203 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com