Welding positioning equipment based on AGV transmission

A welding positioning and equipment technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing the effective utilization rate of the process area, fixing the line body structure, and high cost investment, so as to improve the process area Utilization rate, reduction of cost and time, effect of reduction of retrofit cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached to the following figure 1 -5 and the specific embodiments will further describe the present invention in detail, and the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

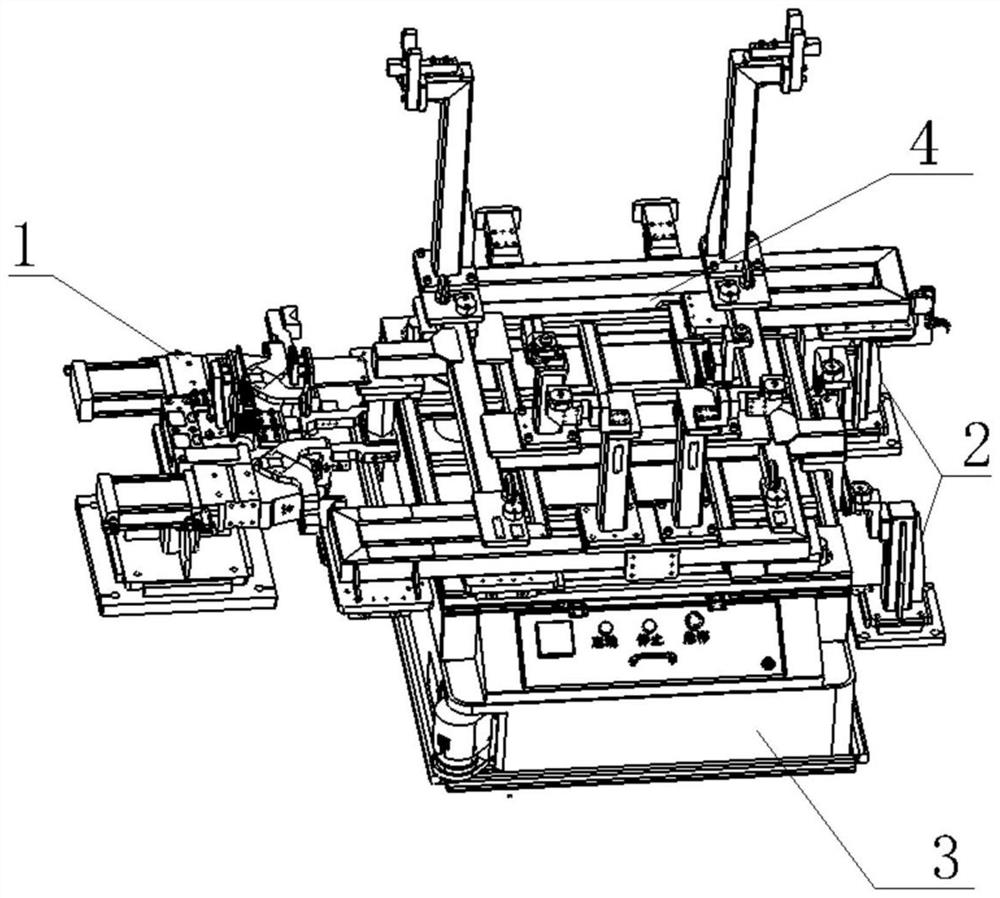

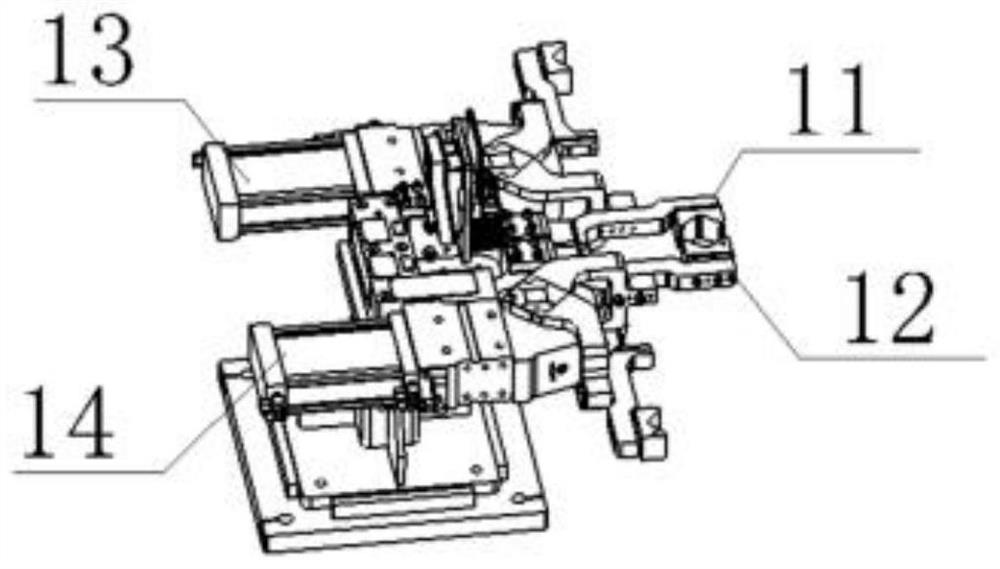

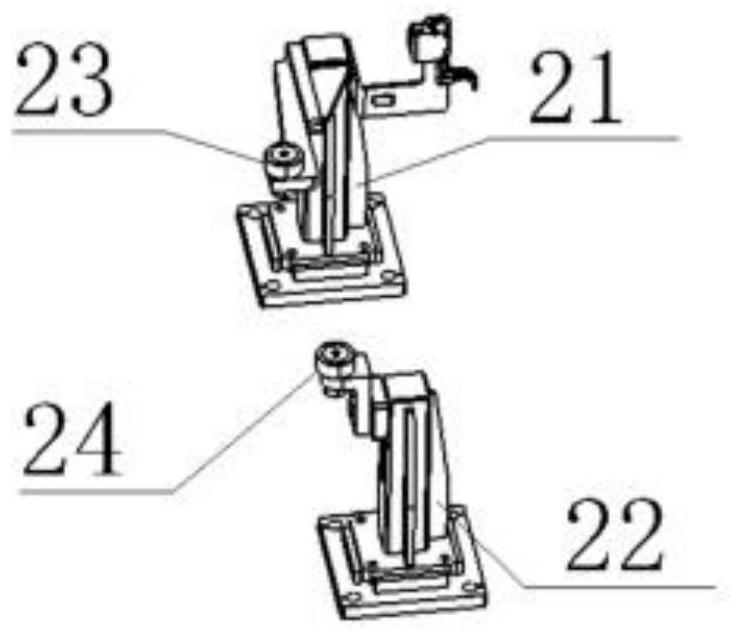

[0028] Refer to the attached figure 1 As shown, a welding positioning equipment based on AGV transmission includes: a ground positioning and clamping mechanism 1, a ground positioning guide mechanism 2, an AGV conveying unit 3, and a body-in-white clamp unit 4. The vehicle body fixture unit 4 is provided with a ground positioning guide mechanism 2 on the side of the parking station of the AGV conveying unit 3. The ground positioning guide mechanism 2 is connected to the body-in-white fixture through the first guide wheel 23 and the second guide wheel 24 respectively. The first clamp guide assembly 42 and the second clamp guide assembly 43 of the unit 4 are in contact and matched for positioning, and a grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com