Tool scaffold for cargo oil tank of chemical carrier

A chemical tanker and scaffolding technology, applied in the field of shipbuilding, can solve the problems of long special coating period of cargo oil tanks, sand and paint cannot be completed at one time, and the influence of shipping schedule, etc. The effect of safety and security, connection work convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

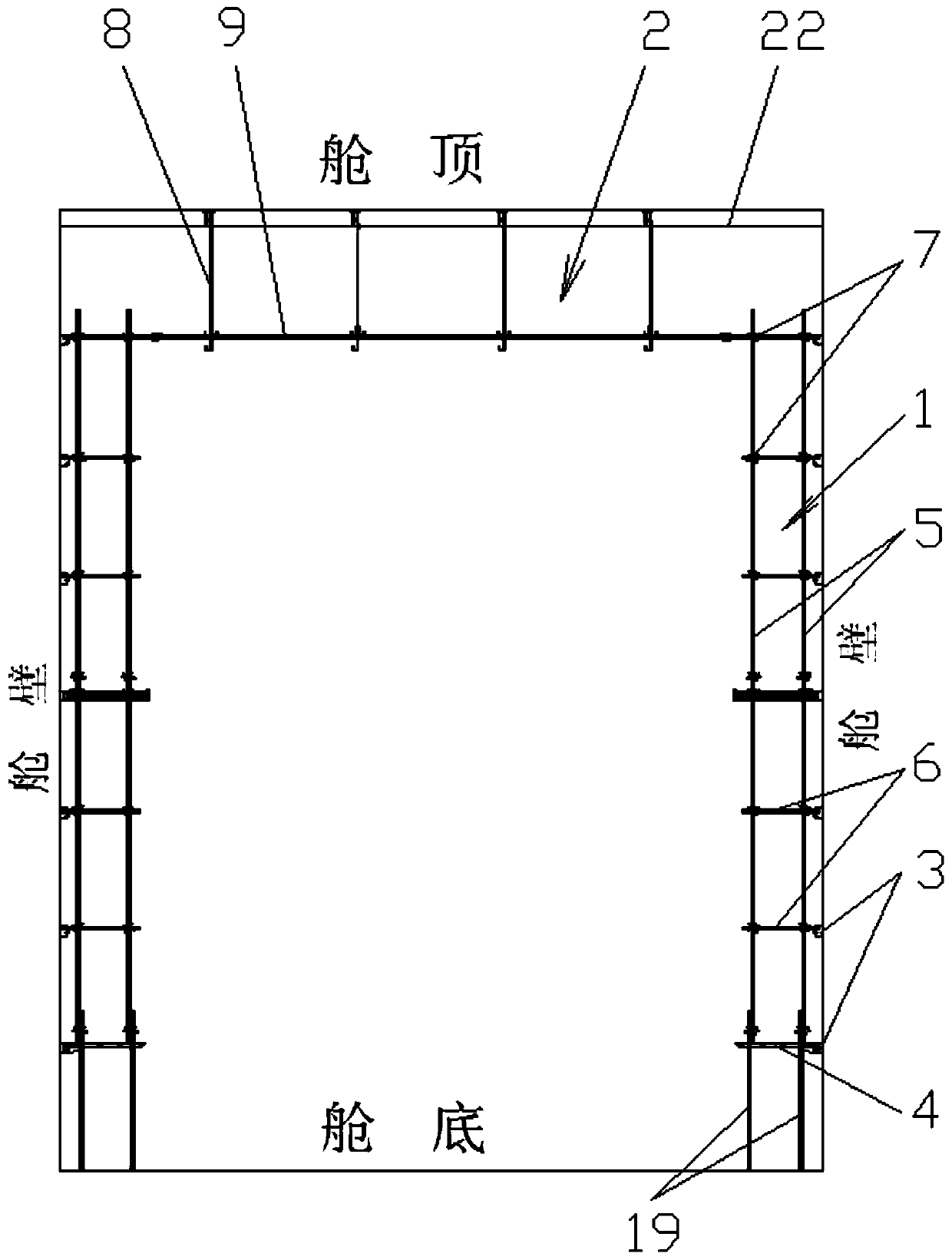

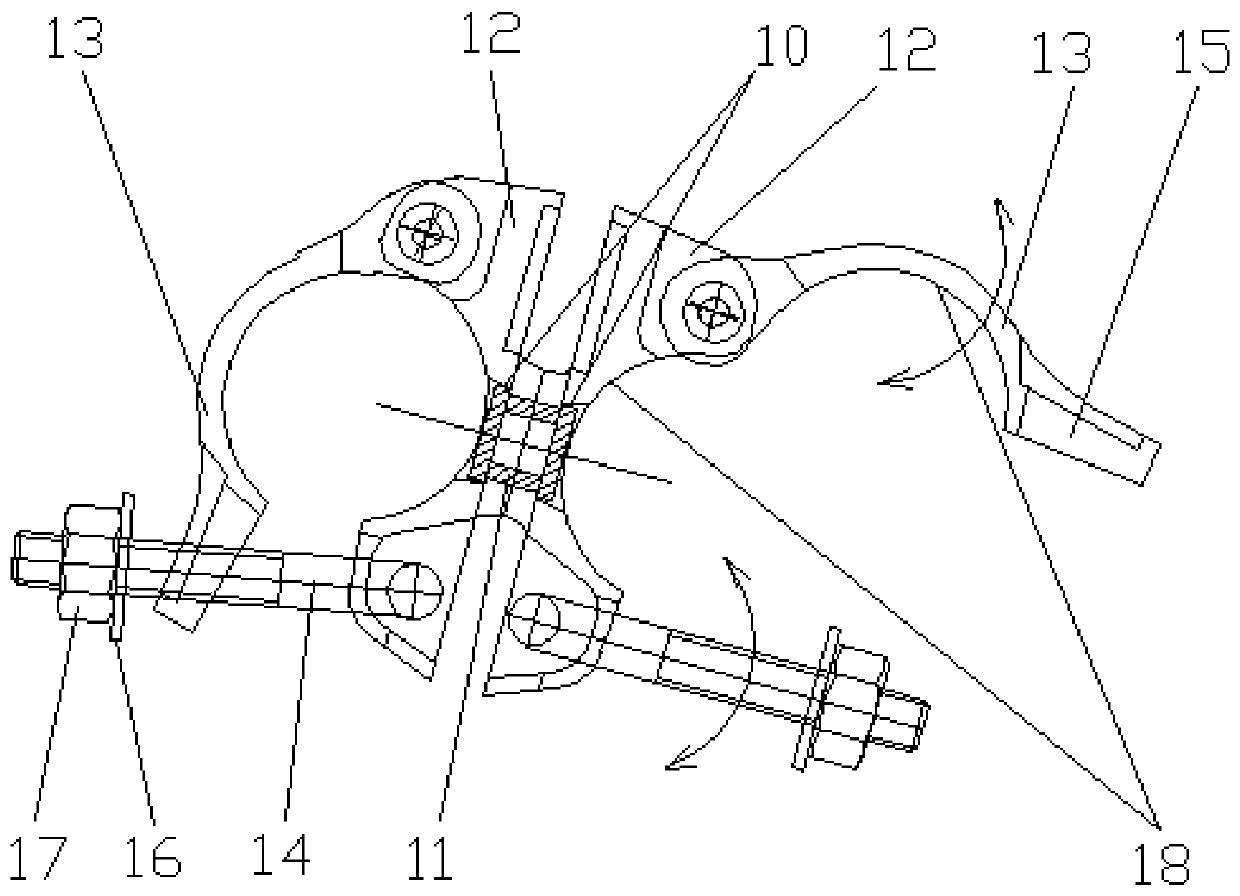

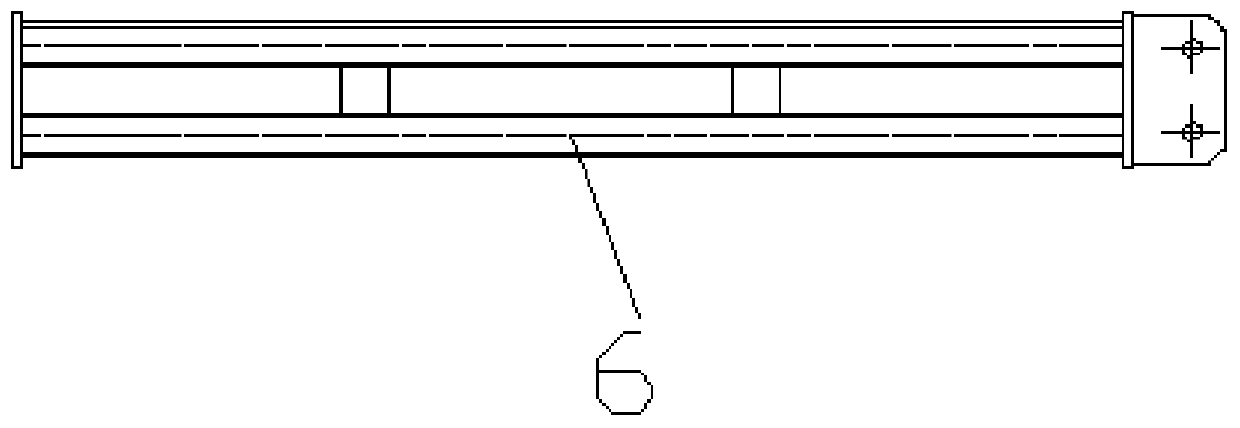

[0038] like Figures 1 to 6Shown is an embodiment of a chemical tanker cargo oil tank tooling scaffolding of the present invention, including a surrounding bulkhead scaffolding module 1 and a top hanging scaffolding module 2, and the surrounding bulkhead scaffolding module 1 includes the surrounding bulkheads arranged and connected along the bulkhead. A number of angle steel brackets 4 on the surrounding bulkhead eye plates 3, and a number of pairs of supporting vertical rods 5 erected on the angle steel bracket 4, and between each pair of supporting vertical rods 5 from bottom to top A number of steel pipe brackets 6 are connected at intervals, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com