Tray device for handling carrier plate

A pallet and carrier board technology, applied in the field of pallet devices, can solve the problems of easy damage and difficult handling of pallet devices, and achieve the effect of reducing leverage force and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Before describing the exemplary embodiments in further detail with reference to the accompanying drawings, some basic considerations upon which the exemplary embodiments of the present invention are developed will be outlined.

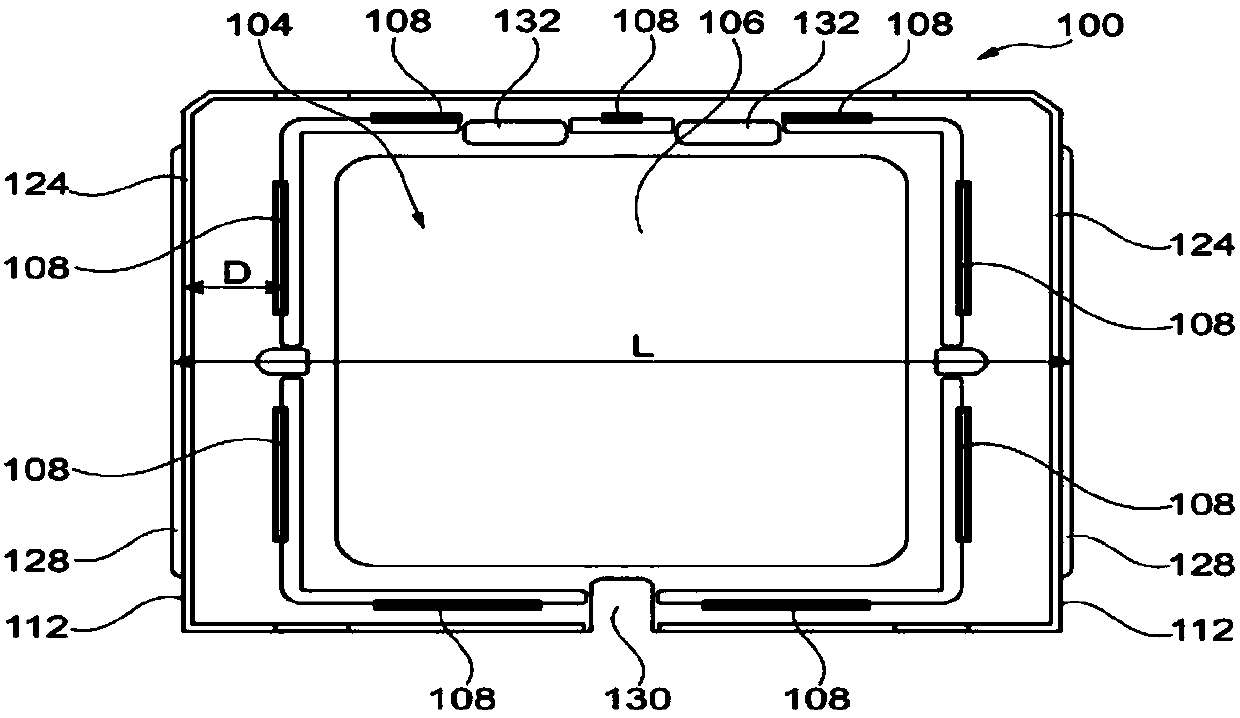

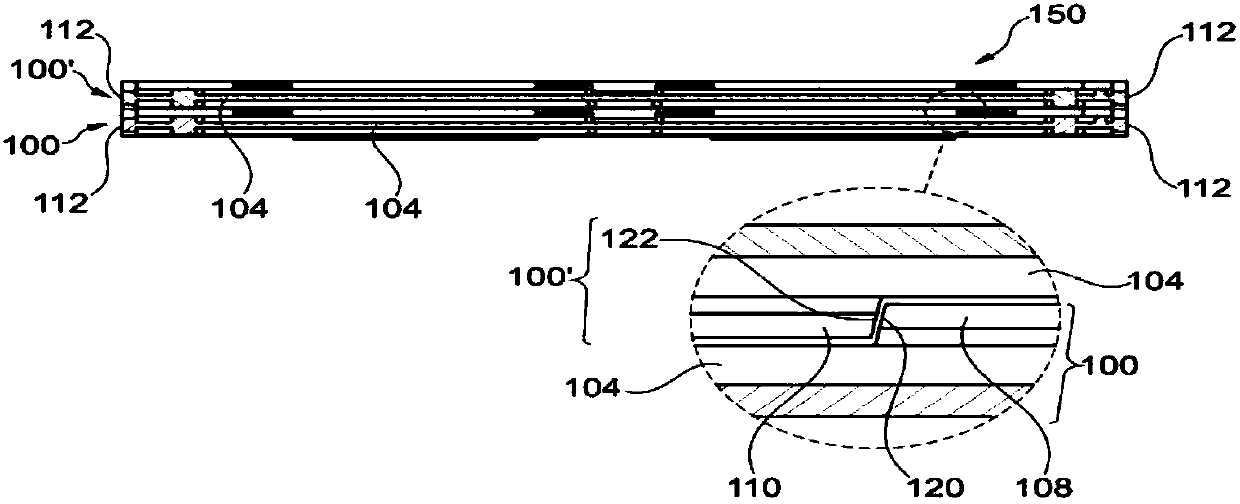

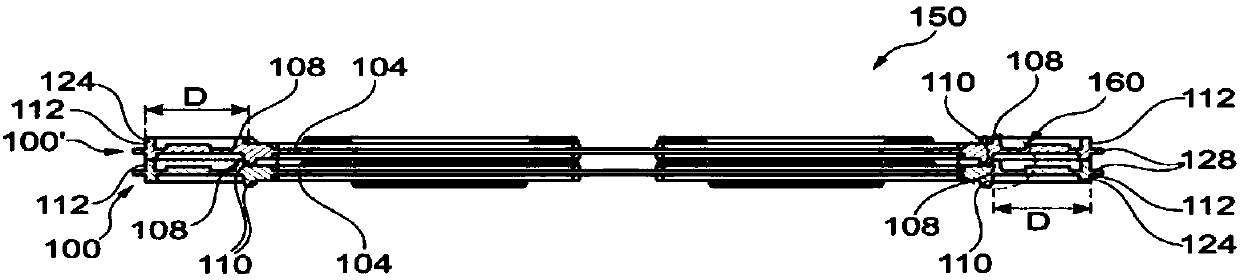

[0044] According to an exemplary embodiment of the present invention, there may be provided a multi-purpose tray device (in particular, a general-purpose quarter-carrier pallet device) for handling a carrier. In particular, exemplary embodiments of the present invention allow for the standardization of pallet arrangements for handling carriers of different shapes and sizes, such as quarter carriers. Very advantageously, such a stackable tray arrangement can be provided to be fault-resistant and avoid damage during stacking and unstacking.

[0045] The quarter carrier pallet assembly can be used during the post-production process (specifically from quarter carrier routing (routing, routing) to quarter carrier cutting) for shipping A carrier for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com