Cable automatic retracting system for pure electric hydraulic excavator

A hydraulic excavator, automatic retractable and retractable technology, applied in the direction of cable arrangement between relatively moving parts, cable installation, electrical components, etc. Achieve the effect of avoiding cable mopping, high reliability and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

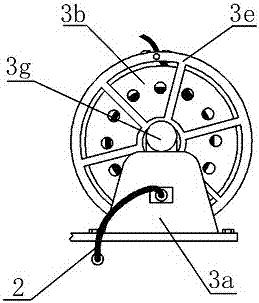

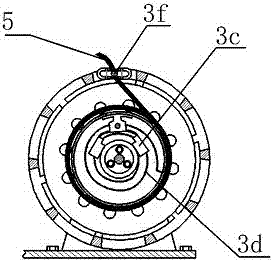

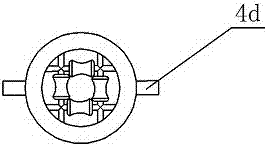

[0012] Such as figure 1 As shown, the present invention is an automatic cable retractable system for a pure electric hydraulic excavator, which is composed of a power output system and a power input system. The power output system consists of a battery trailer 1, a two-way plug 2, a cable retractable device 3, and an adjustable lead screw The branch line device 4 and the tensile cable 5 are composed. The power input system is composed of the cantilever extension device 6, the hydraulic support device 7, the fixed branch line frame 8, and the cable 9. The battery is installed on the battery trailer 1, and the cable retractable device 3 is connected to the Lead screw branch line device 4 is installed above the battery, cantilever extension device 6 is fixed on the excavator walking frame, hydraulic support device 7 is installed at the end of cantilever extension device 6, and fixed branch line frame 8 is installed above the hydraulic support device 7.

[0013] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com