Automatic plate feeding device and plate machining production line

A technology of automatic feeding and sheet metal, which is applied in the field of automatic feeding device of sheet metal and sheet metal processing production line, can solve the problems of complex feeding process, different actions, and increased difficulty of feeding operation, and achieve material retrieving control The process is simple, the scope of application is expanded, and the effect of stable sheet position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example refers to figure 1 The coordinate system shown is described.

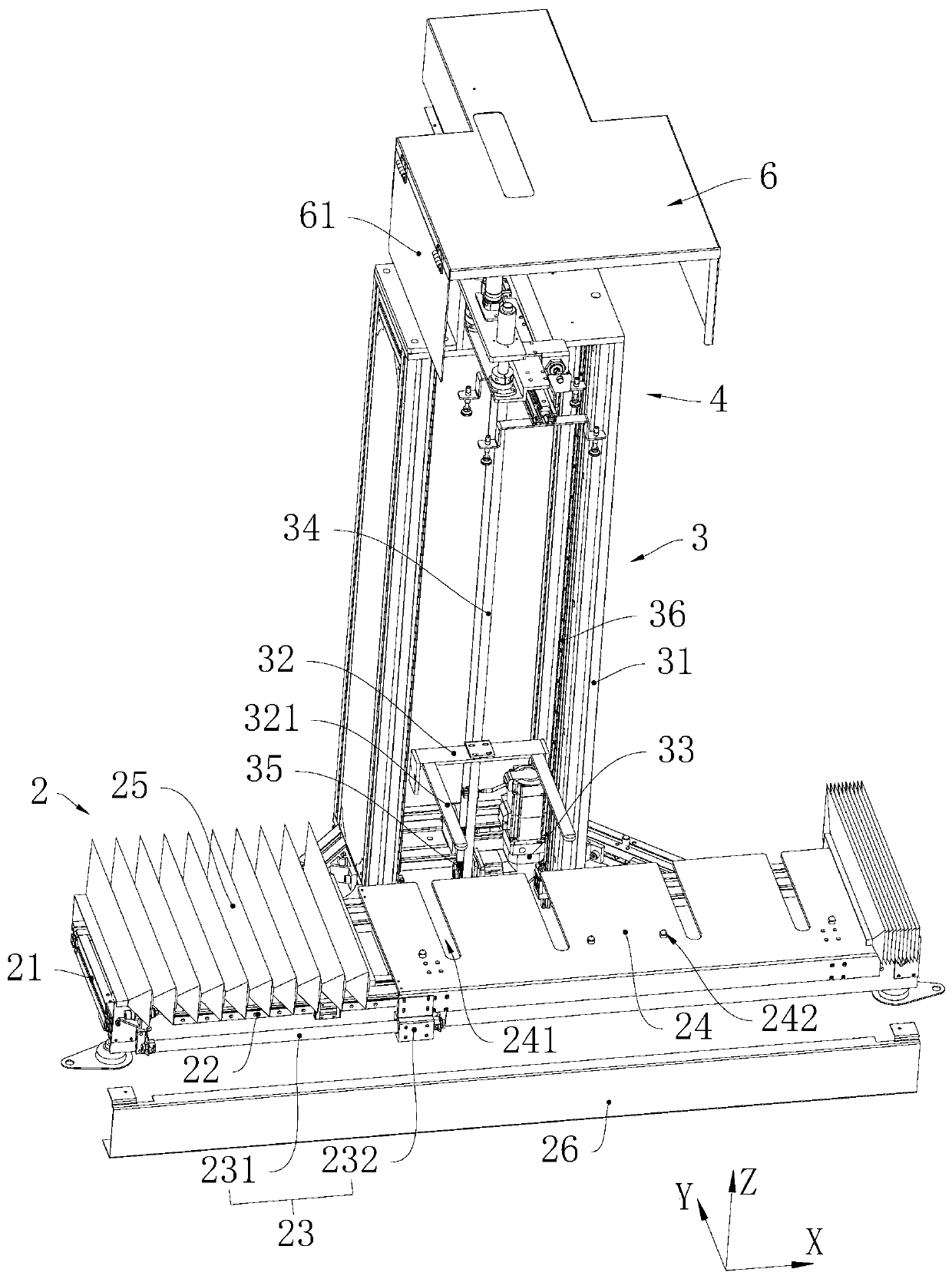

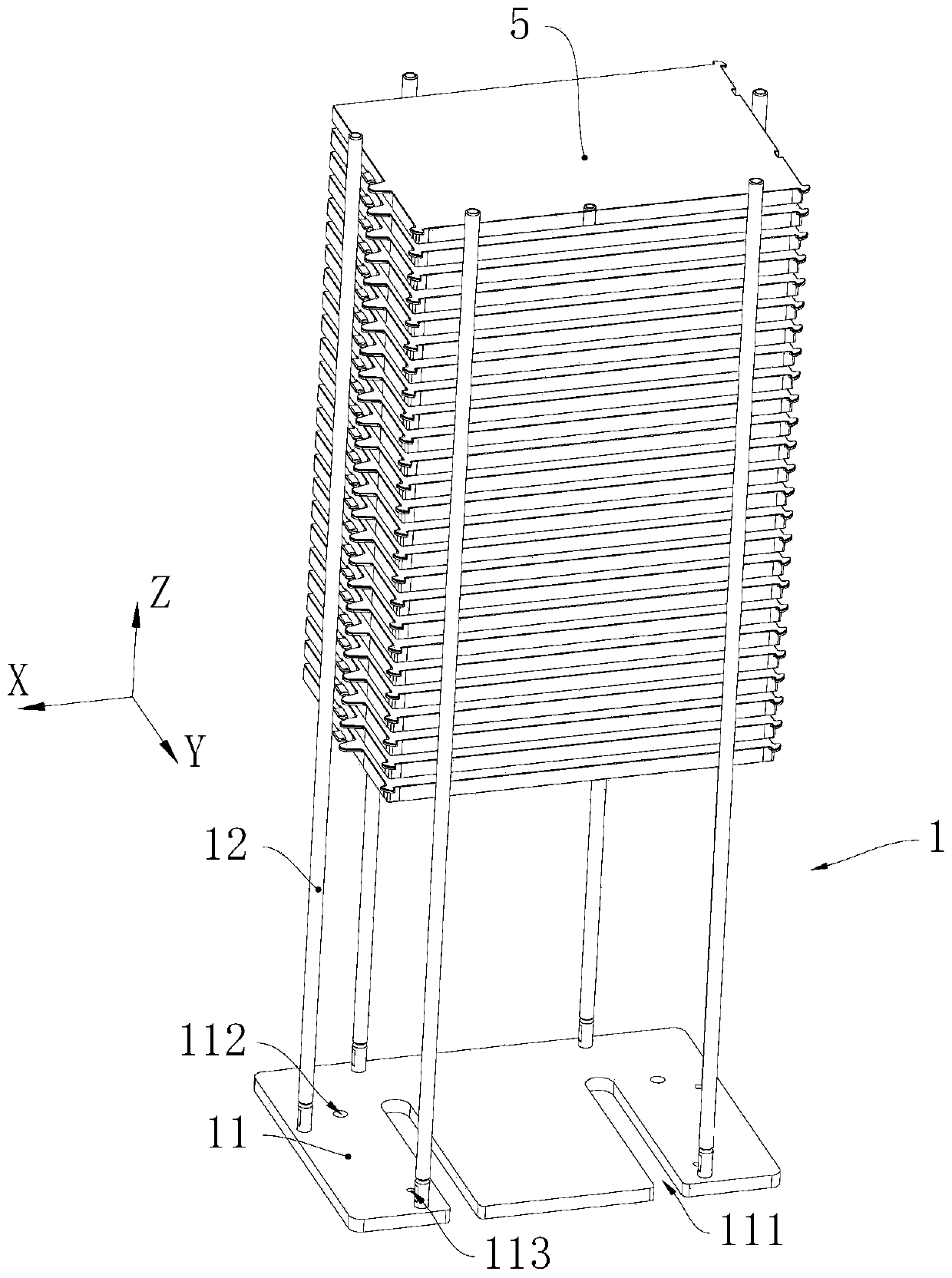

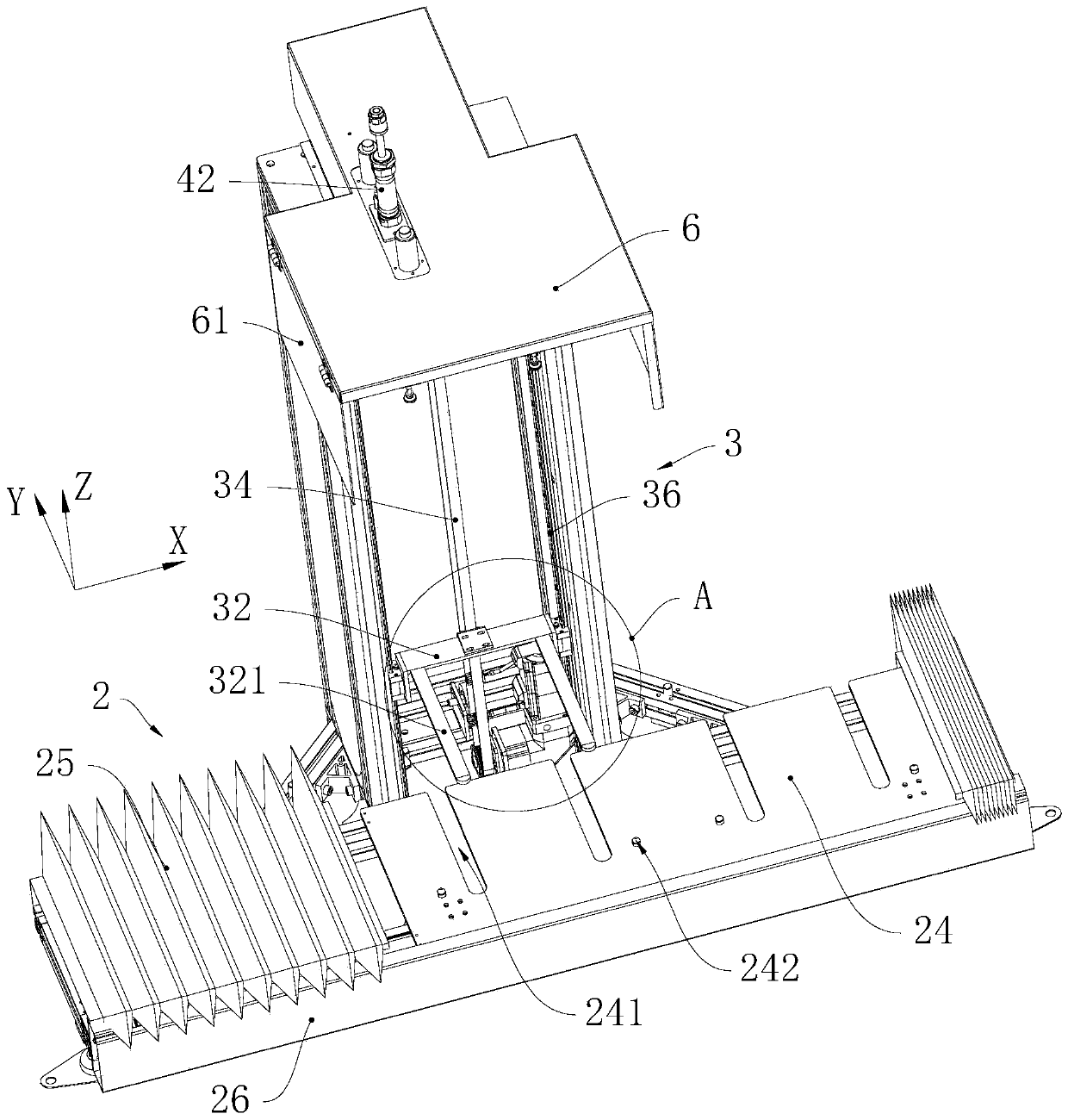

[0042] The sheet metal processing production line of the present embodiment includes the automatic feeding device of the present embodiment, and the automatic feeding device of the present embodiment provides sheets for the sheet metal processing procedure in the sheet metal processing production line of the present embodiment, please refer to Figure 1 to Figure 8 , the automatic feeding device of this embodiment includes a storage rack 1, a horizontal feeding assembly 2, a vertical feeding assembly 3 and a retrieving assembly 4, and a plurality of square plates 5 are stacked on the storage rack 1 along the Z-axis direction, The storage rack 1 is detachably installed on the horizontal feeding assembly 2, the horizontal feeding assembly 2 drives the storage rack 1 to move along the X axis, the vertical feeding assembly 3 drives the square plate 5 to move along the Z axis, and the vertical feedin...

Embodiment 2

[0069] Please refer to Figure 8 and Figure 9 In this embodiment, a double guide rod cylinder 49 is used to replace the first cylinder 42, guide rod 43 and linear bearing 44 in the first embodiment of the automatic feeding device, and the cylinder body 491 of the double guide rod cylinder 49 is fixedly connected to the base plate 410. Both guide rods 492 of the guide rod cylinder 49 are fixedly connected with the frame plate 45 .

[0070] Optionally, the double guide rod cylinder 49 can be that one cylinder extends two guide rods, or two synchronous telescopic cylinders each extend one guide rod.

[0071] The remaining parts of the second embodiment of the automatic feeding device for sheet metal and the sheet metal processing production line are the same as the first embodiment of the automatic feeding device for sheet metal and the sheet material processing production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com