Fabric with breathable hollow hole tissue structure

A technology of weave structure and holes, applied in the direction of fabrics, leno fabrics, leno fabrics, etc., can solve the problems that are not easy to see, warp and weft yarns do not have elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

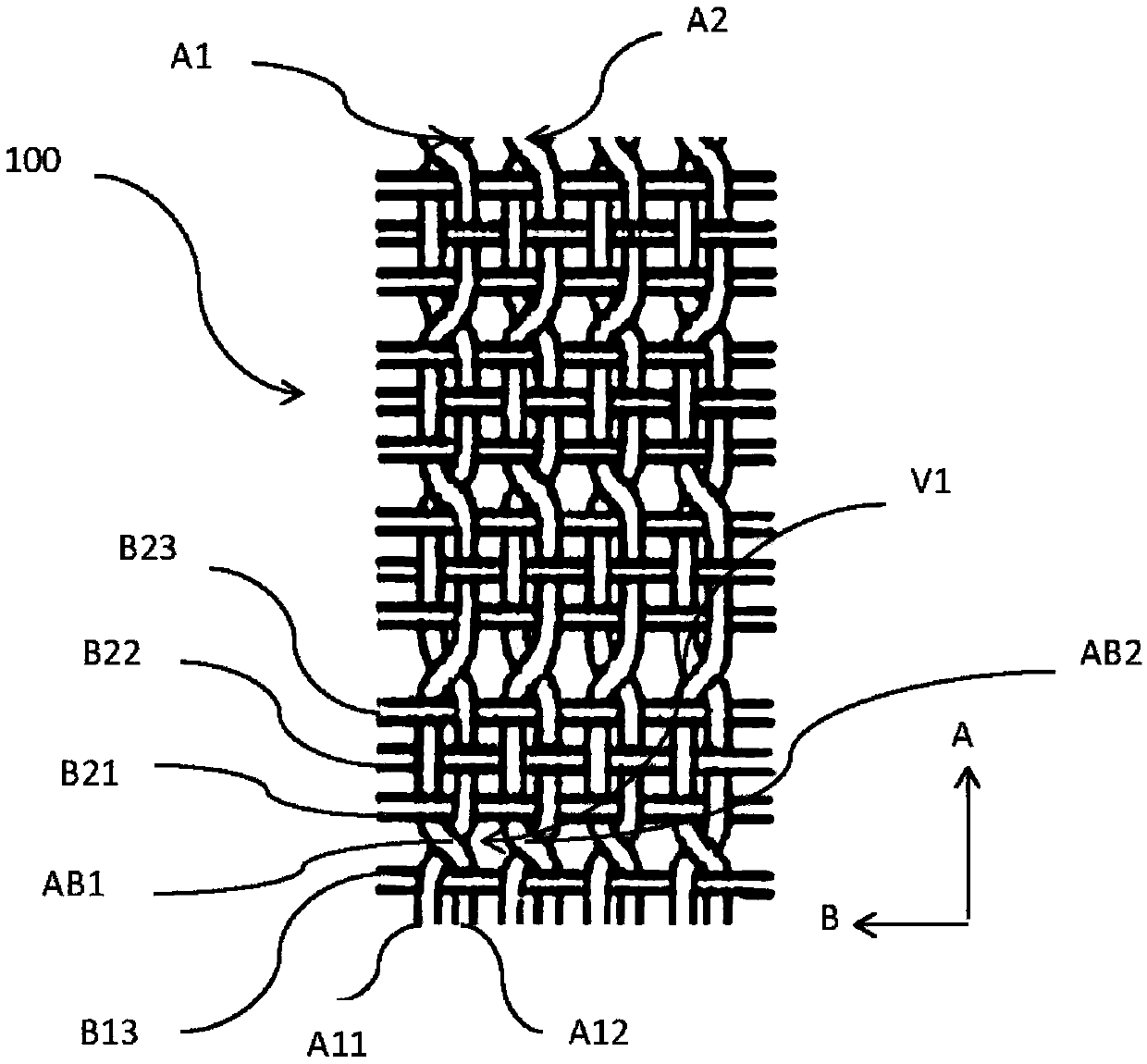

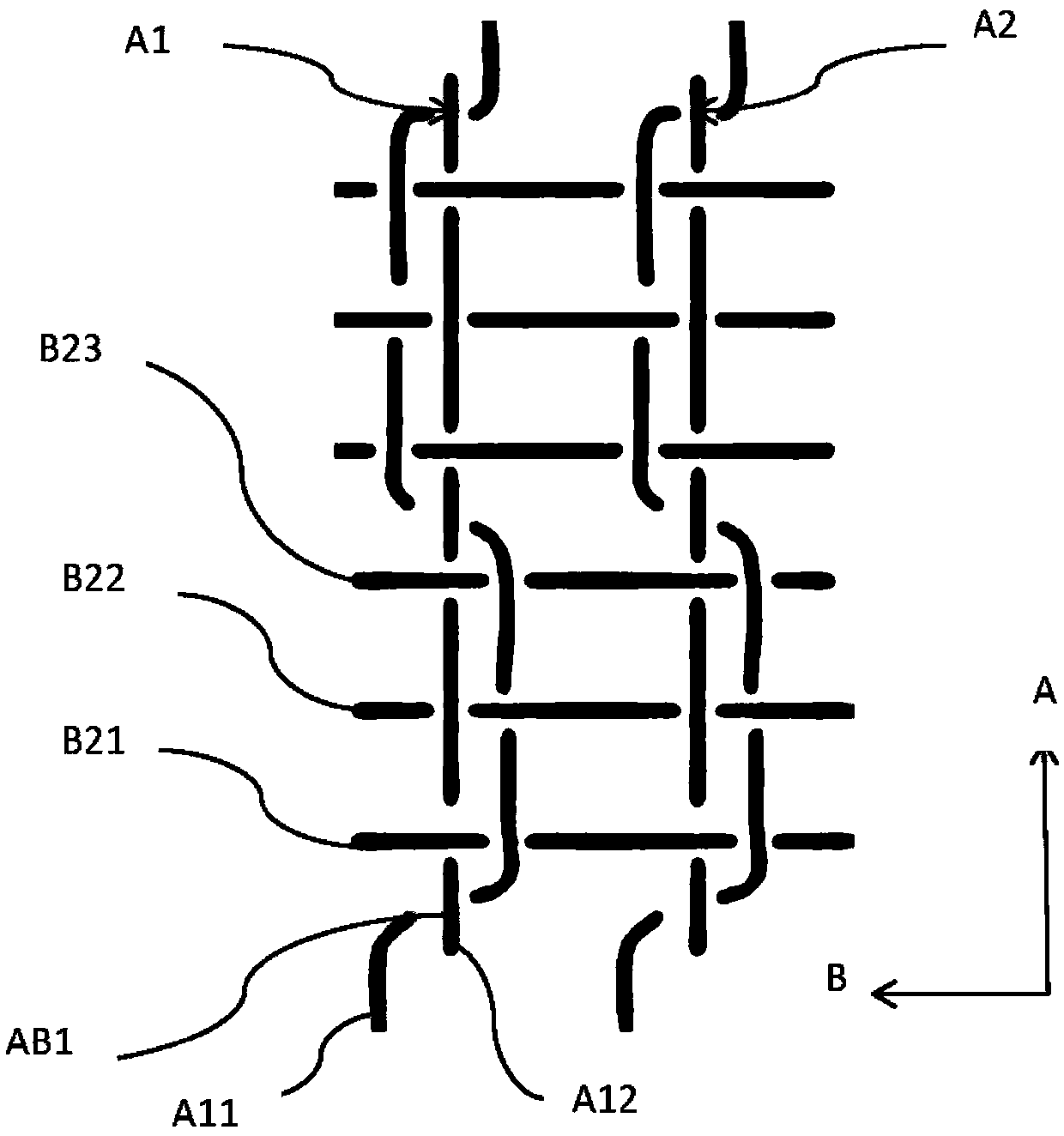

Embodiment 1

[0046] Take Spandex (70 Deny) 26wt% and Nylon66 (70 Deny) 74wt%, wherein polyurethane fiber (spandex) is selected from Formosa Asahi Elastic Fiber Co., Ltd., and Nylon66 is selected from the product of Invista Co., Ltd. of the United States CORDURA, with a production speed of 220m / min under the weaving condition, two warp yarns A11 and A12 form a group A1 intersect each other to form an intersection point AB1, in which warp yarn A11 passes through weft yarn B13 and runs through three weft yarns B21, B22, B23 as a repeating unit , and the hollow hole V1 is formed between the intersection point AB1 and the intersection point AB2 of another group A2, thus forming a 2X3 leno weave 100, and Table 1 refers to the fabric characteristics with a breathable basket hole structure. Good cooling feeling-○; good contact comfort-○; good softness-◎; good durability-◎; appearance-empty basket; dyeing fastness-5.

Embodiment 2

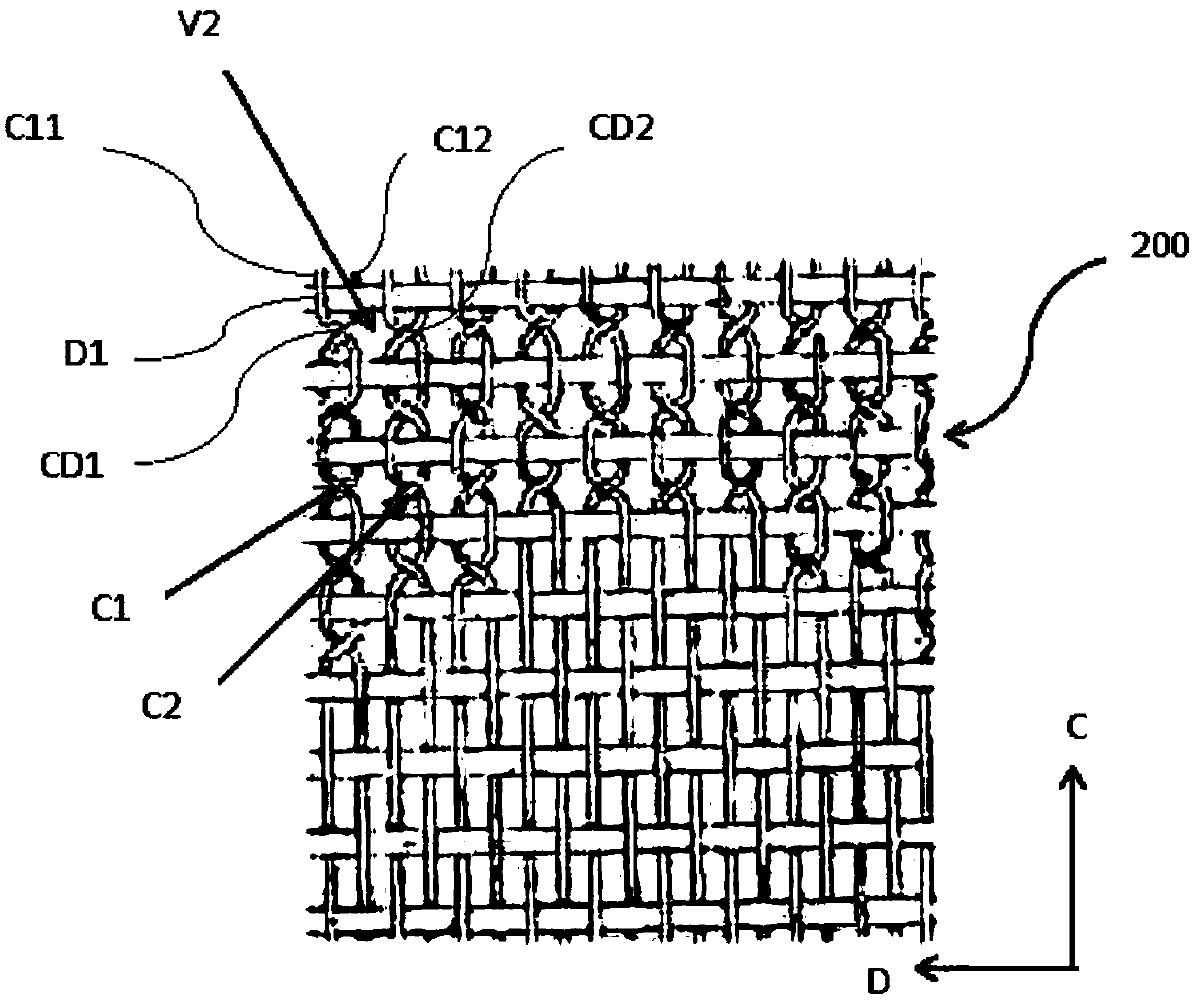

[0048] Get Spandex (70 Deny) 26wt% Nylon6 (70 Deny) 26wt%, wherein polyurethane fiber (Spandex) is selected from Formosa Asahi Elastic Fiber Co., Ltd. product, and Nylon6 is selected from Taiwan Chemical Fiber Co., Ltd. product DOPEDYE's environmentally friendly yarn, and at a weaving production speed of 230m / min, two warp yarns C11 and C12 are collected as a group. C1 intersects each other to form an intersection CD1, in which the warp yarn C11 passes through a weft yarn D1 as a repeating unit, and its intersection point The hollow hole V2 is formed between CD1 and the cross point CD2 of another group C2, thus forming a 2X1 leno weave 200, and as shown in Table 1, it refers to the fabric characteristics with a breathable hollow hole structure, which shows a good cool feeling -◎; good contact comfort-○; good softness-○; good durability-◎; appearance-empty; dyeing fastness-5.

Embodiment 3

[0050] Take 20wt% of Spandex (40 denier) and 80wt% of polyester (50 denier), wherein the polyurethane fiber (Spandex) is selected from the product of Formosa Asahi Elastic Fiber Co., Ltd., and the polyester fiber is selected from Lili Textile Co., Ltd. Co., Ltd. production speed is 225m / min with the sword track shuttle loom, and the warp yarns E11, E12, E13, and E14 are collected as a group. E1 intersect each other to form an intersection point EF1, and the warp yarn E11 runs through a weft yarn F1. And the empty hole V3 is formed between its intersection point EF1 and the intersection point EF2 of another group E2, thus forming 4X1 leno weave 300, and table 1 refers to the fabric characteristic with air-permeable basket hole structure, which shows Good cool feeling - ○; good touch comfort - ◎; good softness - ○; good durability - ○; appearance - hollow; color fastness - 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com