Fabricated partition wall installation structure fabricated rapidly

An installation structure and prefabricated technology, applied in the direction of walls, sound insulation, insulation, etc., can solve the problems of high labor cost, high cost of light steel keel, cumbersome construction steps, etc., and achieve simple installation steps, low construction cost and labor cost , Easy and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

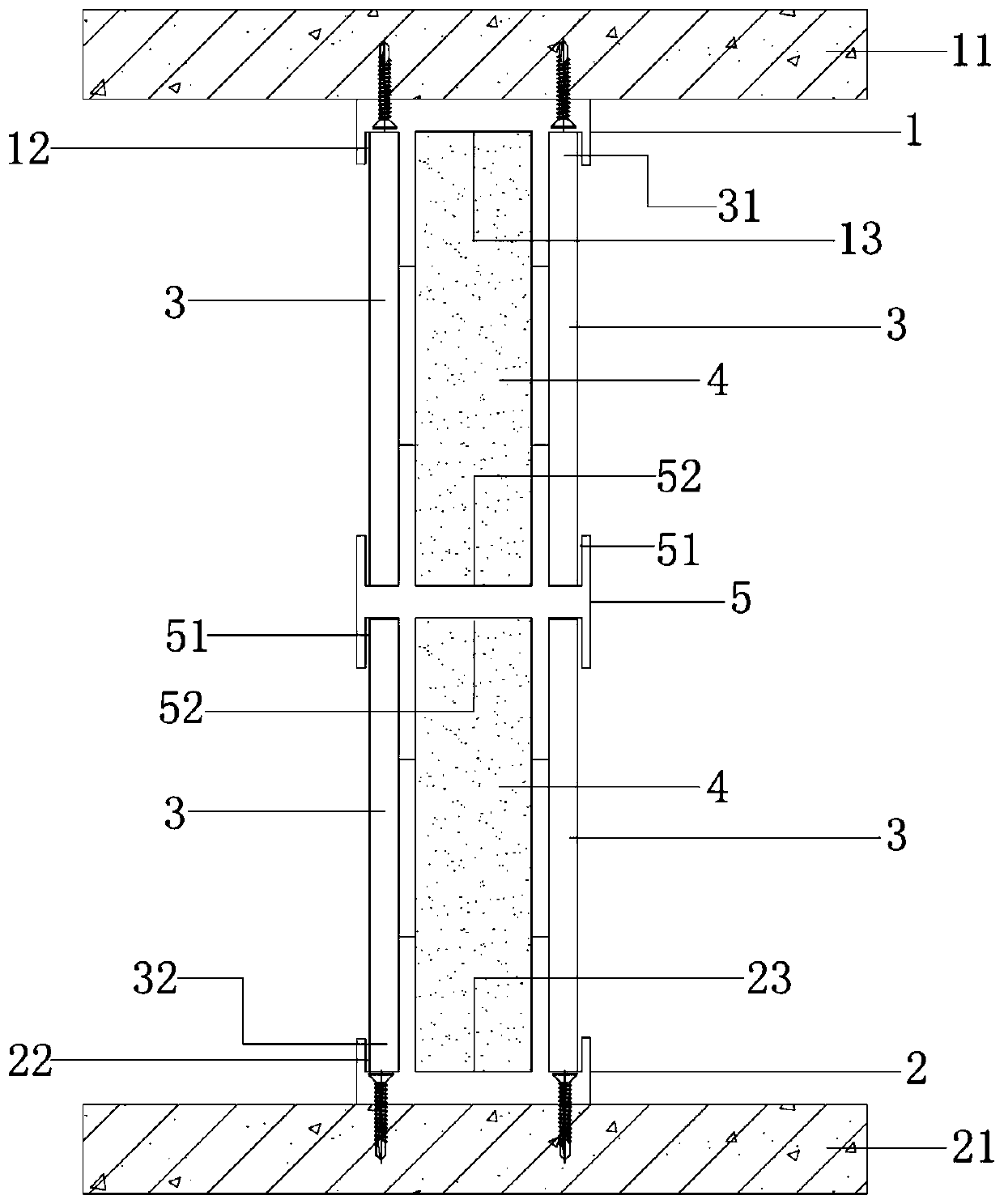

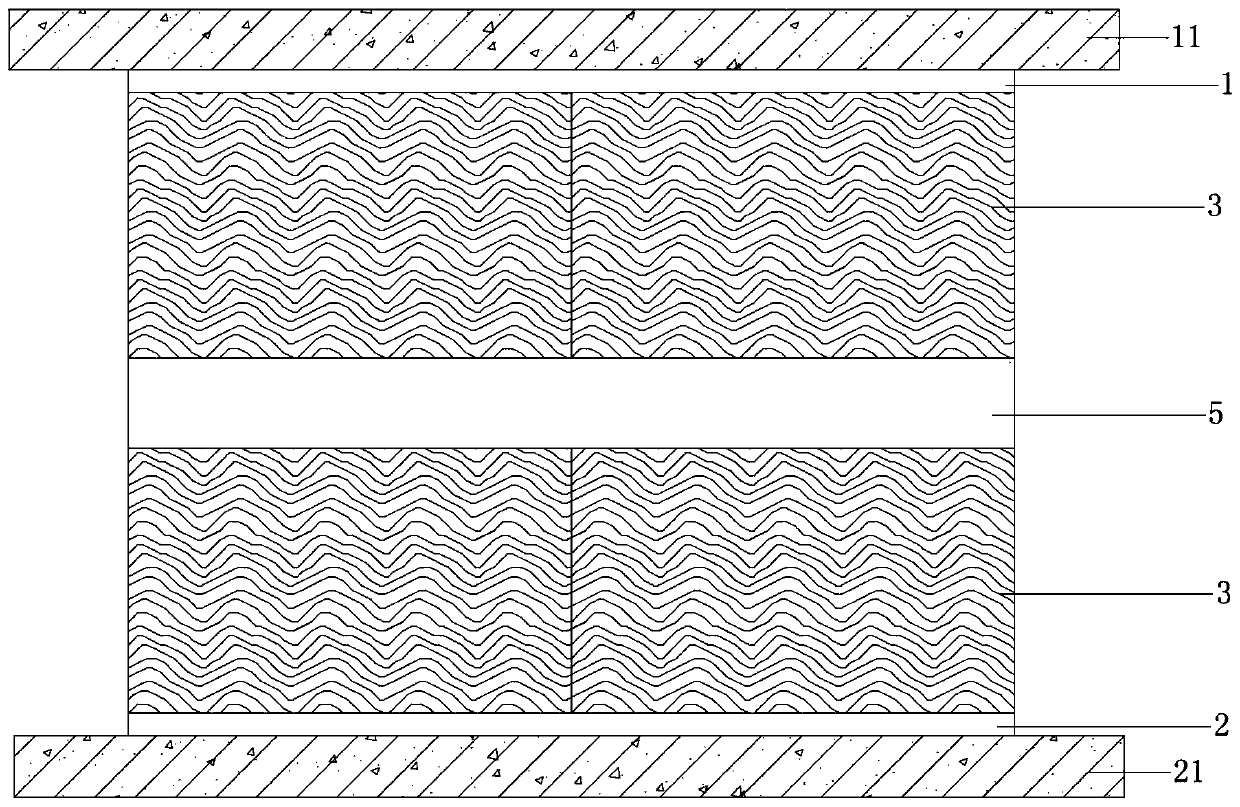

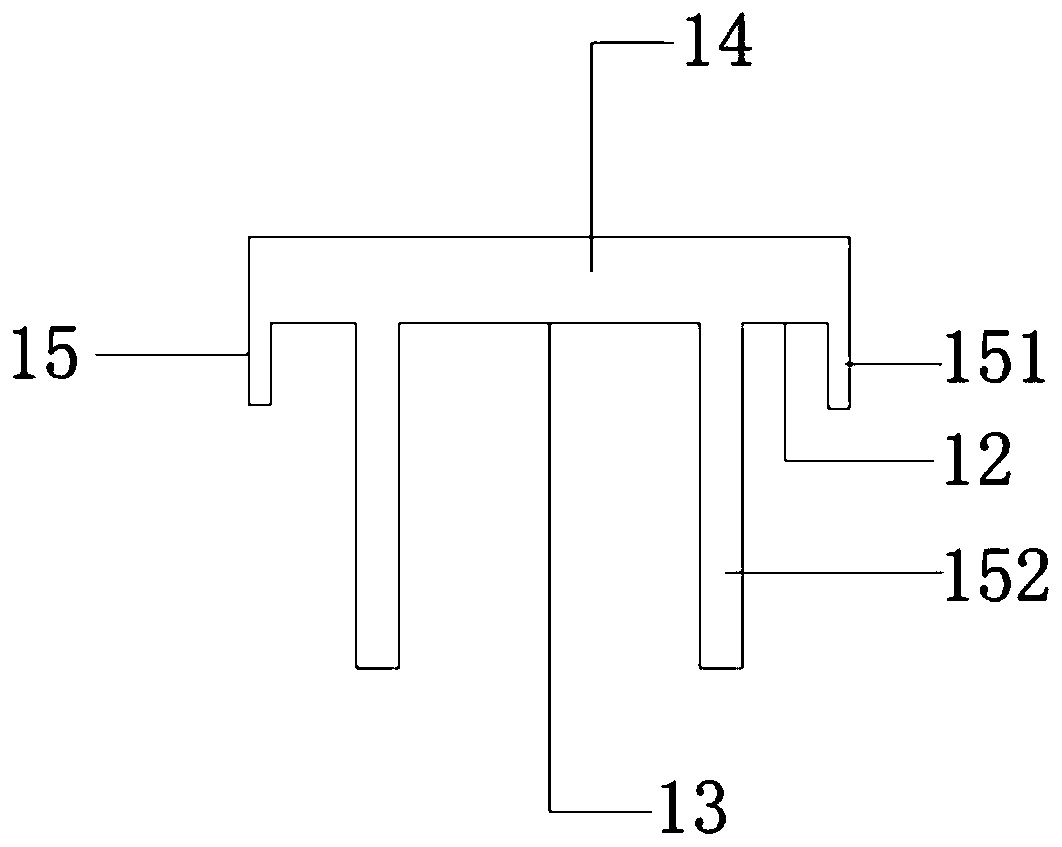

[0031] see Figure 1 to Figure 4 , the figure shows a quick-assembled prefabricated partition wall installation structure provided by Embodiment 1 of the present invention. First, a partition wall top fixing member 1 is provided, which is fixedly connected to the building top surface 11, and the top of the partition wall is fixed The bottom surface of the part 1 is provided with two symmetrical partition wall top fixing grooves 12; secondly, the partition wall bottom fixing part 2 is provided, which is fixedly connected to the building ground 21, and the top surface of the partition wall bottom fixing part 2 is provided with two symmetrical parts. The bottom fixing groove 22 of the partition wall; two parallel and symmetrical partition wall panels 3 are provided again, and the top 31 of each partition wall panel 3 is stuck in the fixing groove 12 at the top of the partition wall, and the bottom end 32 is stuck in the fixing groove at the bottom of the partition wall Within 22....

Embodiment 2

[0039] Others are the same as those described in the above-mentioned embodiments, except that, on the basis of the above-mentioned embodiments, sound-insulating cotton is provided, which is suitable for the installation of partition walls using sound-insulating cotton; see Figure 1 to Figure 4 The top fixing groove 13 of the soundproof cotton is formed between the top fixing grooves 12 of the two partition walls, the bottom fixing groove 23 of the soundproof cotton is formed between the fixing grooves 22 at the bottom of the two partition walls, the top of the soundproof cotton 4 is stuck in the top fixing groove 13 of the soundproof cotton, The bottom end of the soundproof cotton 4 is stuck in the fixing groove 23 at the bottom of the soundproof cotton.

[0040] Specifically, see Figure 1 to Figure 4 , On the fixing member 1 at the top of the partition wall, a fixing groove 13 at the top of the sound insulation cotton is formed between the two first rib components 15 .

[...

Embodiment 3

[0043] Others are the same as those described in the above-mentioned embodiment, the difference is that, on the basis of the above-mentioned embodiment, an intermediate fixing part for the partition wall is provided, which is suitable for the installation of the partition wall where the height of the partition wall needs to be divided into multiple partition wall units; see Figure 1 to Figure 5 , in the height direction of the partition wall, each adjacent two partition wall boards 3 are connected through the partition wall intermediate fixing member 5, and two partition wall intermediate fixing grooves 51 are respectively arranged on the opposite sides of the partition wall intermediate fixing member 5 , the end of the partition wall panel 3 snaps into the fixing groove 51 in the middle of the partition wall.

[0044] Specifically, see Figure 1 to Figure 5 The partition wall intermediate fixing member 5 includes a third fixing plate 53, two symmetrical third rib assemblies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com