Co-extrusion wood-plastic hanging-buckle-type screwless corner capping seal

A closing strip, screwless technology, applied in the direction of construction, building structure, etc., can solve the problems of long construction time, complicated construction, affecting the beauty of the wall, etc., and achieves a clean installation site, beautiful structural appearance, and improved ease of operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

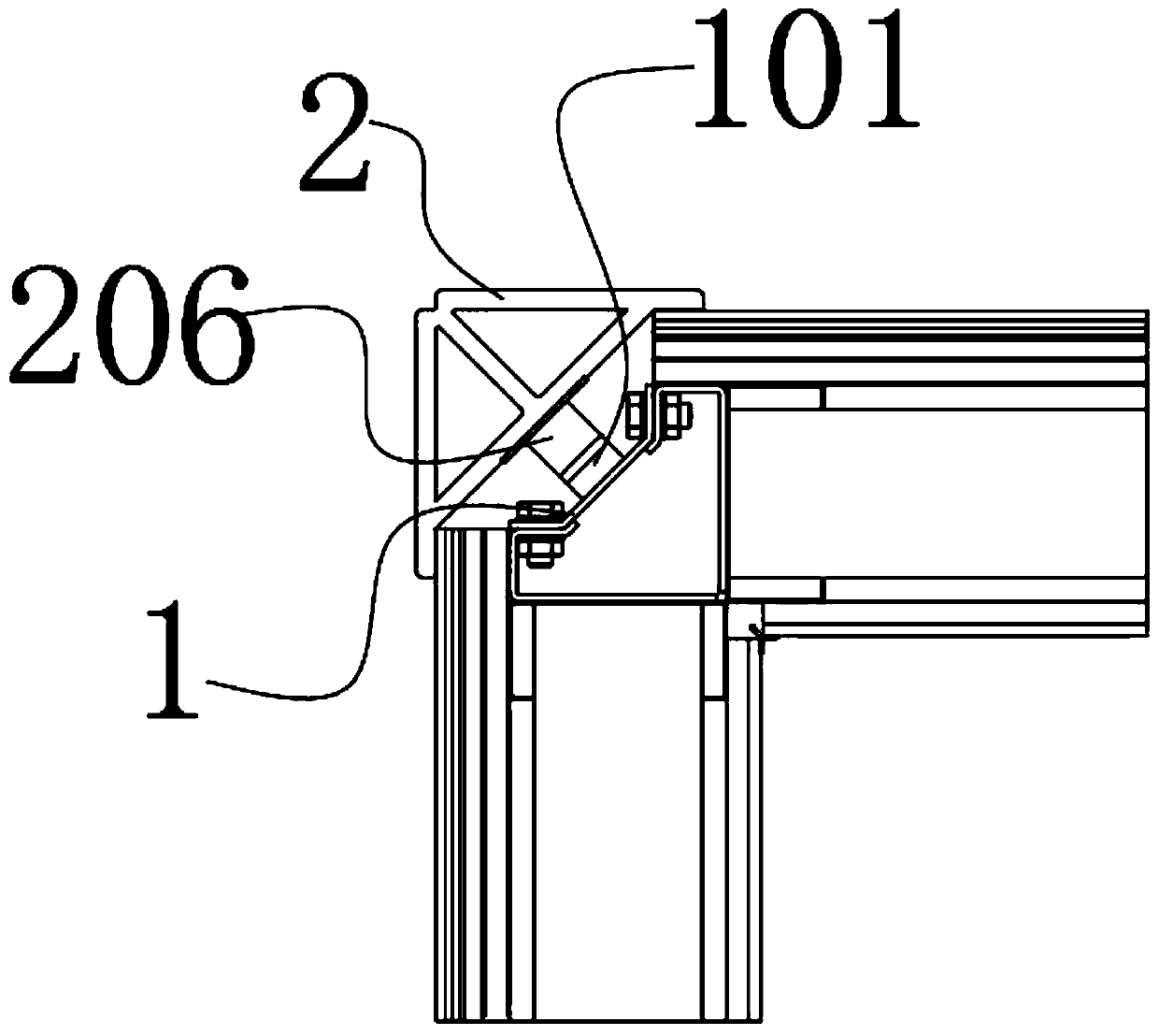

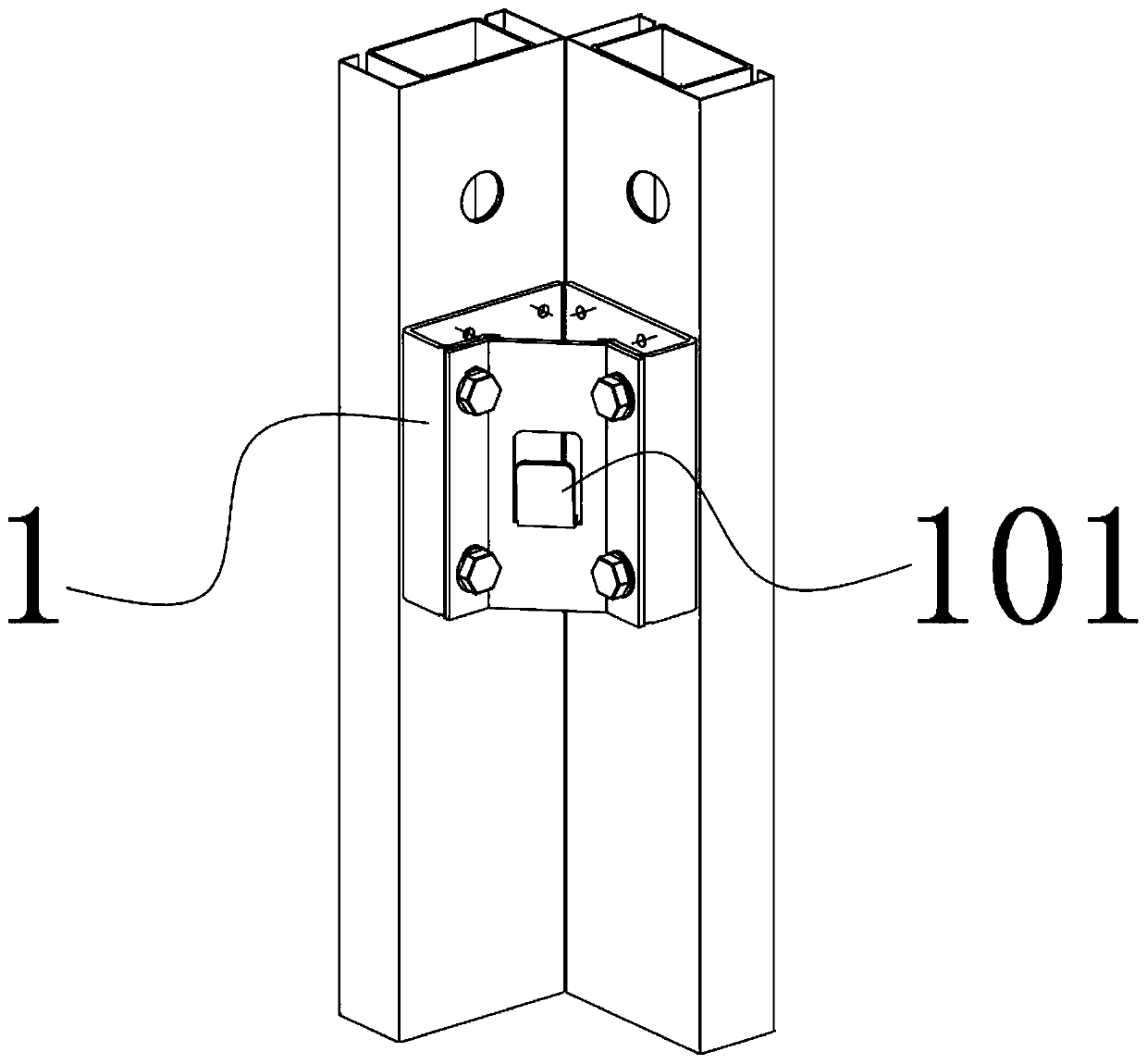

[0032] see Figure 1-6 , is a schematic diagram of the overall structure in an embodiment; including: closing strip fixing seat 1, there are a plurality of closing strip fixing seats 1, and the closing strip fixing seat 1 is increased or decreased with the height of the wall of the module body to improve The firmness of the installation of the closing strip 2;

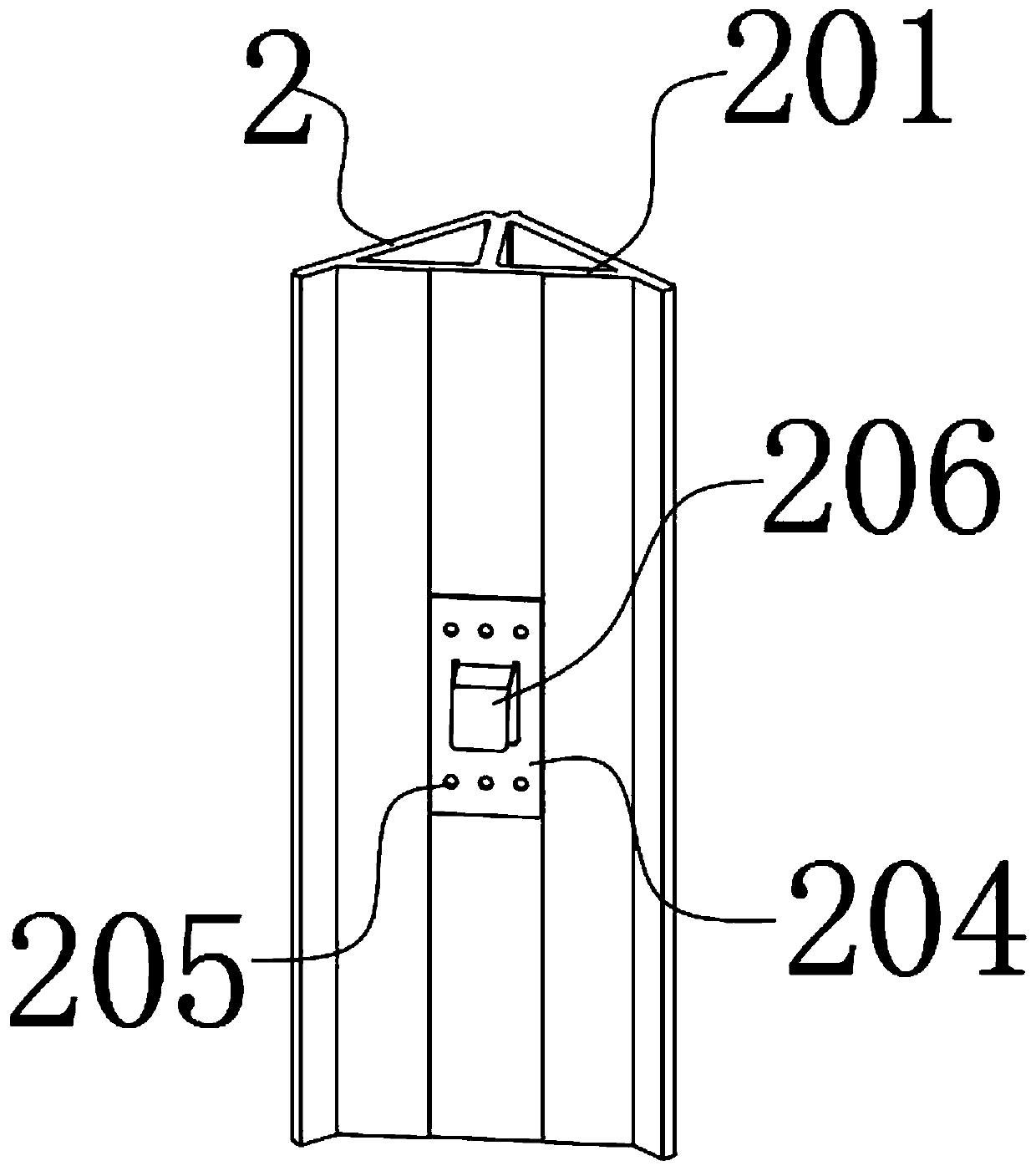

[0033] Closing strip 2, the inside of closing strip 2 is provided with closing strip hook 206, and closing strip hook 206 is provided with a plurality of, and closing strip hook 206 is arranged on the hook base 204 and is established as one with the hook base 204, and the hook base 204 is provided with multiple One, the hook base 204 is installed on the inner support plate 201 of the closing strip 2, which is convenient to engage with the closing strip fixing seat 1, and the closing strip 2 is fixed at the angle of the wall;

[0034] Among them, the closing strip fixing seat 1 is fixedly installed in the angle gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com