Clean room engineering color plate mounting manipulator

A technology of color steel plate and clean room, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of large number of personnel, low installation efficiency, and safety, so as to increase equipment stability, improve efficiency, medium volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

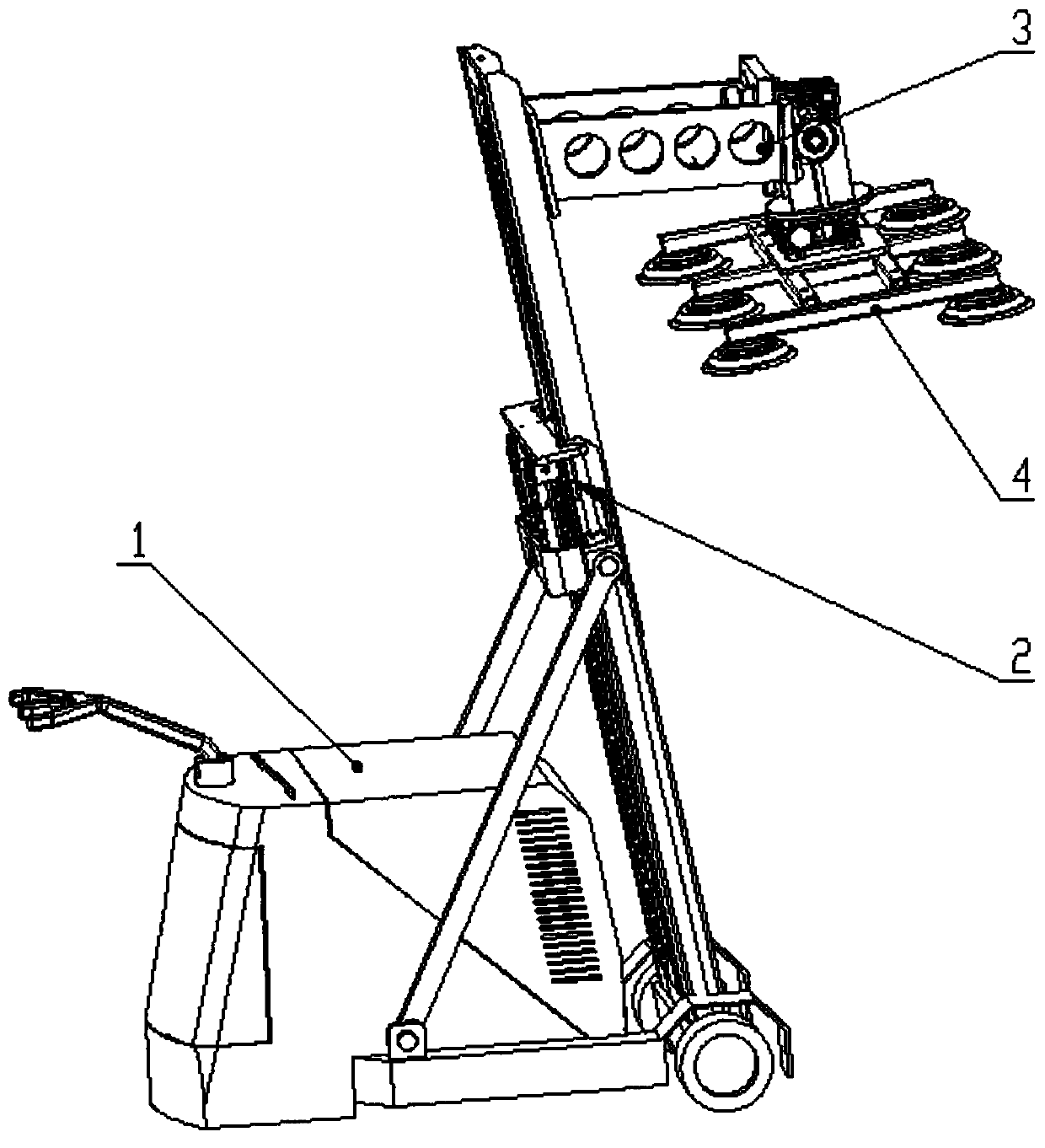

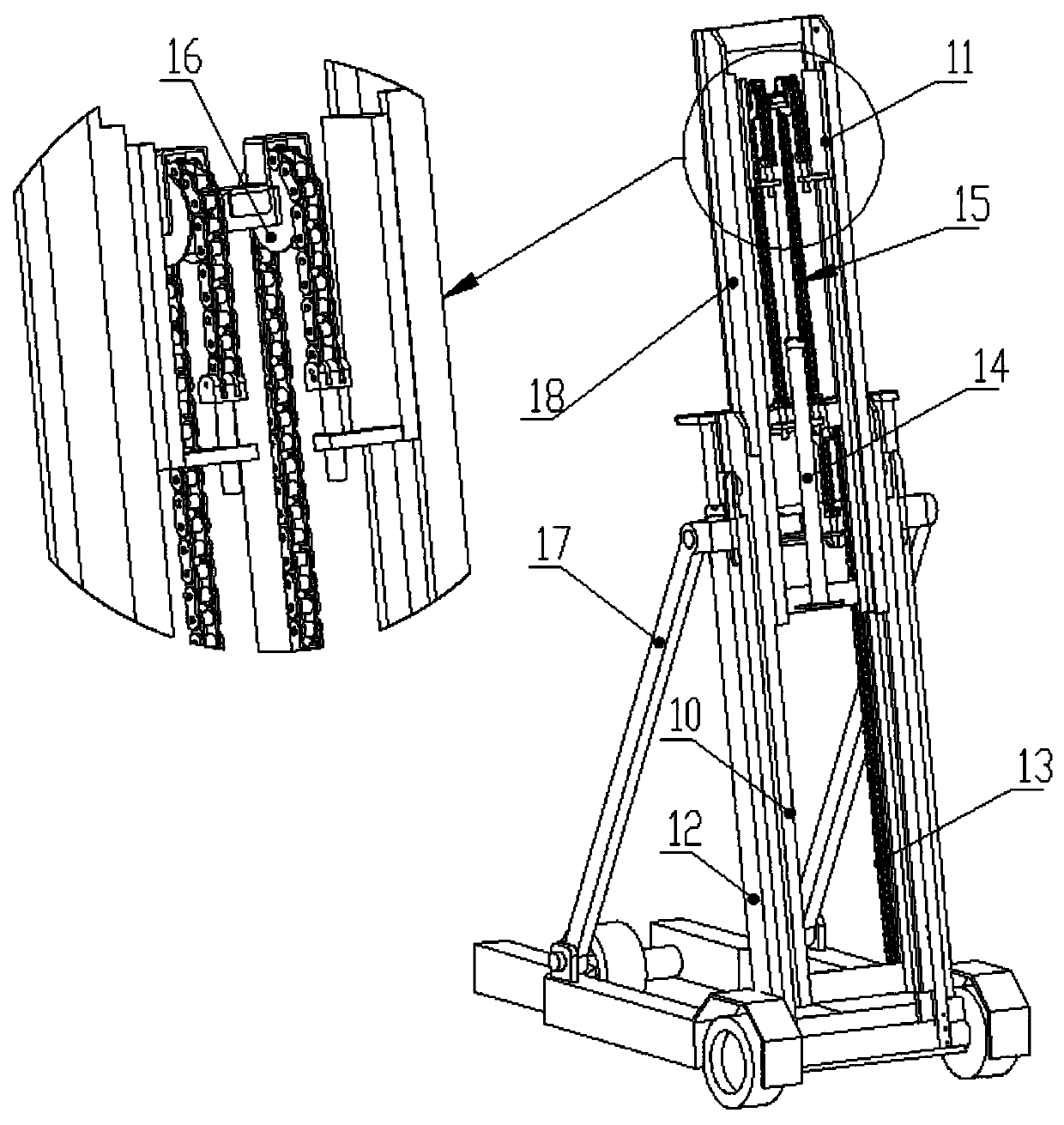

[0032] Attached below Figure 1-5 The specific embodiment of the present invention will be further described.

[0033] Manipulator for installation of color steel plates in clean room engineering, including walking and control mechanism 1, hydraulic lifting mechanism 2, hydraulic translation and turning mechanism 3, vacuum sucker suction mechanism 4, walking and control mechanism 1 and hydraulic lifting mechanism 2 welding, hydraulic lifting mechanism 2 It is welded with the hydraulic panning and turning mechanism 3, and the hydraulic panning and turning mechanism 3 is connected with the vacuum sucker suction mechanism 4 through bolts;

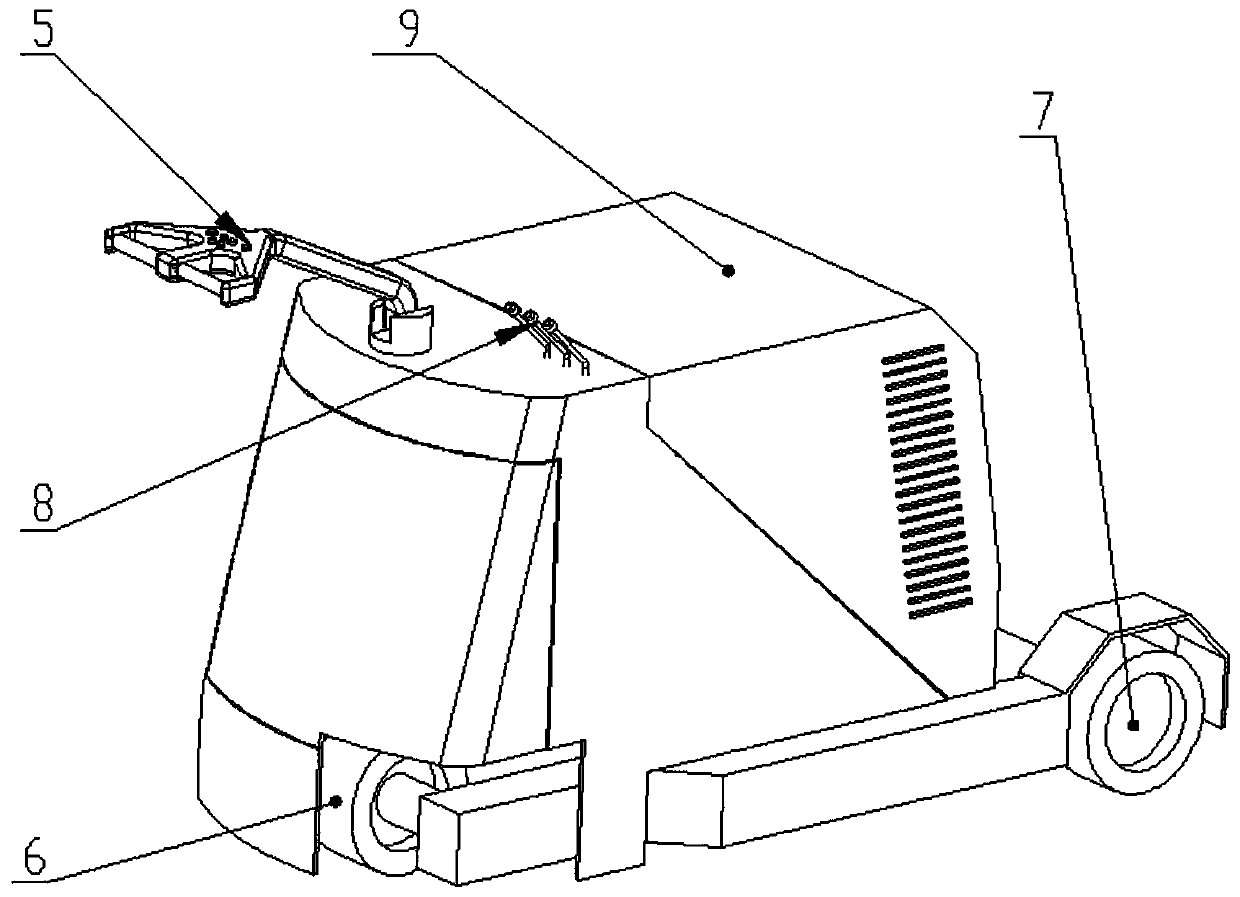

[0034] The walking and control mechanism 1 includes a housing 9, which is provided with a servo motor, a hydraulic station, a vacuum pump, and a storage battery. The top of the housing 9 is equipped with an electric forklift handle assembly 5 and a control rod 8. The bottom wheel of the housing 9 Wheels are installed on the frame;

[0035] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com