Longitudinal steel rail constraining force test method for rail traffic

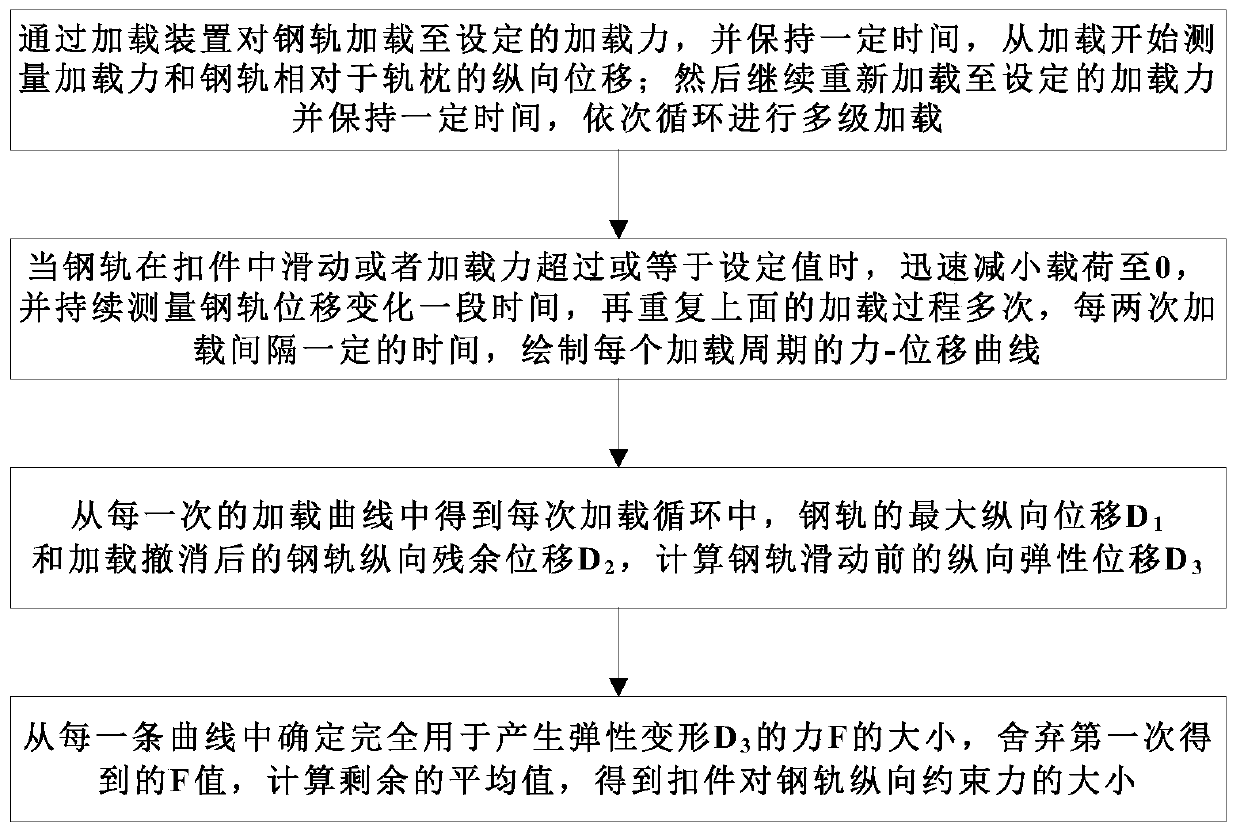

A test method and technology of rail transit, applied in the test of mechanical parts, the test of machine/structural parts, force/torque/work measuring instruments, etc., can solve the problems of difficult operation, complicated test process, inaccurate test results, etc. Achieve the effect of high accuracy, simple test process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

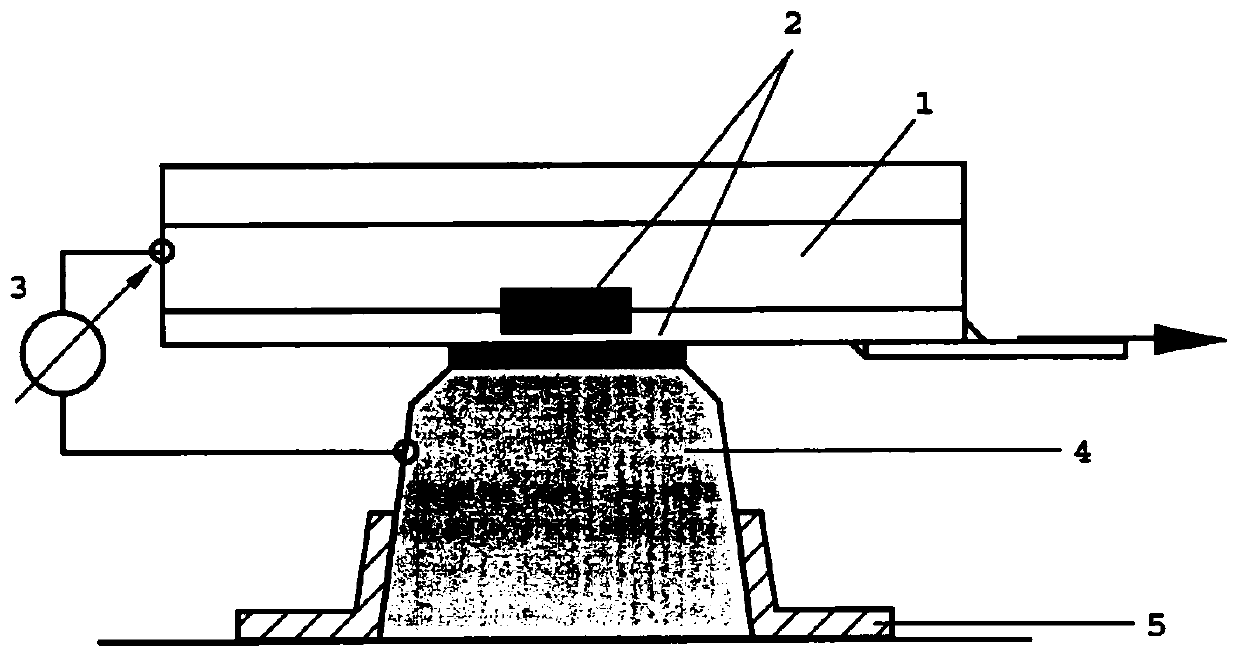

[0024] like figure 2 As shown, for fasteners designed symmetrically with elastic strips, the sleeper 4 is first fixed by the rigid fixture 5, and then the rail 1 is fixed on the sleeper 4 by a single fastener 2, and then the load is applied longitudinally along the rail 1; for the spring strip staggered design Fix the sleeper 4 first, then fix the rail 1 on the sleeper 4 or other supporting structures through two fasteners 2 (the spacing between the fasteners is the standard spacing), and then apply the load along the longitudinal direction of the rail 1. A load-displacement test recording instrument 3 is connected between the rail 1 and the sleeper 4 .

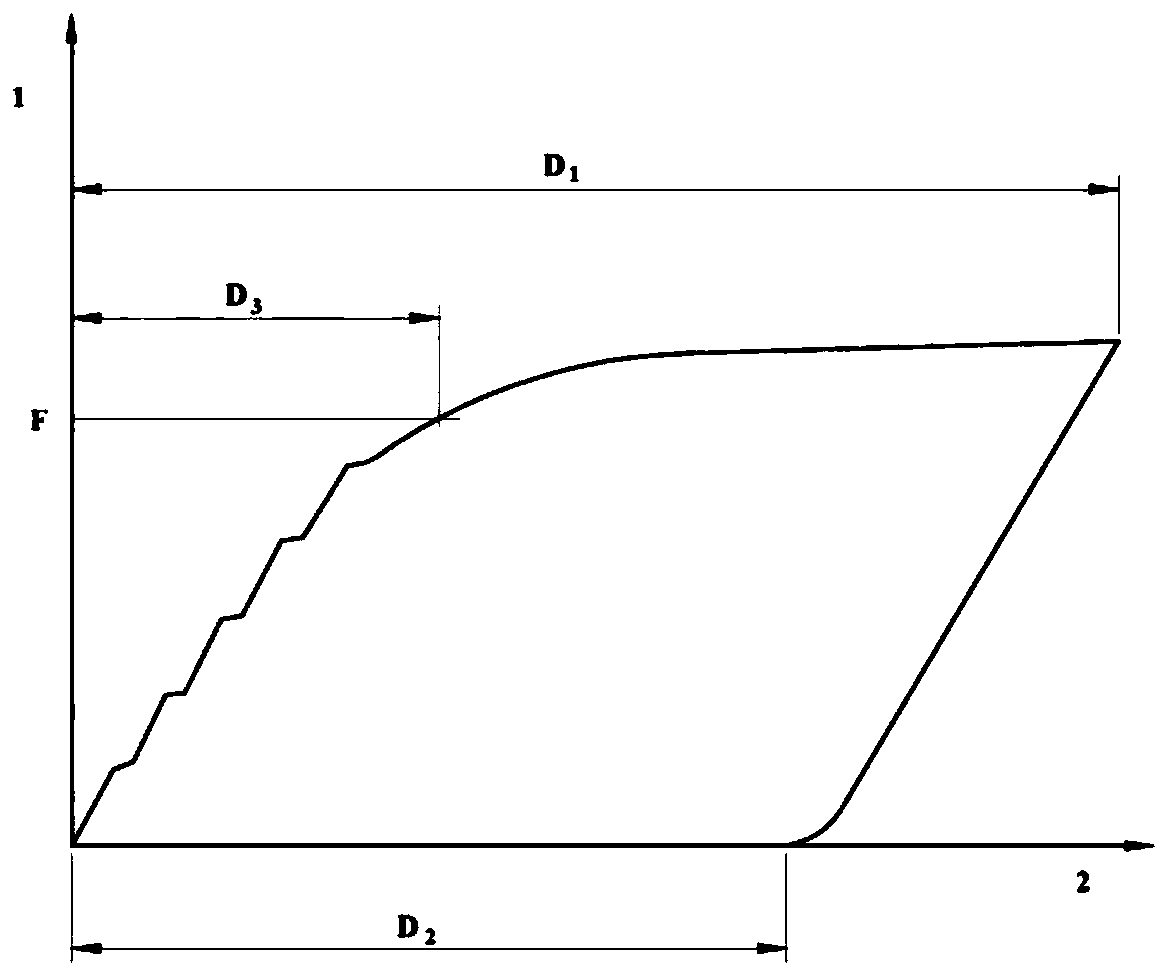

[0025] During the loading process, record the displacement of the rail relative to the sleeper until the loading ends when the rail slides. Then the maximum load under the condition that the rail does not undergo inelastic deformation is obtained on the force-displacement diagram.

[0026] The load-displacement test record...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com