Spring-wrapped jack contact member

A technology of jack contacts and jacks, which is applied in the field of spring-covered jack contacts, can solve the problems of large plugging force, low contact reliability, unreliable contact, etc., and achieves improved deformability and contact reliability. High, wide range of insertion force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

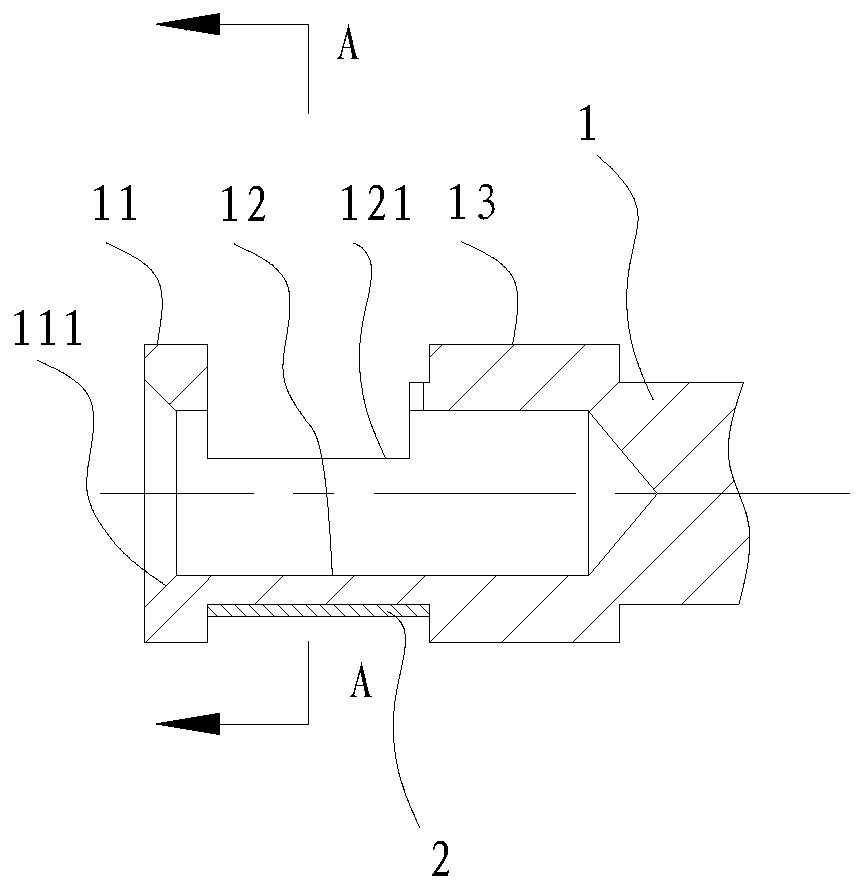

[0044] Such as Figure 1-3 , a spring socket contact, including a socket 1 and a contact ring 2. The insertion end of the socket 1 is a cylindrical body, including a guide section 11, an insertion section 12 and a support section 13. The outer diameter of the insertion section 12 is smaller than the outer diameter of the guide section 11 and the support section 13, and its side A window 121 is opened in the axial center of the wall.

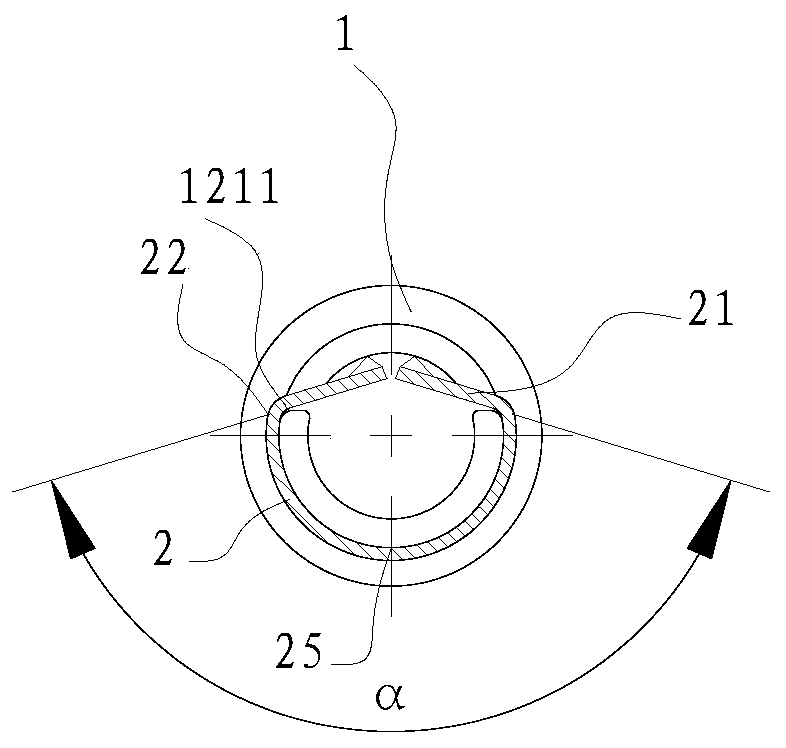

[0045] The contact ring 2 is a plate-shaped body folded into a "U" shape, including two "1"-shaped contact elastic pieces 21 and an arc segment 22 . The four vertices of the contact elastic piece 21 are bent outwards to form a guide portion 23 , and the guide portion 23 faces the outer surface of the “U” shape.

[0046] The contact ring 2 is surrounded by the mating section 12, and the two "1"-shaped contact springs 21 of the "U" shape are bent inward with a tool, so that the two "1"-shaped contact springs 21 form an obtuse angle α, and the con...

Embodiment 2

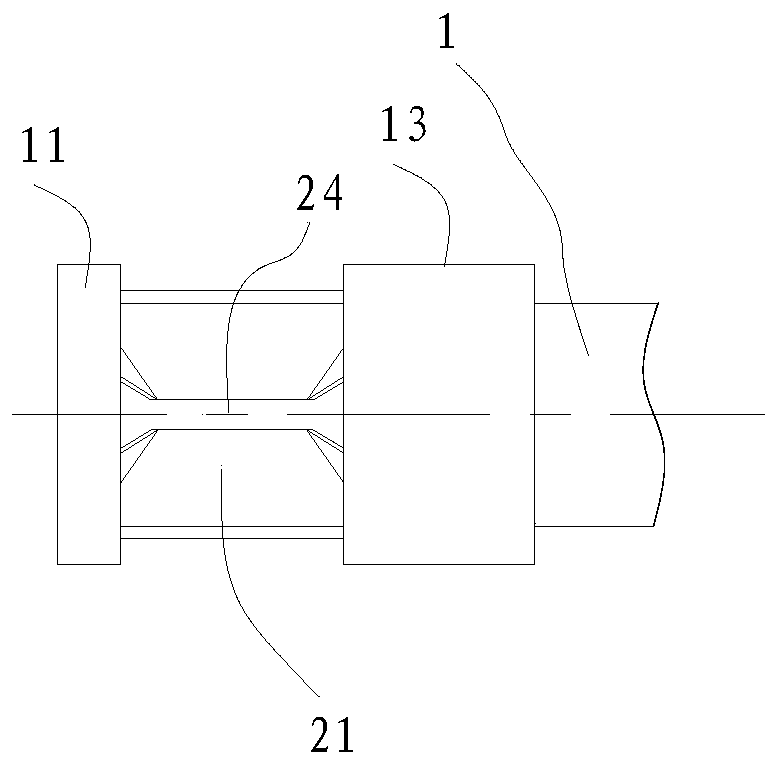

[0048] Such as Figure 4-8 The difference between the structure of embodiment 2 and embodiment 1 is that two or more windows 12 are opened on the mating section 12, and there are two or more windows 12 on the corresponding contact ring 2, and these windows and contact The rings 2 are arranged alternately and staggered in the axial direction of the socket 2, and also uniformly distributed in the radial direction, so as to balance the contact force structure of the contact pair and increase the contact area and electrical contact reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com