Patents

Literature

34results about How to "Guaranteed elastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

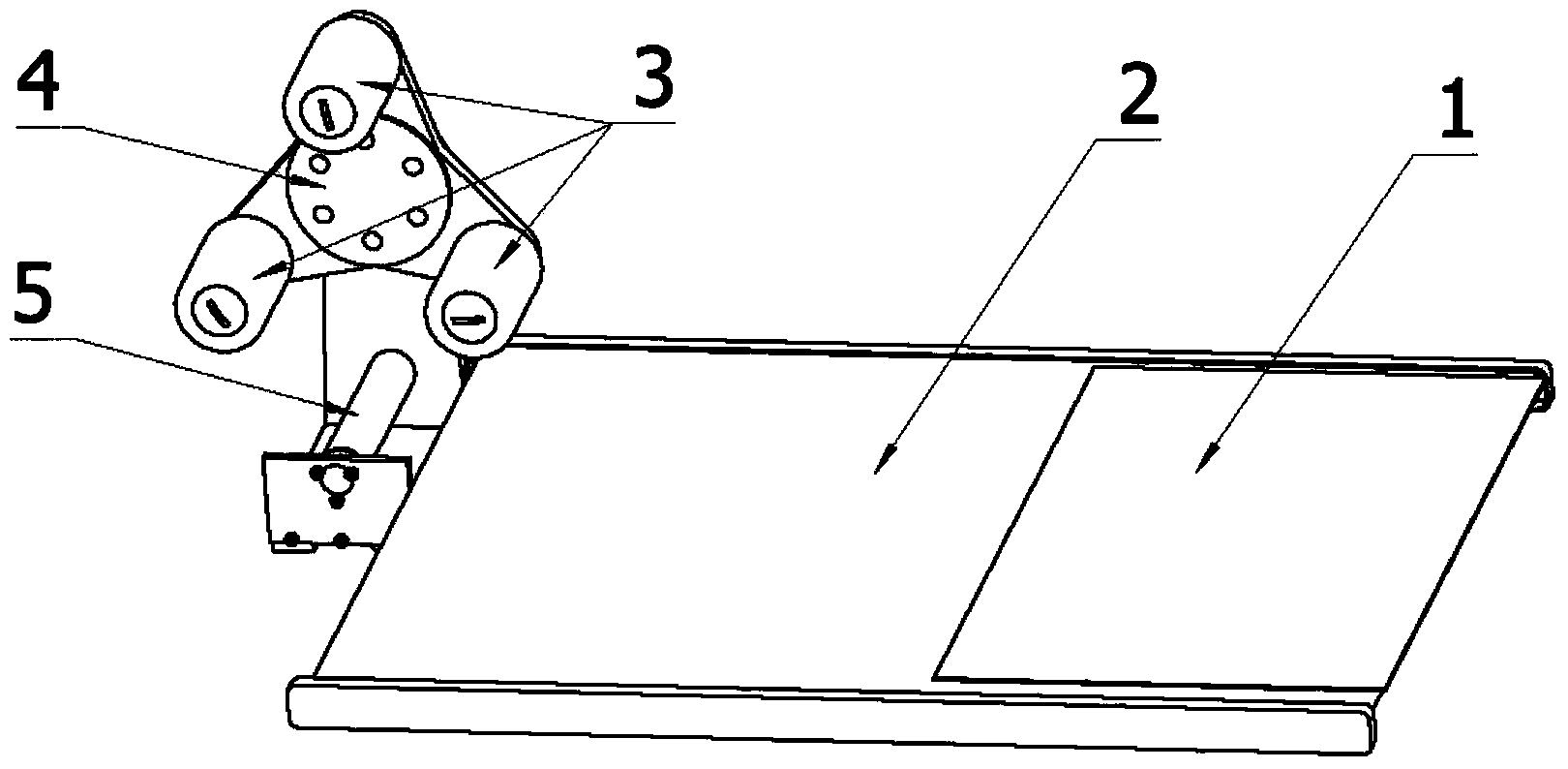

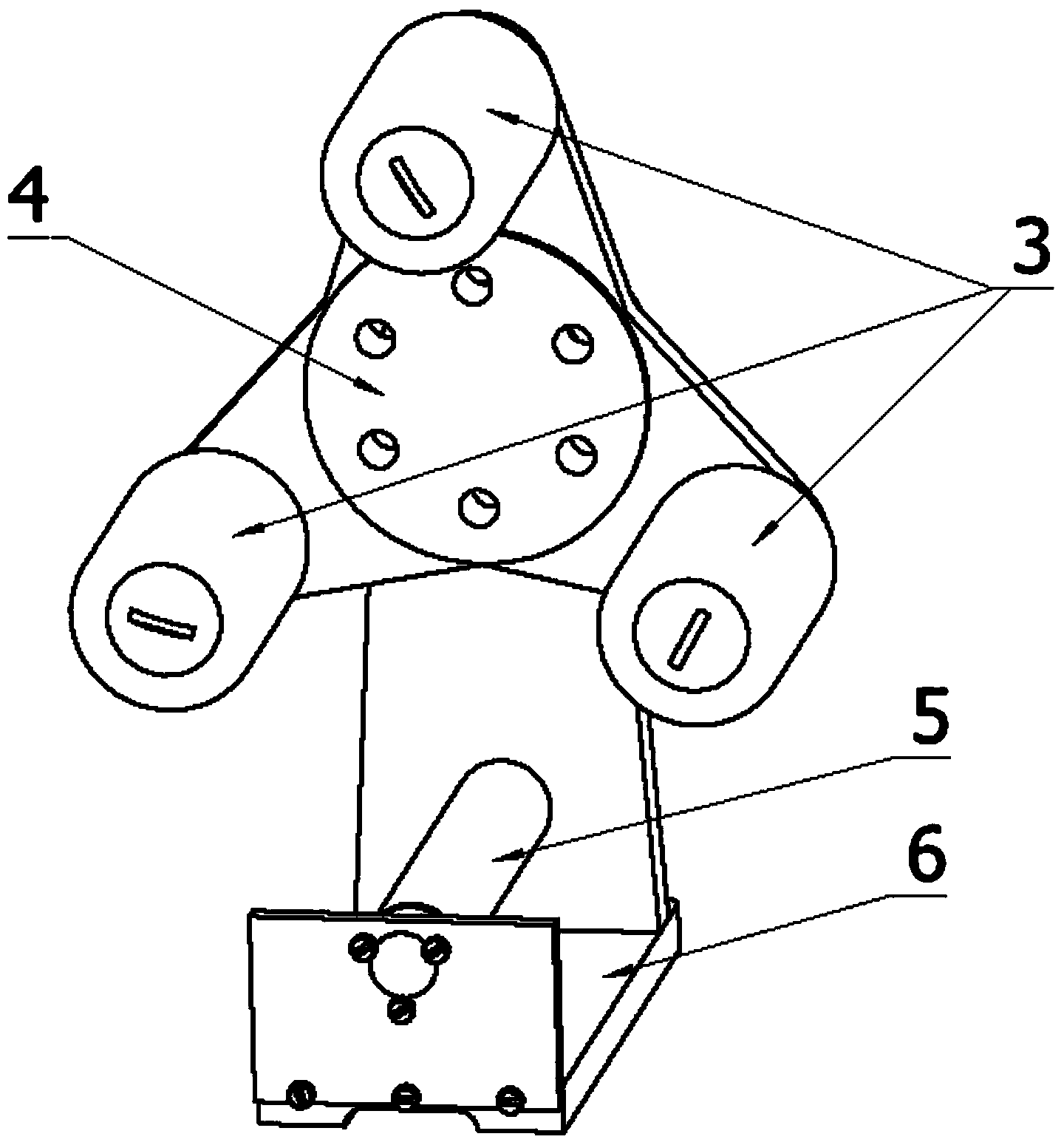

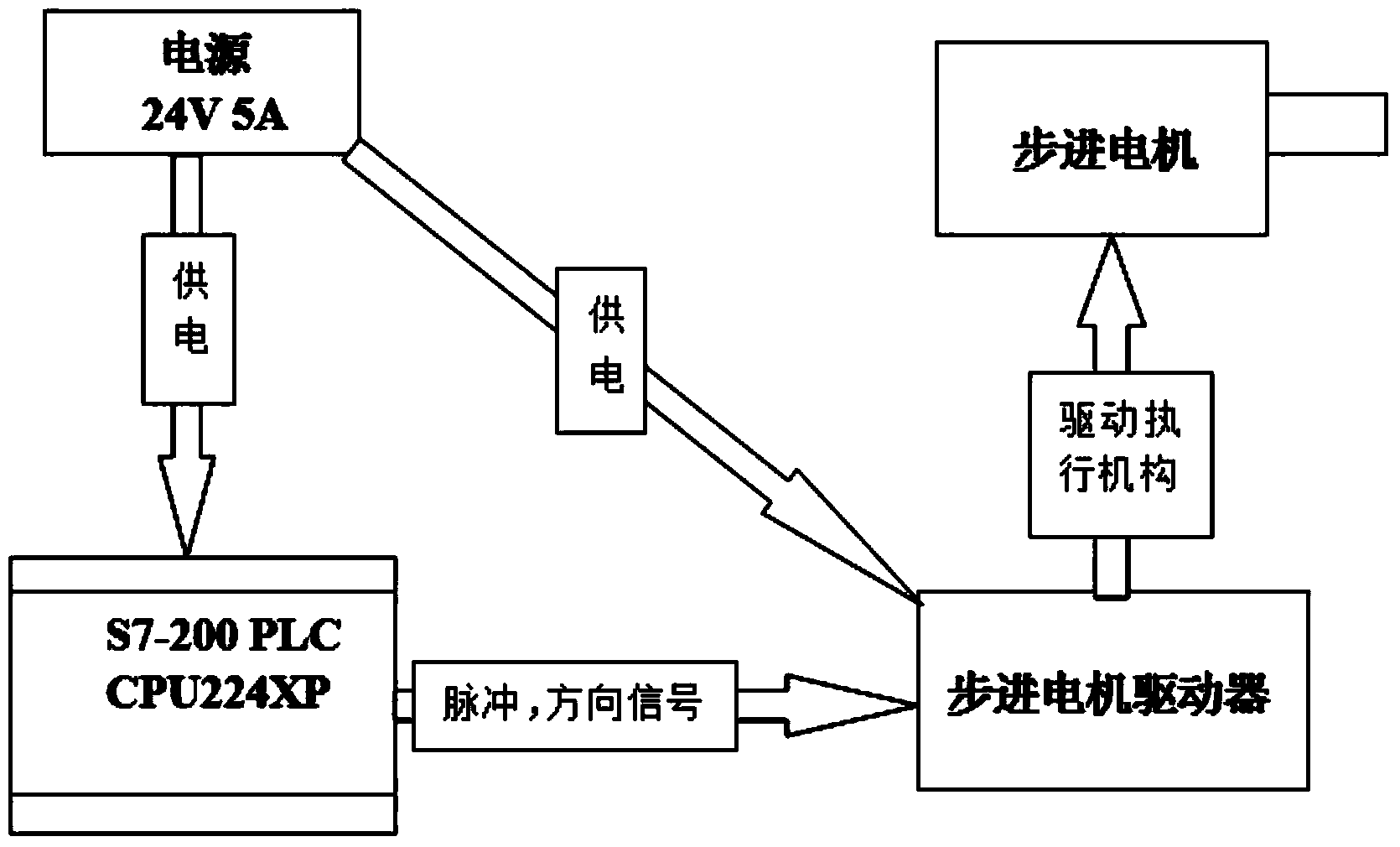

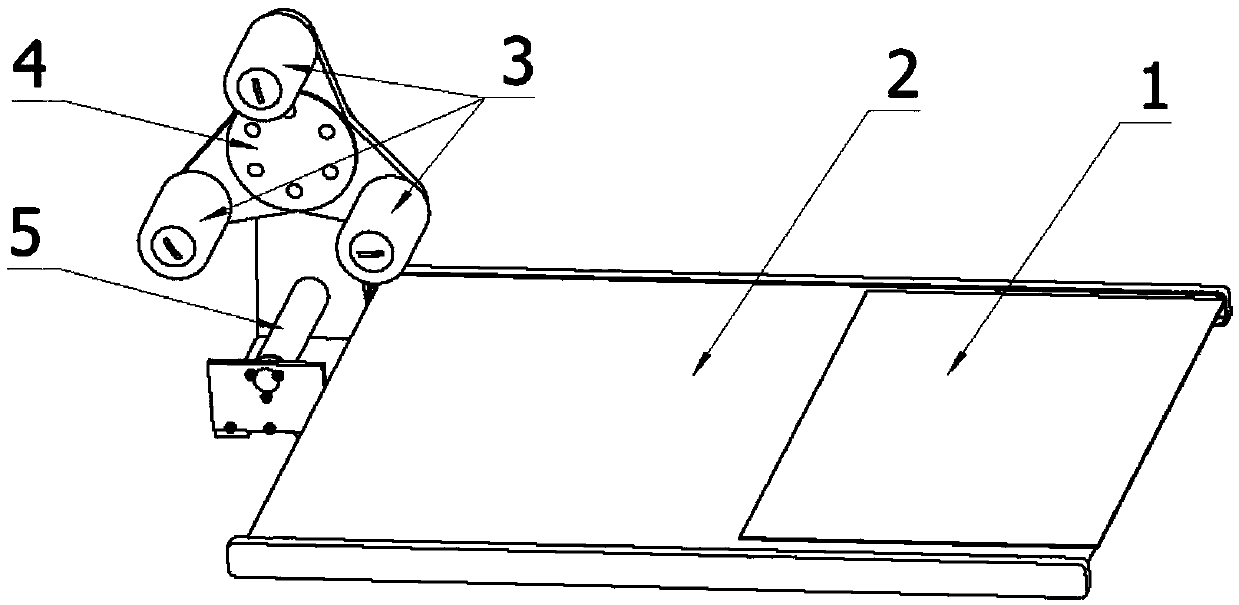

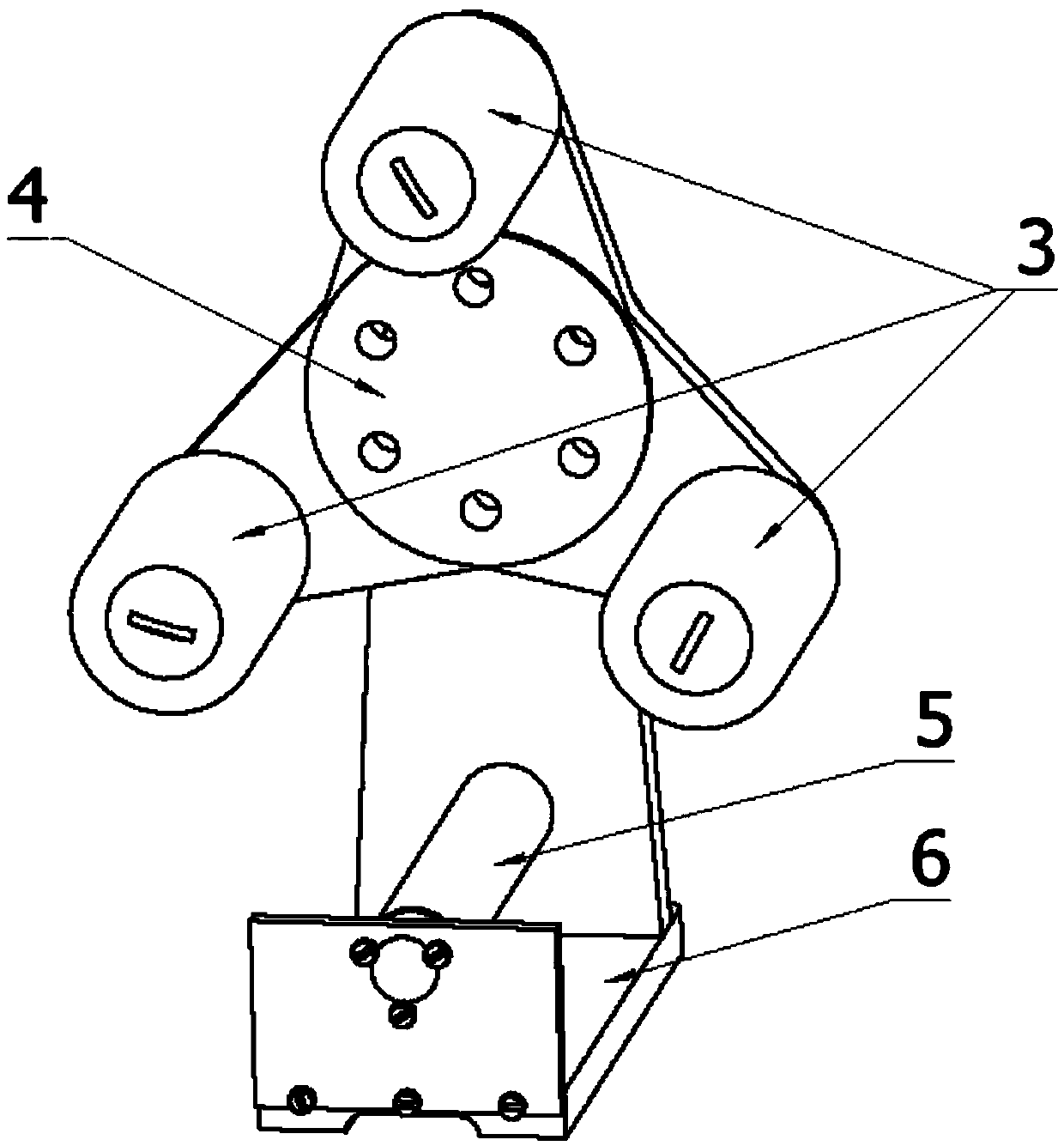

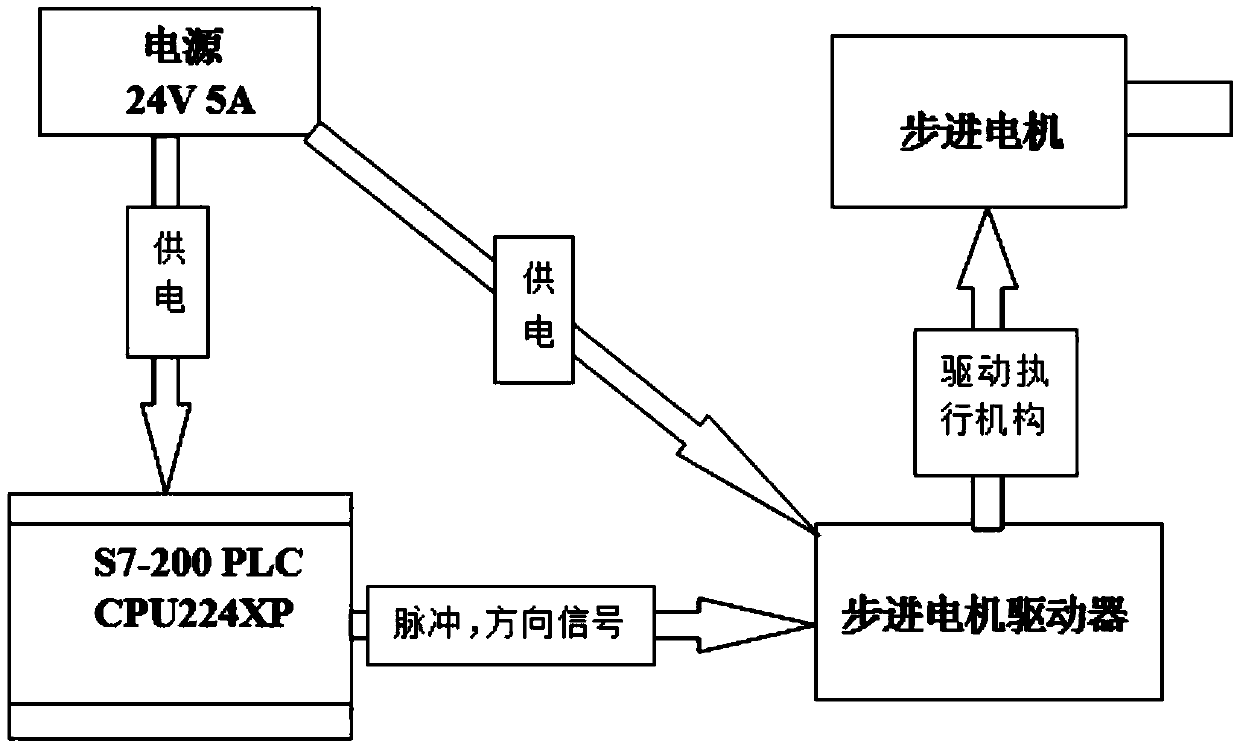

Friction type bag opener applicable to various materials

ActiveCN104071387AImprove bag opening efficiencyIncrease the level of automationPackagingProgrammable logic controllerPlastic bag

The invention relates to a friction type bag opener applicable to various materials and belongs the field of packing and unpacking machines and particularly relates preparation processes of finish product packing. The friction type bag opener comprises a mechanical unit and an electric unit, wherein the mechanical unit comprises a conveying belt, movable friction wheels, a movable rack, a fixed friction wheel and a support rack, and the electric unit is composed of a power source, a PLC (programmable logic controller), a stepping motor driver and a stepping motor; woven bags require bag opening treatment. Due to the fact that the friction coefficient between the rubber of friction parts and plastic bags is larger than that among the plastic bags, the plastic bags can glide and accordingly be opened. The friction type bag opener can achieve automated bag opening operation and replace manual operation, thereby effectively improving the opening efficiency of woven bags and obviously enhancing the automation degree.

Owner:河北航轮科技有限公司

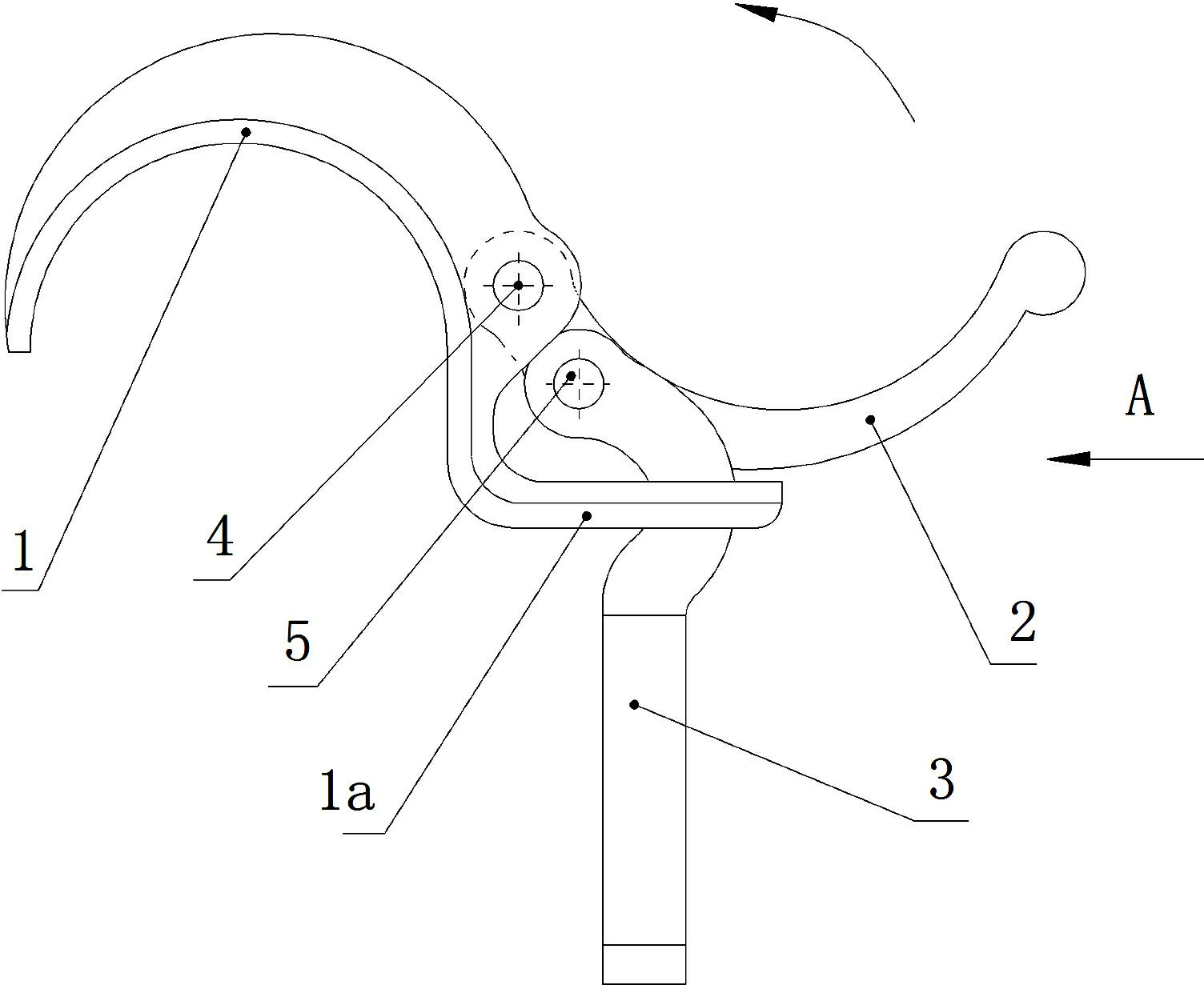

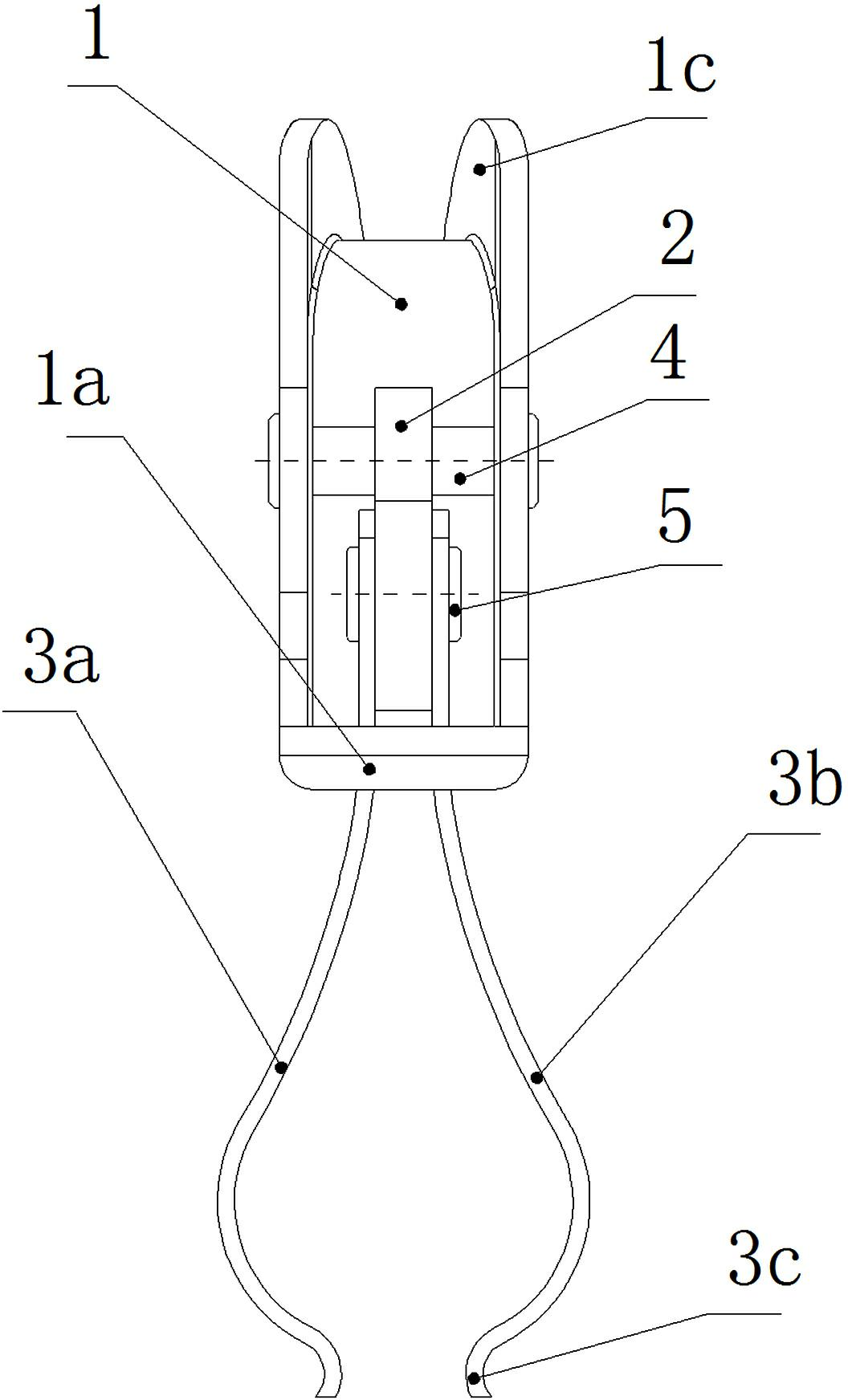

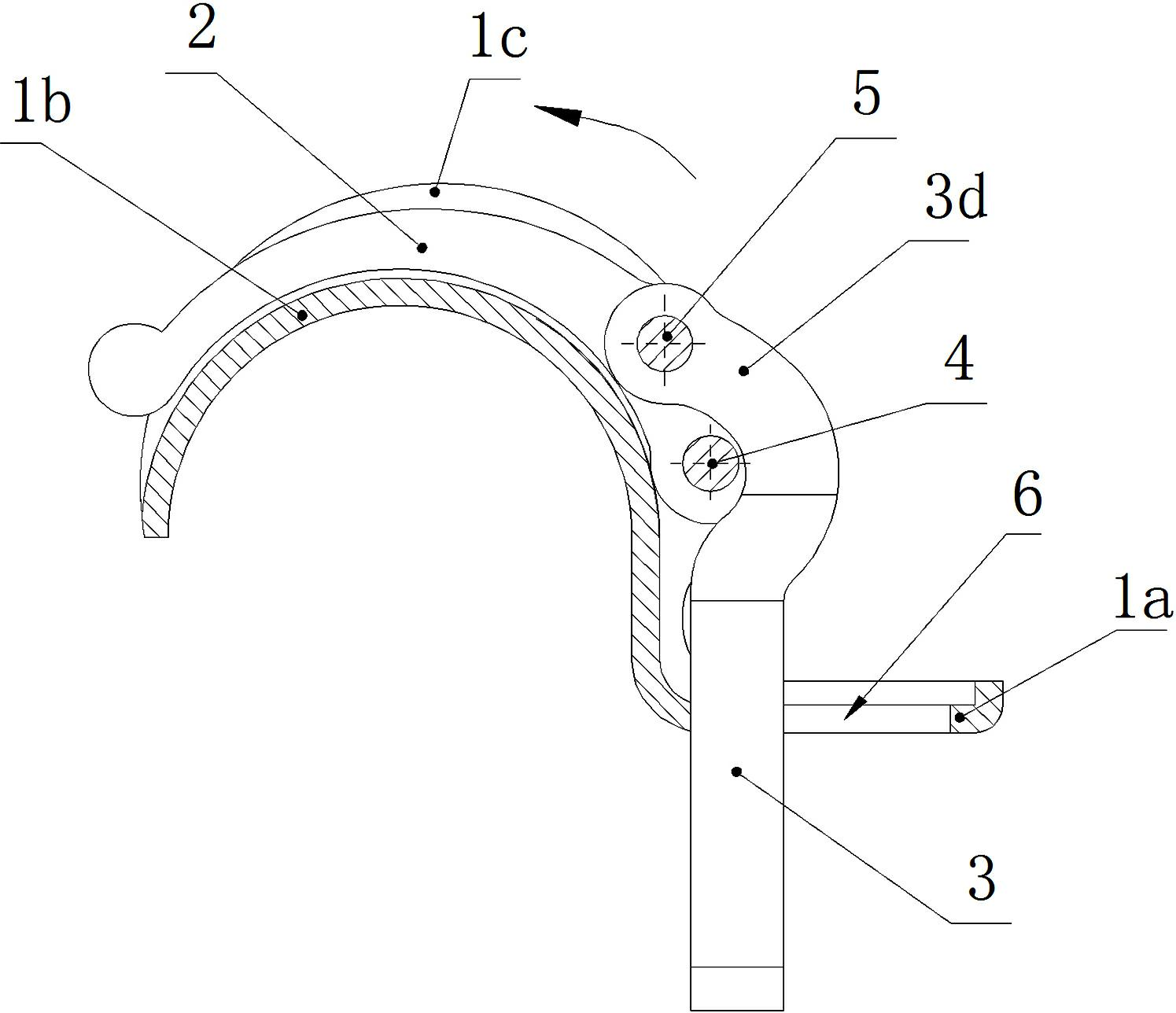

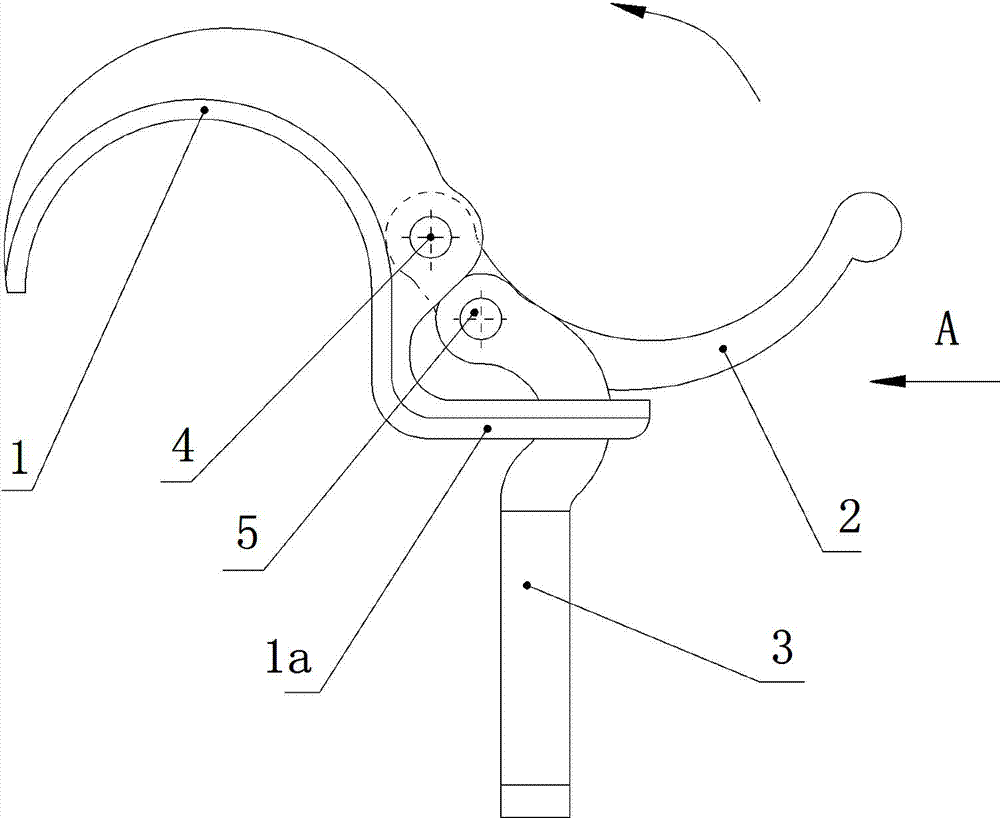

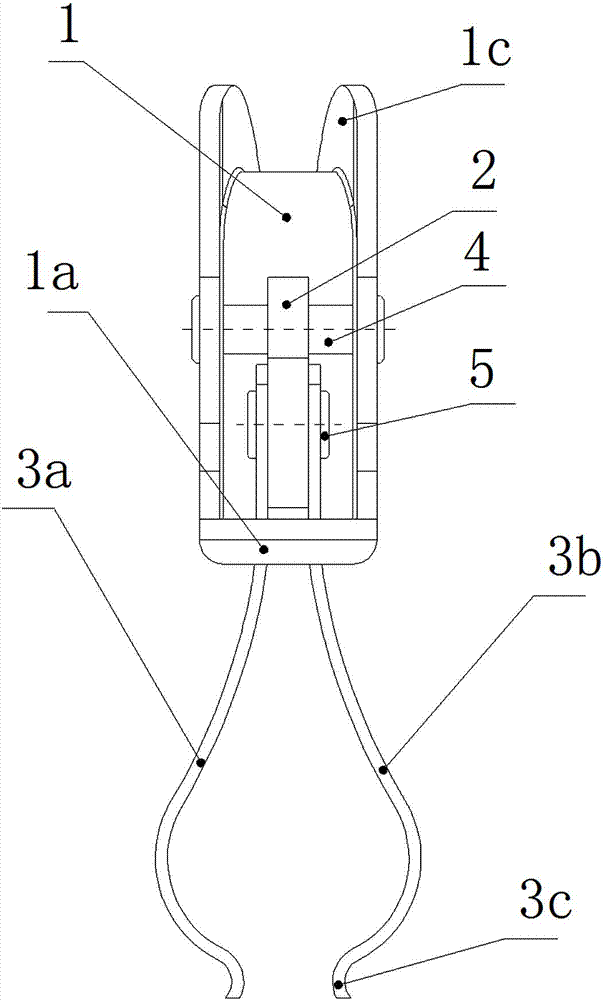

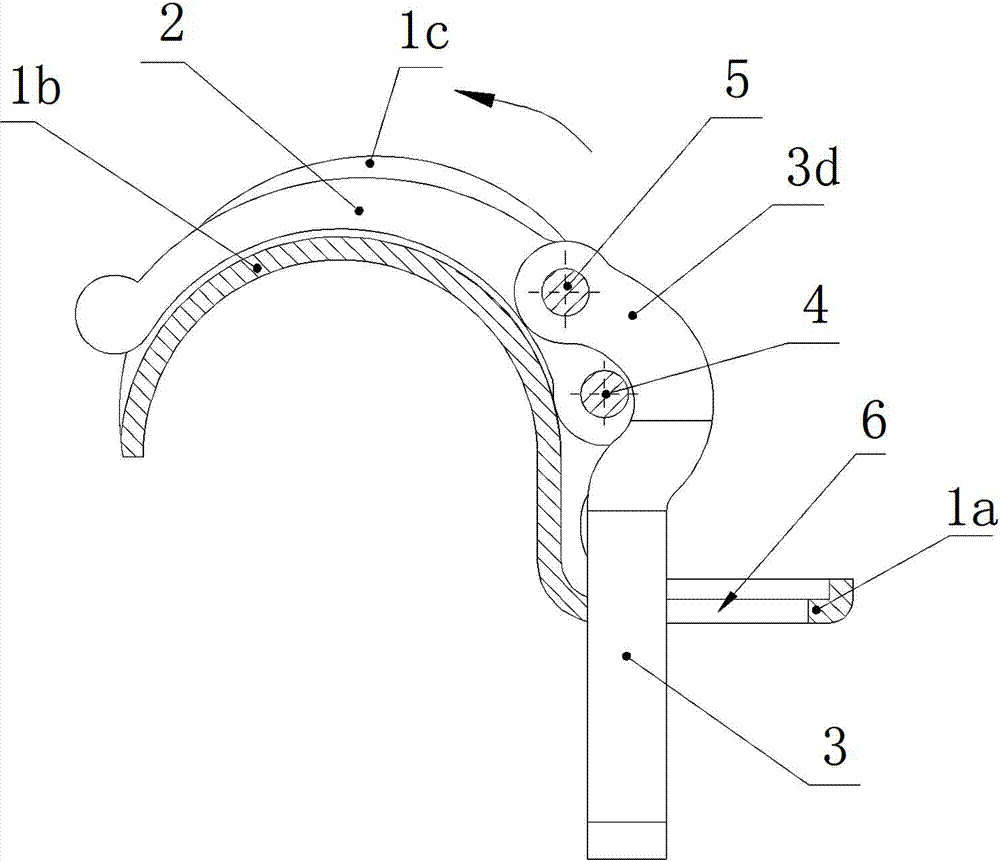

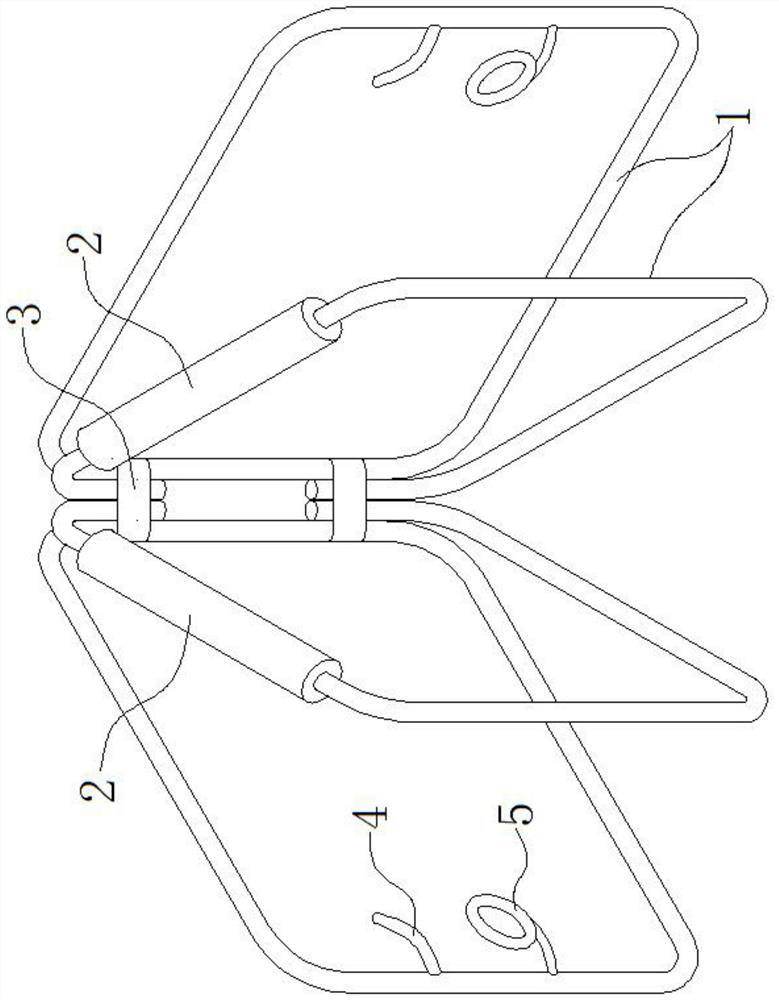

Clamping device for piecing and connecting pouring template of building

InactiveCN102182305ASimple structureFew partsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFree stateEngineering

The invention relates to a clamping device for piecing and connecting a pouring template of a building. The clamping device comprises a support, a moving handle and an elastic clip, wherein the elastic clip is made of spring steel, and is provided with a left and a right clamping parts; the support is provided with a hooking part, and a horizontal extending part used for restraining a rectangular hole of the elastic clip is arranged on the support; the moving handle is hinged with the support by taking the end part at one end of the moving handle as a fulcrum and the other end of the moving handle as a force point, and a gravity point is arranged between the fulcrum and the force point, and is hinged with the upper end of the elastic clip; the elastic clip penetrates through the rectangular hole of the support, and freedom for the displacement of the elastic clip is preserved in the longitudinal direction of the rectangular hole; the lower parts of the left and the right clamping parts of the elastic clip are of an inward opposite bent shape; when in a free state, the lower parts of the left and the right clamping parts open, and the opening distance of the lower parts is greater than the width of the rectangular hole of the support; and the upper parts of the left and the right clamping parts make contact with the long edges of the rectangular hole. The clamping device can be used for rapidly fastening and connecting the pieced pouring template, and has the advantages of convenience for use, simple structure and easiness for manufacture.

Owner:阮中亮

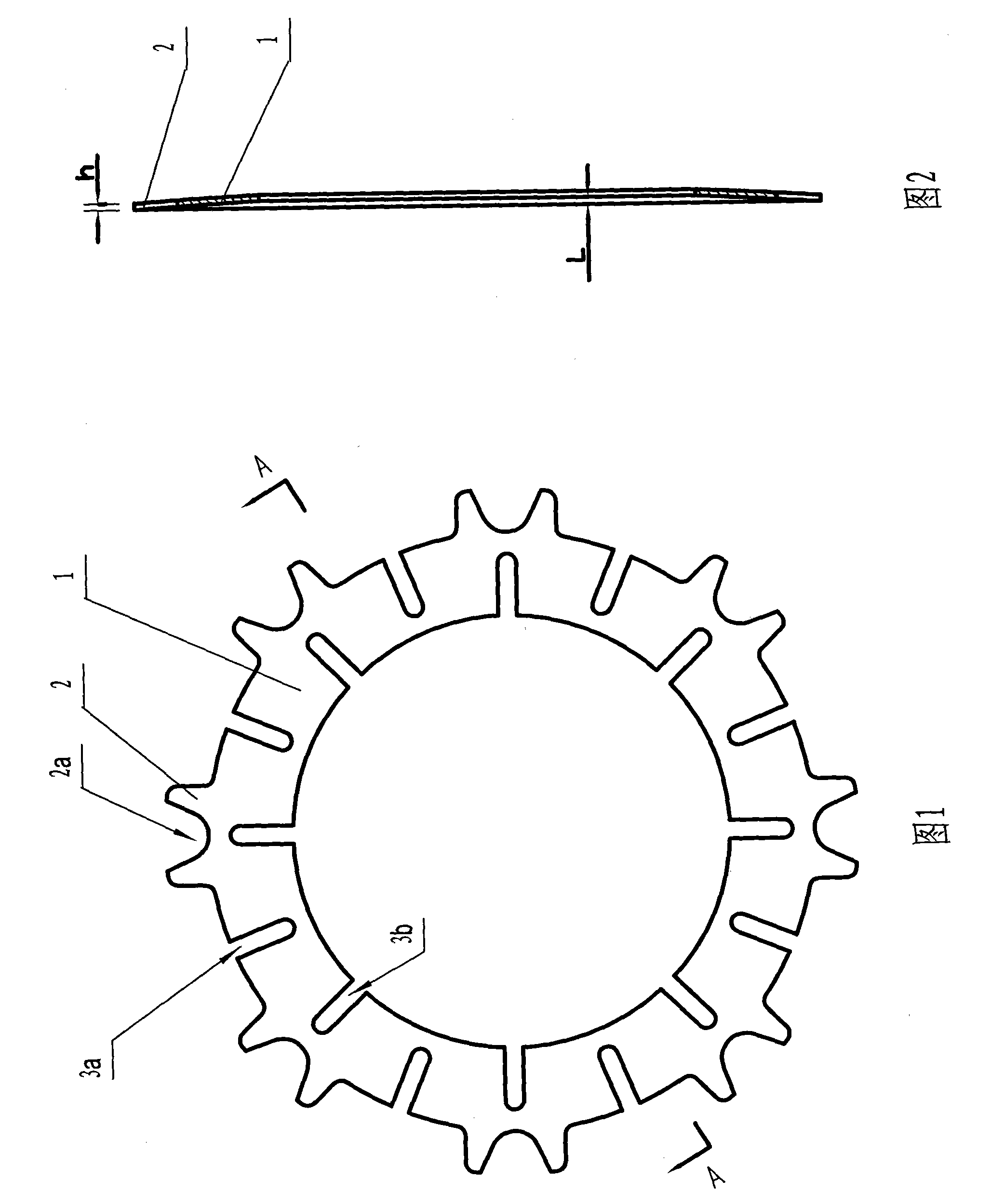

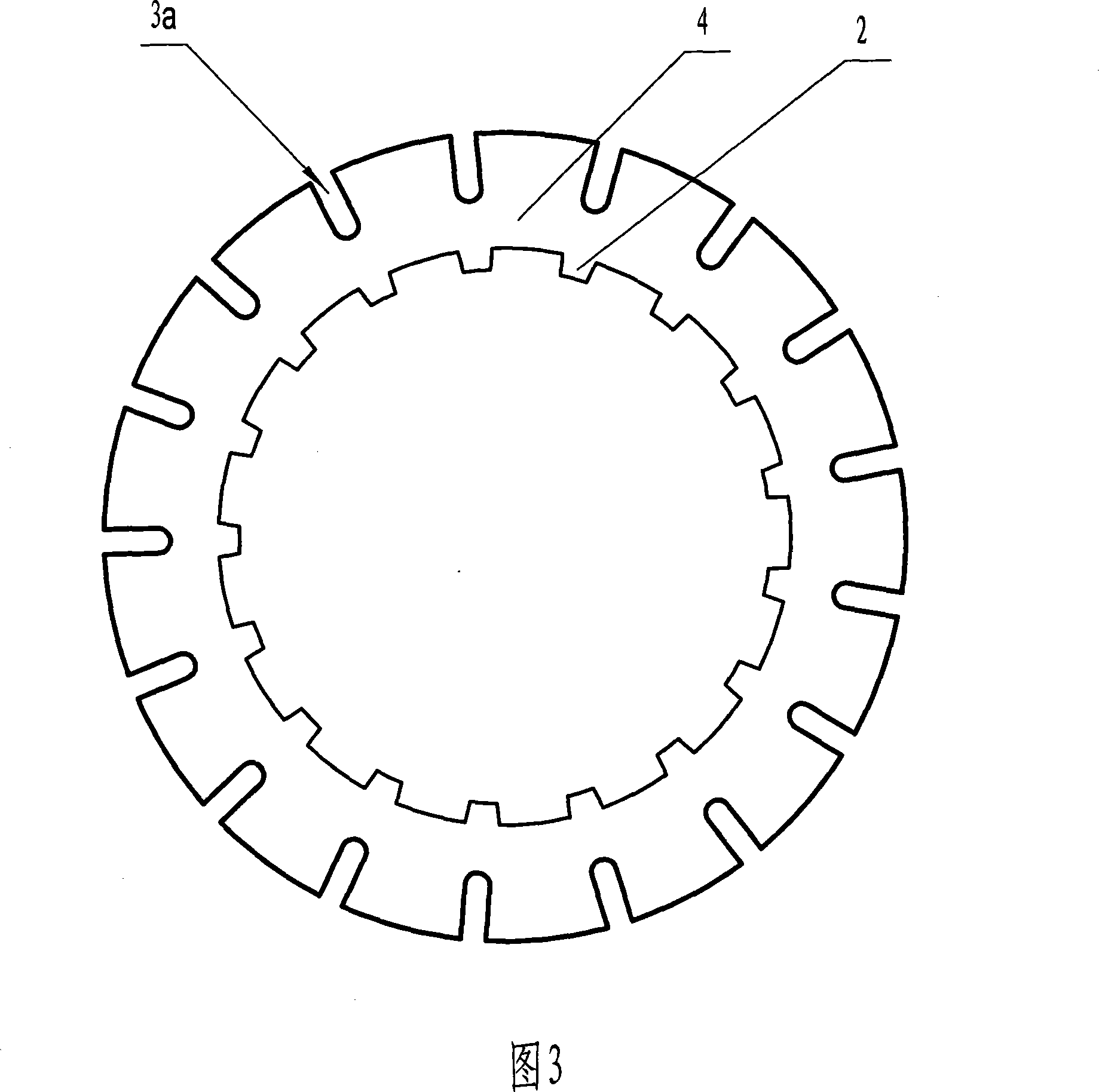

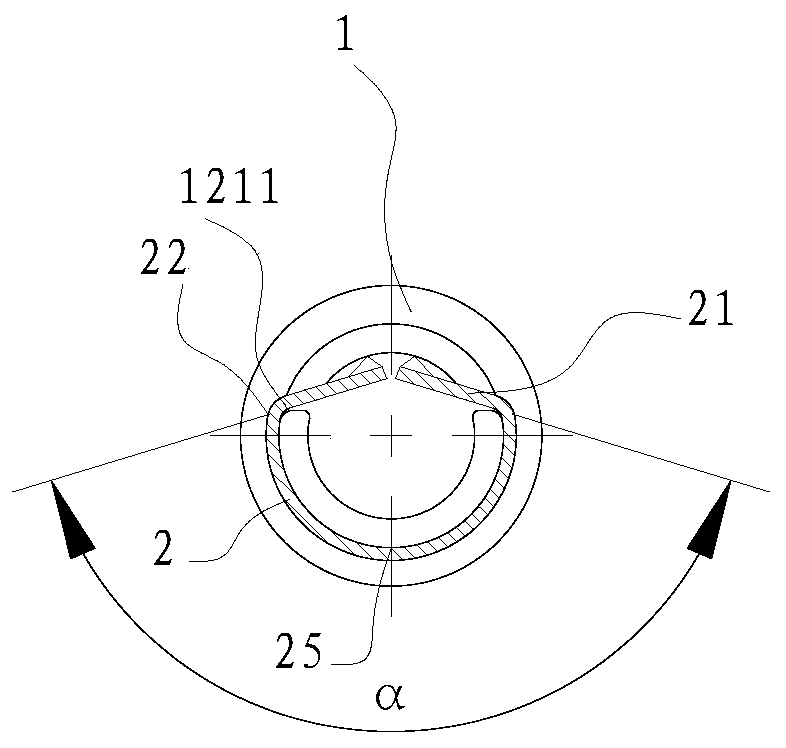

Wet clutch friction plate

The present invention discloses a wet clutch friction wafer which is annular sheet steel, many circumferential fixed protruding gears are placed inner circumference or outer circumference equably, and the friction wafer is annular sheet steel with axial elastic deformation, the end of it is curved surface. When clutch is separated, it can assure full separation between friction wafers by self axial elastic deformation eliminating moebius oil conglutination between friction wafers.

Owner:刘珍利

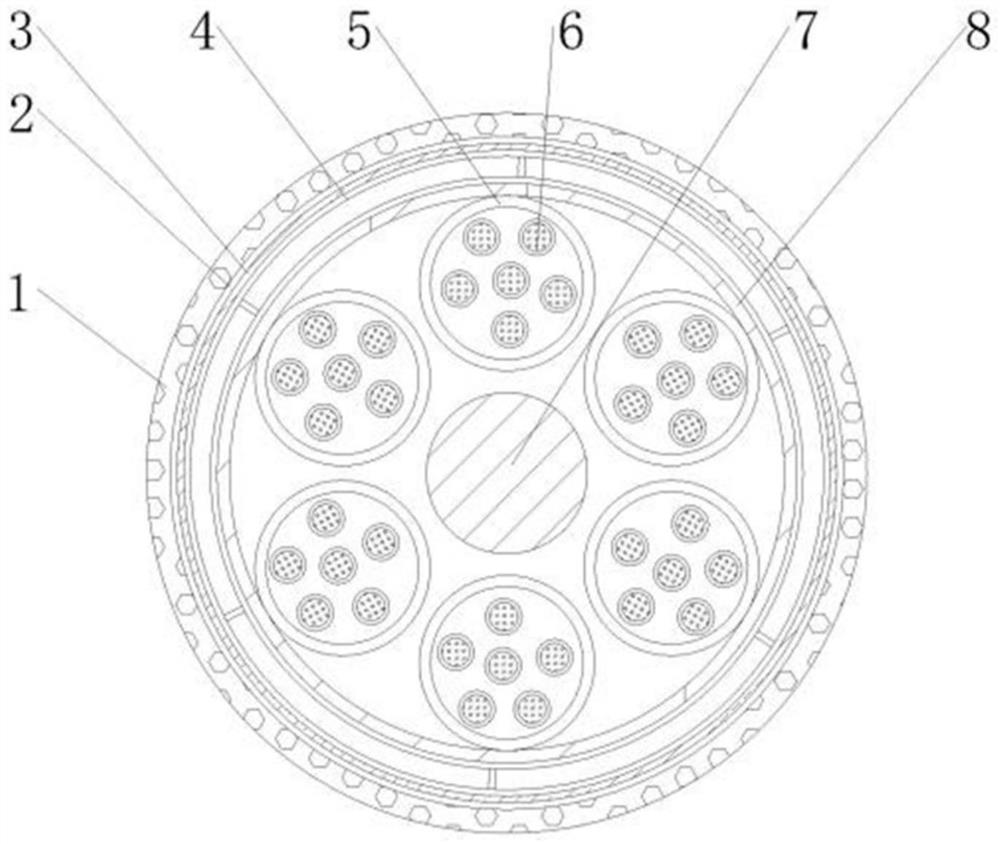

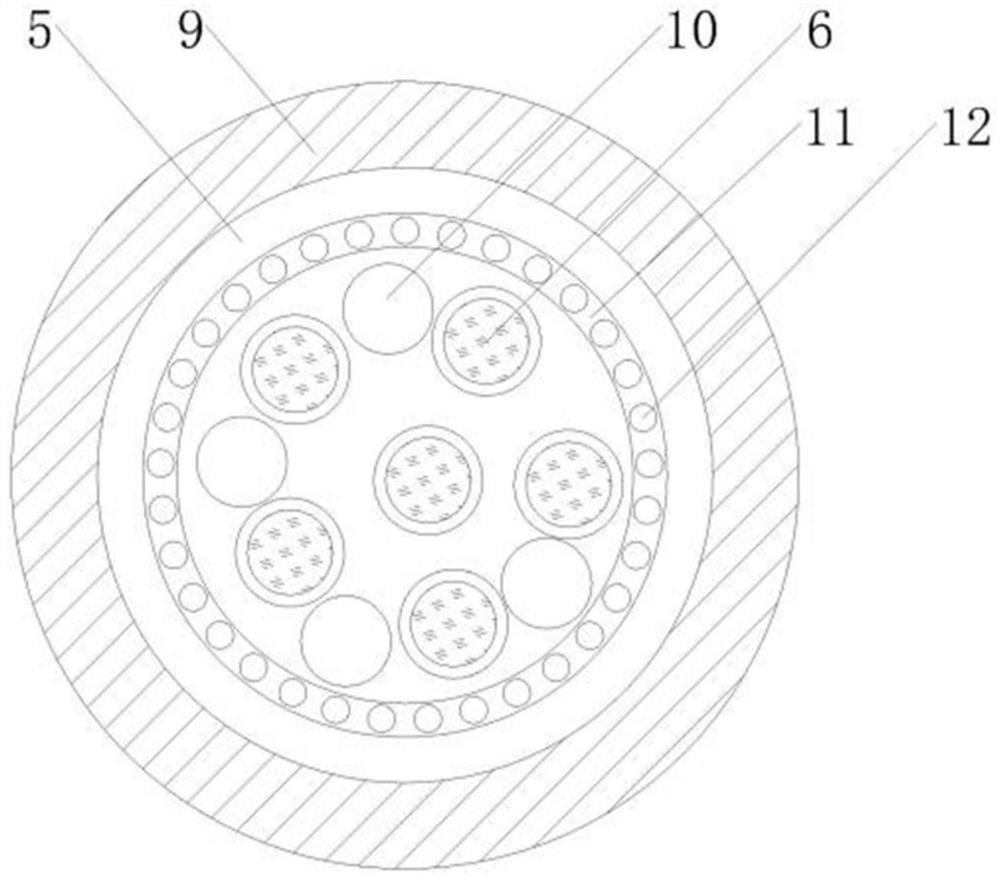

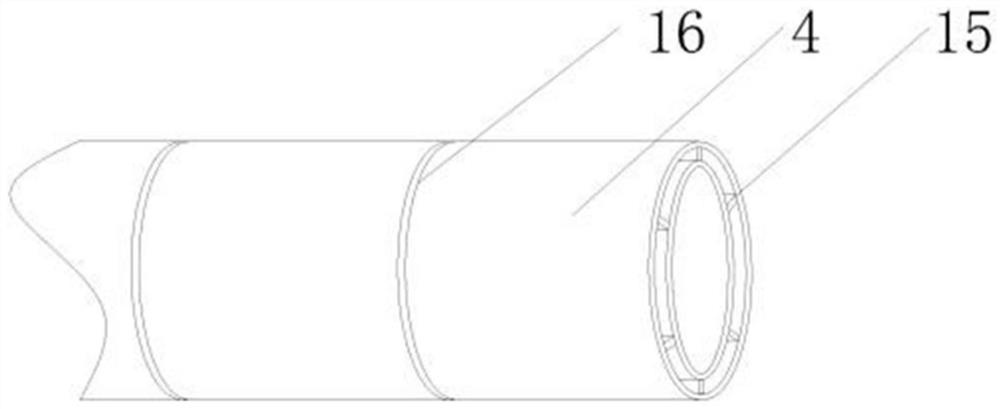

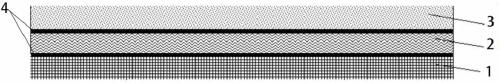

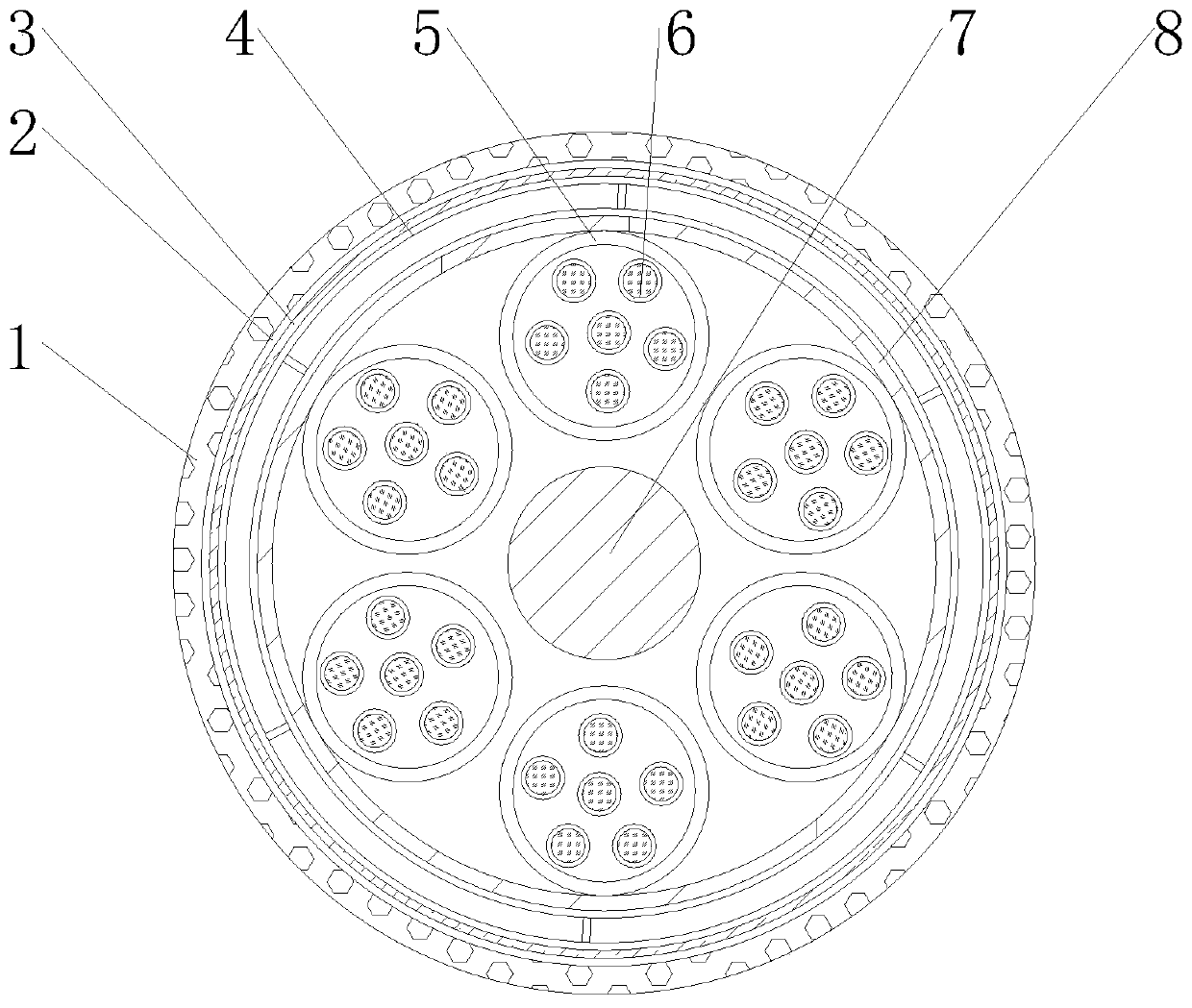

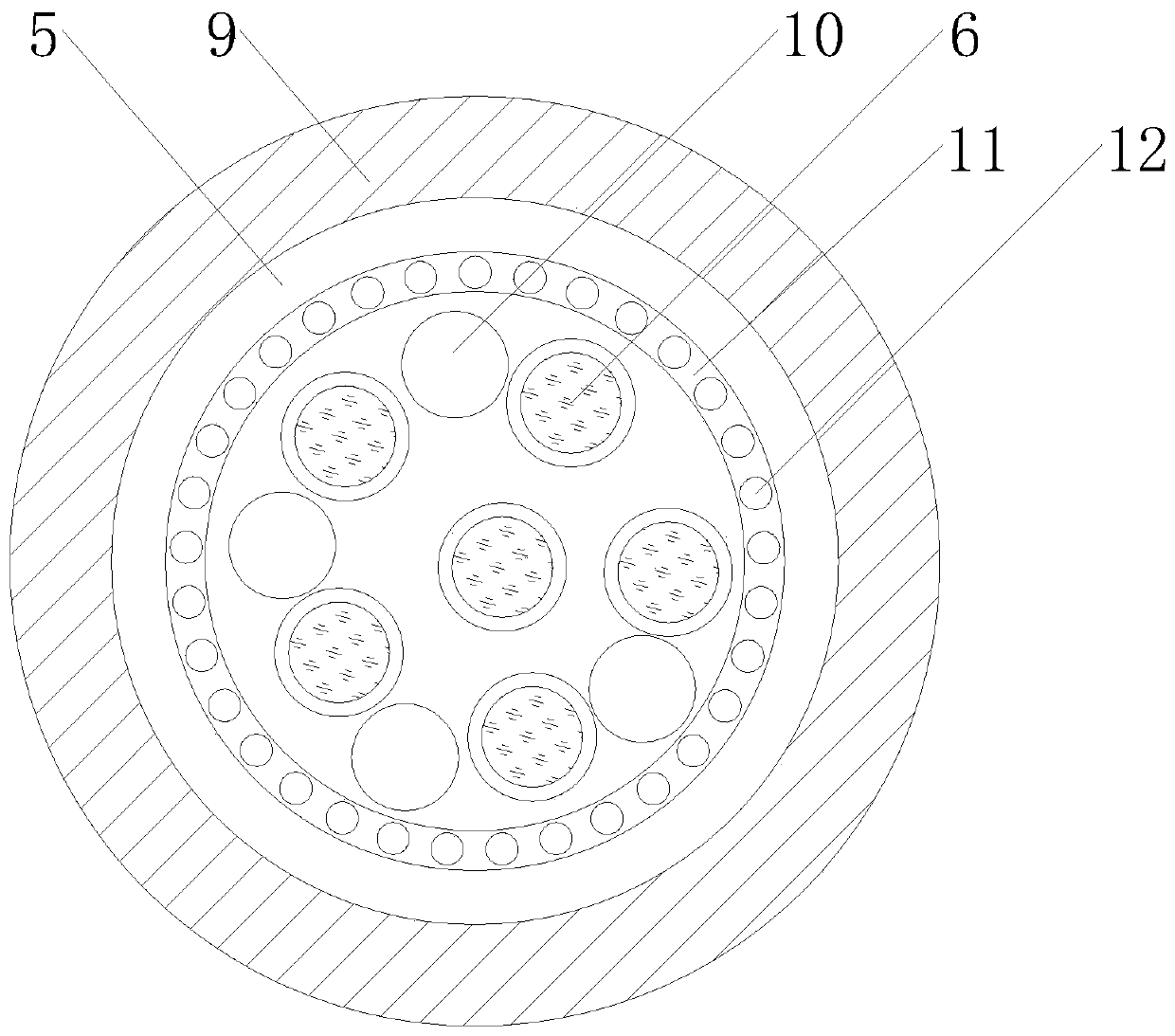

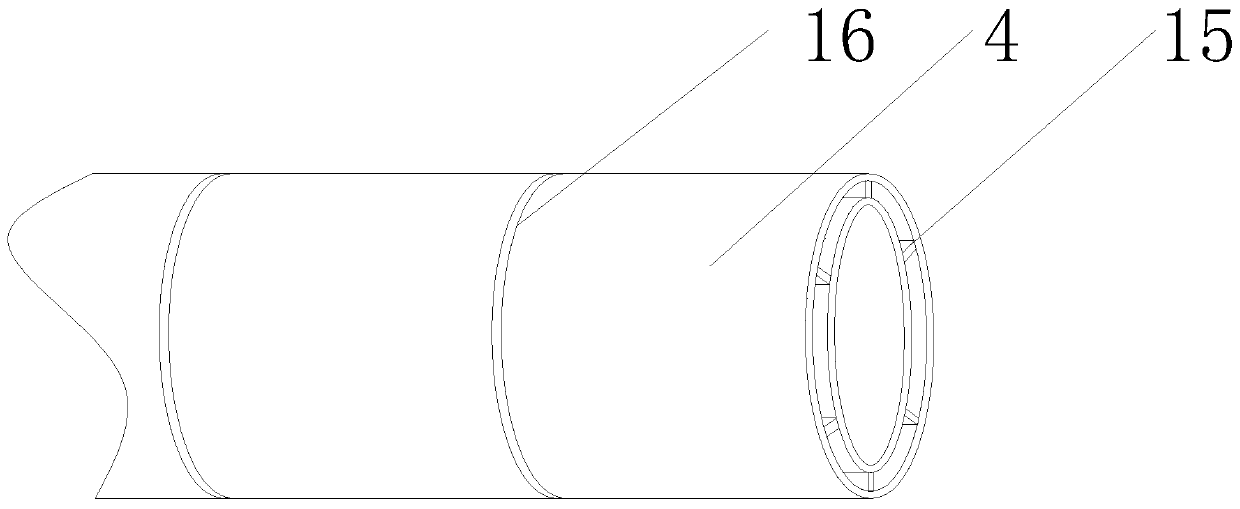

Corrosion-resistant optical cable

ActiveCN111624717AReduce loss of lossPrevent overflowFibre mechanical structuresEngineeringMaterials science

The invention relates to a corrosion-resistant optical cable, which comprises an outer sheath (1), a water-blocking ointment tube (4) arranged in the outer sheath (1) and used for realizing a water-blocking function of the optical cable, and an inner sheath (5) arranged in the water-blocking ointment tube (4), wherein the inner side of the outer sheath (1) is connected with a metal armor layer (3)in a bonding manner, the outer side surface of the metal armor layer (3) is coated with a plastic coating (2), and the inner side of the metal armor layer (3) is connected to the outer side wall of the water-blocking ointment tube (4) in a bonding manner; a cavity is formed in the side wall of the water-blocking ointment tube (4); a transverse spacer (15) is connected into the side wall of the water-blocking ointment tube (4) in a bonding mode; and a vertical spacer (16) used for separating the inner cavity of the water-blocking ointment tube (4) is connected into the side wall of the water-blocking ointment tube (4) in a bonding mode. According to the structure, ointment in the inner cavity of the water-blocking ointment tube is separated, and it is guaranteed that when the whole opticalcable is cut, it is guaranteed that a large amount of ointment is prevented from overflowing due to damage.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

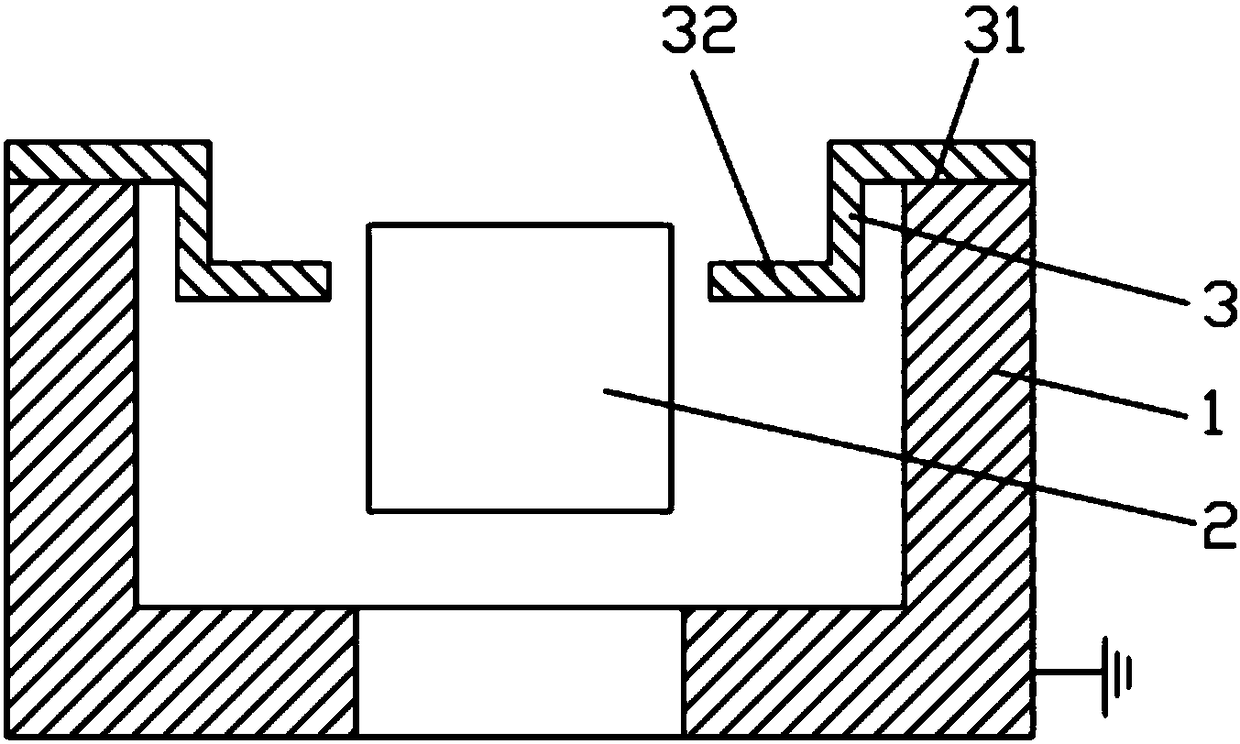

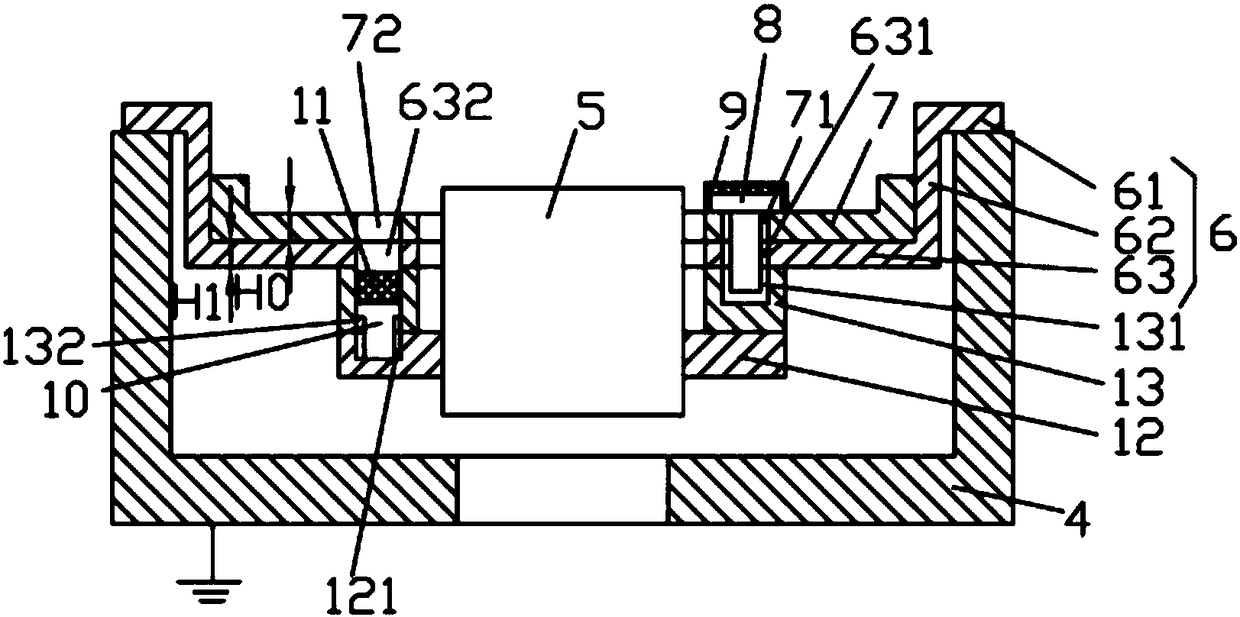

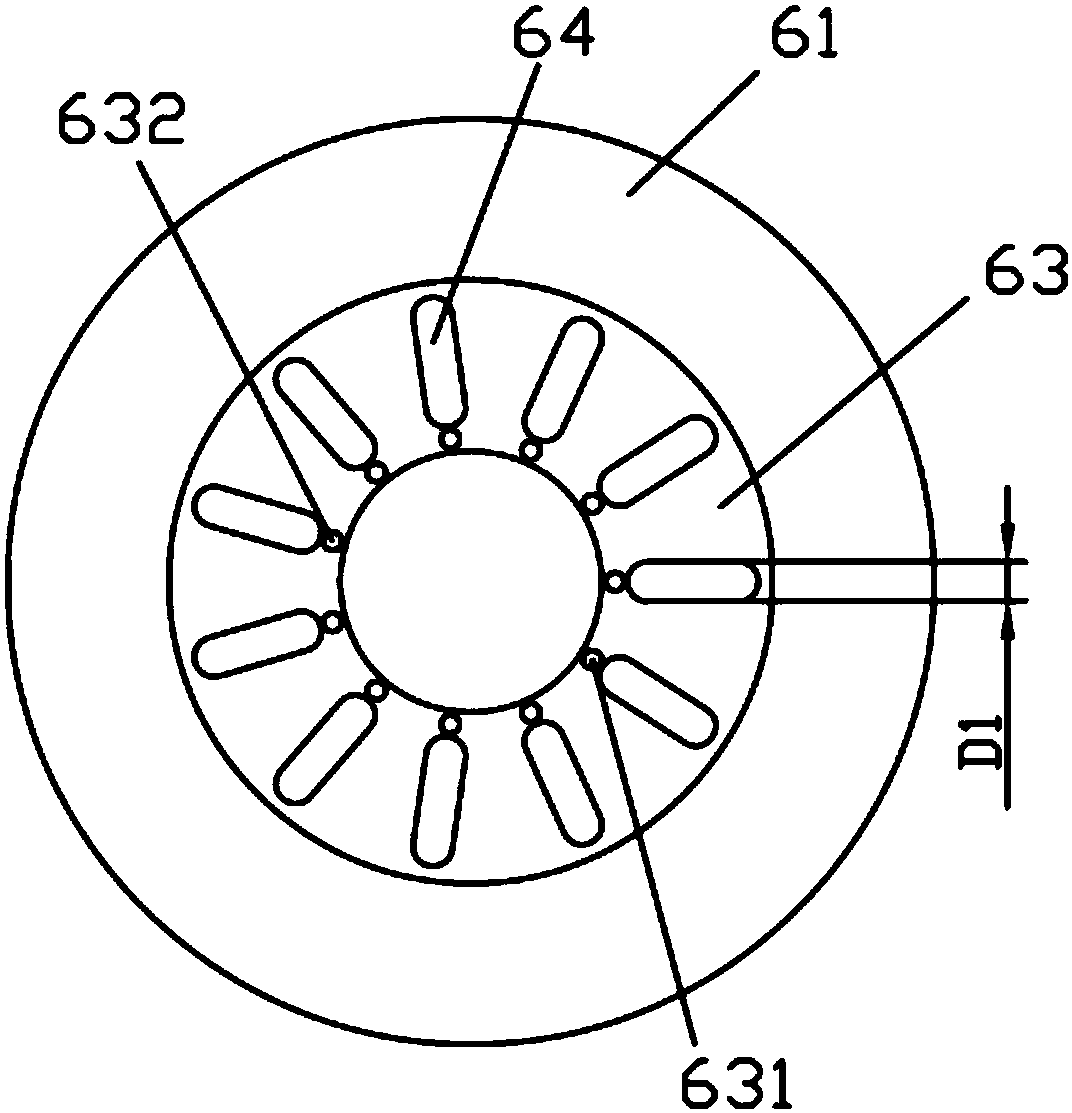

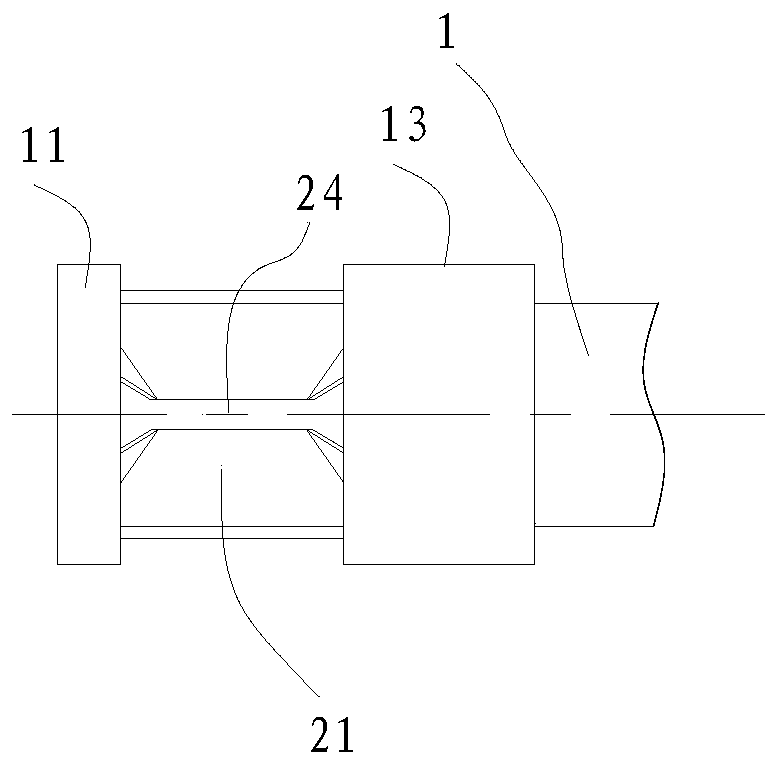

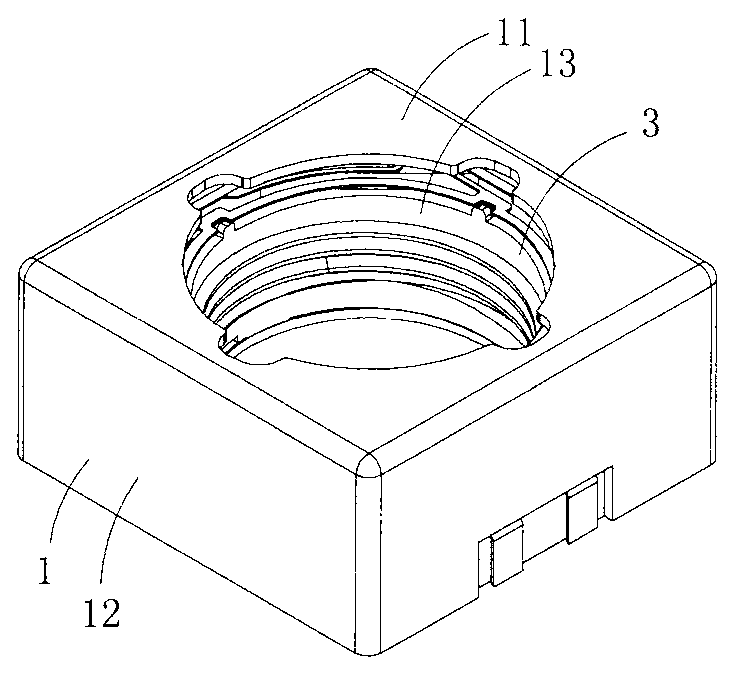

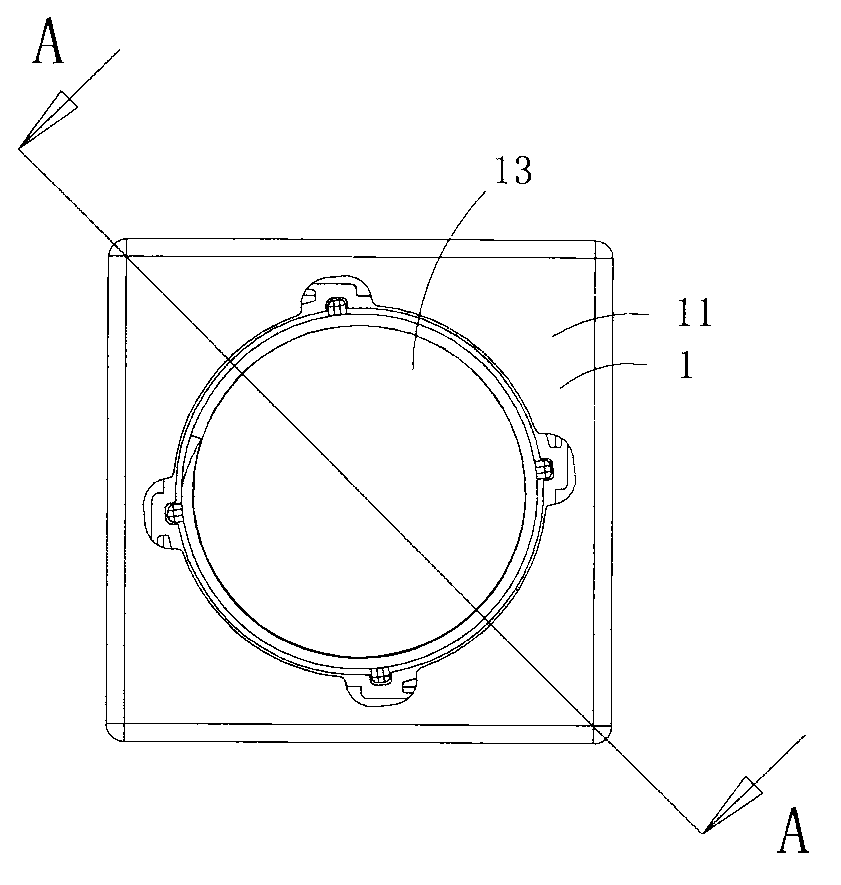

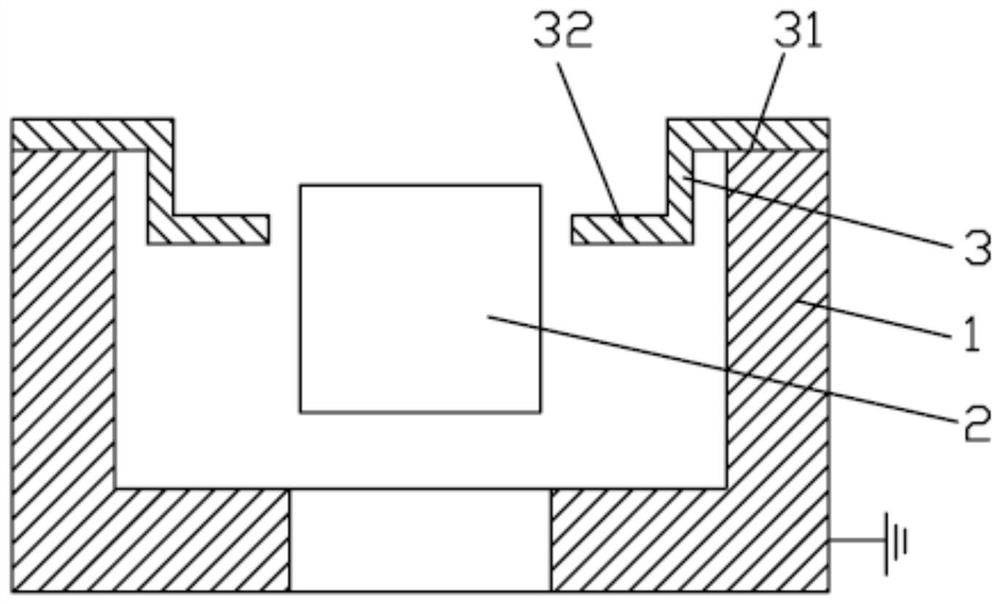

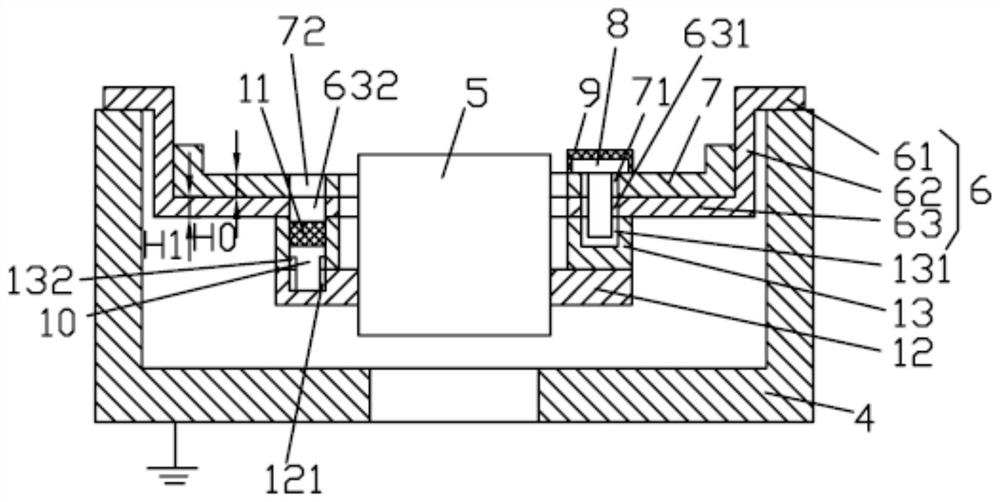

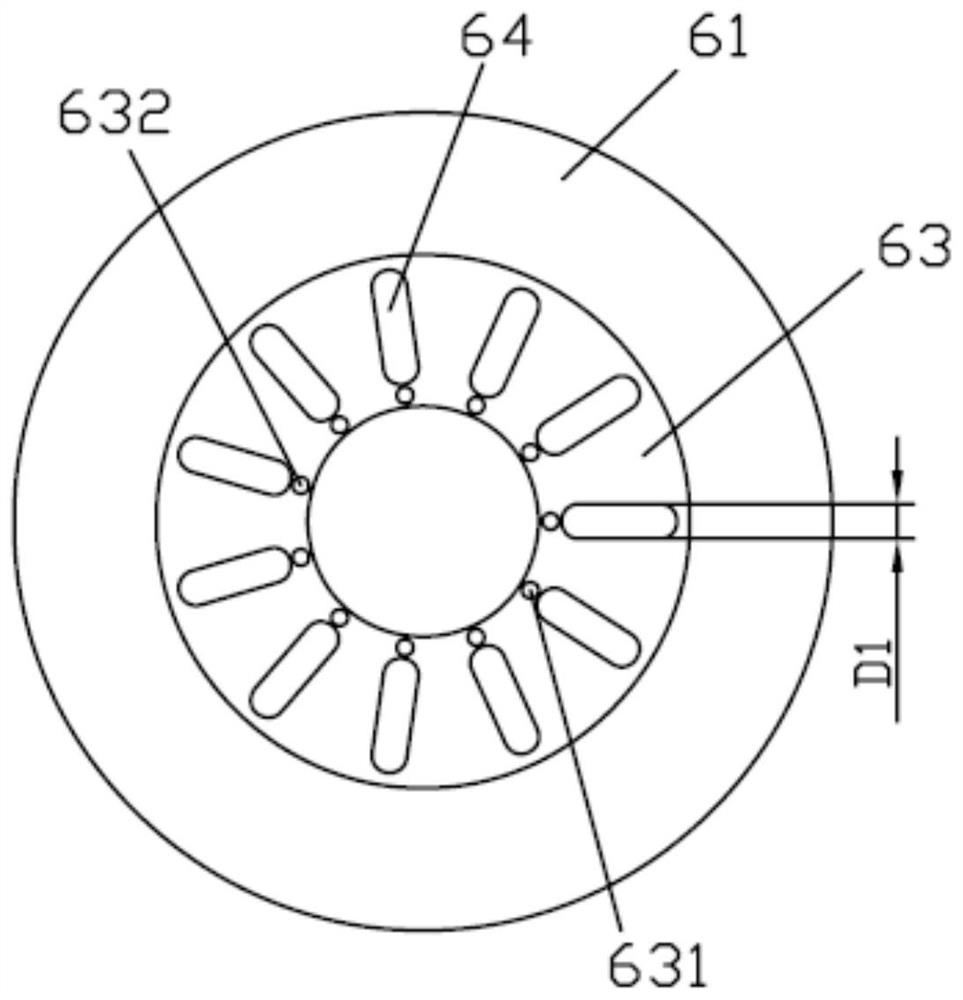

A reaction cavity

ActiveCN108538745AAvoid RF LeakageGuaranteed elastic deformationElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyEngineering

The invention provides a reaction cavity. The reaction cavity includes an earthed cavity, a lower electrode and a liner assembly are arranged in the cavity. The liner assembly include a lining ring, the lining ring includes a cylinder and an annular part, the upper end of the cylinder is connected with the cavity and is connected to the earth through the cavity; the annular part is horizontally arranged in the lower end of the cylinder and surrounds the surrounding of the lower electrode, and the upper part of the annular part is provided with a plurality of first screen holes arranged in thecircumferential direction. The liner assembly also include an annular backing plate, the annular backing plate is superposed on the annular part, multiple second screen holes are arranged in the annular backing plate, the quantity of the second screen holes is corresponding to the quantity of the first screen holes, and the second screen holes and first screen holes are arranged one-to-one correspondingly. The plasma passing the screen holes can be effectively vanished on the surface of the screen holes, and the leakage of the radio frequency can be avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

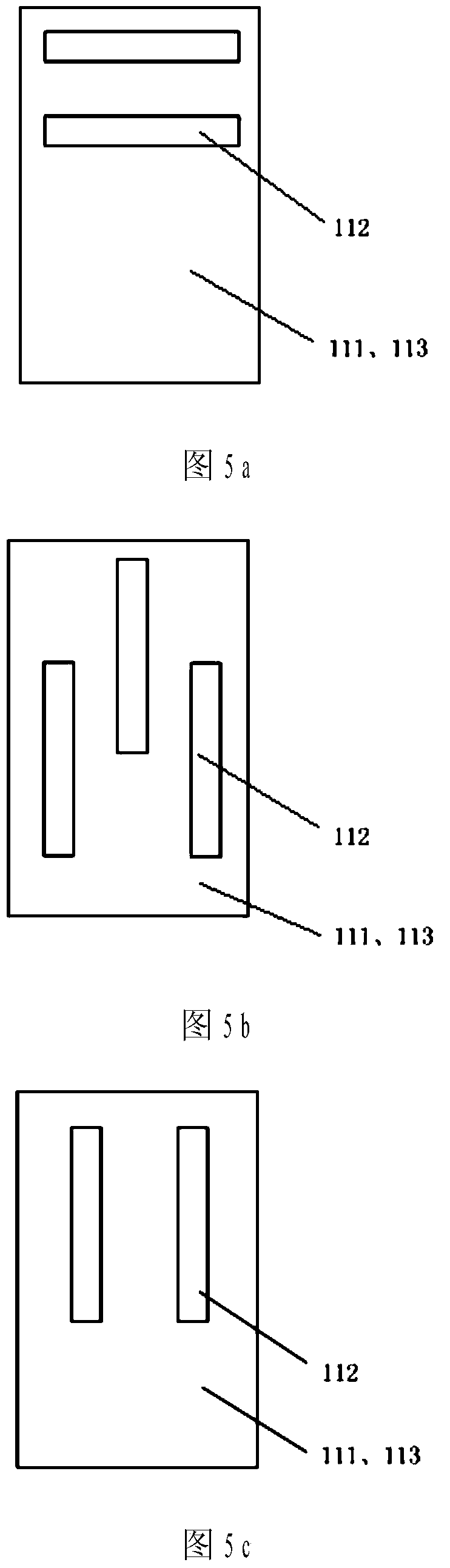

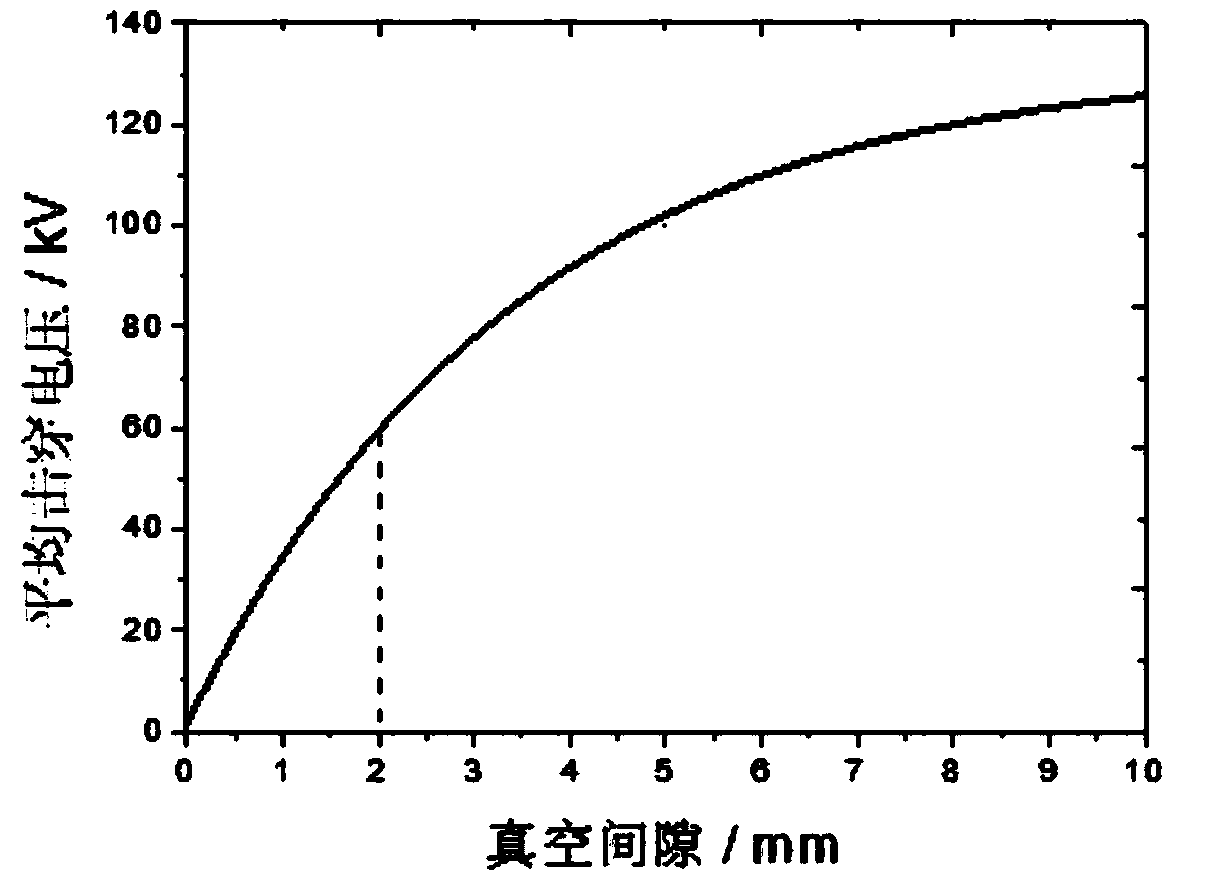

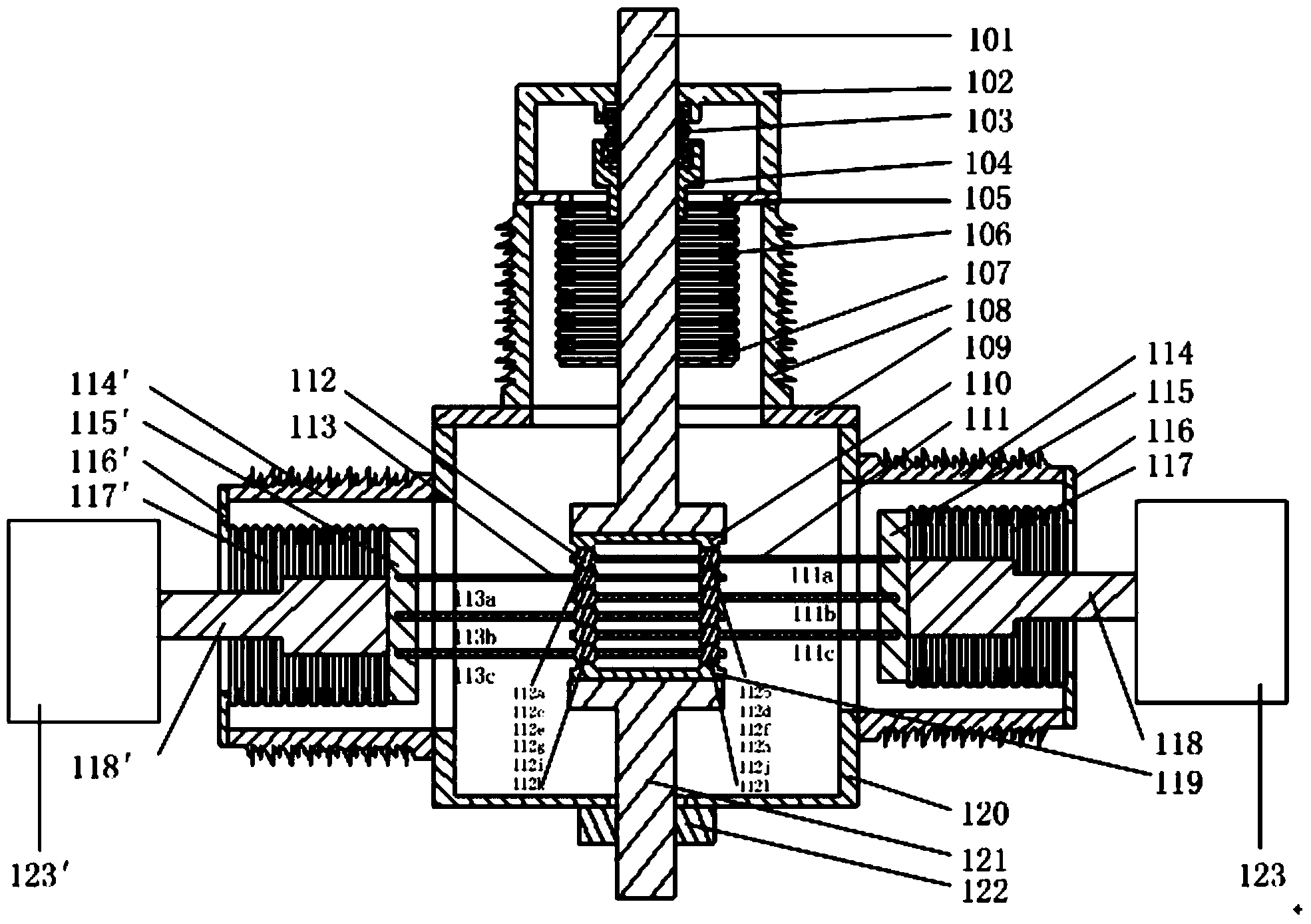

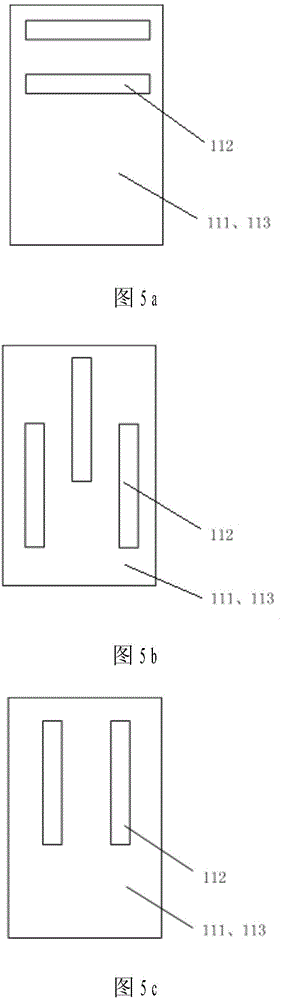

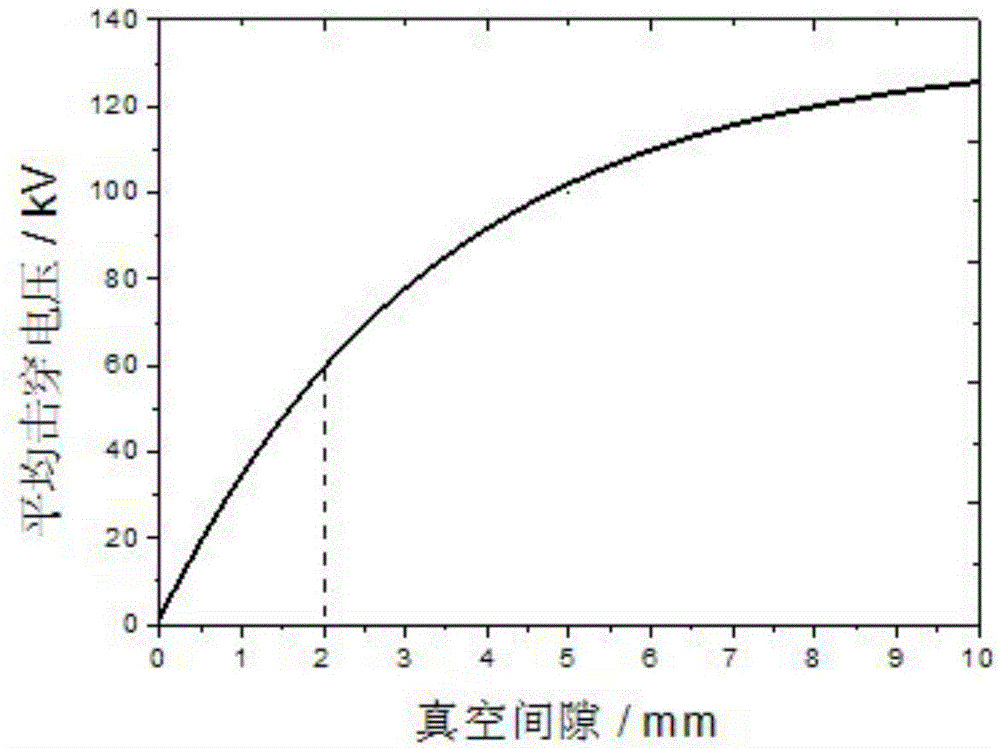

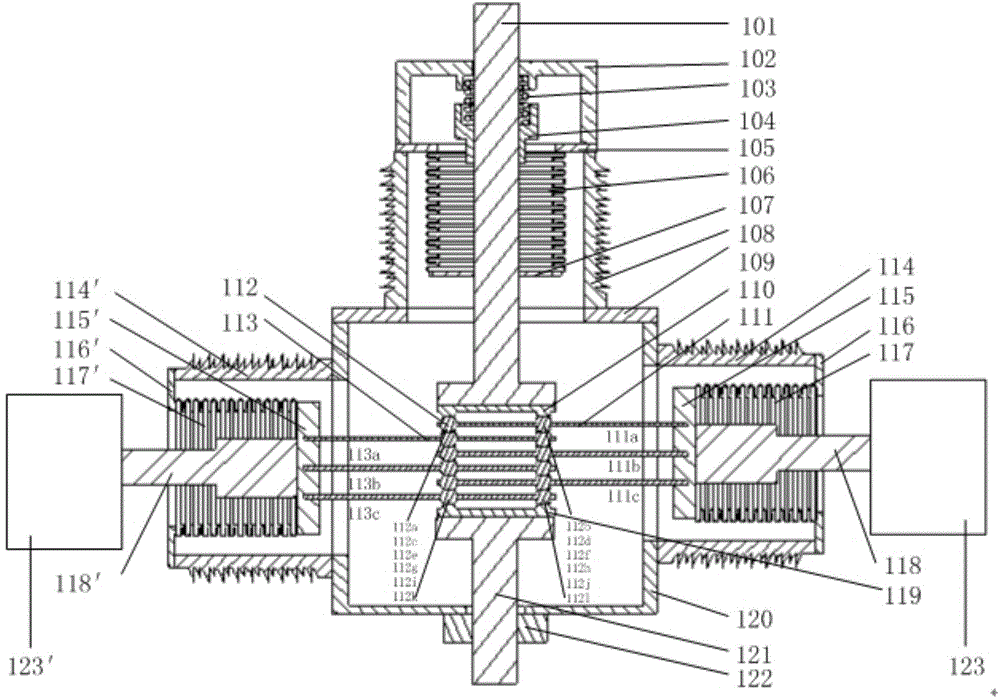

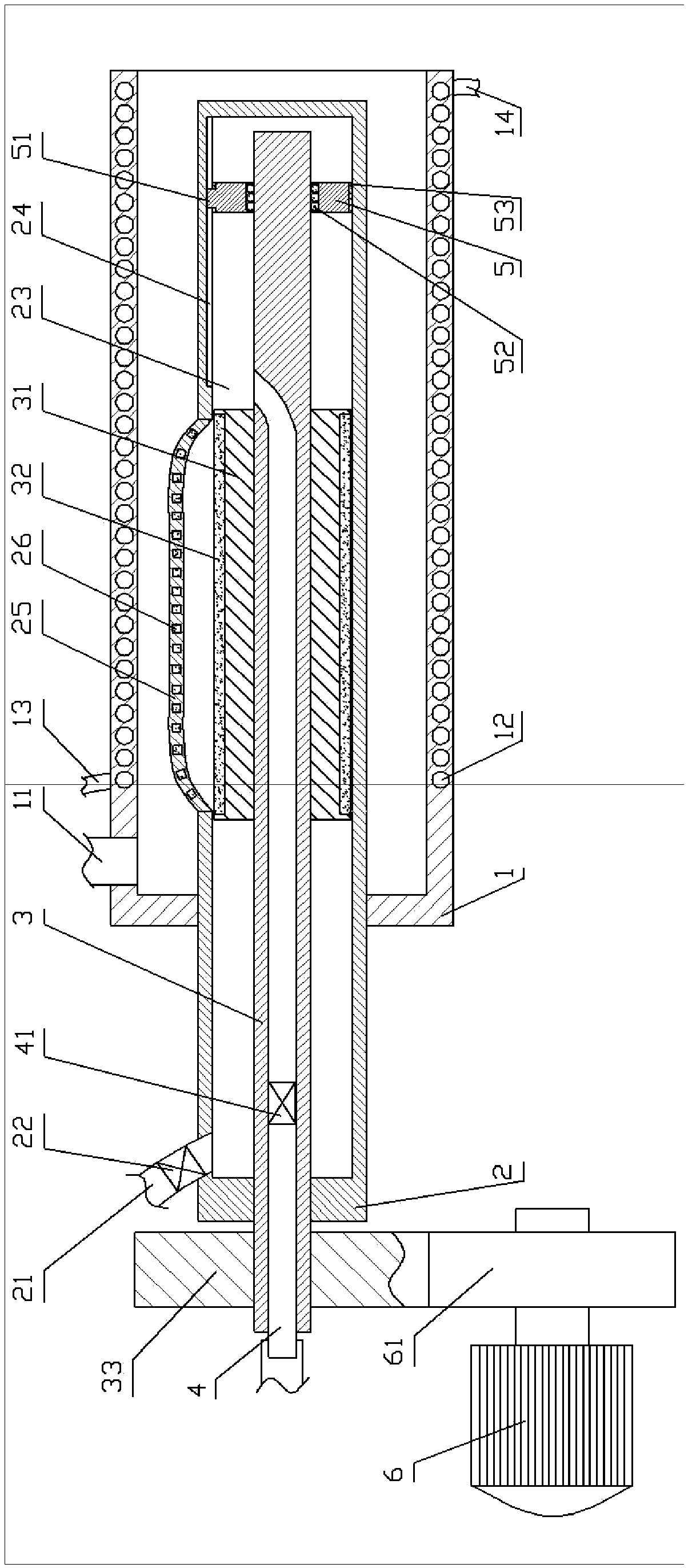

Rapid multi-gap vacuum disconnector

InactiveCN103943406ASolving Design ChallengesSolving the Tricky High Recovery Voltage Withstand ProblemHigh-tension/heavy-dress switchesAir-break switchesEngineeringAuxiliary electrode

Provided is a rapid multi-gap vacuum disconnector. The rapid multi-gap vacuum disconnector comprises an electrode structure, current-carrying contacts, a metal carrier structure, a driver, an insulating driving pull rod structure and a vacuum cavity, wherein the electrode structure comprises a movable main electrode connected with a corrugated pipe and a fixed auxiliary electrode, the insulating driving pull rod structure comprises contact carrier fixing sealing plates to which current-carrying contact metal carriers are fixed, corrugated pipes and an insulating driving pull rod, the corrugated pipes and the insulating driving pull rod are connected with the contact carrier fixing sealing plates, the current-carrying contacts are installed on the current-carrying contact metal carriers respectively, and working modes are switched through the insulating driving pull rods; the insulating driving pull rods drive the current-carrying contacts to shift through the contact carrier fixing sealing plates and the current-carrying contact metal carriers connected with the contact carrier fixing sealing plates, so that a circuit is formed by the main electrode, the auxiliary electrode and the current-carrying contacts when the rapid multi-gap vacuum disconnector is in the current-carrying working state; multi-gap vacuum insulation is formed by the main electrode, the auxiliary electrode and the current-carrying contacts when the rapid multi-gap vacuum disconnector in the isolation working state. According to the rapid multi-gap vacuum disconnector, application of multi-gap vacuum insulation in the rapid disconnector is achieved, and the high-voltage resistance capacity of the rapid multi-gap vacuum disconnector is improved.

Owner:XI AN JIAOTONG UNIV

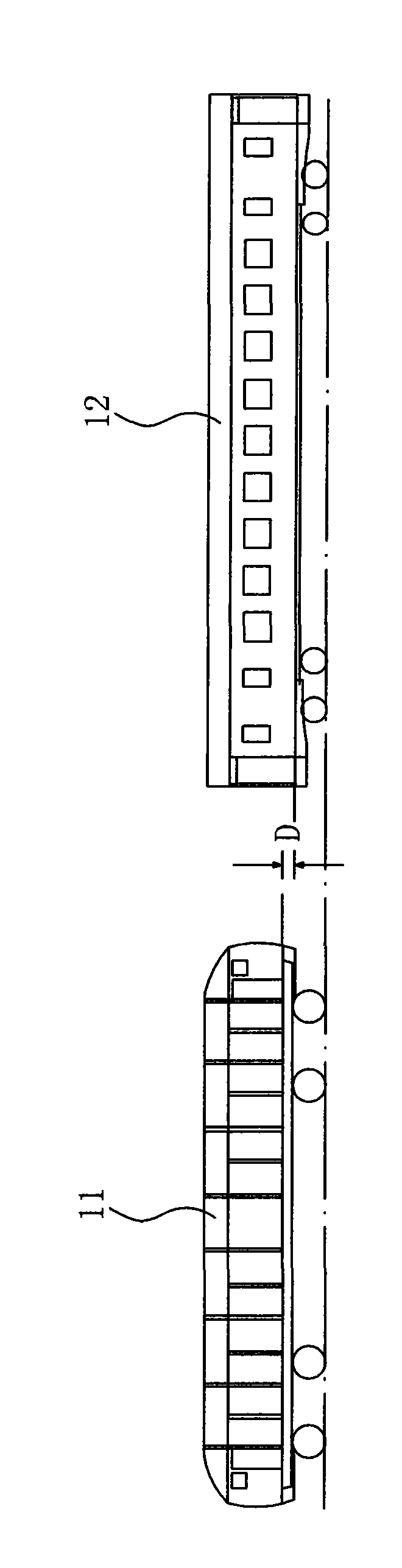

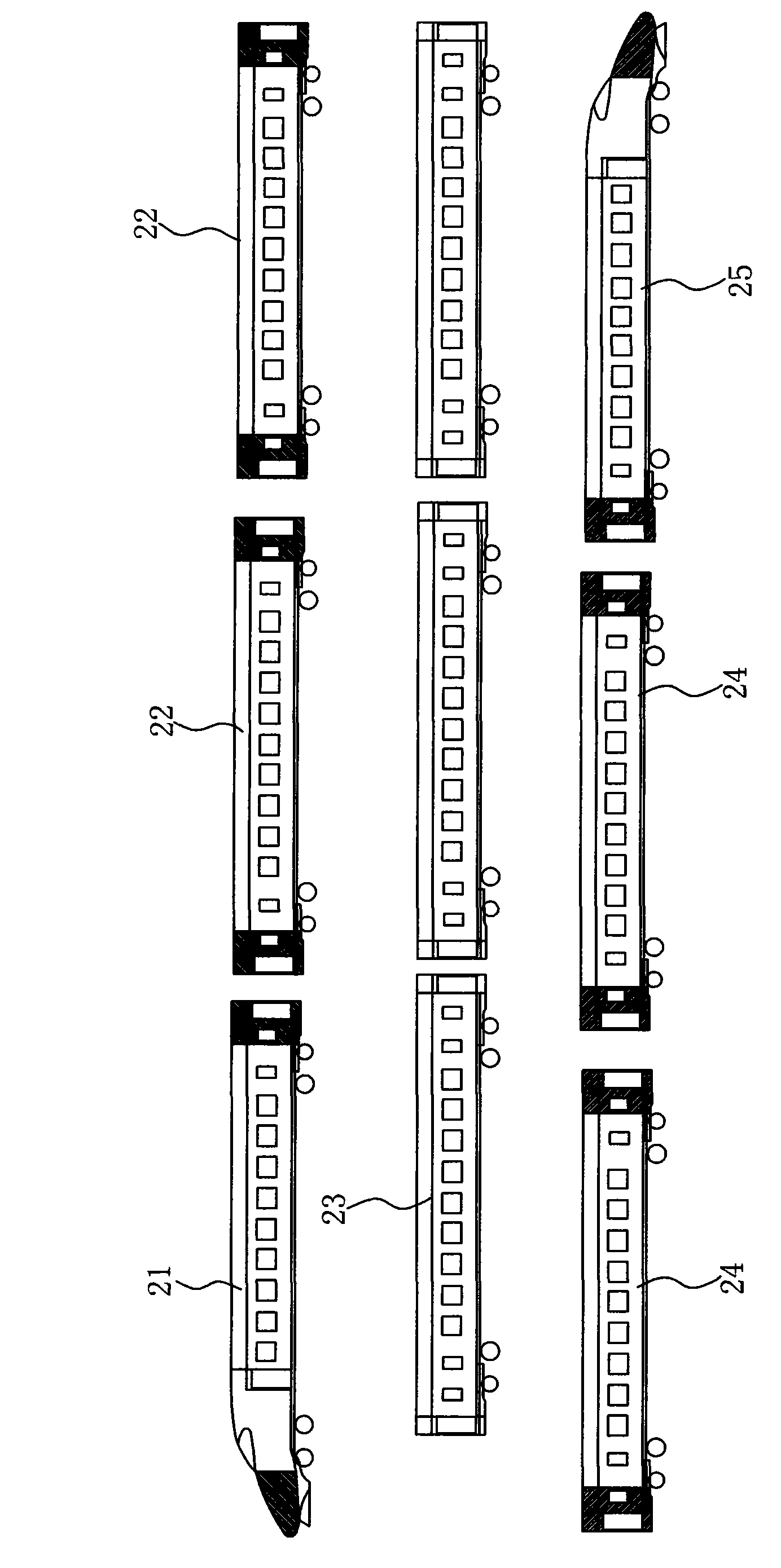

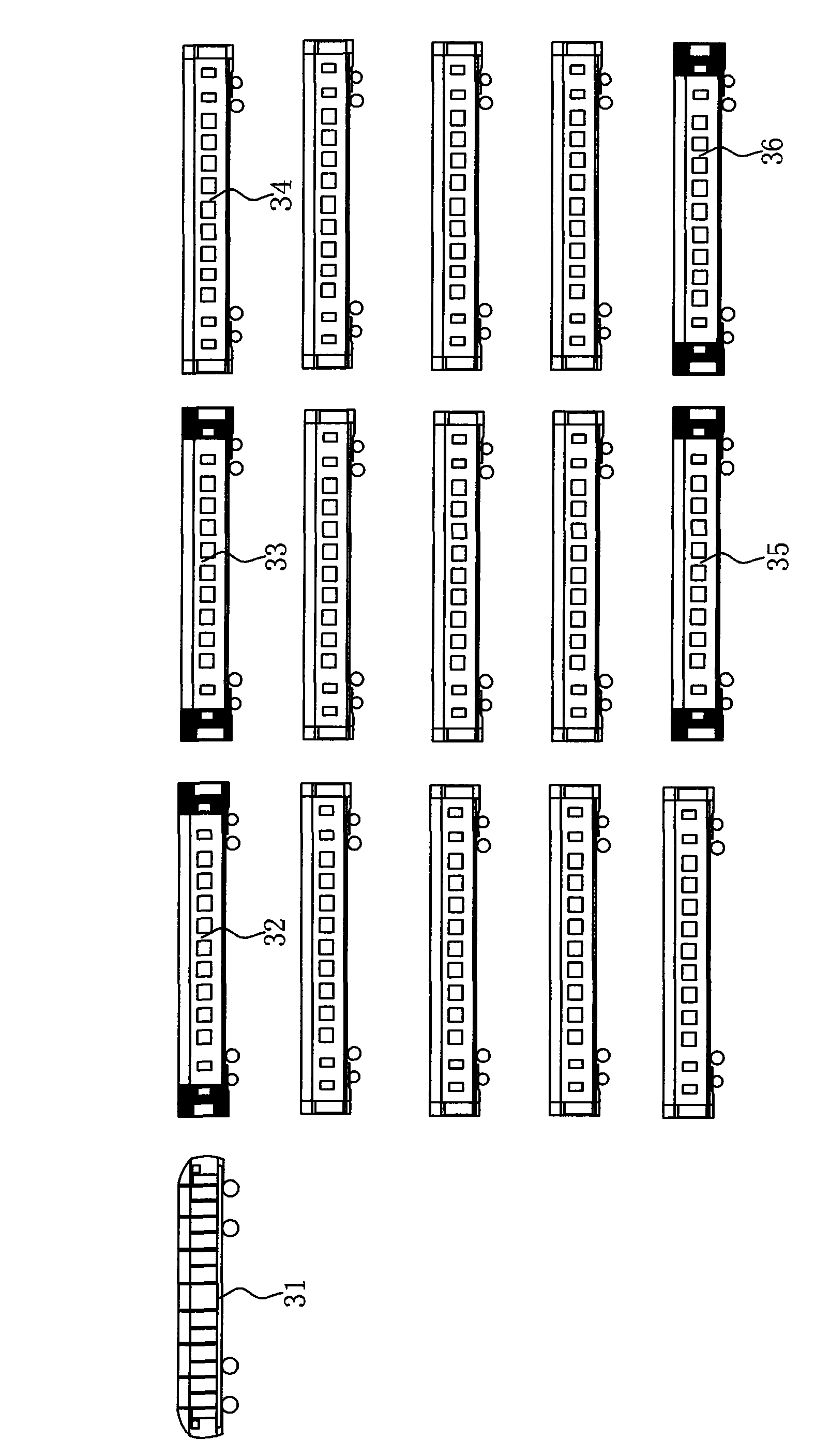

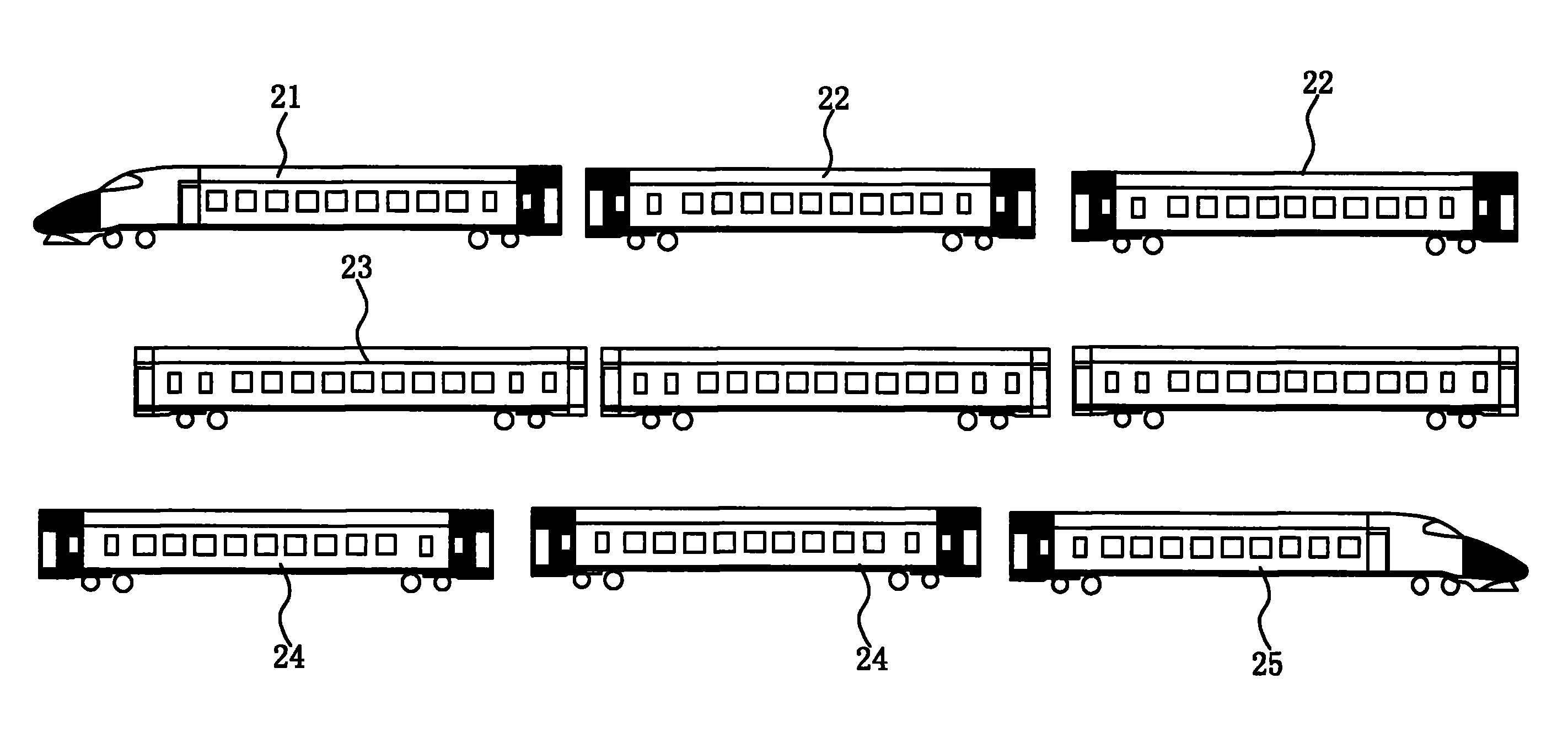

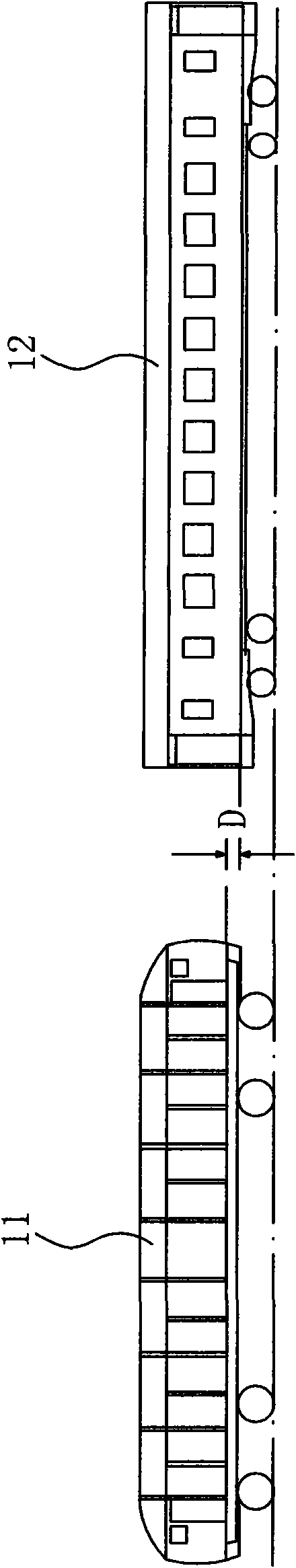

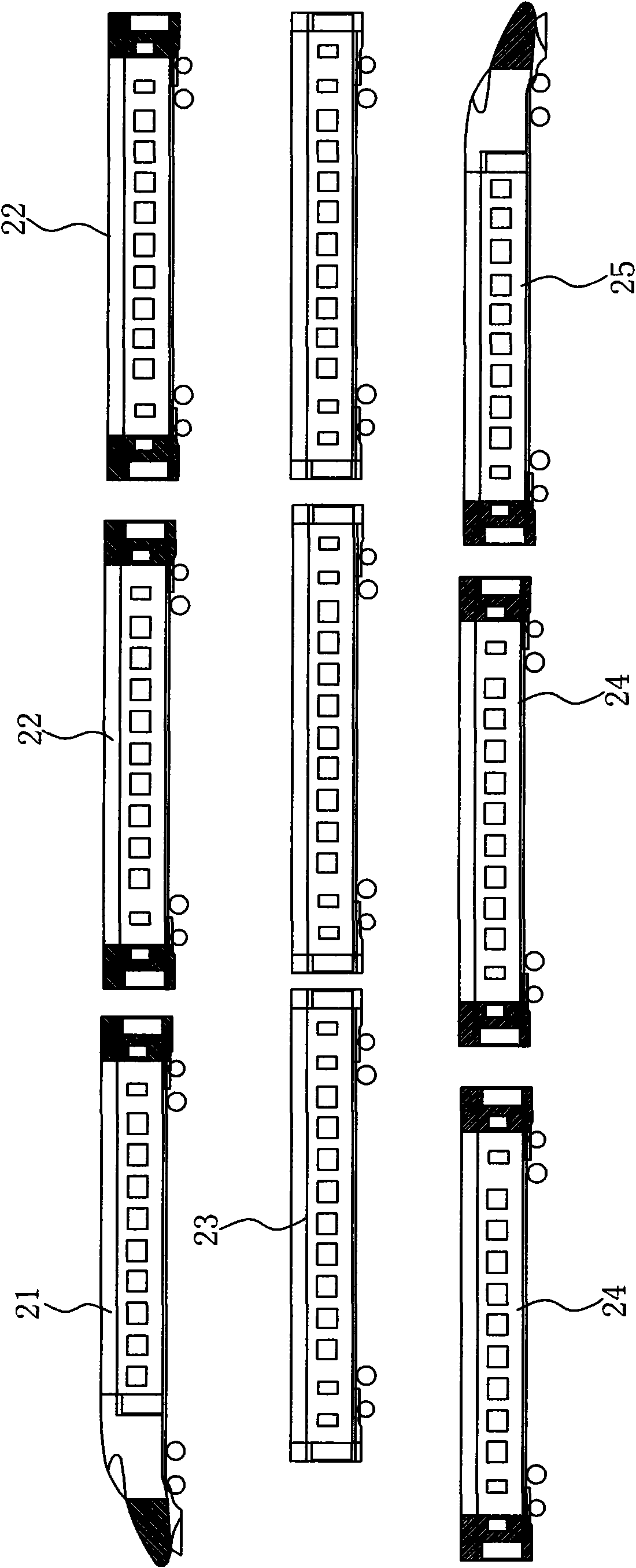

Energy-absorbing safe passenger train

ActiveCN101580067AReduce manufacturing costHarm mitigationAxle-box lubricationPassenger carriagesPassenger trainFront and back ends

The invention discloses an energy-absorbing safe passenger train which comprises an ordinary passenger train set. The invention is characterized in that the energy-absorbing safe passenger train comprises shock-proof energy-absorbing coaches arranged at the front end and the back end of the ordinary passenger train set; the front end and the back end of the ordinary passenger train are respectively provided with two shock-proof energy-absorbing coaches; and the two ends of the shock-proof energy-absorbing coaches are provided with an energy-absorbing structure, and the middle part thereof is a elastic-changing structure. The energy-absorbing safe passenger train overcomes the defect that the safeguards can not be provided effectively when the existing passenger train is collided, can be applicable to power centralized passenger trains and power decentralized passage trains, and can provide passive safeguards to passengers when the passenger train is collided.

Owner:CENT SOUTH UNIV

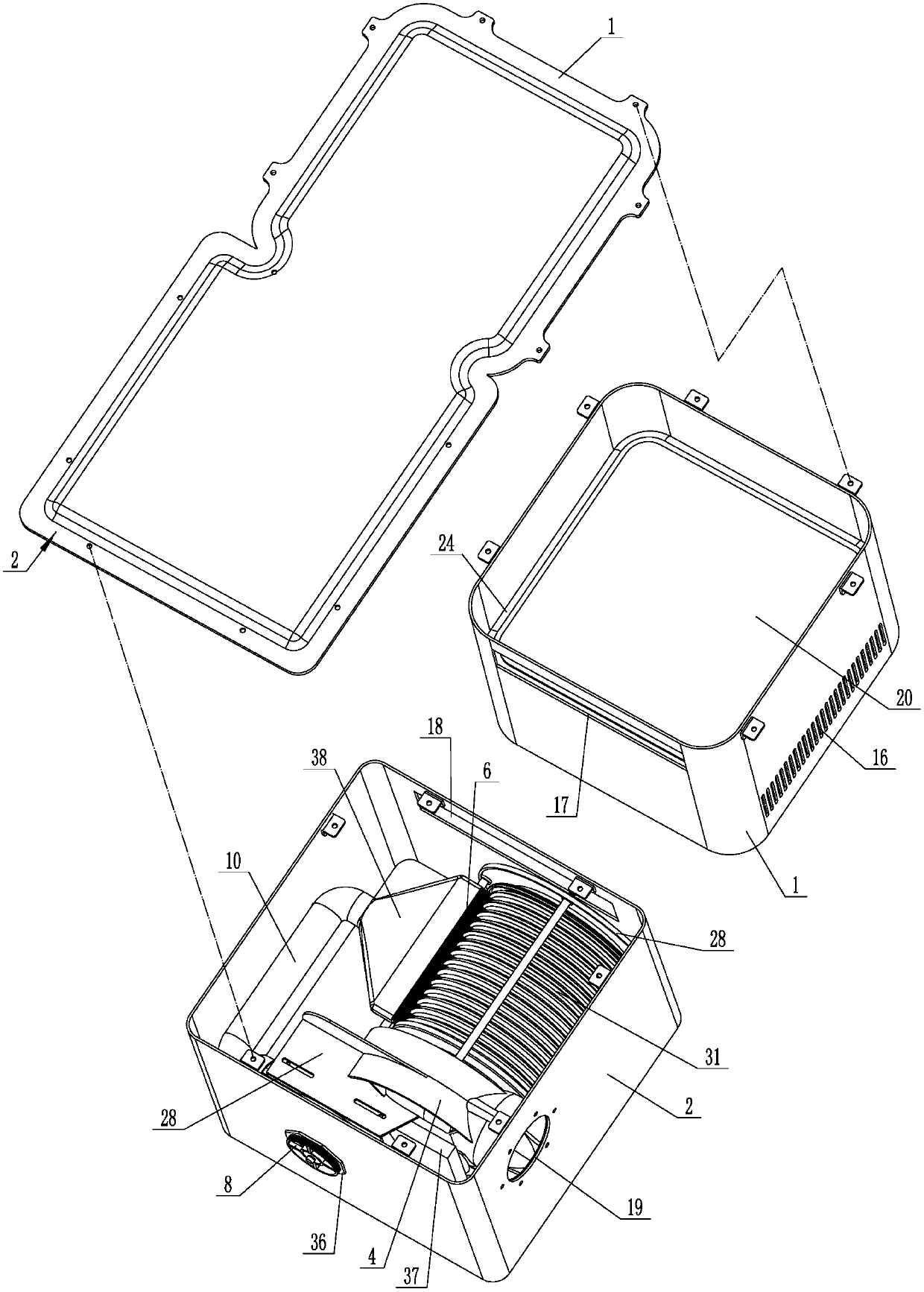

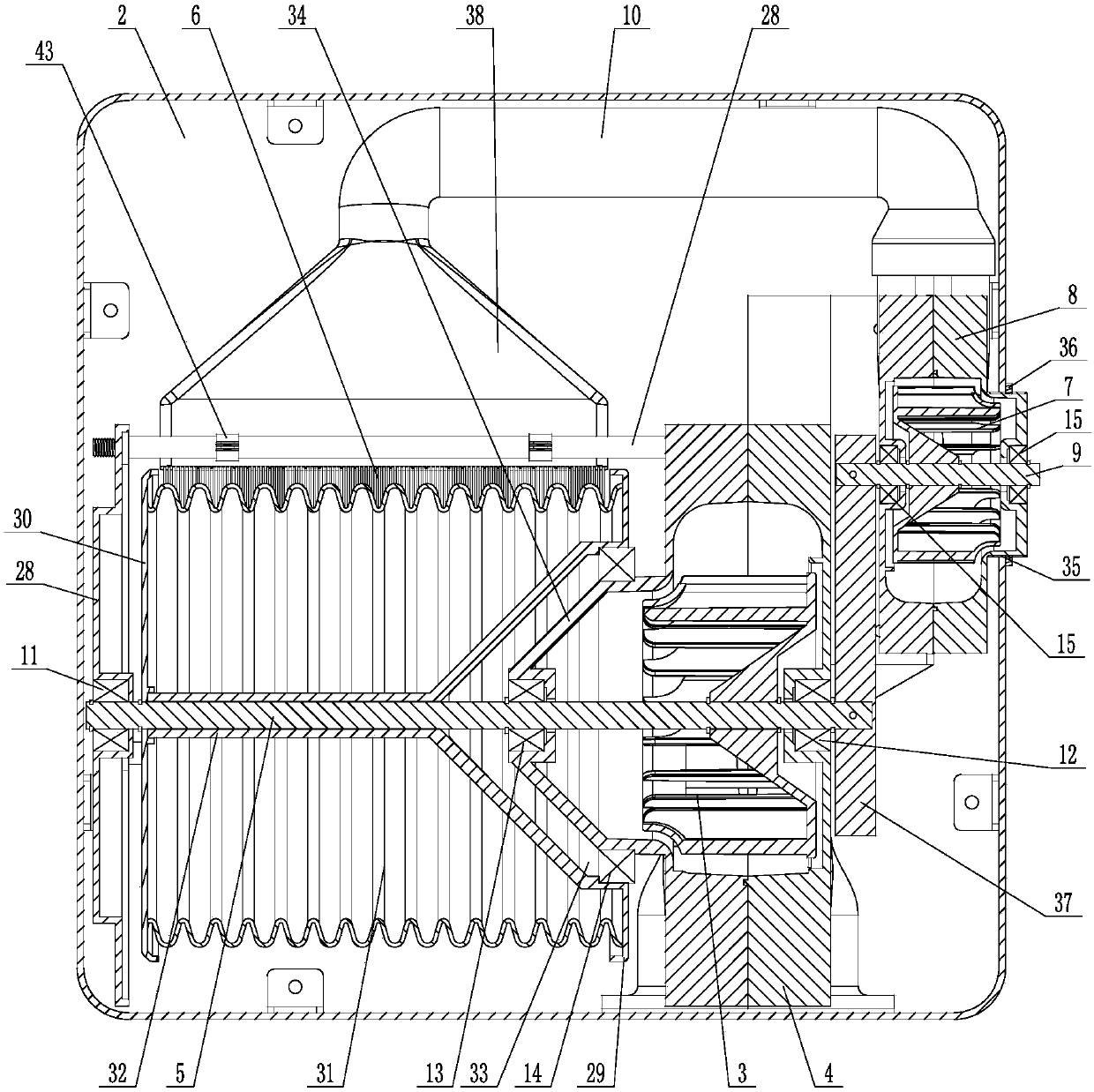

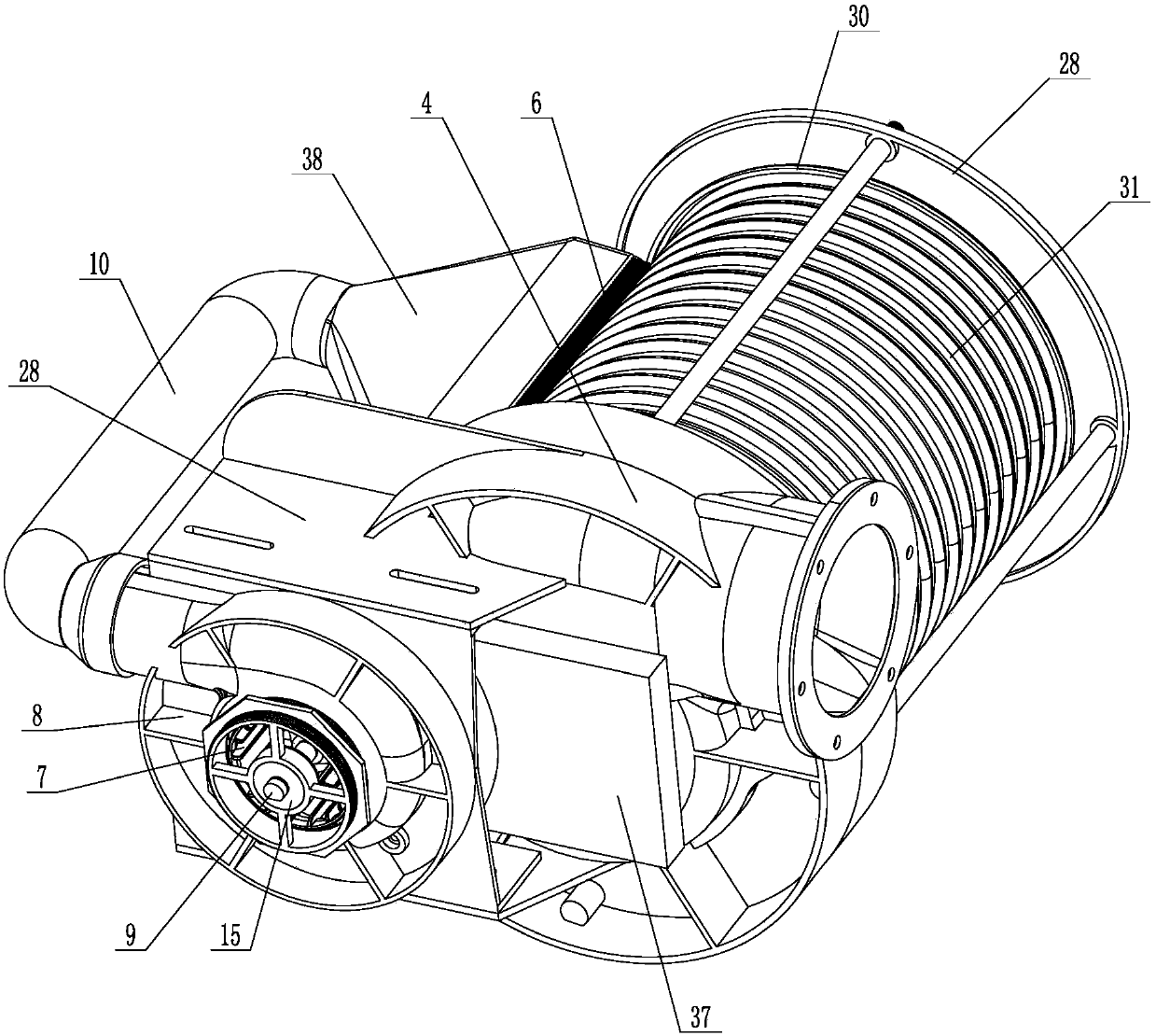

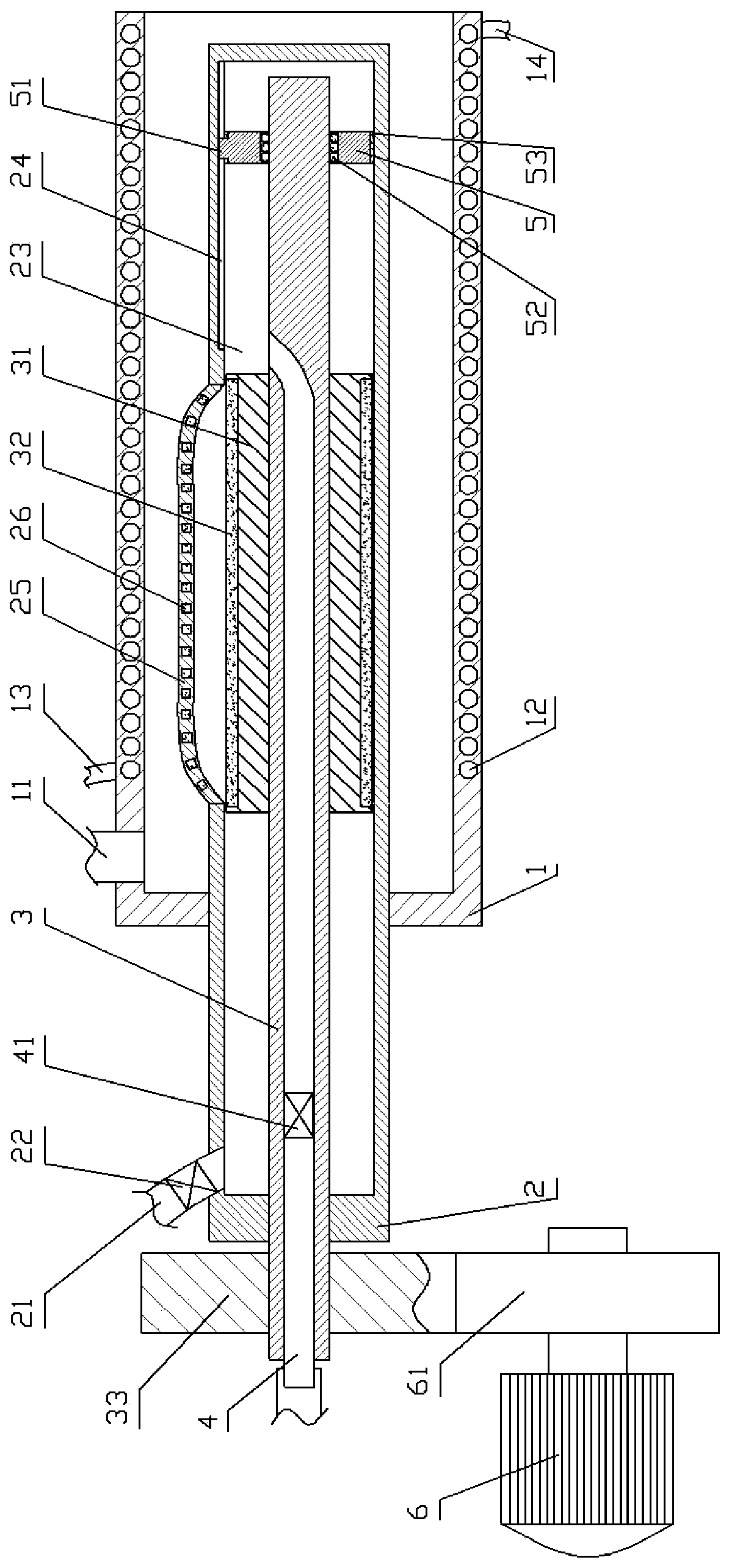

Air filter device

ActiveCN107939566ASimple structureEasy to assemble and disassembleMachines/enginesAir cleaners for fuelAir filterControl theory

The invention relates to an air filter device which comprises a second shell (2), a filter element, a first turbine (3), a first turbine hood (4), a first rotary shaft (5) and a scraping blade (6). The filter element is cylindrical. A second air outlet (19) communicates with a filter element inner cavity through an inner cavity of the first turbine hood (4). The first turbine (3) and the filter element are both connected to the first rotary shaft (5). The first turbine (3) is located in the inner cavity of the first turbine hood (4) and rotationally connected with the first turbine hood (4) through the first rotary shaft (5). The filter element is rotationally connected with the second shell (2) through the first rotary shaft (5). One end of the scraping blade (6) is tightly attached to the peripheral wall of the filter element. The air filter device has the advantages that when in use, the air filter device can remove dirt such as dust and fine sand adsorbed to the surface of the filter element, accordingly, the air inlet amount of an engine is guaranteed, the engine can stably and normally work, and further, the service life of the filter element is greatly prolonged.

Owner:郑良 +1

Friction bag opening machine for various material textures

The invention relates to a friction type bag opener applicable to various materials and belongs the field of packing and unpacking machines and particularly relates preparation processes of finish product packing. The friction type bag opener comprises a mechanical unit and an electric unit, wherein the mechanical unit comprises a conveying belt, movable friction wheels, a movable rack, a fixed friction wheel and a support rack, and the electric unit is composed of a power source, a PLC (programmable logic controller), a stepping motor driver and a stepping motor; woven bags require bag opening treatment. Due to the fact that the friction coefficient between the rubber of friction parts and plastic bags is larger than that among the plastic bags, the plastic bags can glide and accordingly be opened. The friction type bag opener can achieve automated bag opening operation and replace manual operation, thereby effectively improving the opening efficiency of woven bags and obviously enhancing the automation degree.

Owner:河北航轮科技有限公司

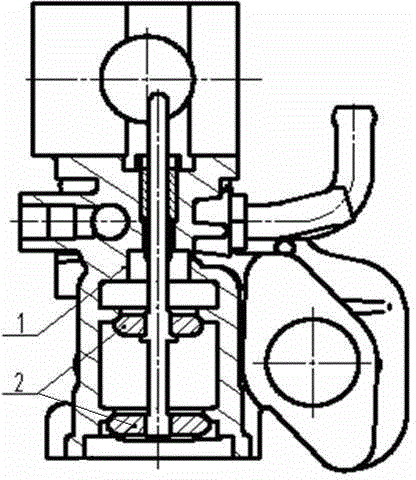

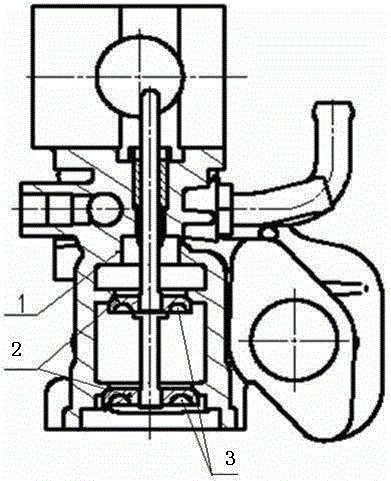

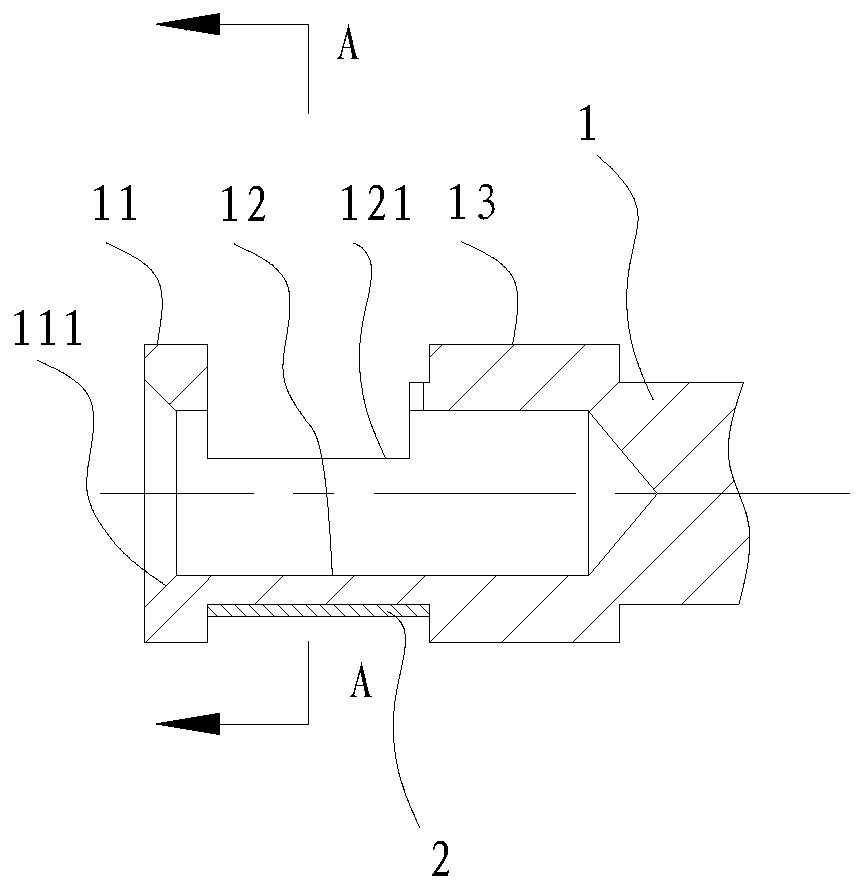

Dual-valve-element sealing structure

InactiveCN104929816AGuaranteed elastic deformationSolve the problem of excessive leakageNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringValve seat

The present invention provides a dual-valve-element sealing structure. The dual-valve-element sealing structure comprises a valve seat assembly and dual valve elements; the bottom of each valve element is provided with an annular groove; the thickness of each valve element is 6mm; and the thickness of the remaining wall of a position, where the annular groove is dug, of each valve element is in a range of 1.5-3 mm. The thickness of each improved valve element is thinned to be 6mm from 7 mm before improvement, each valve element bottom directly impacted by exhaust gas is dug with the annular groove to thin the entity, so that the thickness of the remaining wall of the position where the valve element is thinned is in a range of 1.5-3 mm, and elastic deformation of the valve elements under high temperature can be ensured. According to an EGR valve by adoption of the dual valve elements having the new structure, the problem that leakage rate exceeds standard after operation is solved, and the leakage rate can be smaller and smaller even close to 0 after the EGR operates for some time, and the problem that the leakage rate exceeds the standard is thoroughly solved.

Owner:WUXI LONGSHENG TECH

Pavement pit slot repairing structure

InactiveCN109403176AStable sealing effectLow modulusIn situ pavingsNon-macromolecular adhesive additivesPlasticizerGreek letter alpha

The invention discloses a pavement pit slot repairing structure. The pavement pit slot repairing structure comprises a geogrid layer, a cement-emulsified asphalt mortar layer and a cement-emulsified asphalt concrete layer which are sequentially arranged in a to-be-repaired pit slot from bottom to top, wherein an adhesive layer is arranged between the inner surface of the to-be-repaired pit slot and each of the geogrid layer, the cement-emulsified asphalt mortar layer and the cement-emulsified asphalt concrete layer; an adhesive comprises raw materials as follows: butyl cellosolve, n-butyl alcohol, methylacrylic acid, styrene, triethylene glycol dimethacrylate, poly2,6-dimethyl-1,4-phenyl ether, polyvinyl acetate, dimethylethanolamine, alpha,omega-dihydroxyl polydimethylsiloxane, nano-silica, graphite powder, a tackifier, a chain extender, a cross-linking agent and a plasticizer. The geogrid layer, the cement-emulsified asphalt mortar layer and the cement-emulsified asphalt concrete layer are tightly bonded with the original pavement to form an overall stressed structure by the special adhesive, and after one-year usage of the repairing structure, joints are free of cracks, no falling phenomenon is produced, and the stable sealing effect is realized.

Owner:CHONGQING JIAOTONG UNIVERSITY

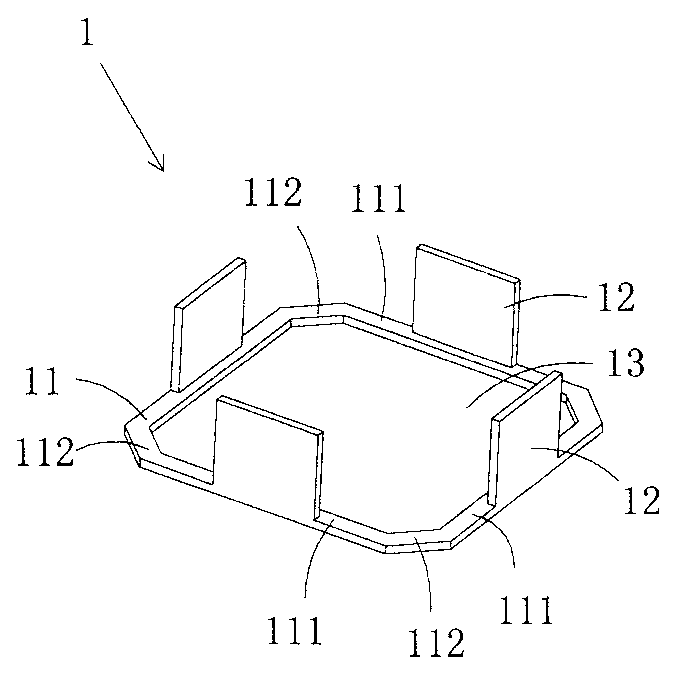

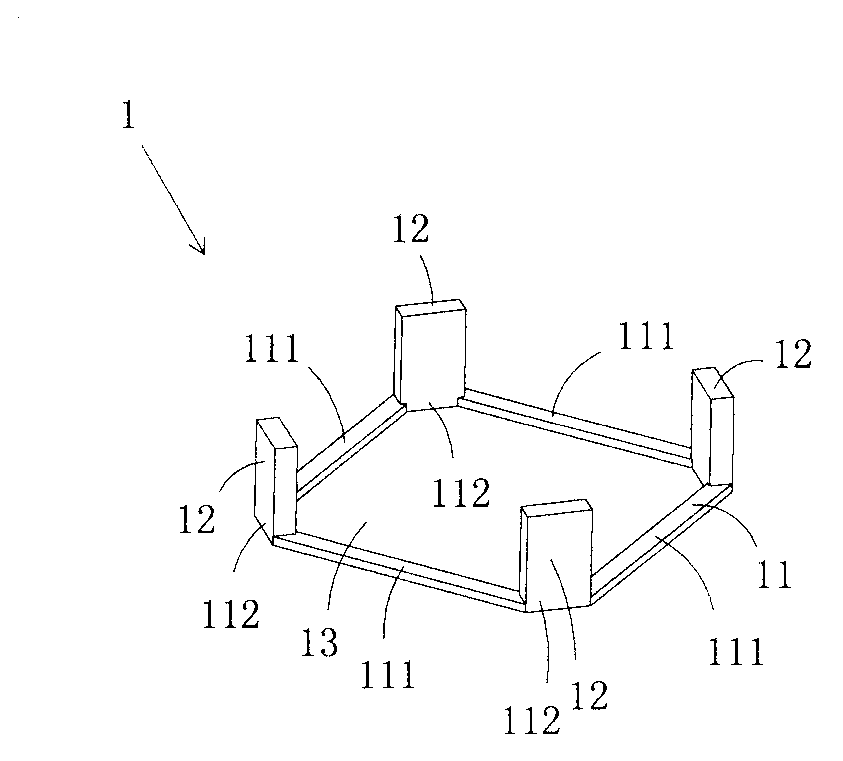

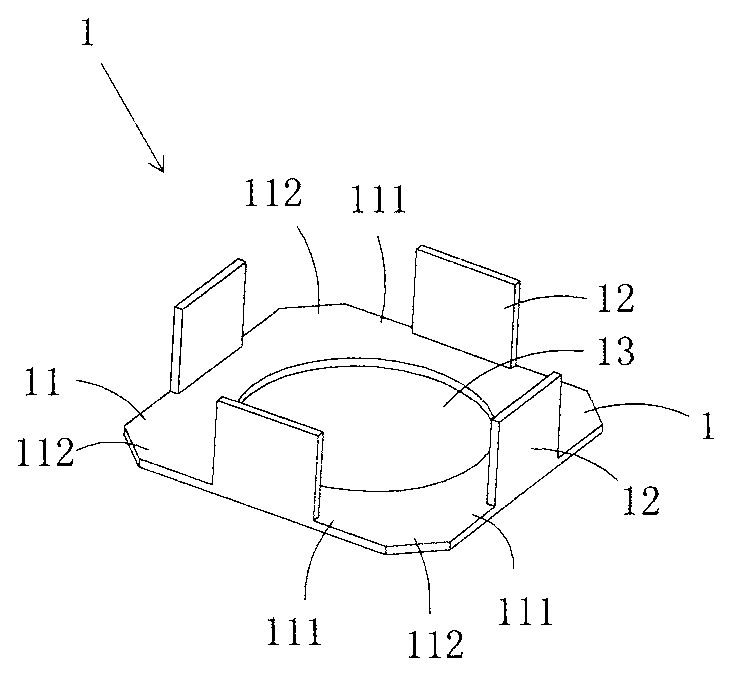

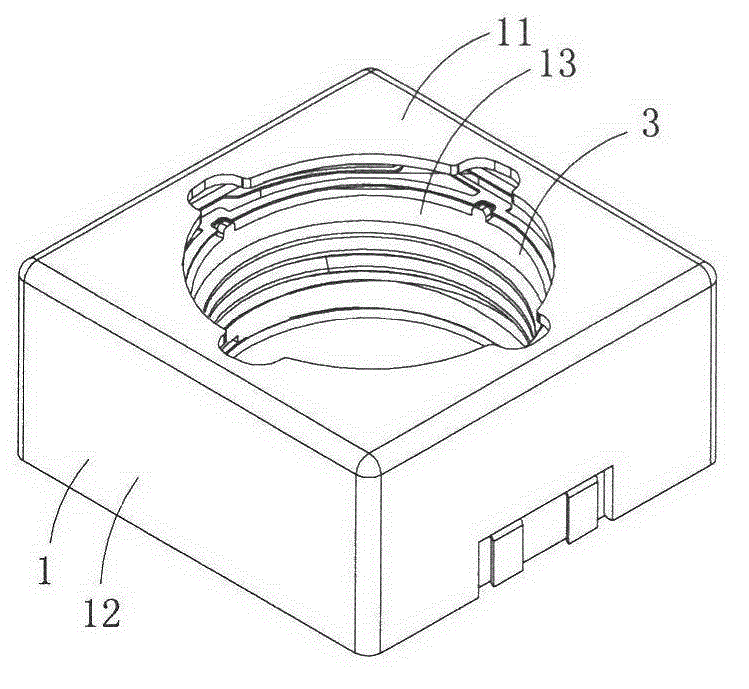

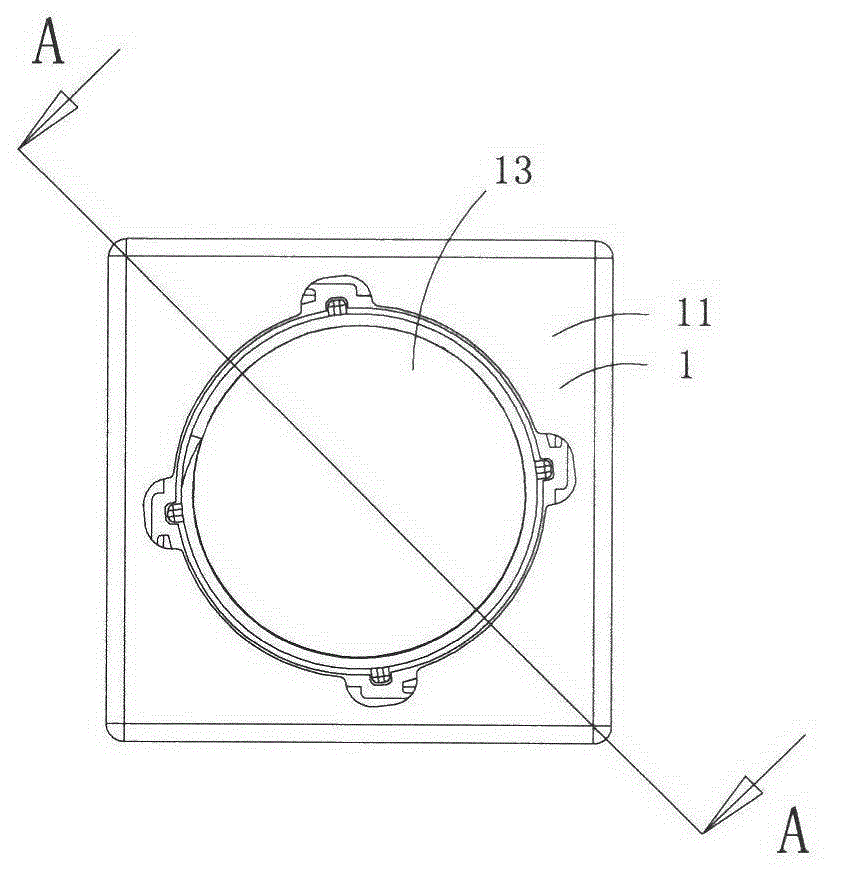

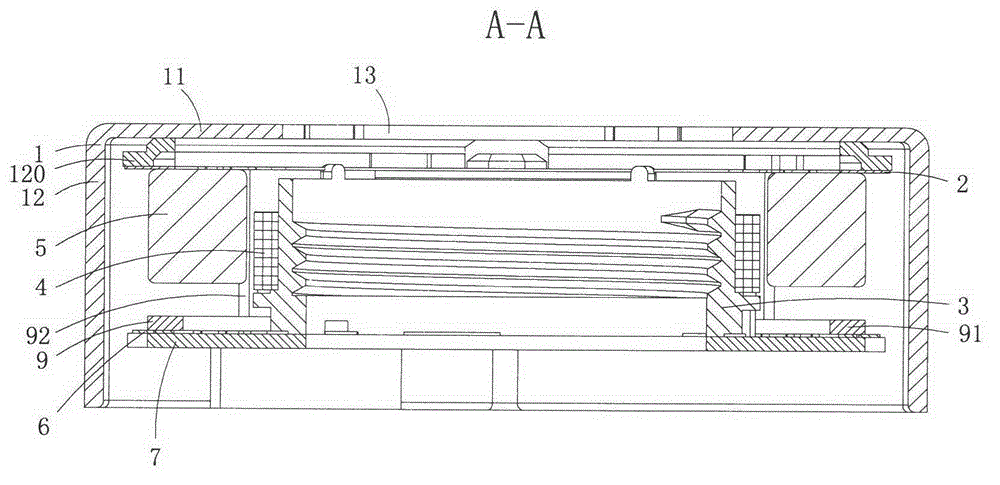

Positioning support for micro drive motor

InactiveCN103001444AGuaranteed machining accuracyGuaranteed elastic deformationDynamo-electric machinesDrive motorLinear drive

The invention discloses a positioning support for a micro drive motor. The positioning support comprises a platy body and a plurality of support bosses, the a through hole is arranged at the center of the platy body, the support bosses projecting from the platy body are used for butting against an outer ring of an external upper spring piece, and each support boss is positioned on the side as same as the platy body. The positioning support is capable of effectively controlling the space between the outer ring of the upper spring piece and the outer edge of a lower spring piece, and accordingly linear drive effect is improved.

Owner:深圳市光控数码光电有限公司

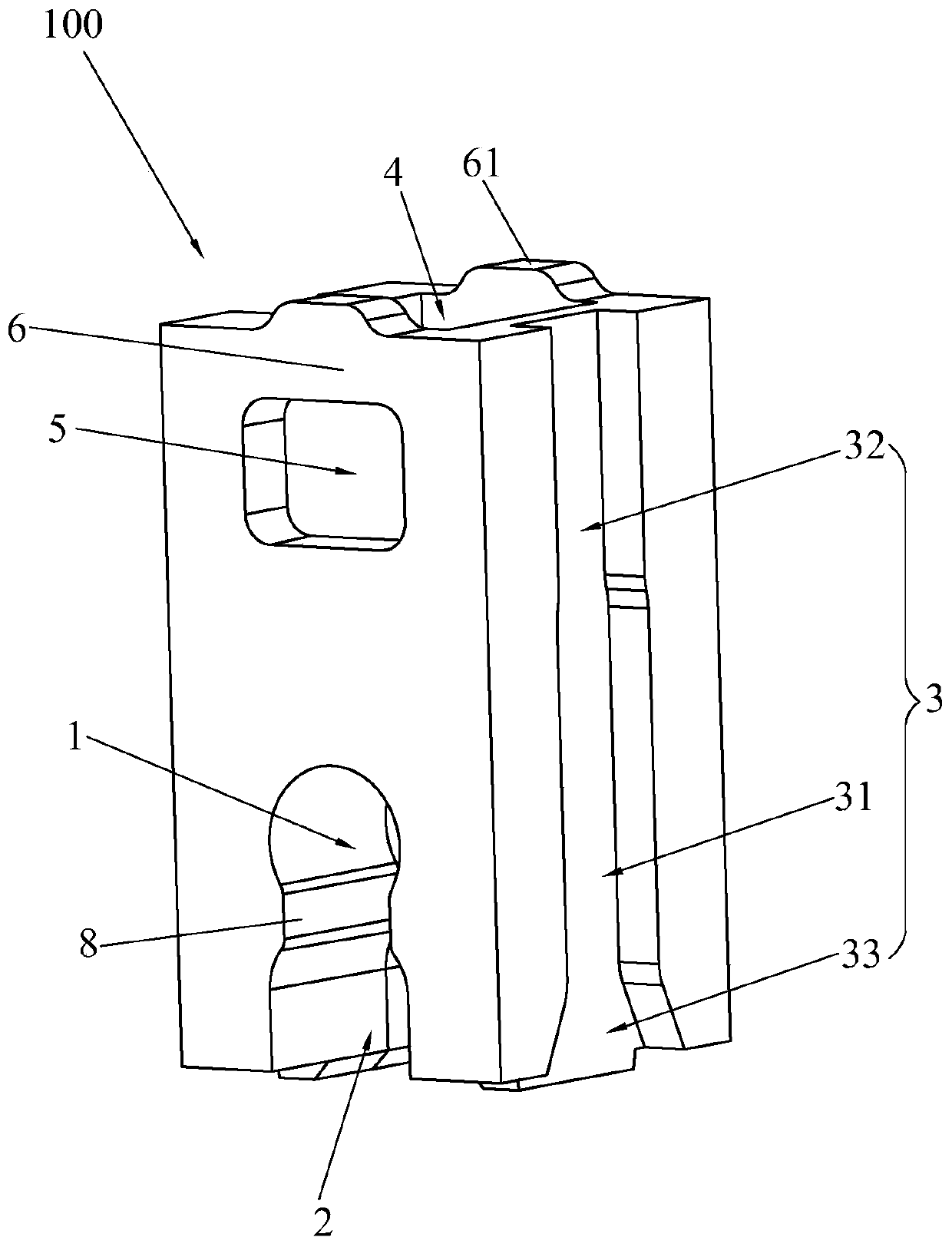

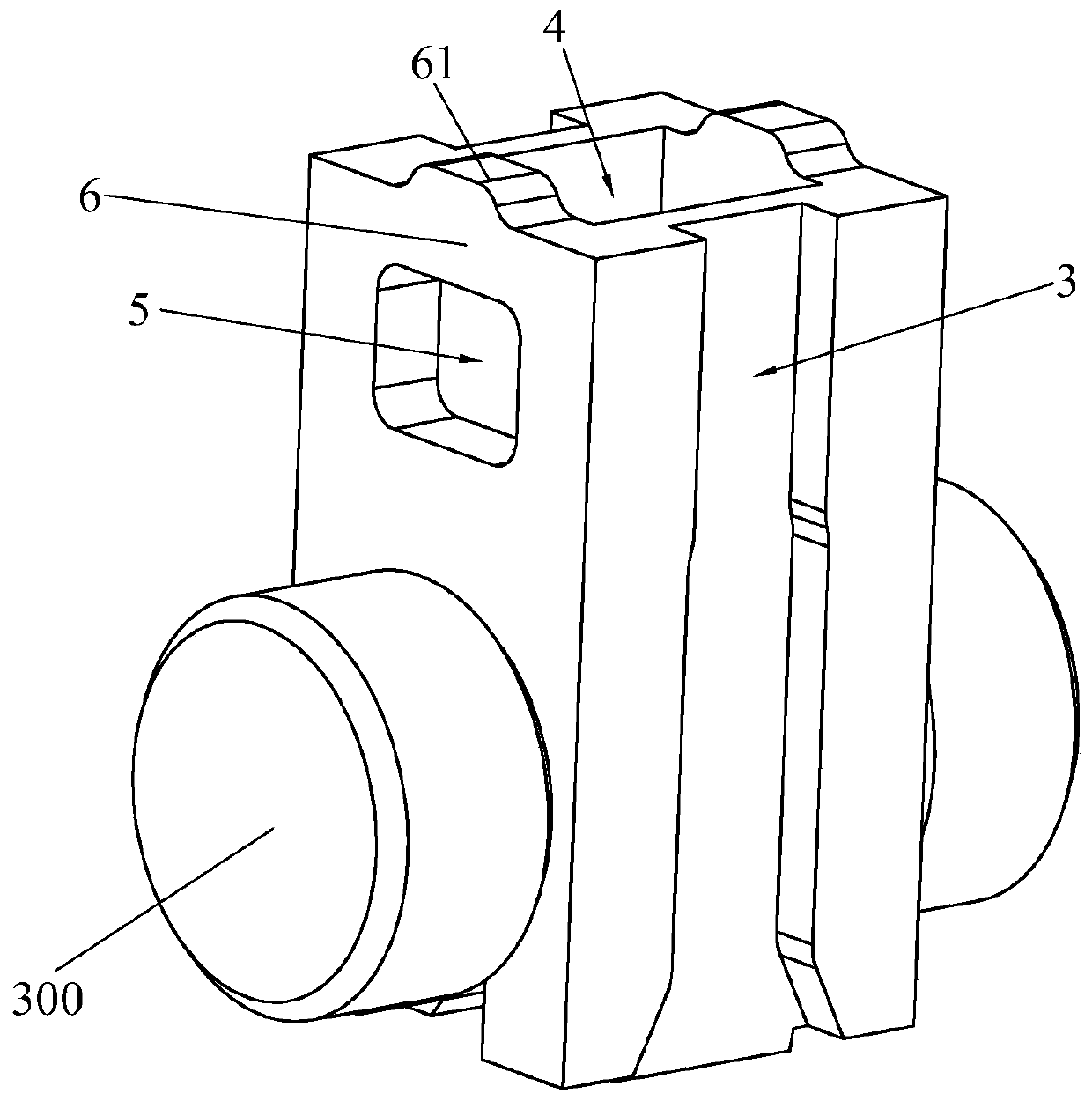

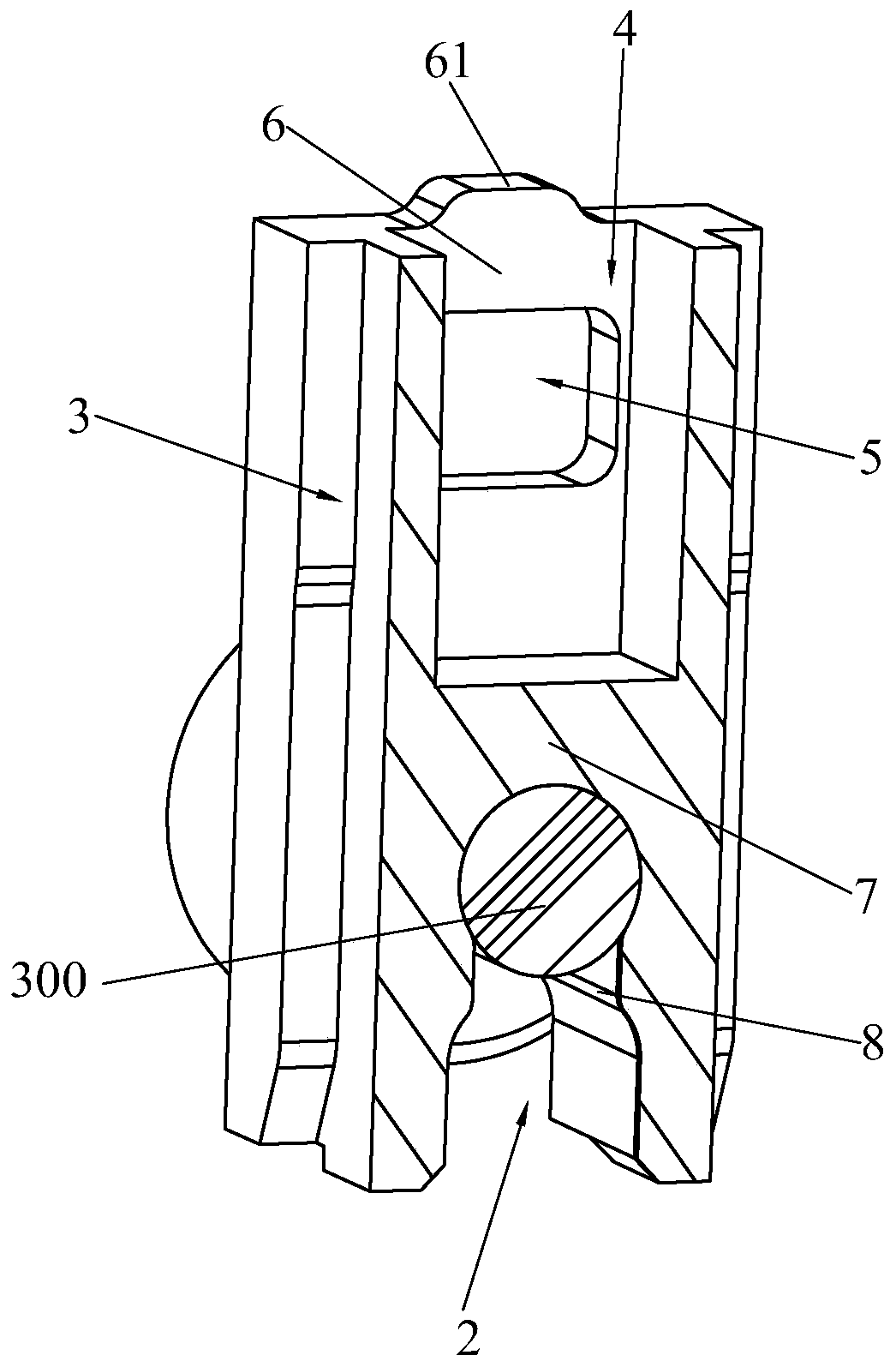

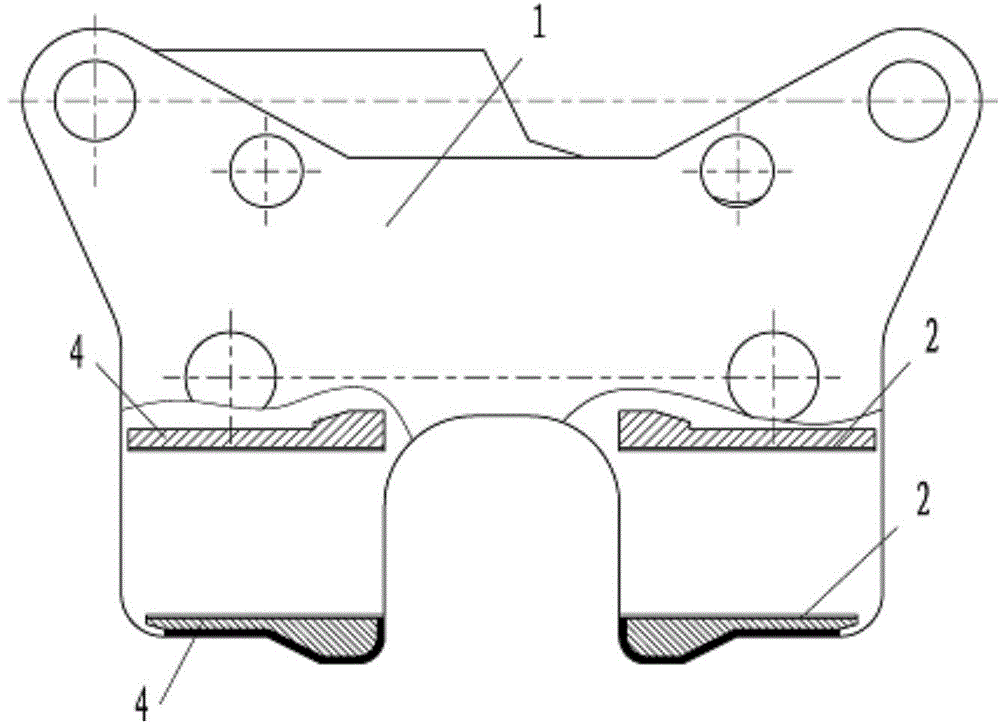

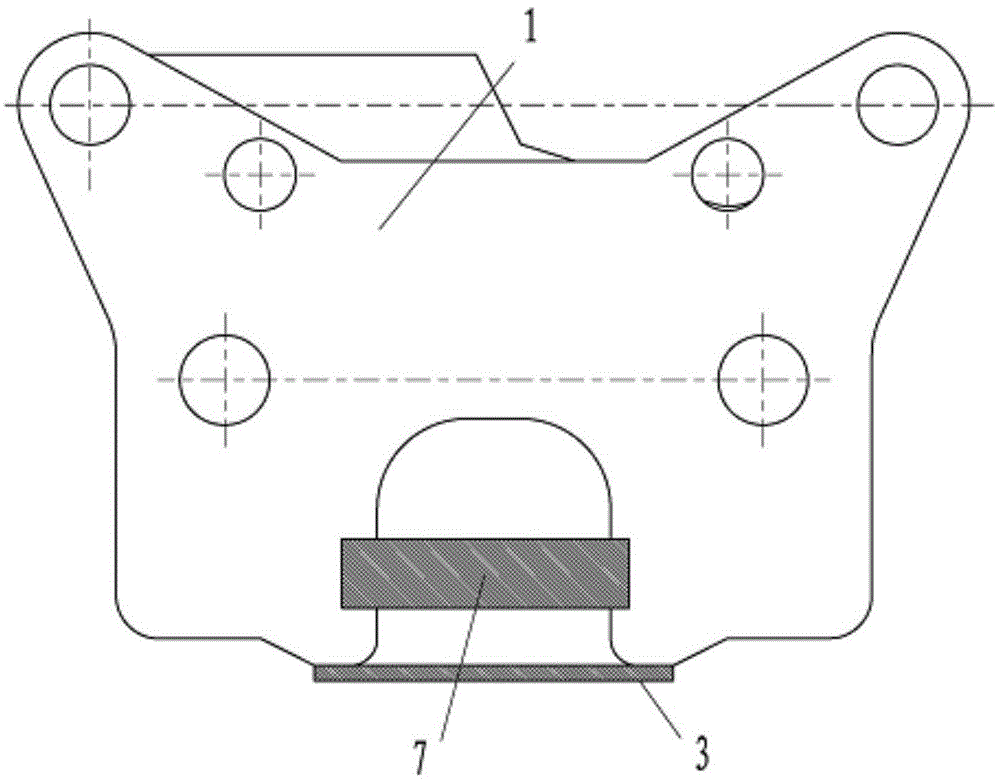

Flying bar fixing seat and cavity filter

PendingCN111048875AAvoid installation failuresAvoid shakingWaveguide type devicesStructural engineeringMechanical engineering

Owner:DONGGUAN ACE TECH

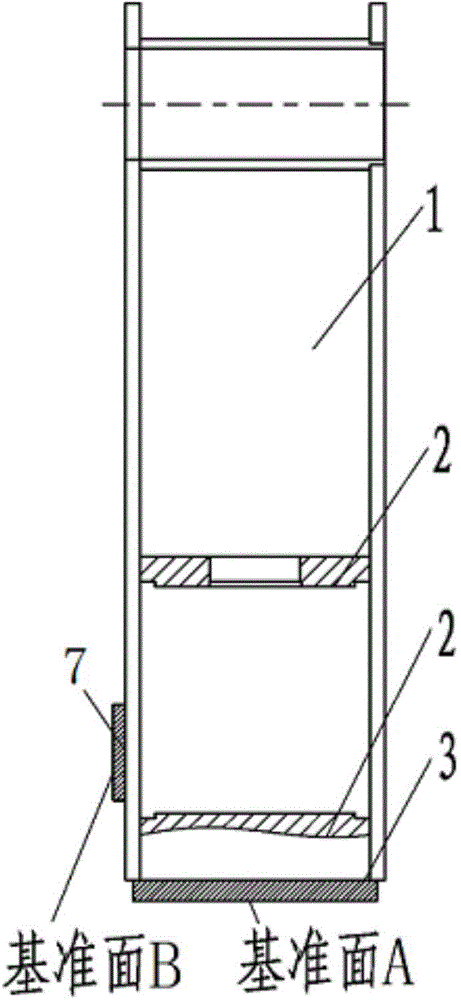

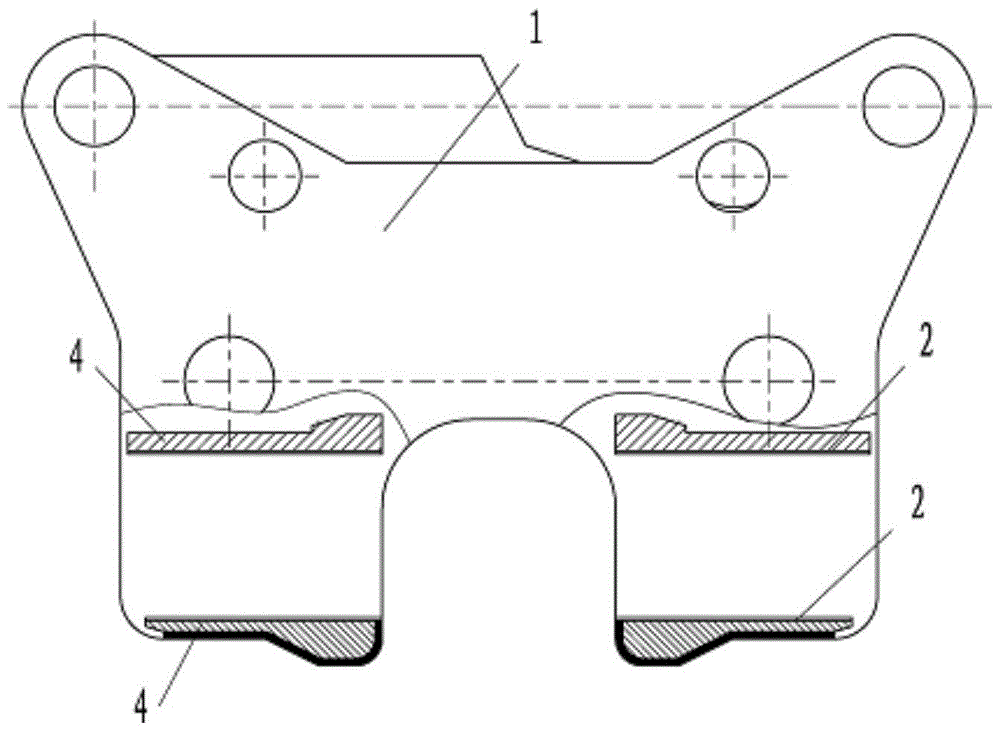

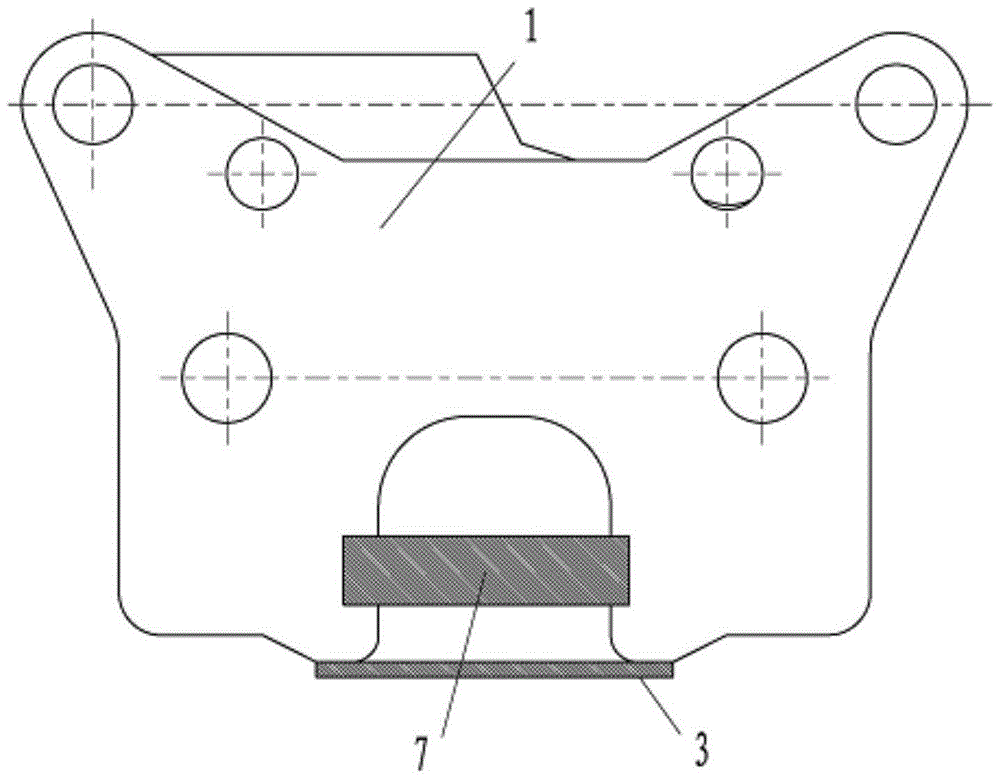

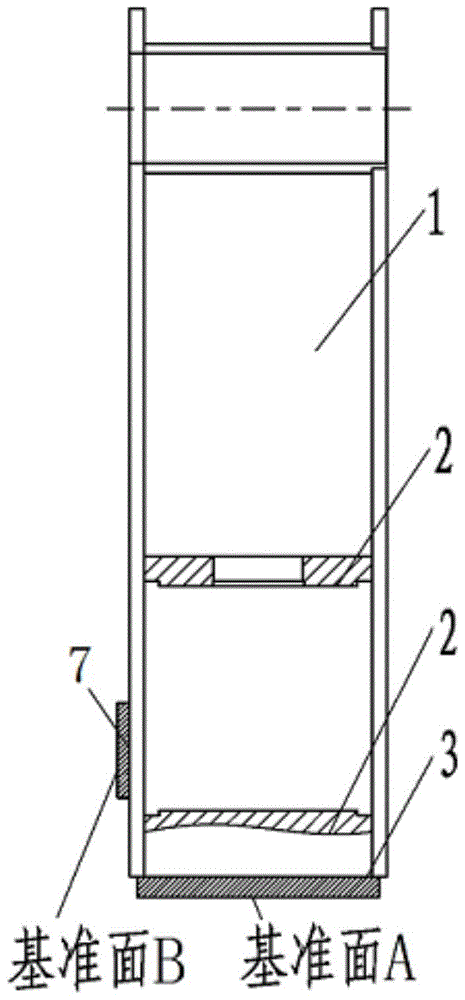

Method for slotting and cutting inner wall of noncontinuous box

ActiveCN104668884AImprove rigidityReduce distortionPlaning/slotting machinesProcess supportEngineering

The invention discloses a method for slotting and cutting the inner wall of a noncontinuous box. The method includes: step 1, making two process supports, and machining a reference face; step 2, machining six connecting holes; step 3, machining a right inner wall face; step 4, machining a left inner wall face. By the method, machining of the noncontinuous box on a slotting machine is realized, and shape and position accuracy of each machined face is guaranteed effectively; the problem of machining rebound deformation caused by rigidity difference of the noncontinuous box is solved; the problem of deformation of a toolbar due to the fact that the toolbar extends out excessively is solved; the problems of positioning and centering when the noncontinuous box is machined on the slotting machine are solved; requirements on position degree between holes in the box and the left inner wall face as well as the right inner wall face of the box are met, the method is high in universality, and production efficiency is improved effectively.

Owner:BAOJI PETROLEUM MASCH CO LTD

Energy-absorbing safe passenger train

ActiveCN101580067BReduce manufacturing costHarm mitigationAxle-box lubricationPassenger carriagesPassenger trainFront and back ends

Owner:CENT SOUTH UNIV

Spring-wrapped jack contact member

InactiveCN110247230AIncreased deformabilitySimple structureCoupling contact membersEngineeringProcess requirements

A spring-wrapped jack contact member includes a cylindrical jack and a contact ring. The sidewall of the jack is provided with a window. The contact ring wraps the window on the outer wall of the jack. The contact ring is provided with a contact spring. The contact spring is bent towards the inside of the jack and protrudes into the jack through the window. The contact ring wraps a contact section so as to achieve a wide insertion force range, a low process requirement, high contact reliability. Further, the spring-wrapped jack contact member is simple in structure, small in size, practical and convenient, and can economically meet the requirement of a situation for a long mechanical life and large-scale vibration.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

A multi-gap vacuum isolating switch

InactiveCN103943406BImprove high voltage withstand capabilityHigh mechanical strengthHigh-tension/heavy-dress switchesAir-break switchesAuxiliary electrodeVacuum chamber

Provided is a rapid multi-gap vacuum disconnector. The rapid multi-gap vacuum disconnector comprises an electrode structure, current-carrying contacts, a metal carrier structure, a driver, an insulating driving pull rod structure and a vacuum cavity, wherein the electrode structure comprises a movable main electrode connected with a corrugated pipe and a fixed auxiliary electrode, the insulating driving pull rod structure comprises contact carrier fixing sealing plates to which current-carrying contact metal carriers are fixed, corrugated pipes and an insulating driving pull rod, the corrugated pipes and the insulating driving pull rod are connected with the contact carrier fixing sealing plates, the current-carrying contacts are installed on the current-carrying contact metal carriers respectively, and working modes are switched through the insulating driving pull rods; the insulating driving pull rods drive the current-carrying contacts to shift through the contact carrier fixing sealing plates and the current-carrying contact metal carriers connected with the contact carrier fixing sealing plates, so that a circuit is formed by the main electrode, the auxiliary electrode and the current-carrying contacts when the rapid multi-gap vacuum disconnector is in the current-carrying working state; multi-gap vacuum insulation is formed by the main electrode, the auxiliary electrode and the current-carrying contacts when the rapid multi-gap vacuum disconnector in the isolation working state. According to the rapid multi-gap vacuum disconnector, application of multi-gap vacuum insulation in the rapid disconnector is achieved, and the high-voltage resistance capacity of the rapid multi-gap vacuum disconnector is improved.

Owner:XI AN JIAOTONG UNIV

Asphalt pavement crack sealing repair method

InactiveCN109457587AImprove liquidityImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesSteam pressureRoad surface

The invention discloses an asphalt pavement crack sealing repair method. The asphalt pavement crack sealing repair method comprises milling a damaged pavement to form milled grooves; heating the damaged parts of the damaged pavement through microwaves to dissipating moisture and air out of the inner cracks of the milled grooves, and sufficiently drying the pavement through a steam pressure pump; injecting sealant into crack filling grooves through a crack filling machine, and controlling the height of filling layers to be 0.3 cm lower than the pavement; 3-4 hours later, at a temperature of 170-190 DEG C, uniformly laying SBS (styrene butadiene styrene) modified asphalt onto the surfaces of the milled grooves. The sealant is prepared from raw materials including butyl glycol, n-butyl alcohol, methylacrylic acid, styrene, triethylene glycol dimethacrylate, poly-2, 6-dimethyl-1,4-diphenyl ether, polyvinyl acetate, dimethylethanolamine, alpha, omega-hydroxyl polydimethylsiloxane and nanosilicon dioxide; after being cooled down a normal-temperature or low-temperature state, the sealant can be high in elasticity; one year after the sealant is applied, sealing joints have no crack or falling-off and achieve stable sealing effects.

Owner:CHONGQING JIAOTONG UNIVERSITY

A corrosion-resistant optical cable

ActiveCN109445053BReduce loss of lossPrevent overflowFibre mechanical structuresDesiccantEngineering

The invention belongs to the technical field of optical cables, and specifically relates to a corrosion-resistant optical cable, which includes an outer sheath, a plastic coating, a metal armor layer, a water-blocking grease tube, an inner sheath, an optical fiber, a metal reinforcement, an Water belts, cooling fins, filler cords, reinforcement sleeves, wires, desiccant filler strips, elastic holes, transverse spacers and vertical spacers. In the present invention, a horizontal spacer and a vertical spacer are arranged in the inner cavity of the water-blocking ointment tube, so as to separate the ointment in the inner cavity of the water-blocking ointment tube, and ensure that when the entire optical cable is cut, through the vertical Reduce the loss of grease to the spacer, and prevent the oil from overflowing due to damage when the surface of the water-blocking grease tube is damaged through the transverse spacer.

Owner:SHENZHEN XINAOKE CABLE

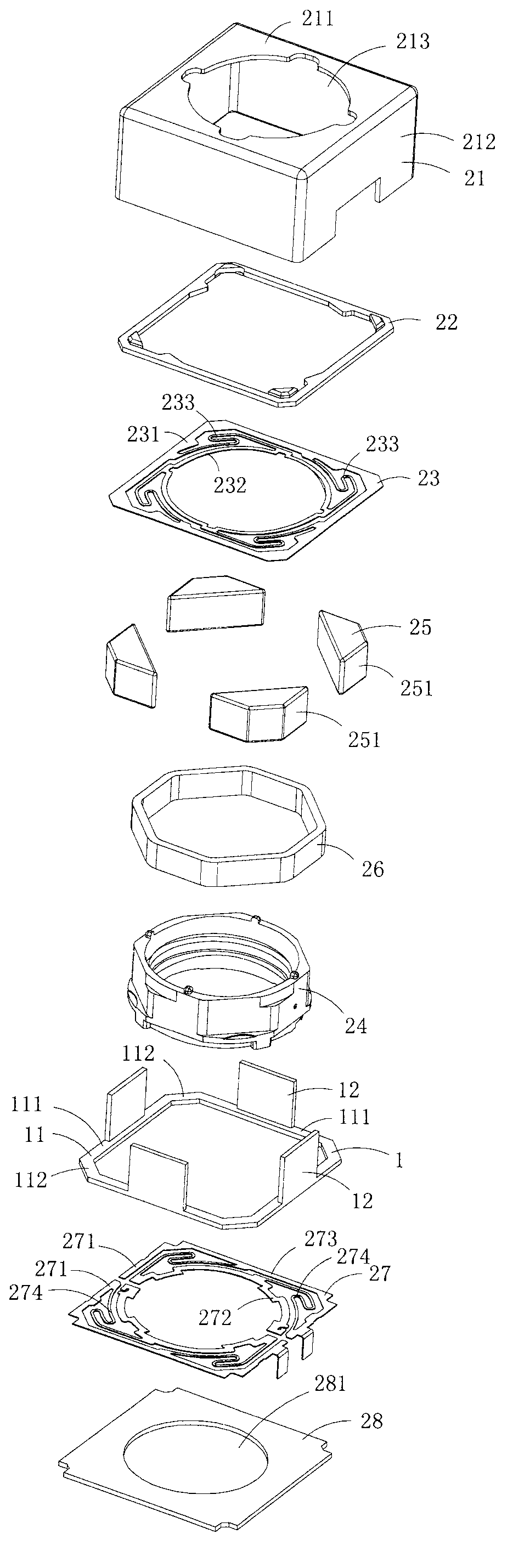

Modified miniature driving motor

InactiveCN103001442AGuaranteed spacingEffective spacing controlDynamo-electric machinesEngineeringMagnet

The invention discloses a modified miniature driving motor which comprises an upper cover, an upper gasket, an upper spring piece, a carrier, a coil component, a magnet component, a lower spring component and a lower gasket. The magnet component comprises four magnets in shapes of trapezoid basically, a side face, close to the coil component, of each magnet is an N pole or S pole, the side face, far away from the coil component, of each magnet is an S pole or N pole, the magnets are arranged at an inner corner formed by clamping of two adjacent side walls of the upper cover, gaps are reserved between two adjacent magnets, the lower gasket comprises a press plate in a shape of rectangular frame basically and supporting plates protruding upwards from the press plate, each supporting plate is positioned in the gaps between two adjacent magnets, and the top surface of each supporting plate is abutted on an outer ring of the upper spring piece. The modified miniature driving motor can effectively guarantee linear driving effect.

Owner:深圳市光控数码光电有限公司

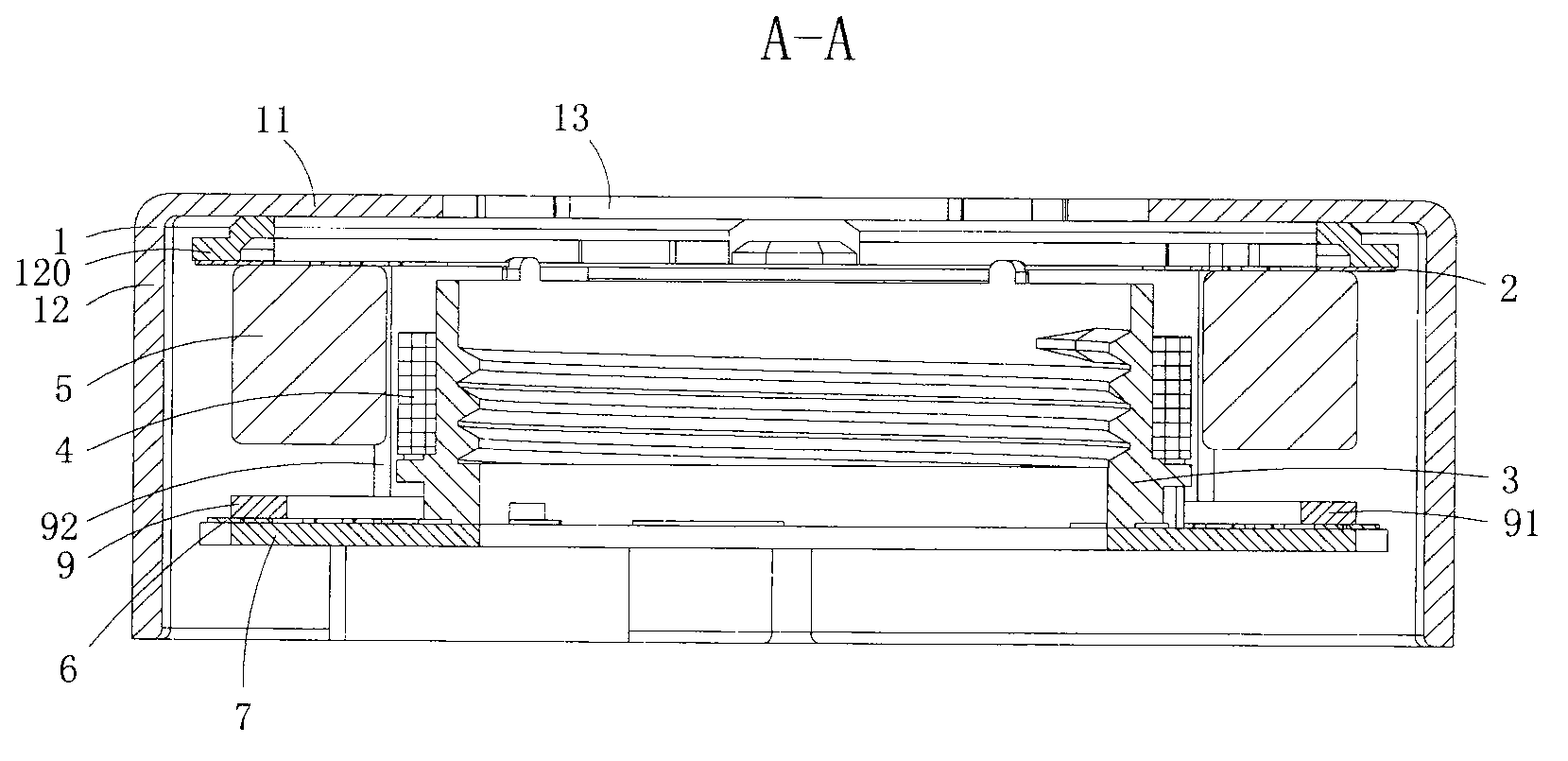

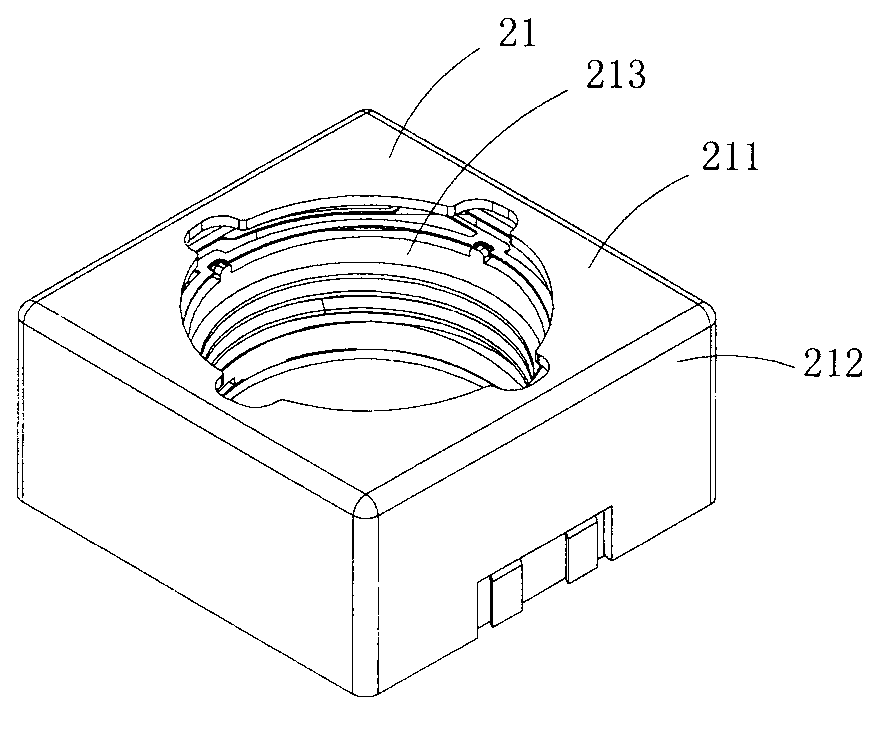

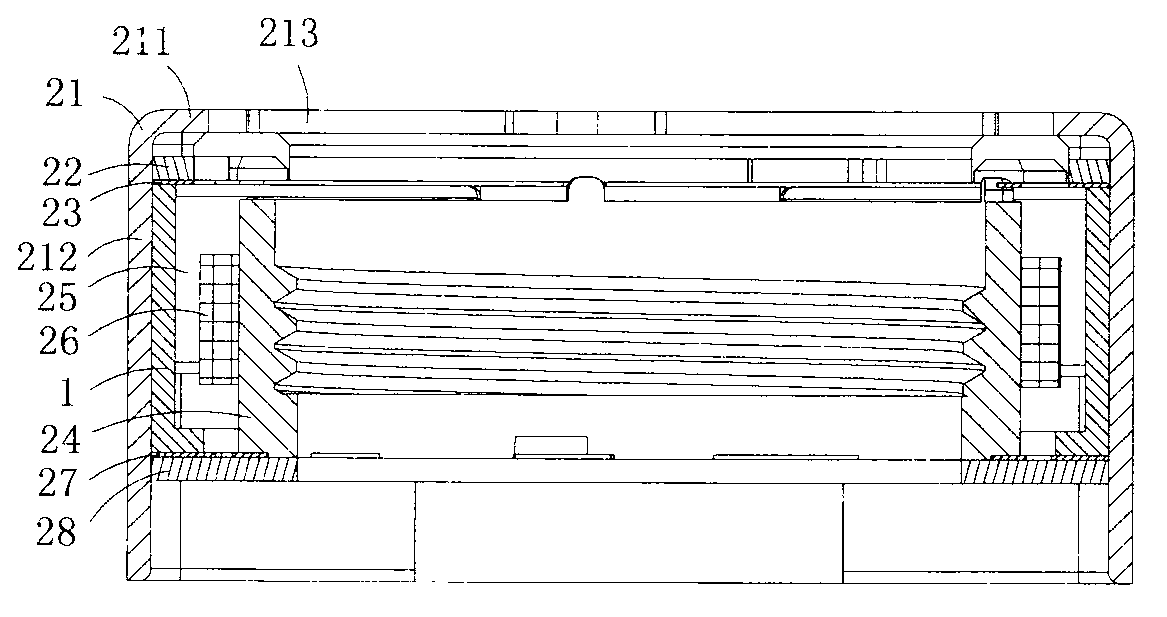

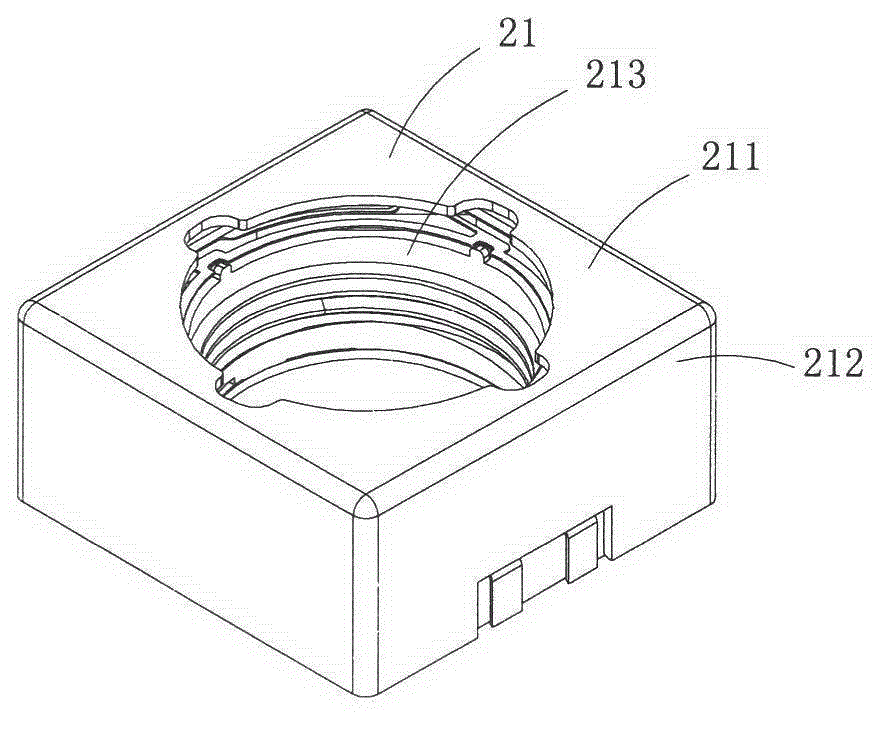

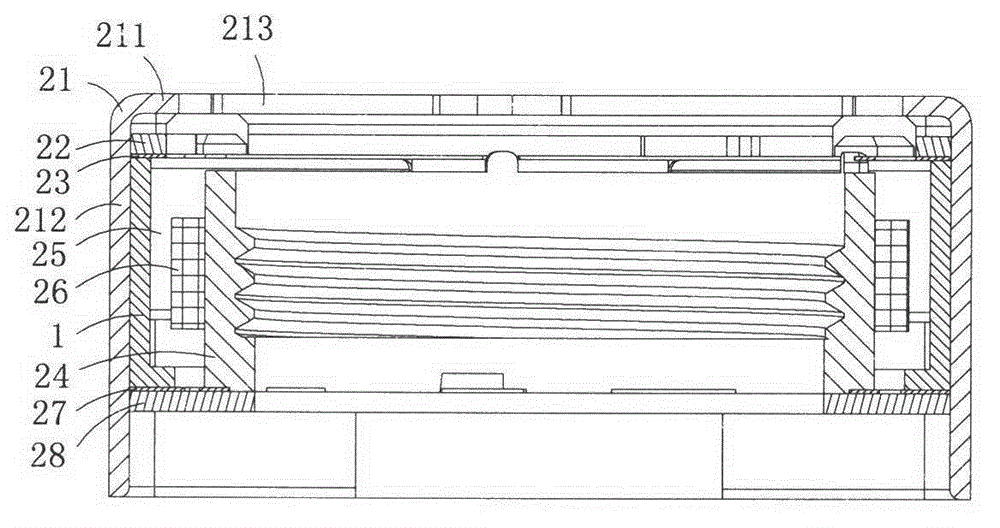

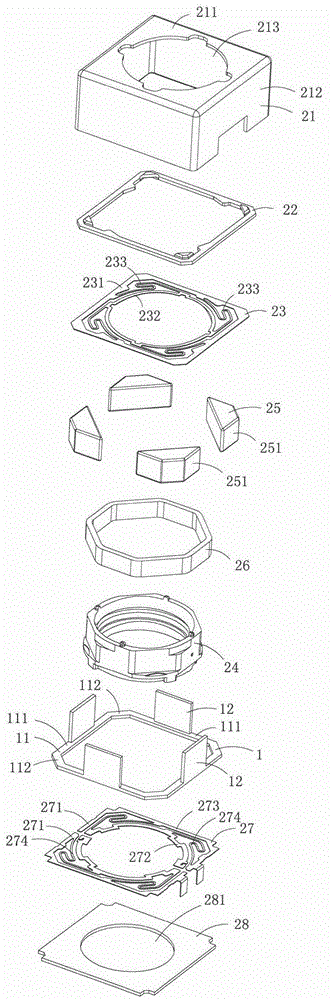

Miniature driving motor

InactiveCN103001443AImprove linear drive effectImprove impact resistanceDynamo-electric machinesLinear driveMagnet

The invention discloses a miniature driving motor which comprises an upper cover, an upper gasket, an upper spring strip, a carrier, a magnet assembly, a coil assembly, a lower spring assembly, a positioning support and a base. The positioning support comprises a platy body and a plurality of supporting bosses, a through hole is arranged in the center of the platy body, the supporting bosses are protruded from the platy body and are positioned on the same side of the platy body, outer edges of two lower spring strips are in compression joint on the base fixedly by the platy body, and the supporting bosses are jacked on an outer ring of the upper spring strip. The miniature driving motor has the advantages that the distance from the outer ring of the upper spring strip to the outer edge of each lower spring strip can be effectively controlled, and accordingly a linear driving effect is improved.

Owner:深圳市光控数码光电有限公司

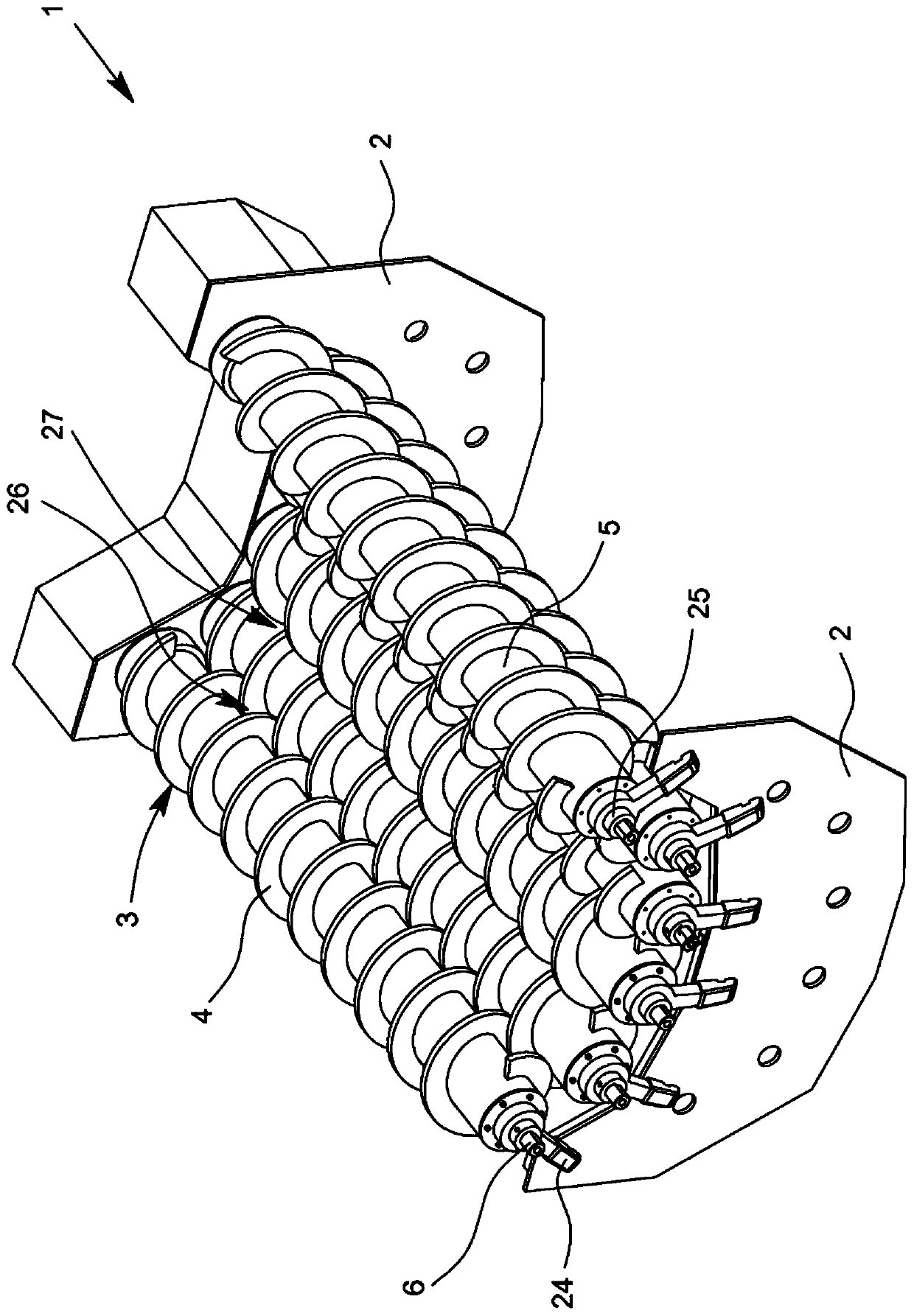

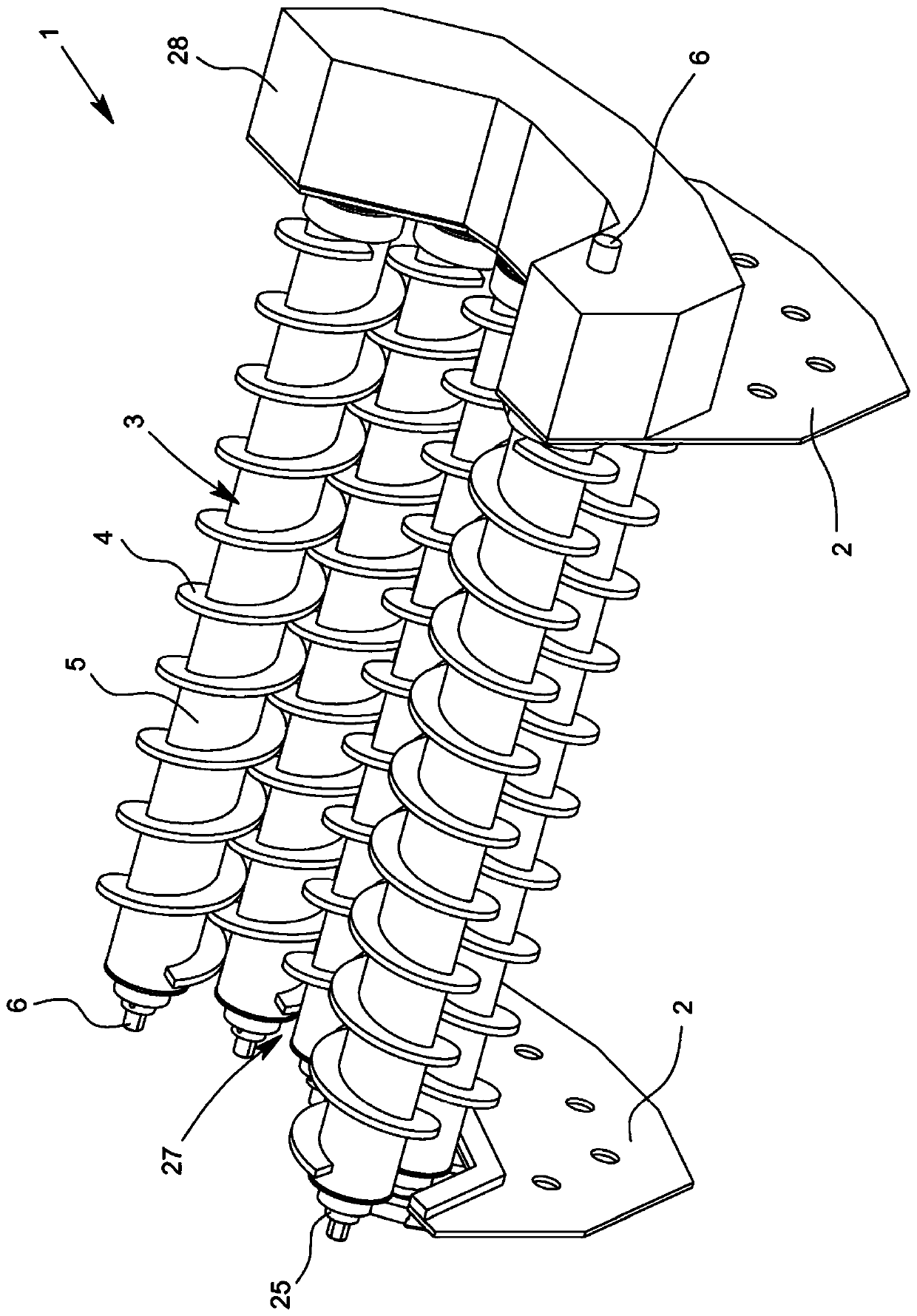

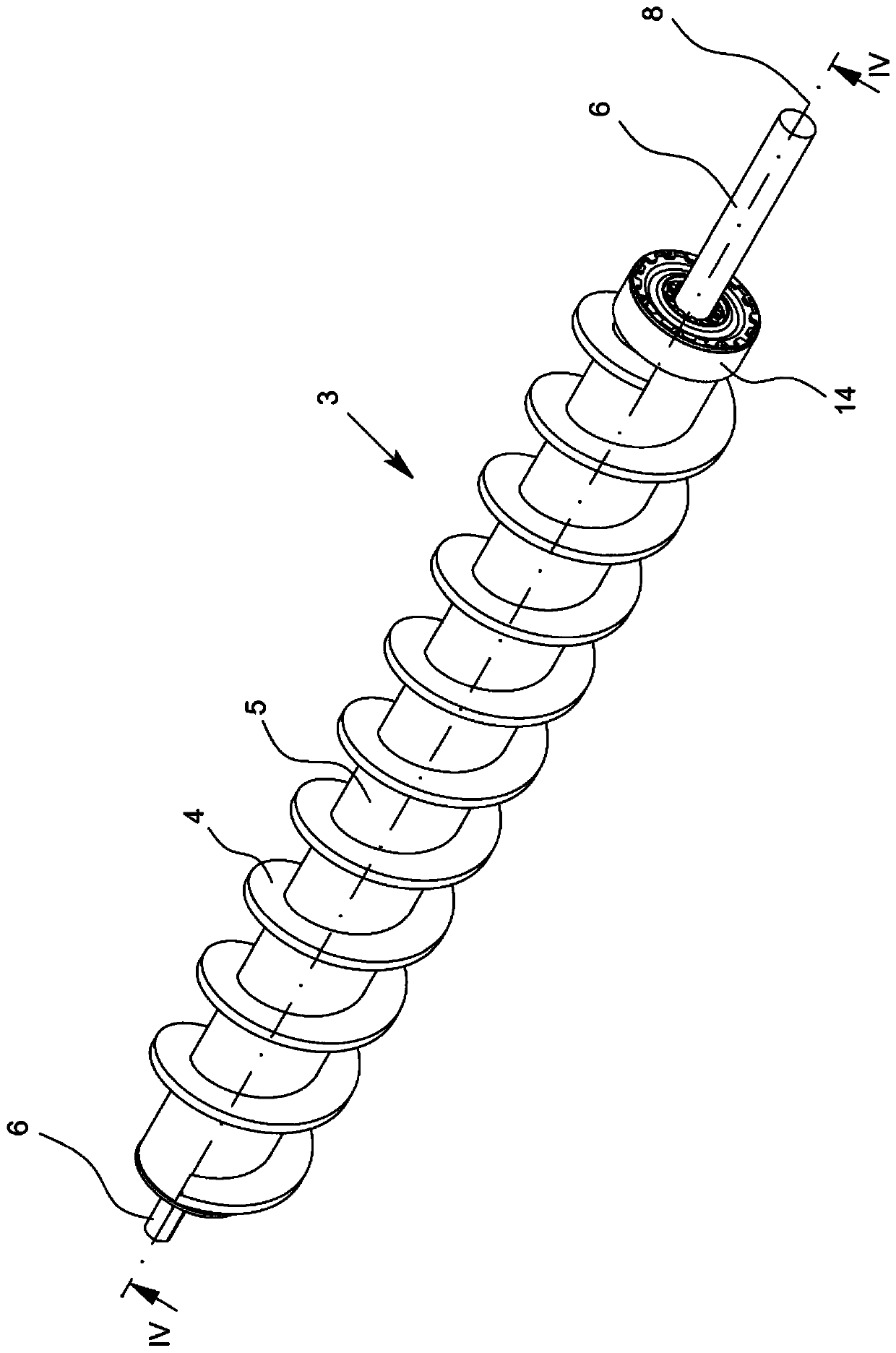

Device for the classification of material being classified

ActiveCN110573266AAvoid damageReduce shockSievingRolling contact bearingsEngineeringMechanical engineering

The invention relates to a device for classifying (1) material being classified, preferably into two fractions, and preferably soil, such as sticky clayish soil, which device is particularly intendedfor use in a quarry and comprises a machine frame (2) and at least two spiral shafts (3) rotatably mounted on said machine frame (2), wherein at least one spiral shaft (3) comprises a core tube (5) with at least one outer screw helix (4), and at least one bearing journal (6). According to the invention, the core tube (5) is mounted elastically relative to the bearing journal (6) by means of at least one elastic bearing means (7).

Owner:LIG有限责任公司

Clamping device for piecing and connecting pouring template of building

InactiveCN102182305BSimple structureFew partsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFree stateEngineering

The invention relates to a clamping device for piecing and connecting a pouring template of a building. The clamping device comprises a support, a moving handle and an elastic clip, wherein the elastic clip is made of spring steel, and is provided with a left and a right clamping parts; the support is provided with a hooking part, and a horizontal extending part used for restraining a rectangularhole of the elastic clip is arranged on the support; the moving handle is hinged with the support by taking the end part at one end of the moving handle as a fulcrum and the other end of the moving handle as a force point, and a gravity point is arranged between the fulcrum and the force point, and is hinged with the upper end of the elastic clip; the elastic clip penetrates through the rectangular hole of the support, and freedom for the displacement of the elastic clip is preserved in the longitudinal direction of the rectangular hole; the lower parts of the left and the right clamping parts of the elastic clip are of an inward opposite bent shape; when in a free state, the lower parts of the left and the right clamping parts open, and the opening distance of the lower parts is greater than the width of the rectangular hole of the support; and the upper parts of the left and the right clamping parts make contact with the long edges of the rectangular hole. The clamping device can beused for rapidly fastening and connecting the pieced pouring template, and has the advantages of convenience for use, simple structure and easiness for manufacture.

Owner:阮中亮

reaction chamber

ActiveCN108538745BGuaranteed elastic deformationNo need to increase depthElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyMechanical engineering

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A rubber tube forming device

ActiveCN108527816BWill not deformLarge diameterTubular articlesElectric machineryStructural engineering

The invention relates to the field of rubber, and particularly discloses a rubber pipe molding device which comprises a framework, a stepper motor, an extrusion pipe and a core mechanism. A feed pipeis fixed onto the extrusion pipe; the core mechanism comprises an inner rod, a rotary shaft, a liquid inlet pipe, a liquid outlet pipe and a piston, the inner rod can be driven by the stepper motor torotate, an accommodating cavity is arranged in the inner rod, openings are formed in the side walls of the accommodating cavity, elastic sheets are arranged outside the openings and are fixed to theouter wall of the inner rod, first magnets are embedded in the elastic sheets, and second magnets are fixed onto the rotary shaft; the piston is positioned in the accommodating cavity and is in threadfit with the rotary shaft, balls are arranged between the piston and the rotary shaft, a slide groove is formed in the side walls of the accommodating cavity, and a slider is fixed onto the piston; aliquid inlet check valve and a liquid outlet check valve are fixed into the liquid inlet pipe and the liquid outlet pipe, and the liquid inlet pipe and the liquid outlet pipe are communicated with the accommodating cavity. According to the scheme, the rubber pipe molding device has the advantages that tensile force required for pulling rubber pipes can be reduced, and the rubber pipes can be prevented from being dragged to deform.

Owner:宁波高新区新柯保汽车科技有限公司

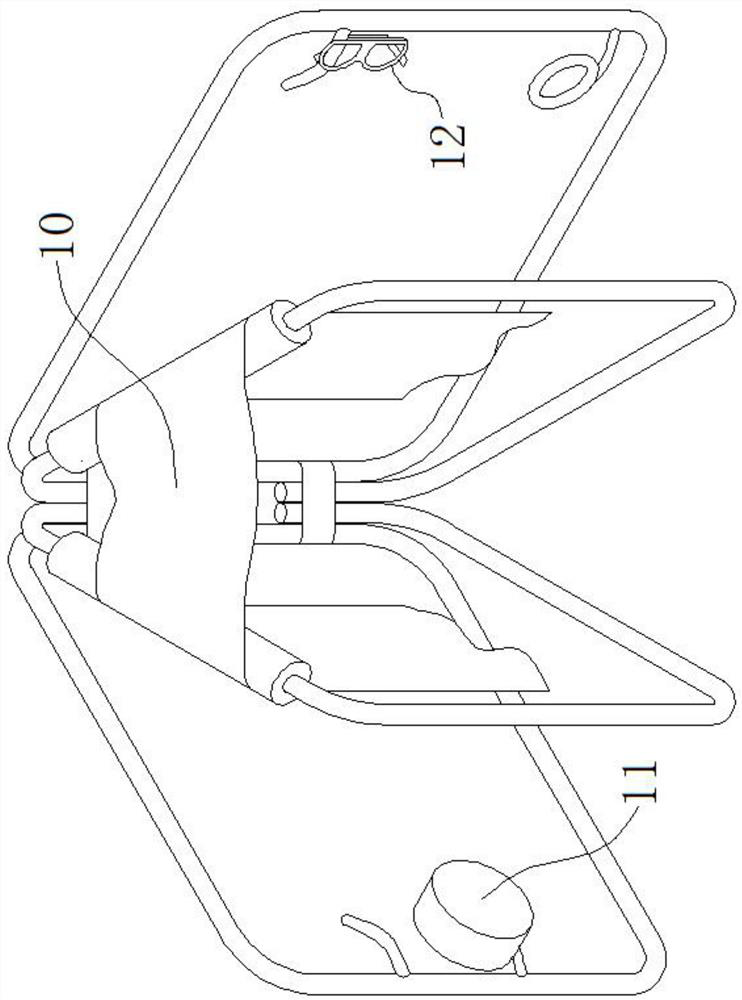

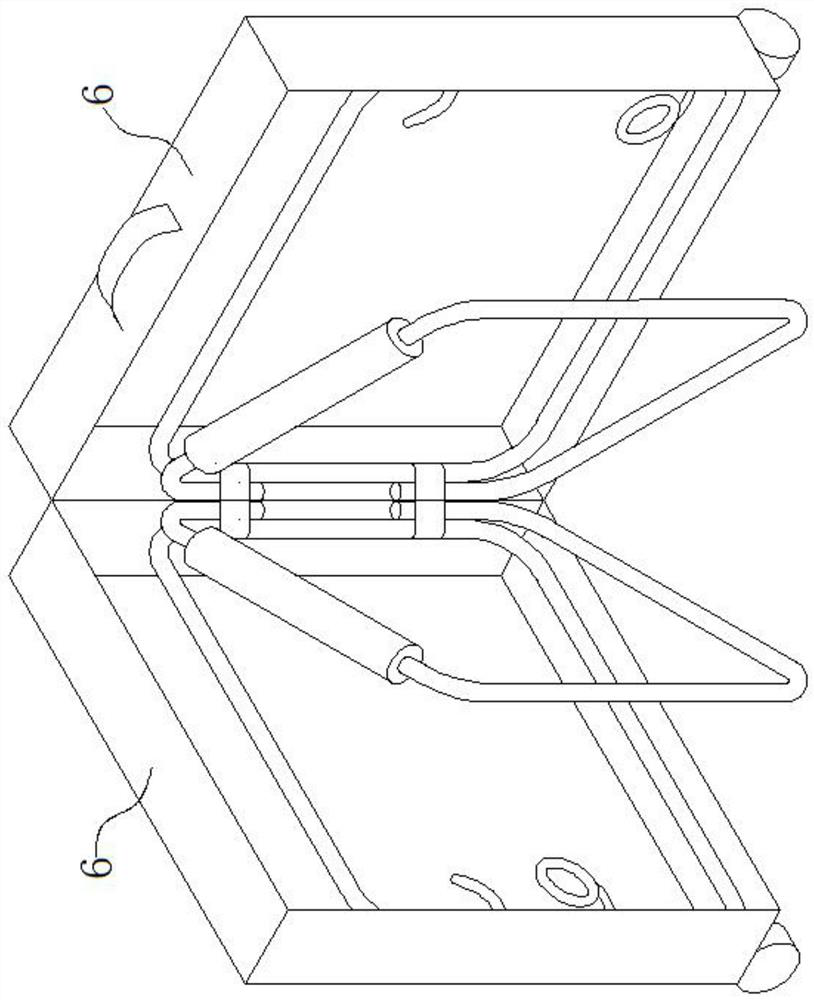

A kind of clothes hanger for radiation department protective equipment

InactiveCN109044061BThe overall structure is stableLower the altitudeApparel holdersClothes hangerStructural engineering

The invention discloses a protective article rack for a radiological department, which comprises rectangular frames, the rectangular frame is formed by bending a pipe with a circular cross section and connecting the head and end, the rectangular frame comprises a pair of horizontal rods which are parallel to each other and a pair of vertical rods which are parallel to each other, the vertical rods at one side of a plurality of rectangular frames are hinged with each other, enabling the plurality of rectangular frames to open and close in a fan shape; a buffer cylinder which sleeves on the horizontal rod above the buffer cylinder; a lead glasses hook, which is fixed on the vertical rod; a lead cap hook, which is fixed on the vertical rod, wherein the lead glasses hook and the lead cap hookare not positioned on the same horizontal plane. The top end of the lead cap hook is provided with a loop. According to the invention, a special placing space is arranged for the lead glasses and lead cap, the placement of the lead clothes is easy, crease damage is not easy to occur, and when the rack is not in use, the space occupied by the whole clothes rack after being folded is small.

Owner:沈江

Micro drive motor

InactiveCN103001443BGuaranteed machining accuracyGuaranteed elastic deformationDynamo-electric machinesDrive motorEngineering

The invention discloses a miniature driving motor which comprises an upper cover, an upper gasket, an upper spring strip, a carrier, a magnet assembly, a coil assembly, a lower spring assembly, a positioning support and a base. The positioning support comprises a platy body and a plurality of supporting bosses, a through hole is arranged in the center of the platy body, the supporting bosses are protruded from the platy body and are positioned on the same side of the platy body, outer edges of two lower spring strips are in compression joint on the base fixedly by the platy body, and the supporting bosses are jacked on an outer ring of the upper spring strip. The miniature driving motor has the advantages that the distance from the outer ring of the upper spring strip to the outer edge of each lower spring strip can be effectively controlled, and accordingly a linear driving effect is improved.

Owner:深圳市光控数码光电有限公司

Rubber pipe molding device

The invention relates to the field of rubber, and particularly discloses a rubber pipe molding device which comprises a framework, a stepper motor, an extrusion pipe and a core mechanism. A feed pipeis fixed onto the extrusion pipe; the core mechanism comprises an inner rod, a rotary shaft, a liquid inlet pipe, a liquid outlet pipe and a piston, the inner rod can be driven by the stepper motor torotate, an accommodating cavity is arranged in the inner rod, openings are formed in the side walls of the accommodating cavity, elastic sheets are arranged outside the openings and are fixed to theouter wall of the inner rod, first magnets are embedded in the elastic sheets, and second magnets are fixed onto the rotary shaft; the piston is positioned in the accommodating cavity and is in threadfit with the rotary shaft, balls are arranged between the piston and the rotary shaft, a slide groove is formed in the side walls of the accommodating cavity, and a slider is fixed onto the piston; aliquid inlet check valve and a liquid outlet check valve are fixed into the liquid inlet pipe and the liquid outlet pipe, and the liquid inlet pipe and the liquid outlet pipe are communicated with the accommodating cavity. According to the scheme, the rubber pipe molding device has the advantages that tensile force required for pulling rubber pipes can be reduced, and the rubber pipes can be prevented from being dragged to deform.

Owner:宁波高新区新柯保汽车科技有限公司

Improved micro drive motor

InactiveCN103001442BGuaranteed spacingEffective spacing controlDynamo-electric machinesEngineeringDrive motor

The invention discloses a modified miniature driving motor which comprises an upper cover, an upper gasket, an upper spring piece, a carrier, a coil component, a magnet component, a lower spring component and a lower gasket. The magnet component comprises four magnets in shapes of trapezoid basically, a side face, close to the coil component, of each magnet is an N pole or S pole, the side face, far away from the coil component, of each magnet is an S pole or N pole, the magnets are arranged at an inner corner formed by clamping of two adjacent side walls of the upper cover, gaps are reserved between two adjacent magnets, the lower gasket comprises a press plate in a shape of rectangular frame basically and supporting plates protruding upwards from the press plate, each supporting plate is positioned in the gaps between two adjacent magnets, and the top surface of each supporting plate is abutted on an outer ring of the upper spring piece. The modified miniature driving motor can effectively guarantee linear driving effect.

Owner:深圳市光控数码光电有限公司

A slotting method for the inner wall of a discontinuous box

ActiveCN104668884BImprove rigidityEasy alignment and clampingPlaning/slotting machinesProcess supportComputer engineering

The invention discloses a method for slotting and cutting the inner wall of a noncontinuous box. The method includes: step 1, making two process supports, and machining a reference face; step 2, machining six connecting holes; step 3, machining a right inner wall face; step 4, machining a left inner wall face. By the method, machining of the noncontinuous box on a slotting machine is realized, and shape and position accuracy of each machined face is guaranteed effectively; the problem of machining rebound deformation caused by rigidity difference of the noncontinuous box is solved; the problem of deformation of a toolbar due to the fact that the toolbar extends out excessively is solved; the problems of positioning and centering when the noncontinuous box is machined on the slotting machine are solved; requirements on position degree between holes in the box and the left inner wall face as well as the right inner wall face of the box are met, the method is high in universality, and production efficiency is improved effectively.

Owner:BAOJI PETROLEUM MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com