Clamping device for piecing and connecting pouring template of building

A clamping device and formwork technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, and construction, etc., which can solve the uneven surface of the building body, high labor intensity of workers, and increased labor costs. and other problems, to achieve the effect of reduced labor intensity, simple structure, and reduced technical requirements for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

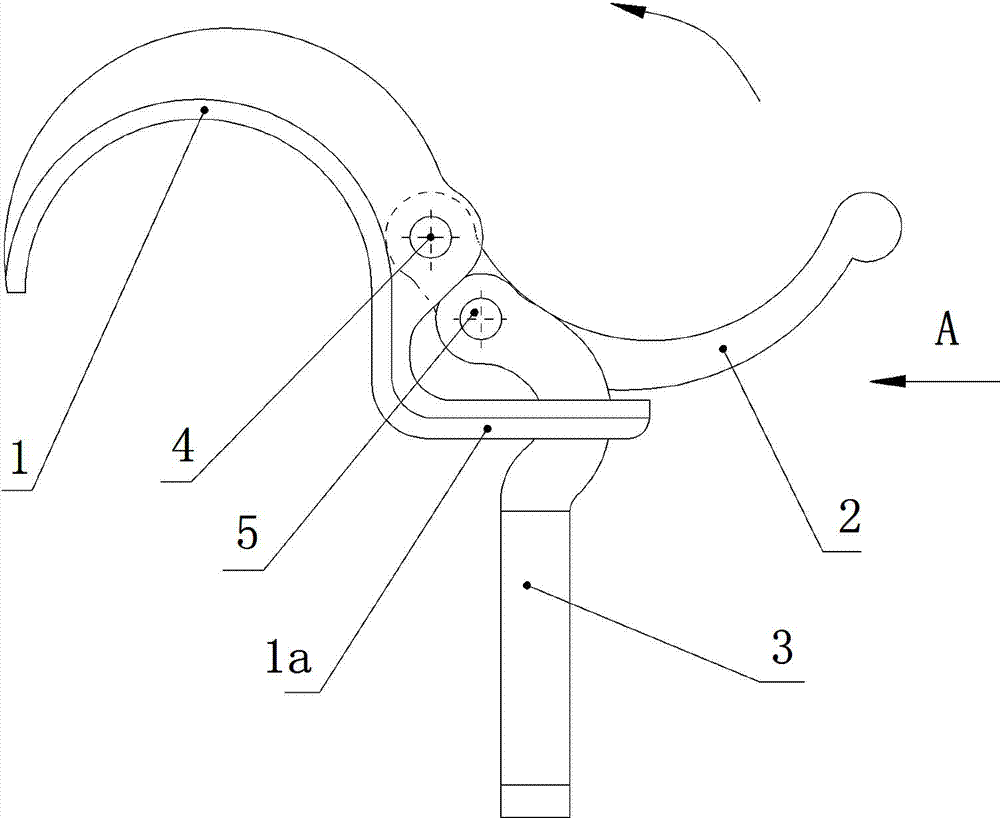

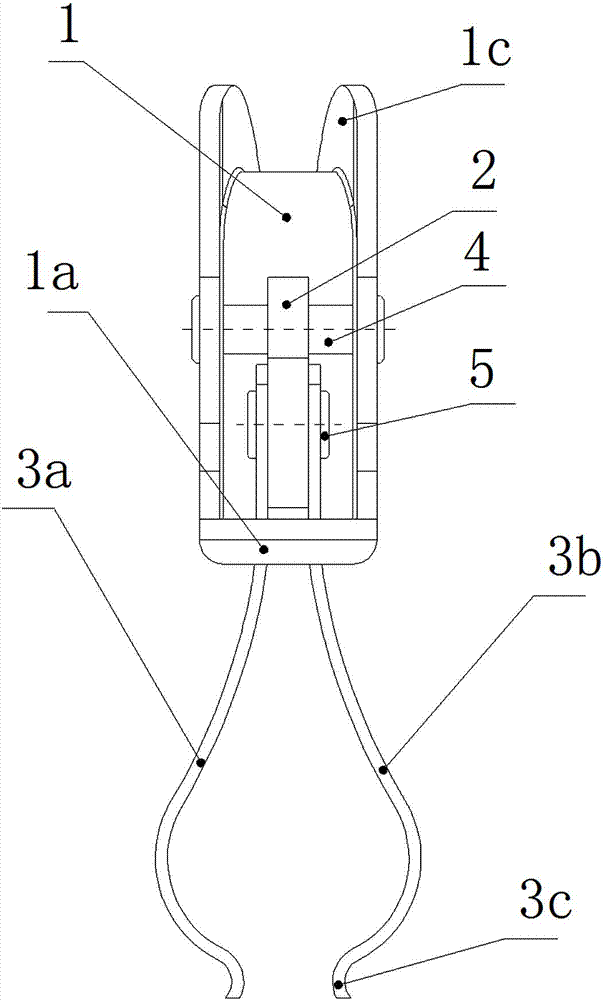

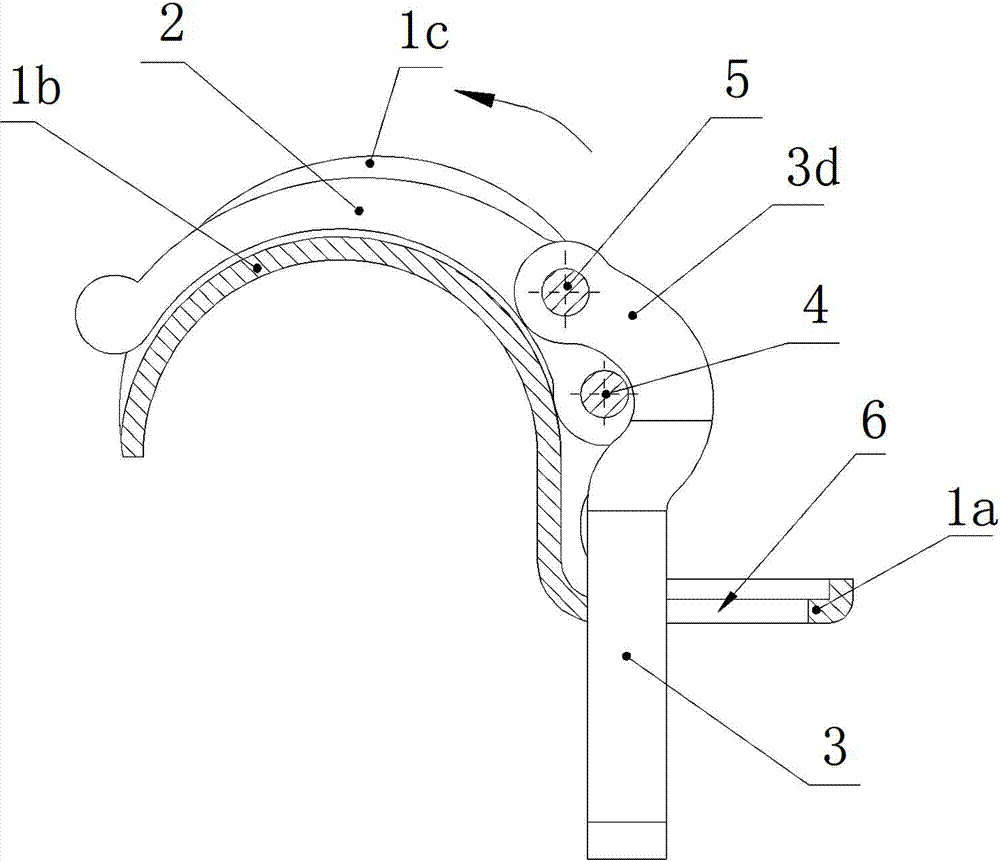

[0033] See Figure 1 to Figure 9 , An embodiment of the clamping device for the splicing and connection of the building pouring formwork includes a bracket 1, a movable handle 2, an elastic clamp 3 made of spring steel with left and right clamping parts. The bracket 1 has a hook portion 1b and a horizontal extension portion 1a that is turned from one end of the hook portion. The horizontal extension portion 1a is provided with a rectangular hole 6 for restraining the elastic clip. The hook portion 1b of the bracket 1 is provided with a round The circular arc groove 1d of the tube buckling, the circular arc groove 1d is set as a semi-circular groove, so that it can grasp the circular tube on the support frame of the construction casting template to form a positioning; of course, the hook part of the bracket can also be provided with The rectangular groove 1e used to buckle with the square tube, so that it can hold the square tube on the support frame of the construction casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com