Air filter device

An air filter and filter technology, which is applied in the direction of fuel air filter, combustion air/combustion-air treatment, charging system, etc., can solve the problem of increasing vehicle use cost, incomplete fuel combustion, and increased fuel consumption and other problems to achieve the effect of improving decontamination ability, prolonging service life and increasing ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

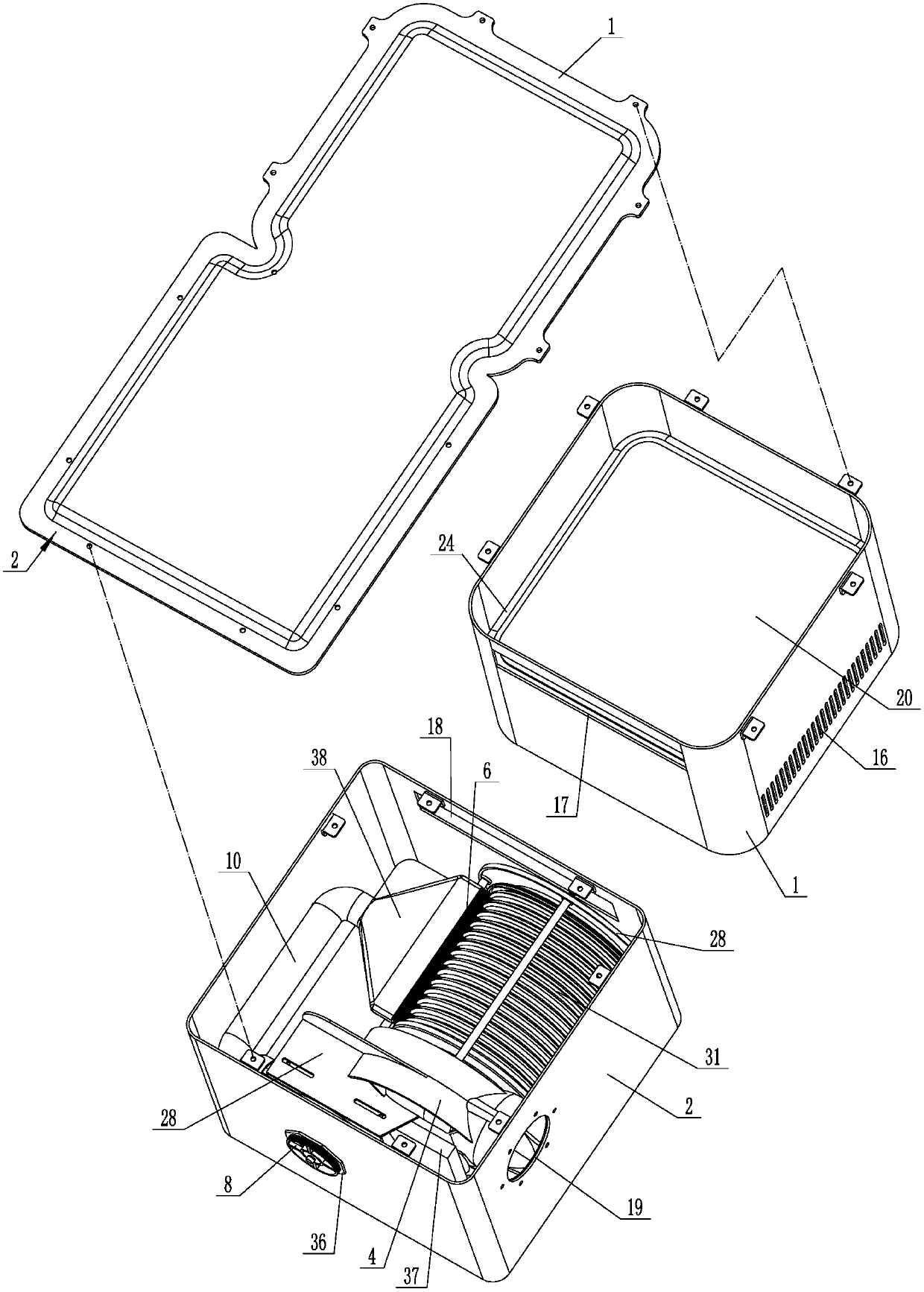

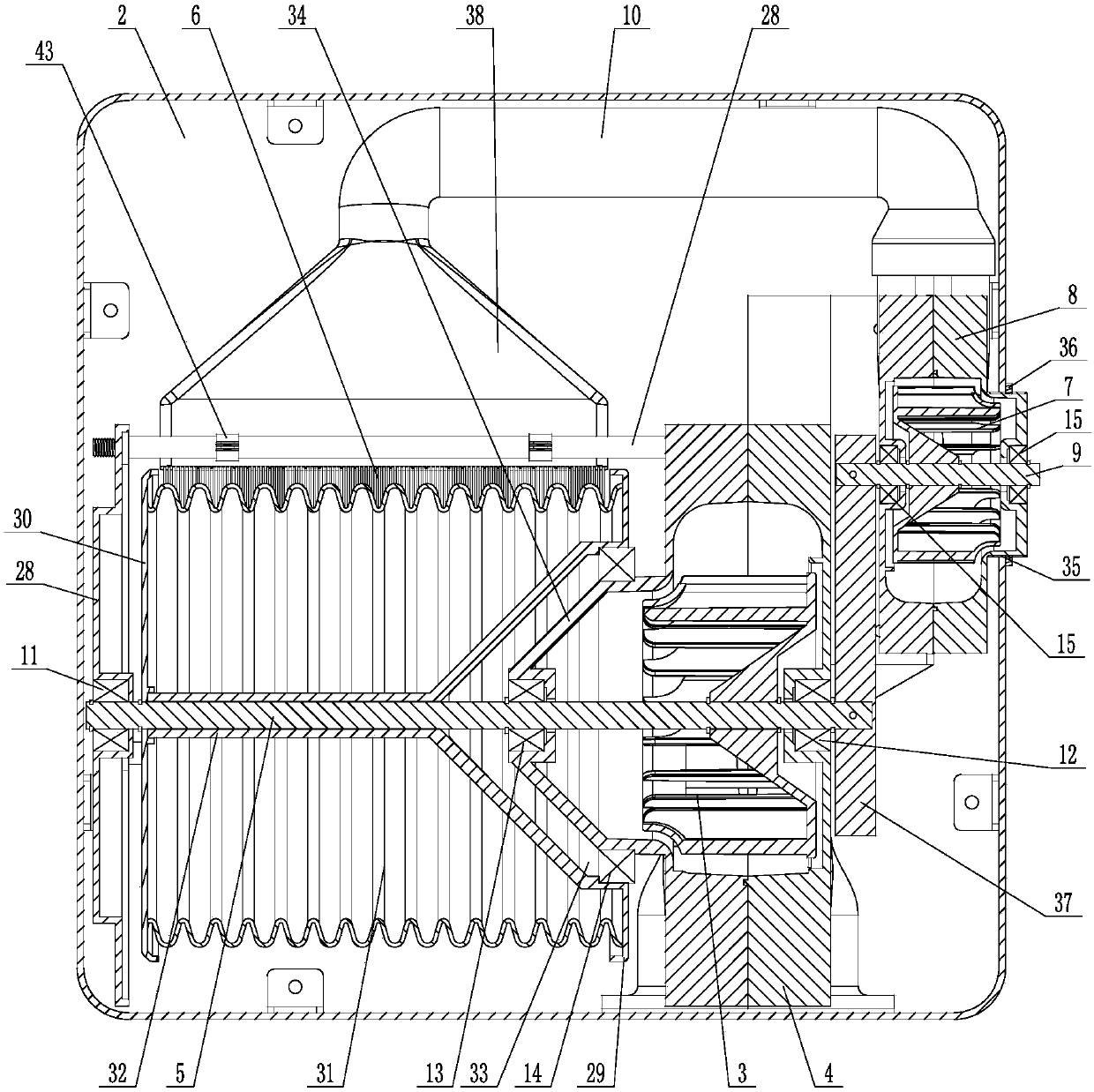

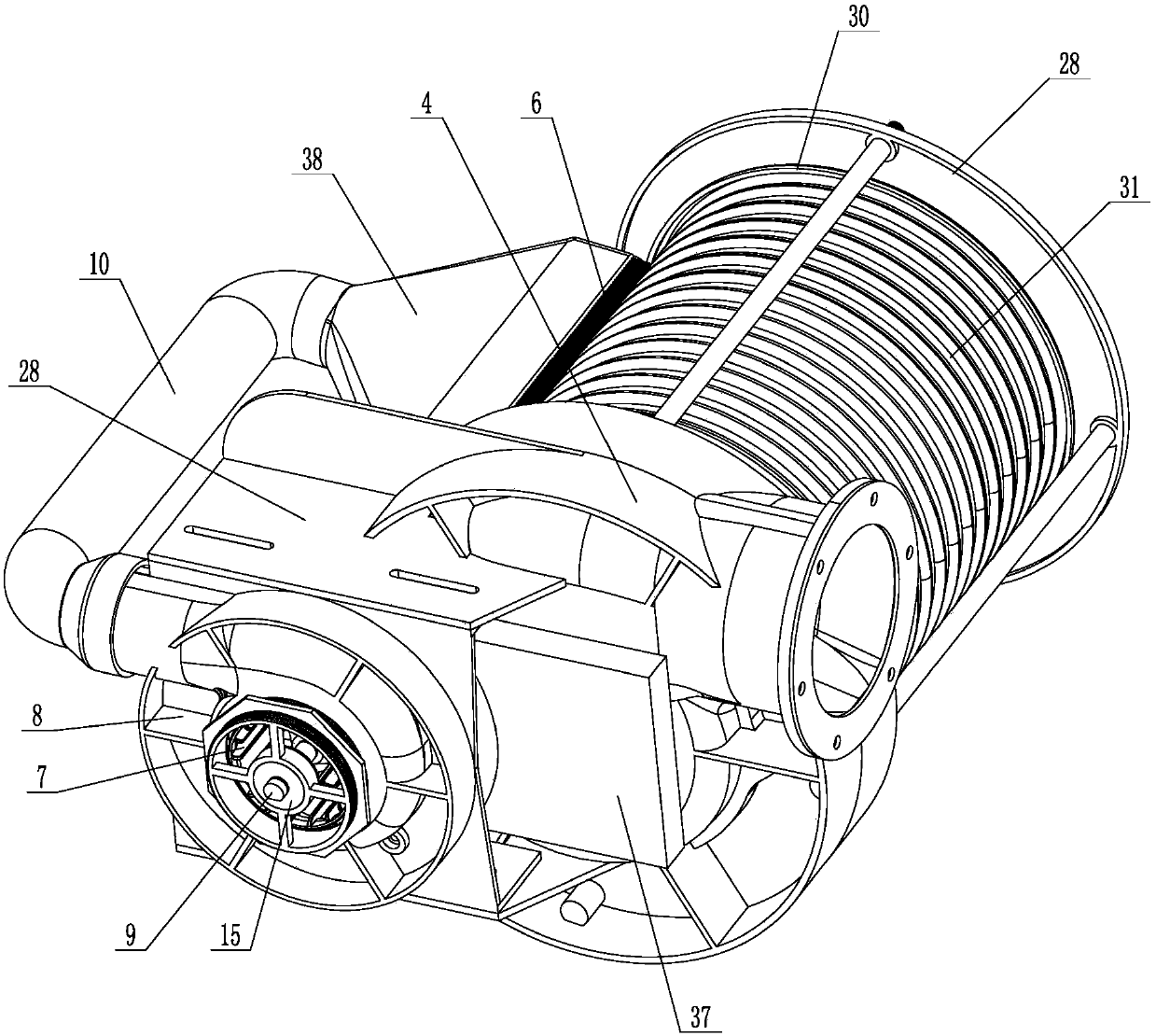

[0037] Such as Figure 1 to Figure 7As shown, the air filter device of the present invention includes a first housing 1, a second housing 2, a filter disposed in the cavity of the first housing 1 and a filter element disposed in the cavity of the second housing 2, The first turbine 3, the first turbine cover 4, the first shaft 5, the scraper 6, the second turbine 7, the second turbine cover 8, the second shaft 9, the suction pipe 10, the first bearing 11, the second bearing 12 , the third bearing 13, the fourth bearing 14 and two fifth bearings 15, the first housing 1 and the second housing 2 all adopt the split structure of the shell cover and the body, so as to facilitate the installation of the air filter device of the present invention Assembling and maintenance, further, the above two bodies can be an integrated structure, such as the two bodies share a side wall, or the shell cover can adopt an integrated structure, and the two bodies are connected to the shell cover. In...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the structure of the transmission mechanism is different, specifically: Figure 8 As shown, the transmission mechanism includes a first transmission wheel 40, a second transmission wheel 41 and a transmission belt 42. The first transmission wheel 40 is connected at one end of the first rotating shaft 5, and the second transmission wheel 41 is connected at one end of the second rotating shaft 9. A transmission wheel 40 and the second transmission wheel 41 are connected by a transmission belt 42. The transmission belt 42 in the present embodiment is a belt, and the first transmission wheel 40 and the second transmission wheel 41 are belt pulleys. The diameter of the first transmission wheel 40 is greater than The diameter of the second transmission wheel 41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com