Friction bag opening machine for various material textures

A bag-opening machine and friction-type technology, which is applied in the field of unpacking machinery and sealing, can solve the problems of high cost and reduce the efficiency of flour processing, and achieve the effect of improving the level of automation and improving the efficiency of bag opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

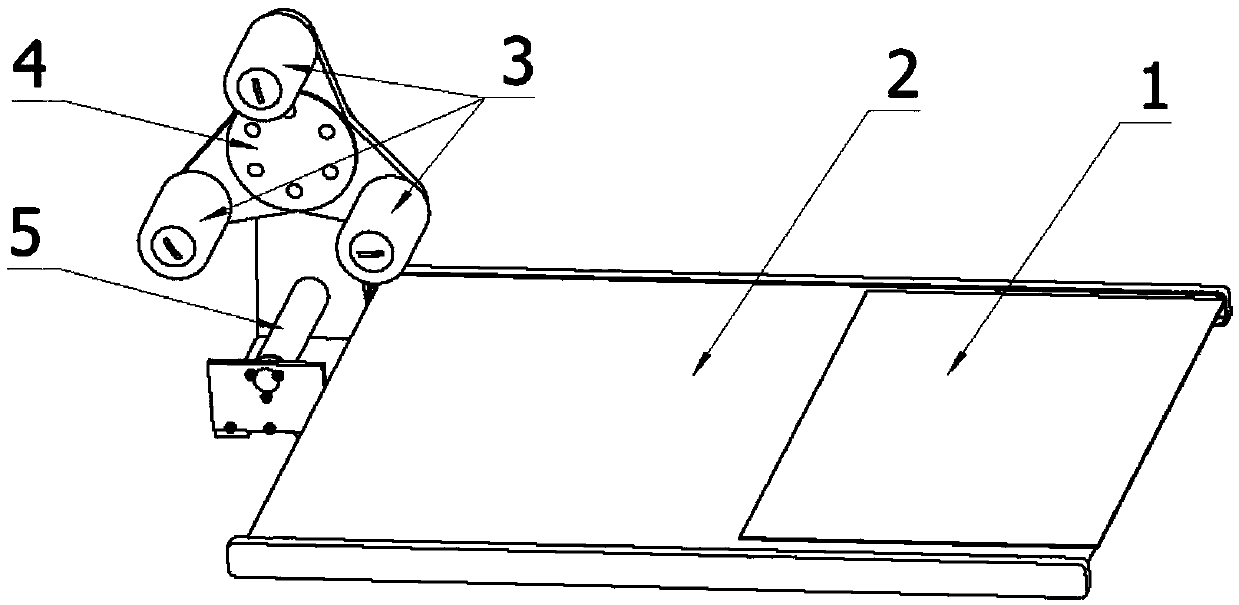

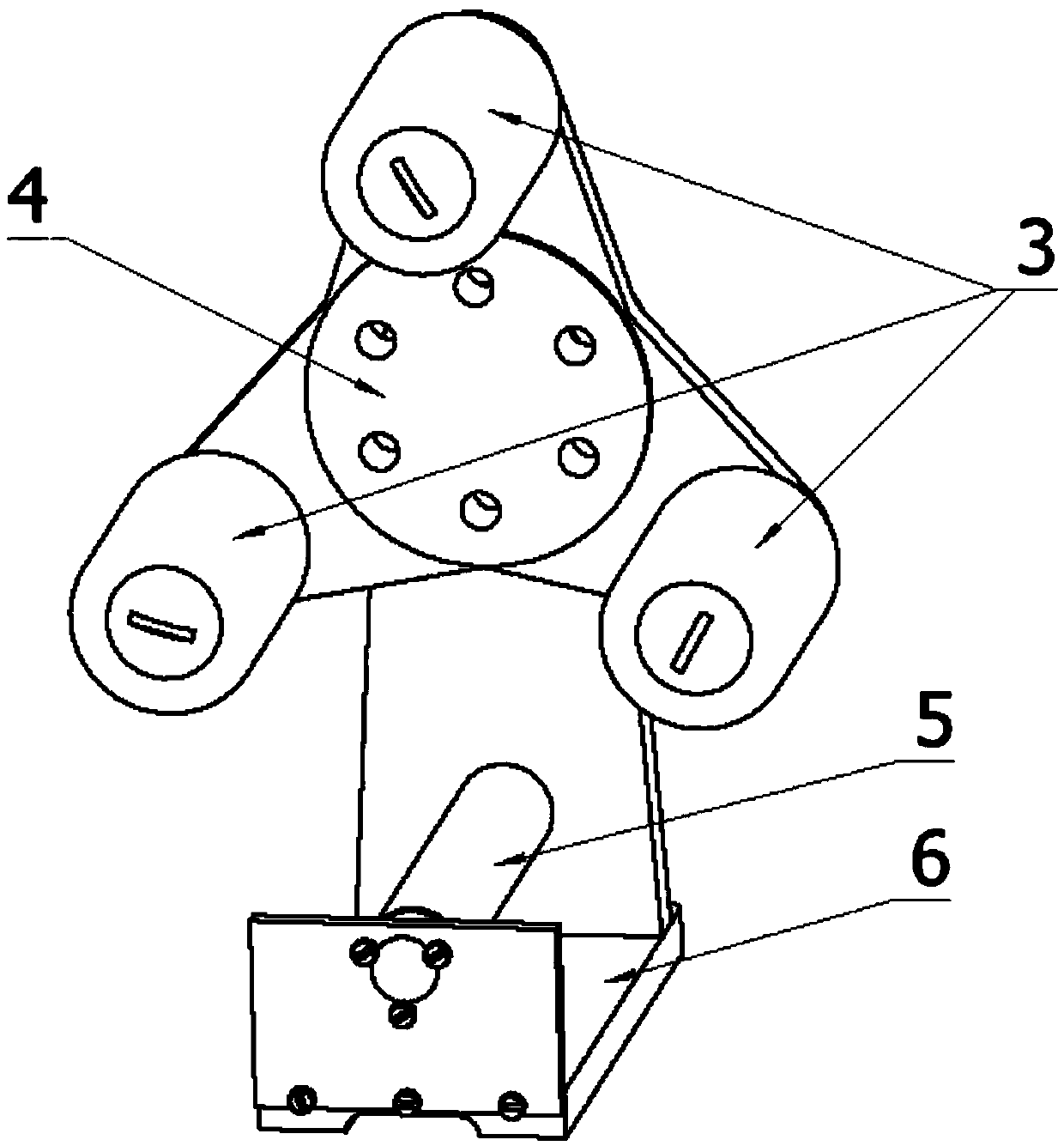

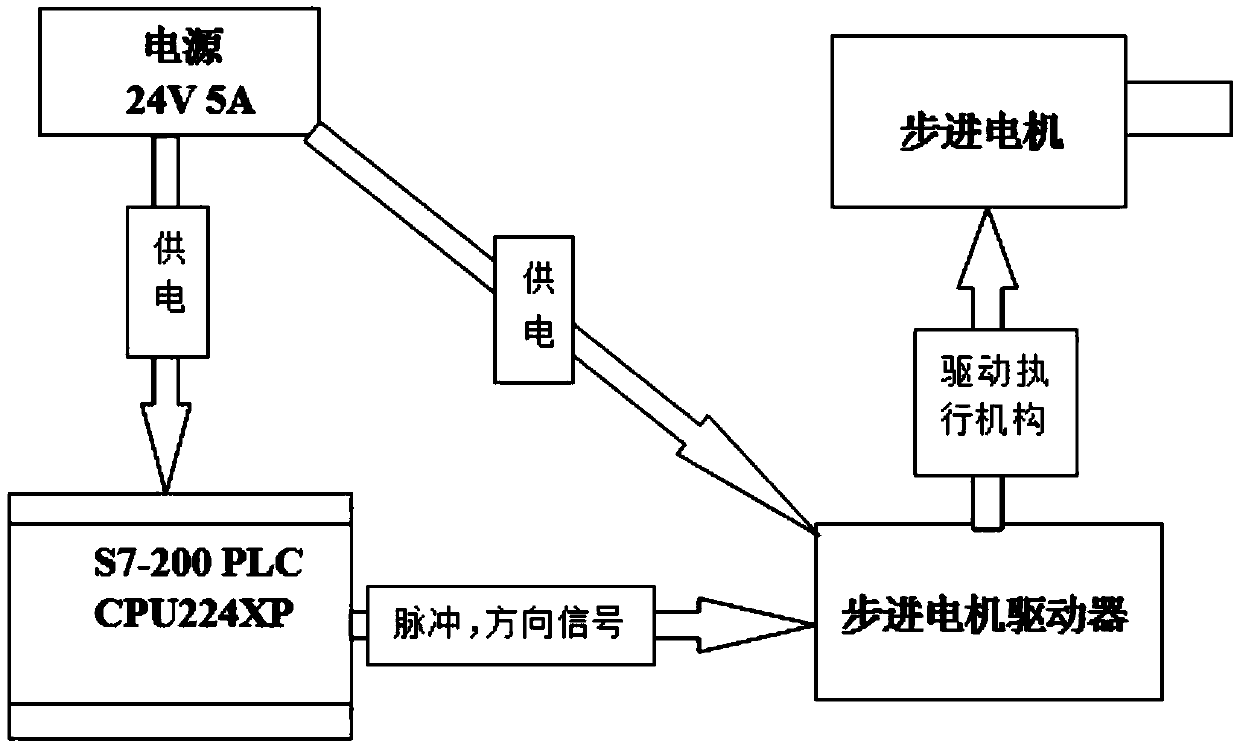

[0025] Working principle of the mechanical part

[0026] The conveying speed of the bag on the conveyor belt is 0.5m / s, and the speed of the motor reaches the opening speed of 1m / s. The length of the conveyor belt is 1200mm, and the next pocket is sent every 3s. The torque is: 1370N·m, the speed is 46r / min, and each operation is 120°; the operation is often 0.5s, and the gap is 2.5s. At the position of the opening of the bag, the friction shaft moves in the direction of the bag; because the friction shaft and the bag generate friction, the difference in friction between the bag and the bag produces relative movement. According to the literature, taking woven bags as an example, the friction coefficient of rubber to hemp rope; and the friction coefficient between hemp rope and hemp rope; when the compression of hard rubber is 15%, the rubber unit elastic force produced is: 10.6kg / cm 2 . According to the elastic formula (1) of rubber due to deformation:

[0027] f 弹 =Sq(1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com