Wet clutch friction plate

A wet clutch and friction plate technology, applied in the clutch field, can solve the problems of separation lag, increased oil viscosity, unsmooth driving control of motorcycles, etc., and achieve the effect of solving incomplete separation and simple structure and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

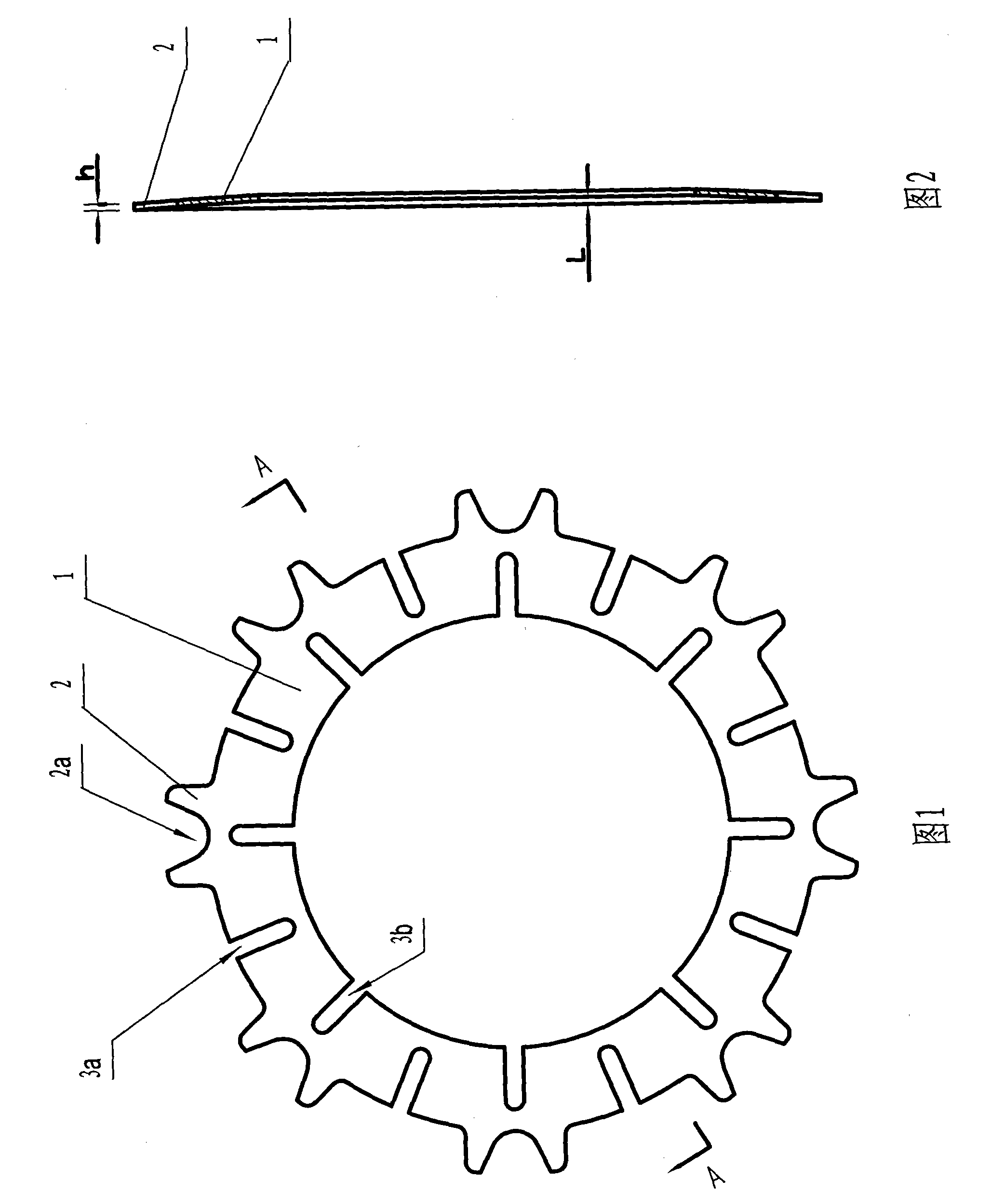

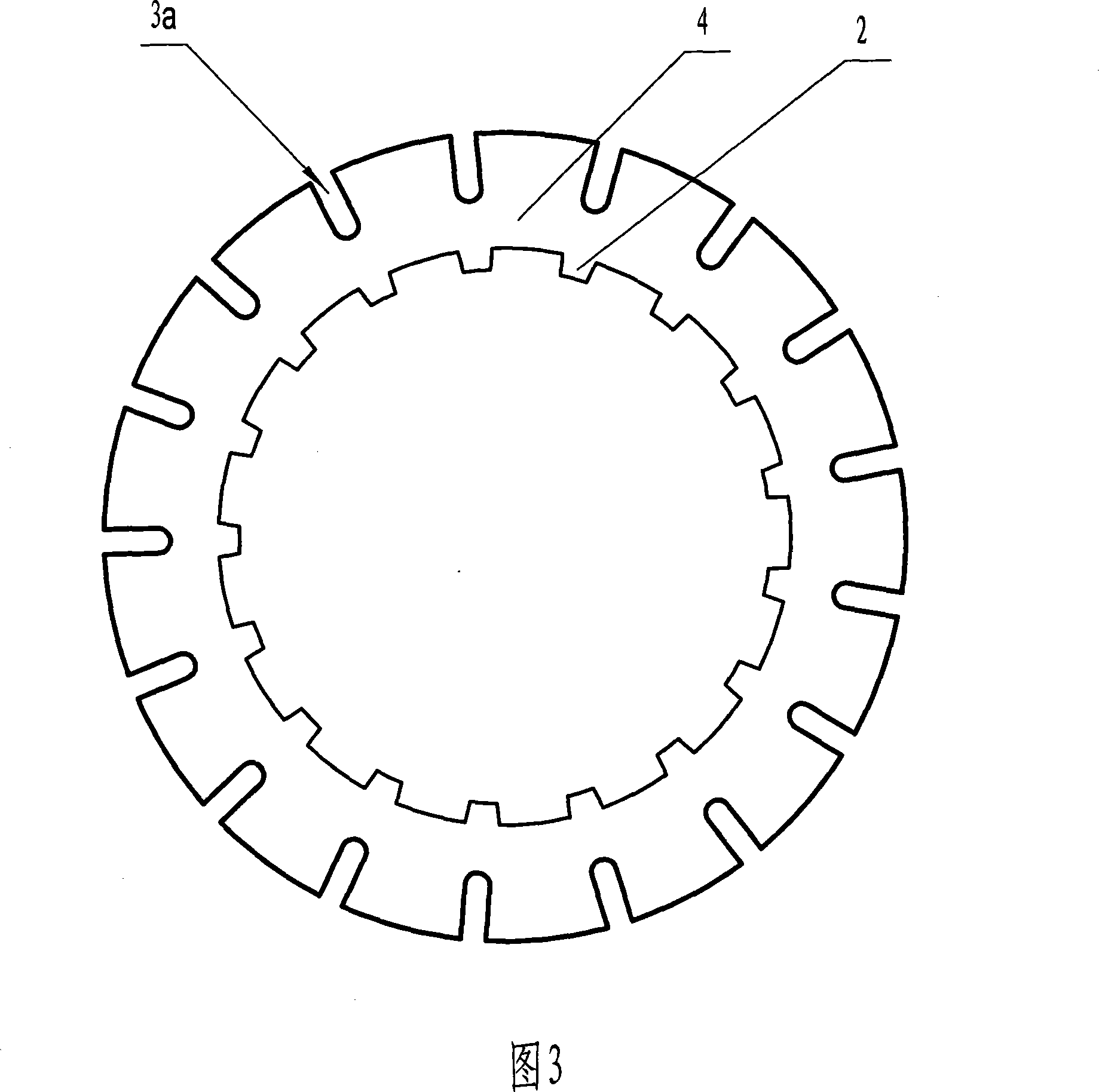

[0013] Referring to Fig. 1 and Fig. 2, it is an embodiment of the friction plate of the present invention used in the active friction plate of the wet clutch of the motorcycle engine. The active friction plate 1 is a ring-shaped steel sheet formed by punching a thin steel plate, and there are a plurality of outer convex teeth 1a integrally formed with the active friction plate 1 for circumferential fixing uniformly distributed on its outer circumference. The active friction plate 1 has 8 outer protruding teeth 1a for circumferential fixing, which are used to engage with the grooves on the clutch cover. Each outer tooth 1a is provided with a notch 2 for the release spring. A plurality of radially extending opening grooves 3b are evenly distributed on the inner circumference of the active friction plate 1, and between two adjacent outer convex teeth 1a for circumferential fixing on the outer circumference of the active friction plate 1 can also be Radial open grooves 3 a are pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com