Rapid multi-gap vacuum disconnector

A vacuum isolation and multi-gap technology, applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., to achieve the effects of enhancing mechanical strength and reliability, improving voltage tolerance, and improving high-voltage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

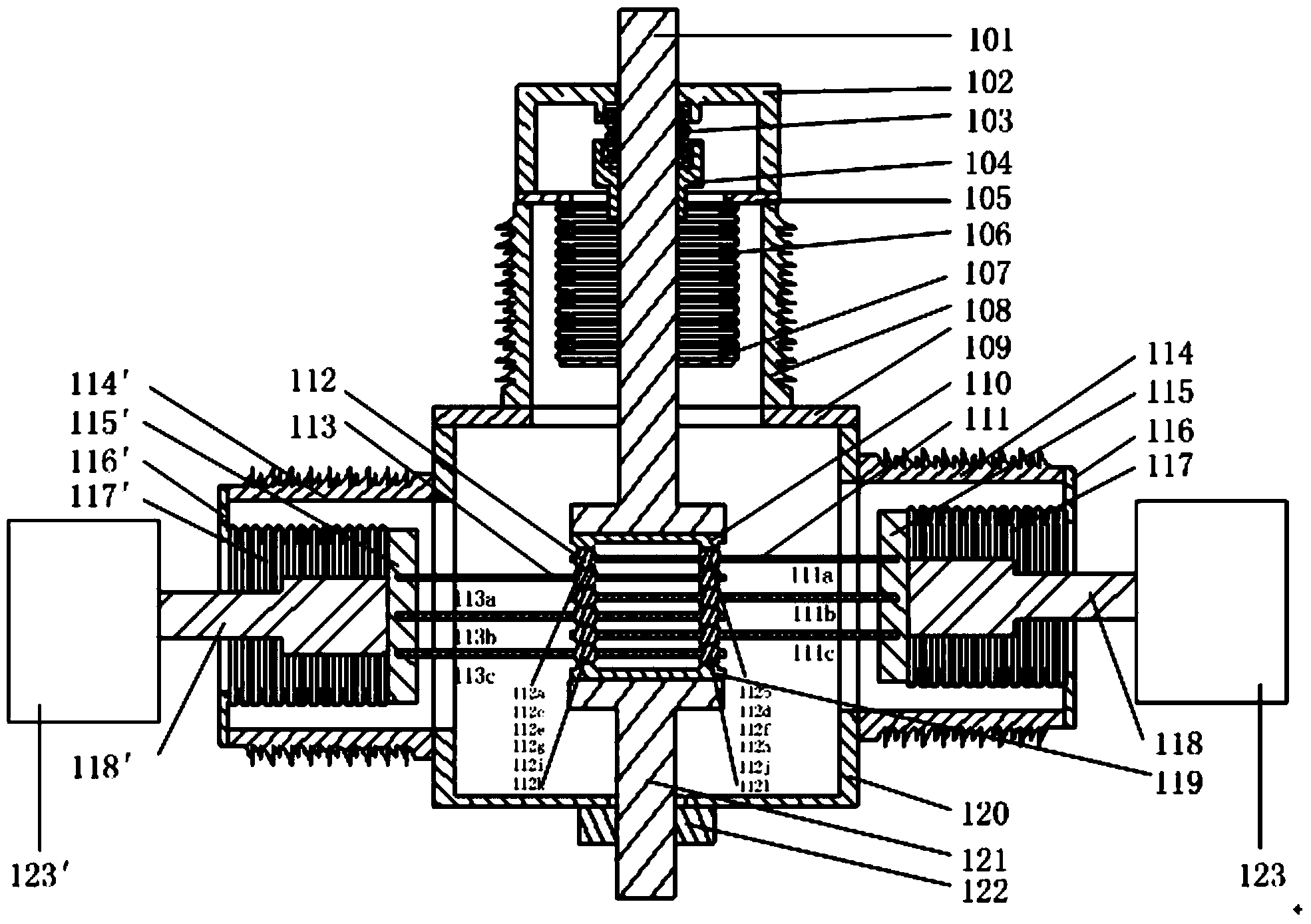

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

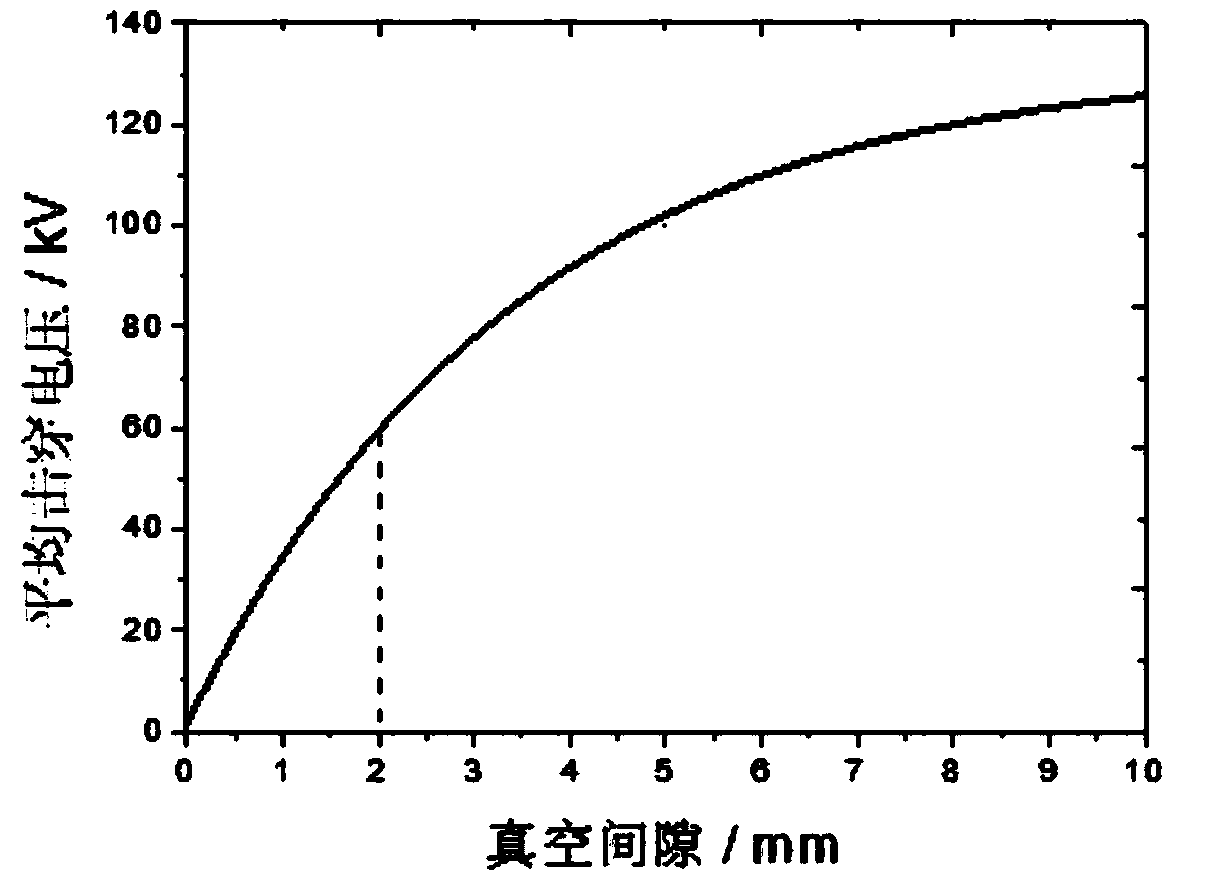

[0036] Such as figure 1 As shown, when the range of the contact gap distance (that is, the vacuum gap) changes, the insulation characteristics of the vacuum gap will also change, and it does not change linearly with the change of the contact gap distance. When the vacuum gap distance d is about in the range of d≤2mm, its breakdown voltage U B As the vacuum gap d increases, it can basically be regarded as a linear change; when the vacuum gap distance increases to d≥2mm, the insulation characteristics of the vacuum gap enter the saturation region, and the breakdown voltage U B The increase slows down with the increase of the vacuum gap d.

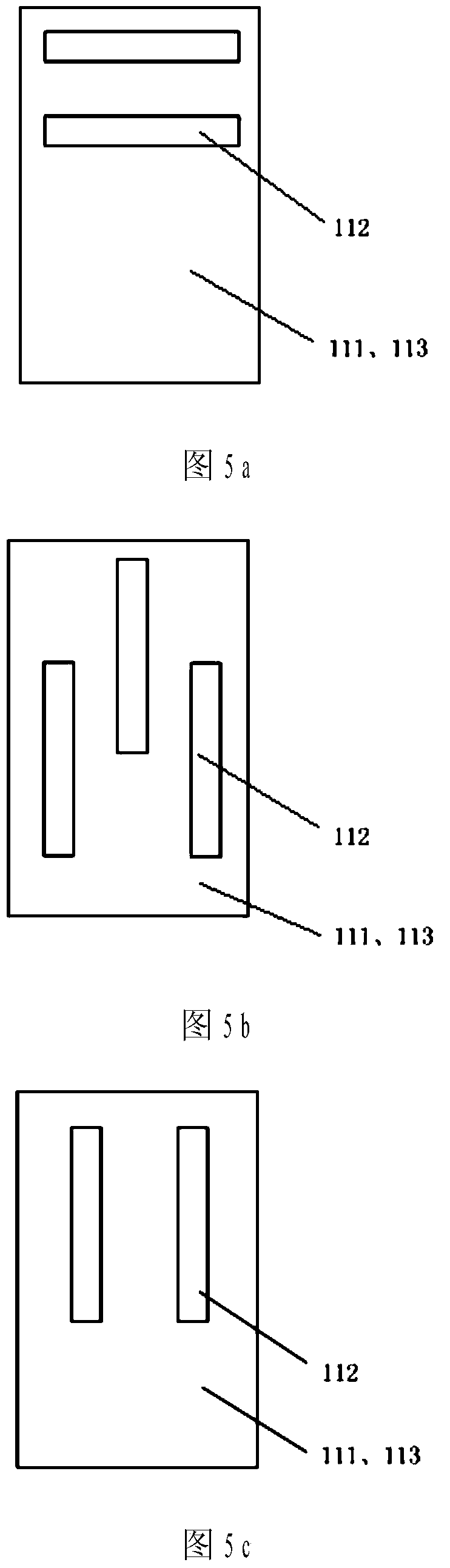

[0037] Such as figure 2 As shown, a fast multi-gap vacuum isolating switch of the present invention includes a cavity 120, a main electrode 101 and a secondary electrode 121 extending into the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com