Improved micro drive motor

A micro-drive motor, an improved technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problem of inability to guarantee the bonding strength, the difficulty of accurately ensuring the distance between the outer ring of the spring leaf and the outer edge of the lower spring leaf, and the difficulty of ensuring the upper spring leaf and the lower spring leaf. and other problems to achieve the effect of improving the linear drive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

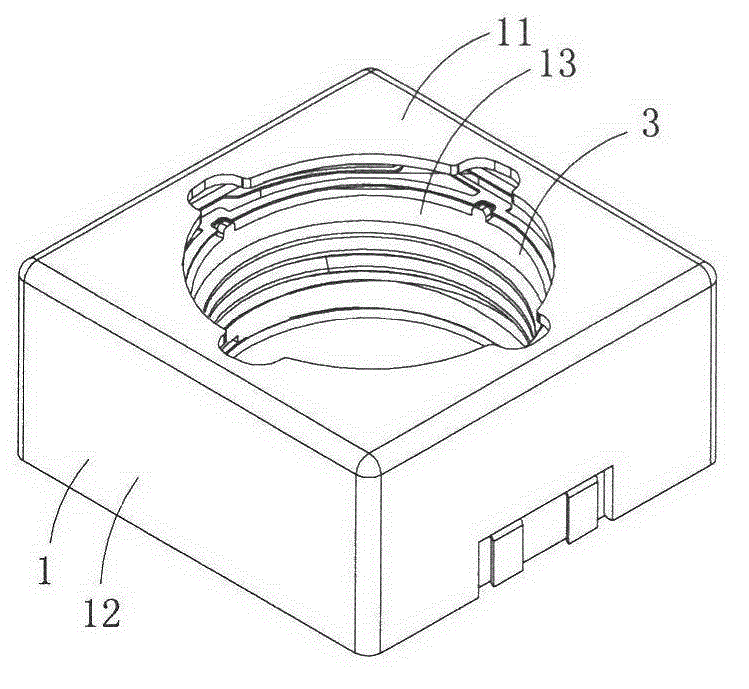

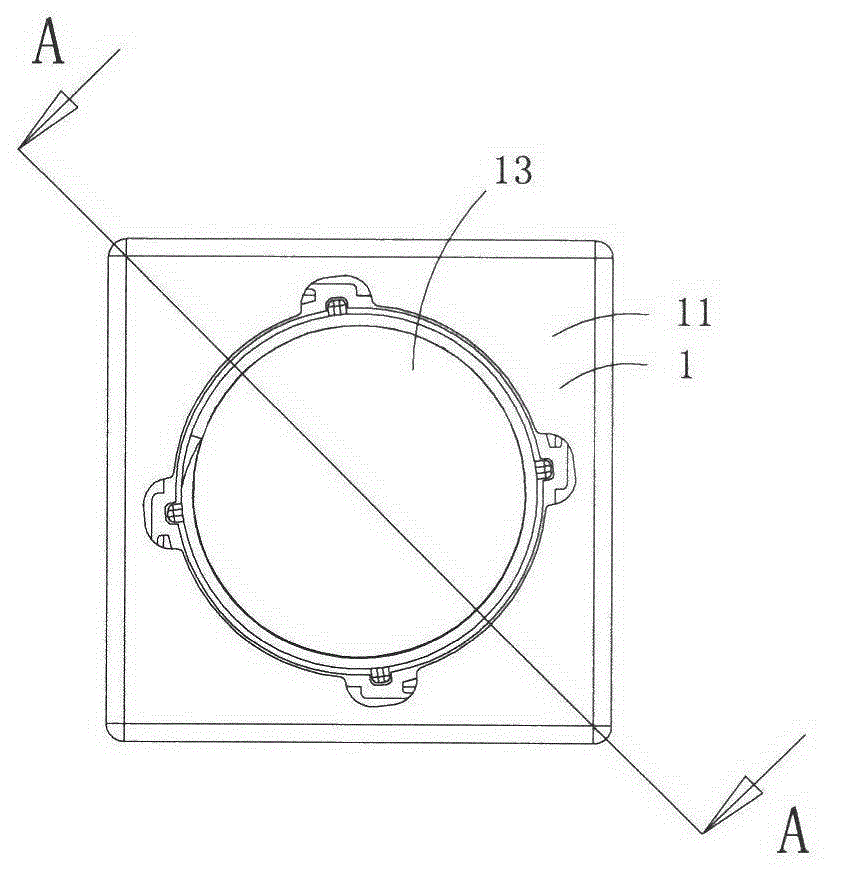

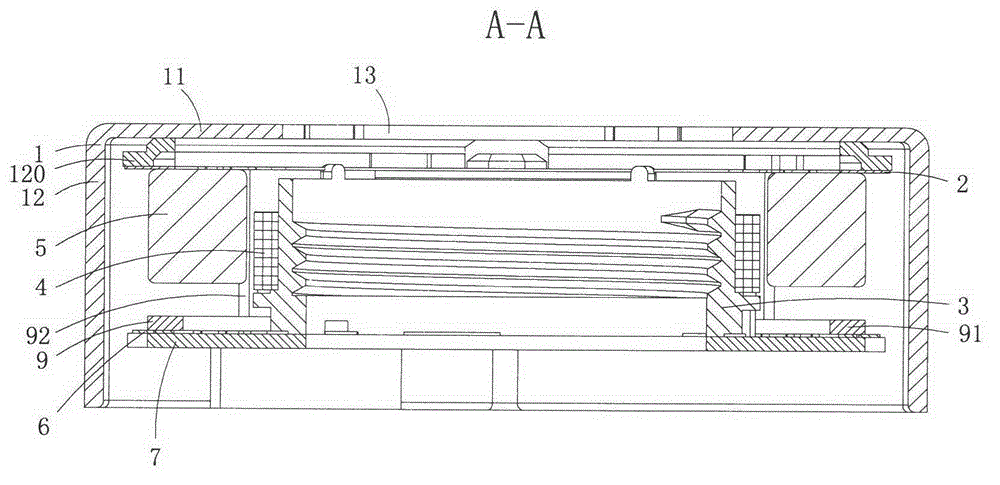

[0022] Figure 1 to Figure 4 A first embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 yes figure 1 A front view of the improved miniature drive motor shown; image 3 yes figure 2 The sectional view of the improved miniature drive motor shown along the A-A line; Figure 4 yes figure 1 An exploded view of the modified micro-drive motor shown.

[0023] Present embodiment is a kind of improved miniature driving motor of driving miniature camera lens assembly, see Figure 1 to Figure 4 As shown, it includes an upper cover 1, an upper gasket 120, an upper spring piece 2, a carrier 3, a coil assembly 4, a magnet assembly 5, a lower spring assembly 6, a magnetic guide 7 and a lower gasket 9; the upper gasket 120 , the upper spring piece 2, the carrier 3, and the lower gasket 9 are all made of non-magnetic materials;

[0024] The upper cover 1 includes a top wall 11 and four s...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, except that: the upper cover 1 is made of magnetically permeable material; a magnetic path is also formed between a side of the magnet assembly 5 close to the coil assembly 4 and the top wall of the upper cover. This structure can effectively improve the utilization efficiency of the magnetic field of the magnet assembly, and can provide a more constant magnetic field for the coil assembly when the coil assembly moves with the carrier, thereby effectively improving the linear driving effect.

Embodiment 3

[0041] This embodiment is basically the same as Embodiment 1, except that: the two ends of each support boss 12 along the circumferential direction of the coil assembly 26 abut against two adjacent magnets 251 . This structure can limit the position of each magnet in the circumferential direction of the coil assembly, increase the impact resistance of the magnet assembly, and is beneficial to improve the passing rate of the drop test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com