Camera module and assembling method

A camera module and circuit board technology, applied in the camera field, can solve problems such as low production efficiency and complicated camera module installation procedures, and achieve the effects of improving production efficiency, saving layout, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

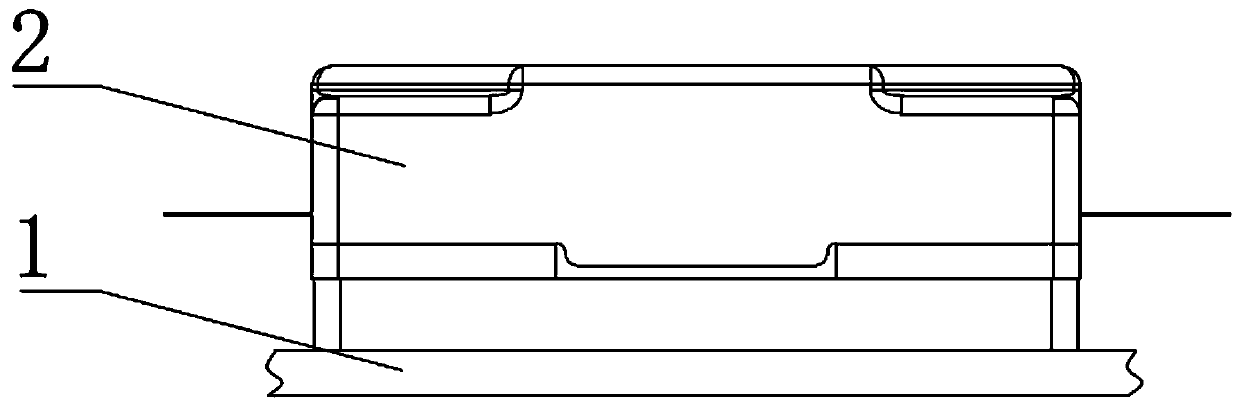

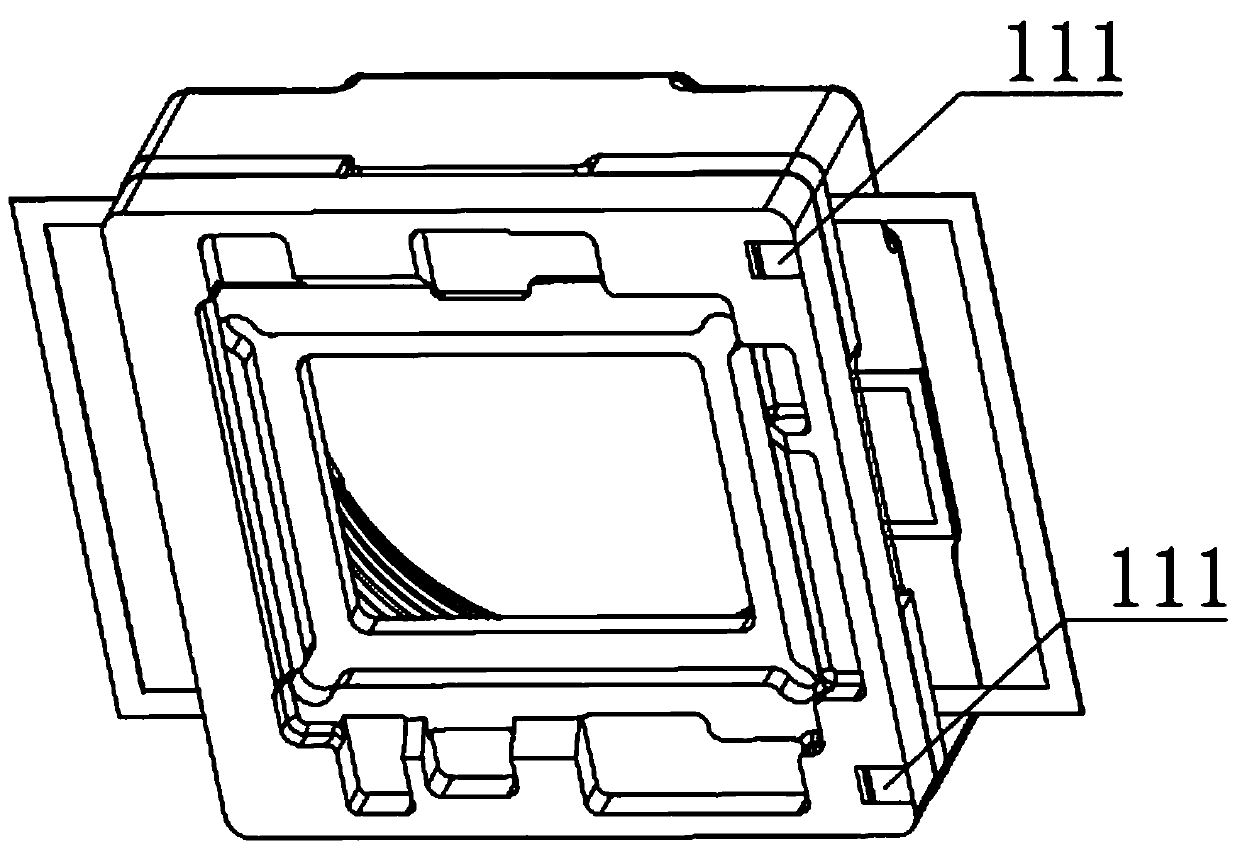

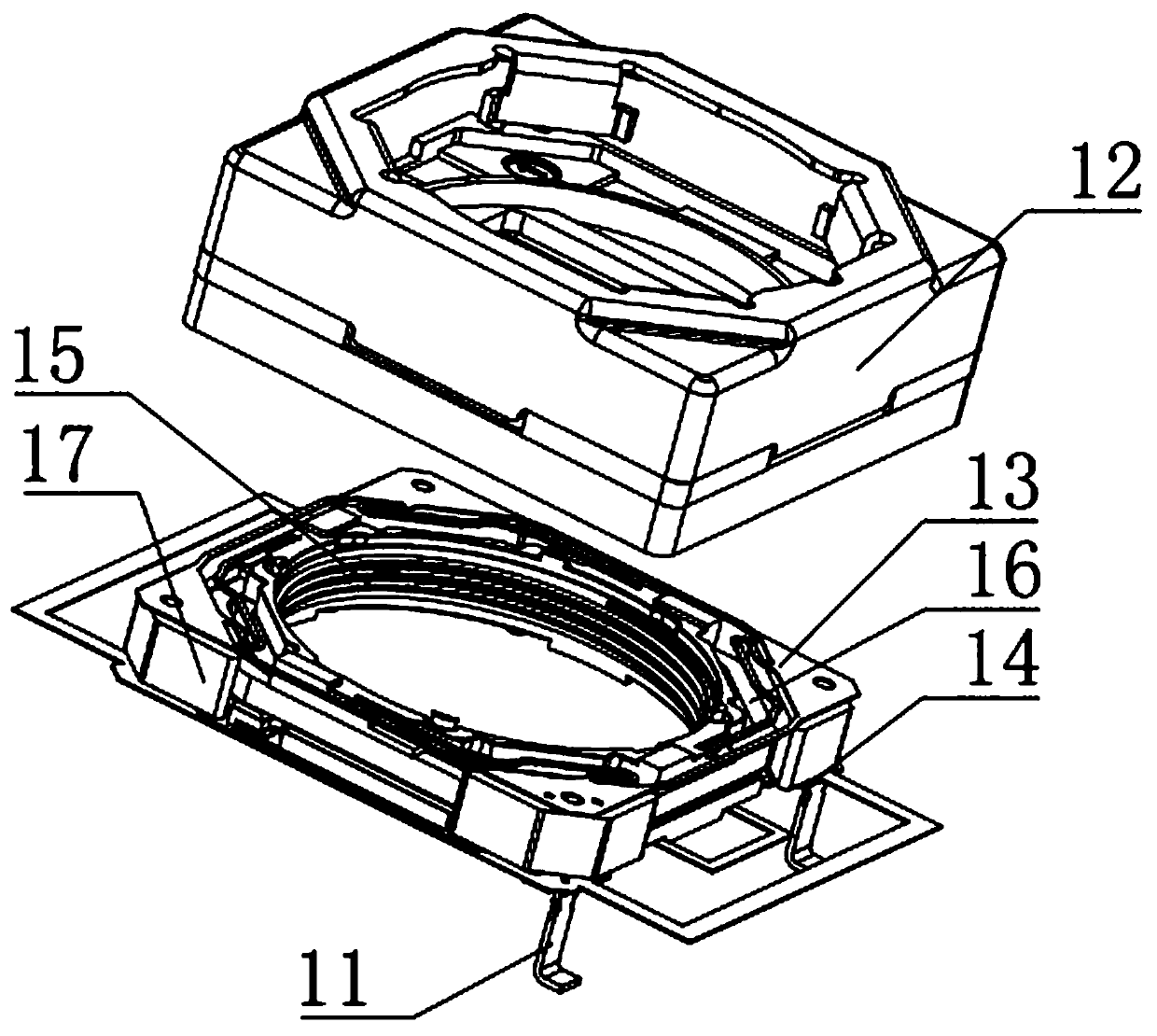

[0025] Such as Figure 1-3 As shown, it shows a camera module provided by the present invention, the camera module includes a circuit board 1 and a voice coil motor 2 arranged on the circuit board 1, and the voice coil motor 2 is provided with a The connecting pin 11 extending from the circuit board 1, and the connecting pin 11 is provided with a contact surface 111 consistent with the arrangement direction of the circuit board 1; The lower surface of the voice coil motor 2 facing the side of the circuit board 1 is flush; electrical connection.

[0026] In this way, the voice coil motor 2 provided by this embodiment is directly arranged on the circuit board 1, which has a simple structure and effectively saves the arrangement of the carrier, which not only simplifies the structure but also effectively reduces the installation process; and by making the connecting pin 11 set The contact surface 111 that is consistent with the layout direction of the circuit board 1 increases ...

Embodiment 2

[0032] Such as Figure 5 As shown, this embodiment provides a camera module assembly method for assembling the camera module as described in the above embodiments, including the following steps: Step 1: Provide a voice coil motor 2 and a circuit board 1, the The voice coil motor 2 is provided with a connecting pin 11 extending toward the circuit board 1, and the connecting pin 11 is provided with a contact surface 111 in the same direction as the circuit board 1, and the contact surface 111 faces the One side of the circuit board 1 is kept flush with the lower surface of the voice coil motor 2 facing the side of the circuit board 1; Step 2: Fix the voice coil motor 2 on the circuit board 1 by SMT process and realize The voice coil motor 2 is electrically connected to the circuit board 1 .

[0033] In this way, the camera module assembly method provided in this embodiment directly fixes the voice coil motor 2 on the circuit board 1, which effectively saves the layout of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com