Coating machine for adhesive product

A technology for coating machines and glue products, which is applied to the device for coating liquid on the surface, coating, surface pretreatment, etc. It can solve the problems of increasing the production cost of the enterprise, the occurrence of glue drawing, and affecting the work efficiency, so as to improve the work efficiency. Efficiency, ensuring uniformity, and ensuring the effect of coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

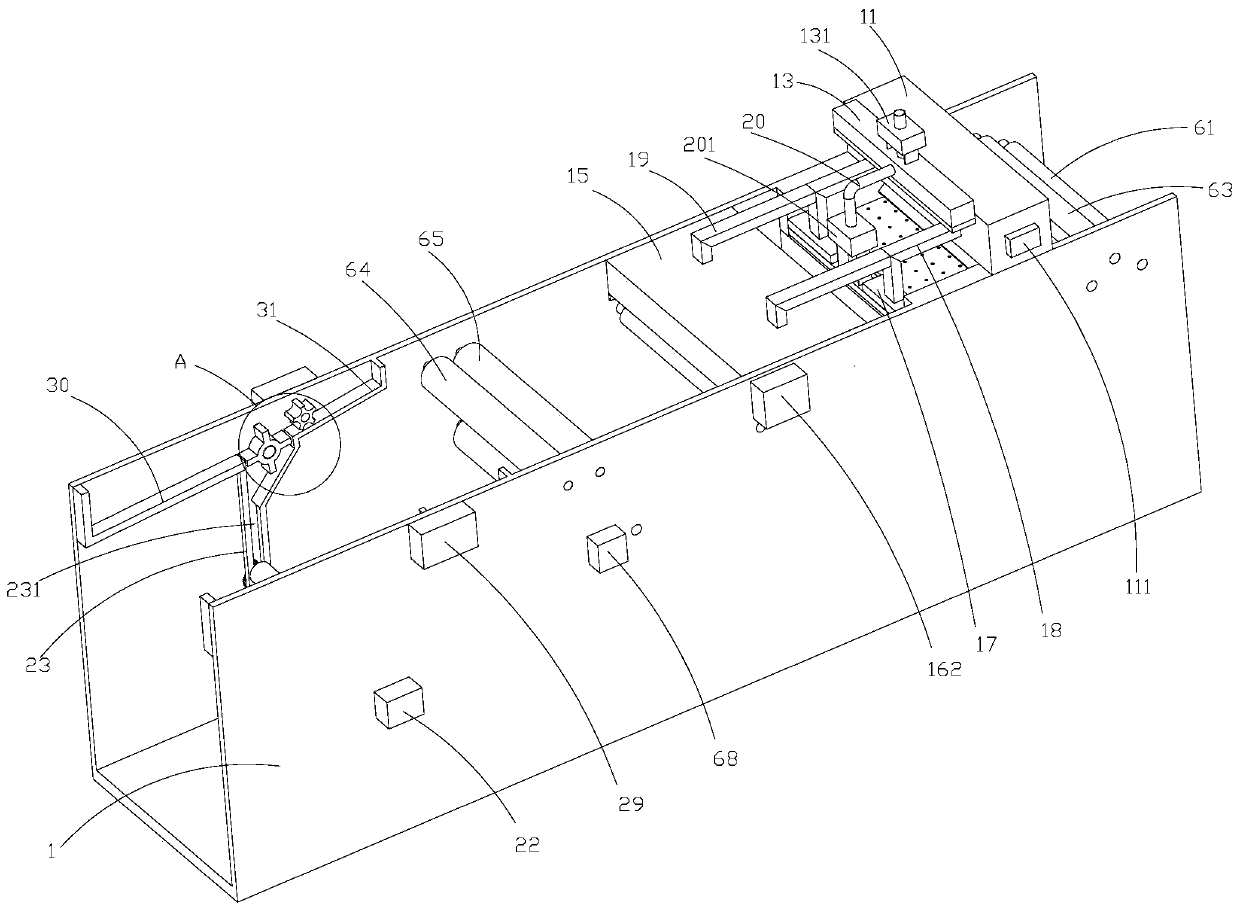

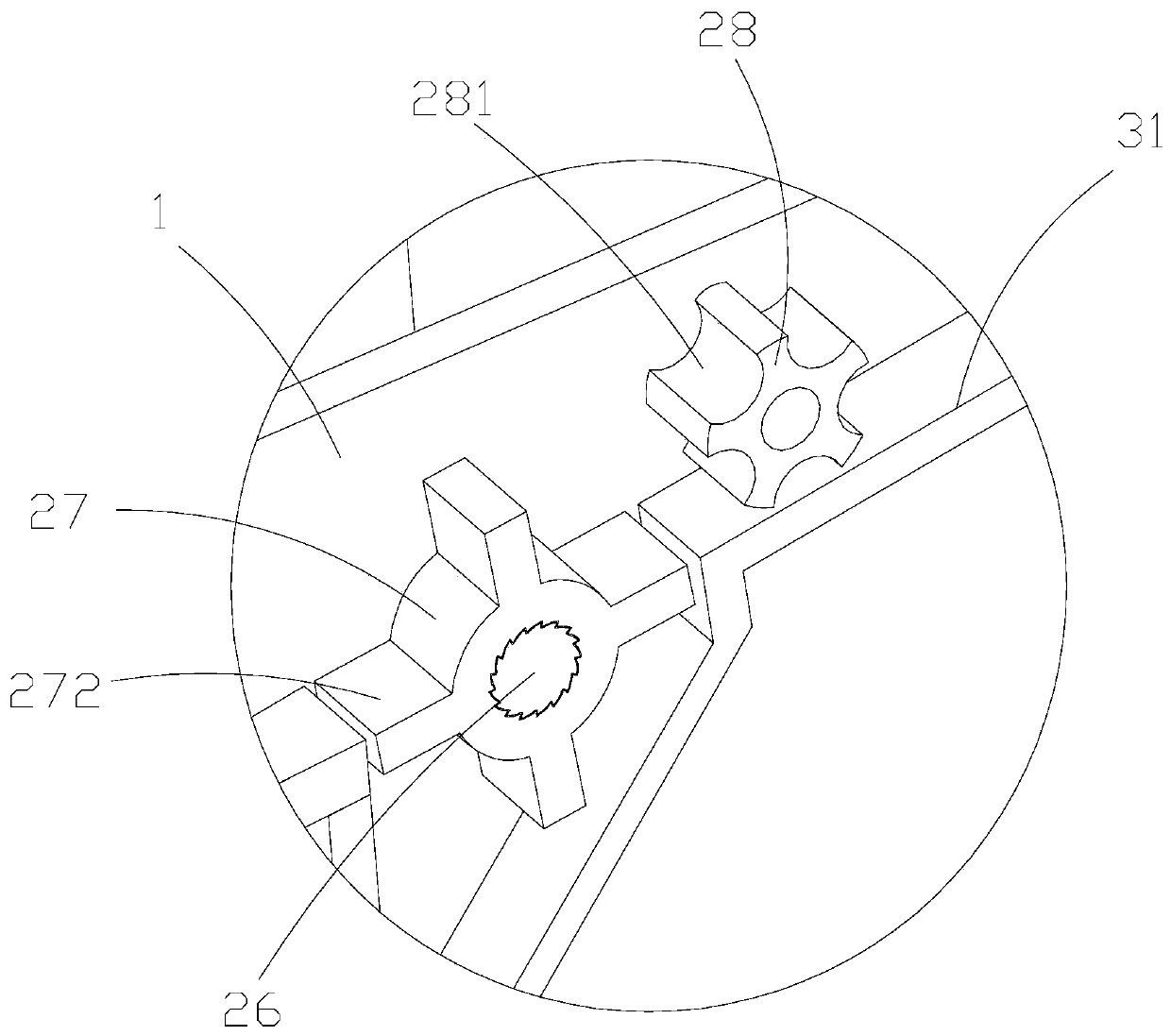

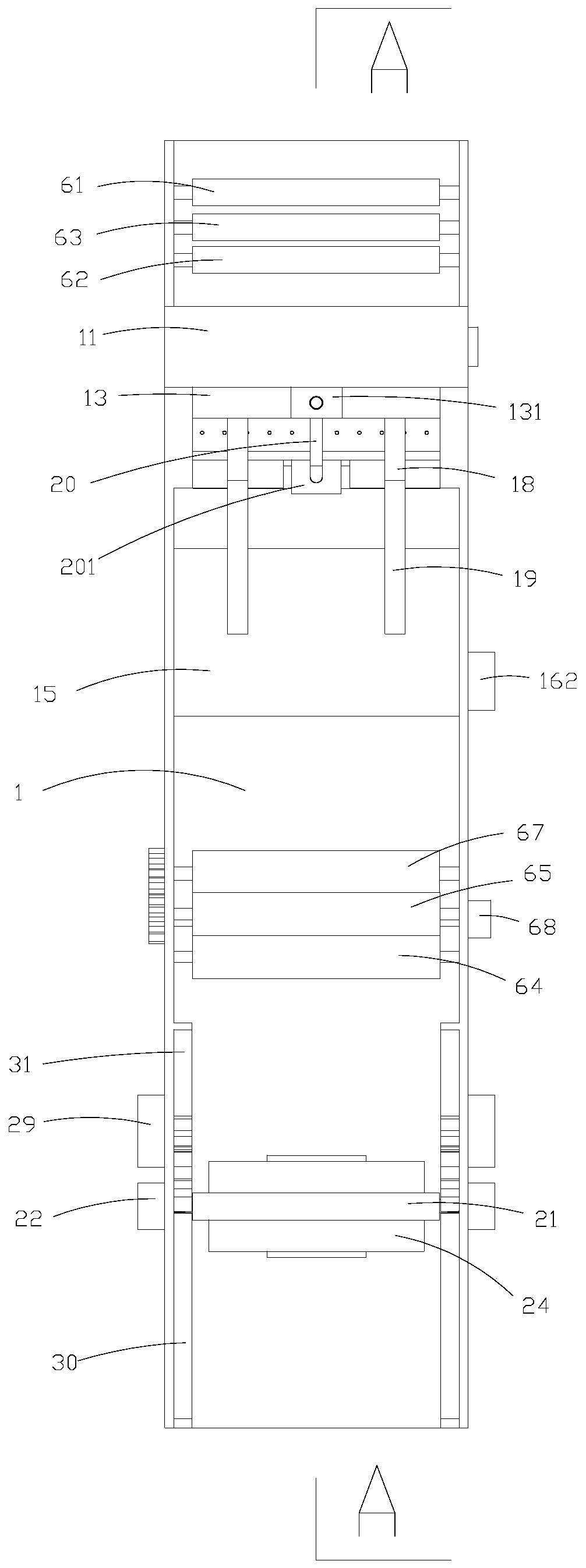

[0024] Such as Figure 1-9 Shown, a kind of self-adhesive product coating machine comprises frame 1, is used for the drying device of cold gel water, is located at the composite device on frame 1, is located at the coating device on frame 1 and is located at The winding device on the frame 1; the composite device includes a first paper feed mechanism, a second paper feed mechanism and a composite mechanism, and the first paper feed mechanism includes the first roller body 61 on the rotatable frame 1, The second roller body 62 that is rotatably arranged on the frame 1 and the third roller body 63 that is rotatably arranged on the frame 1, the first roller body 61 and the second roller body 62 are arranged side by side, and the backing paper can be The first roller body 61 and the second roller body 62 pass above, and the third roller body 63 is arranged between the first roller body 61 and the second roller body 62 and slightly higher than the first roller body 61 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com