Aluminum alloy die-casting mold

A die-casting mold and aluminum alloy technology, which is applied in the field of aluminum alloy forming, can solve the problems of die-casting parts not being able to be automatically removed from the mold, danger, etc., and achieve the effect of facilitating the ejection work, avoiding waste, and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

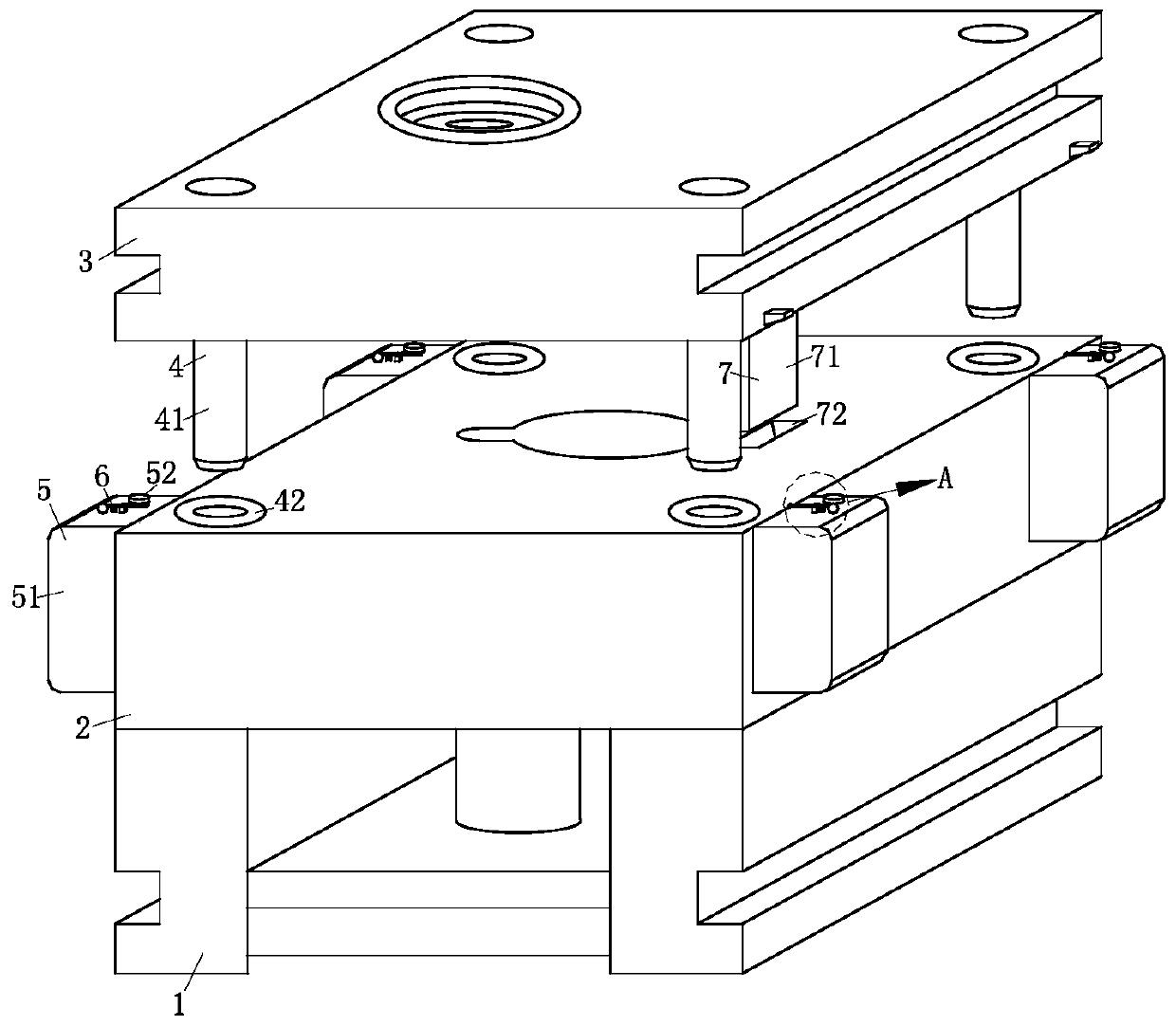

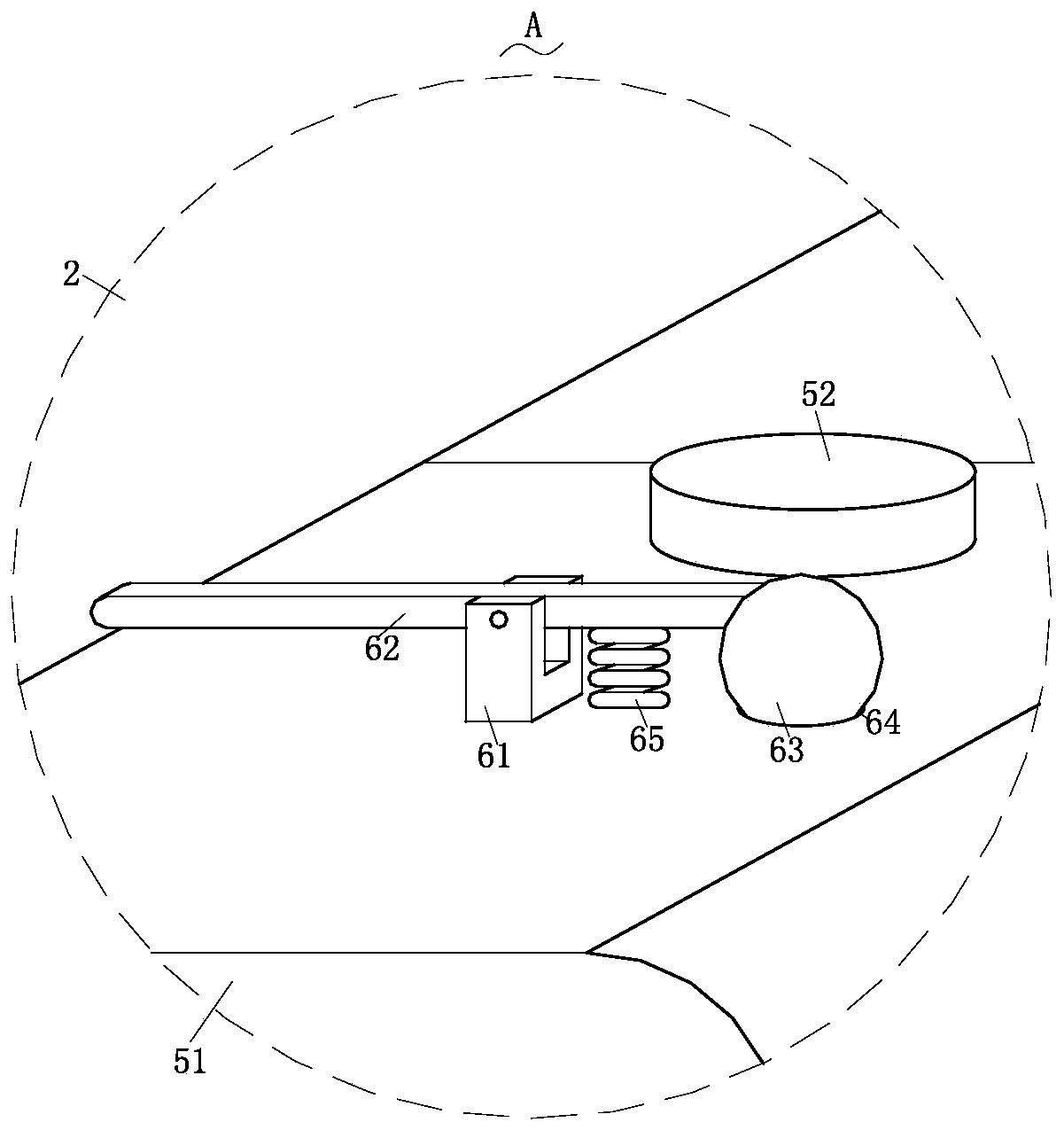

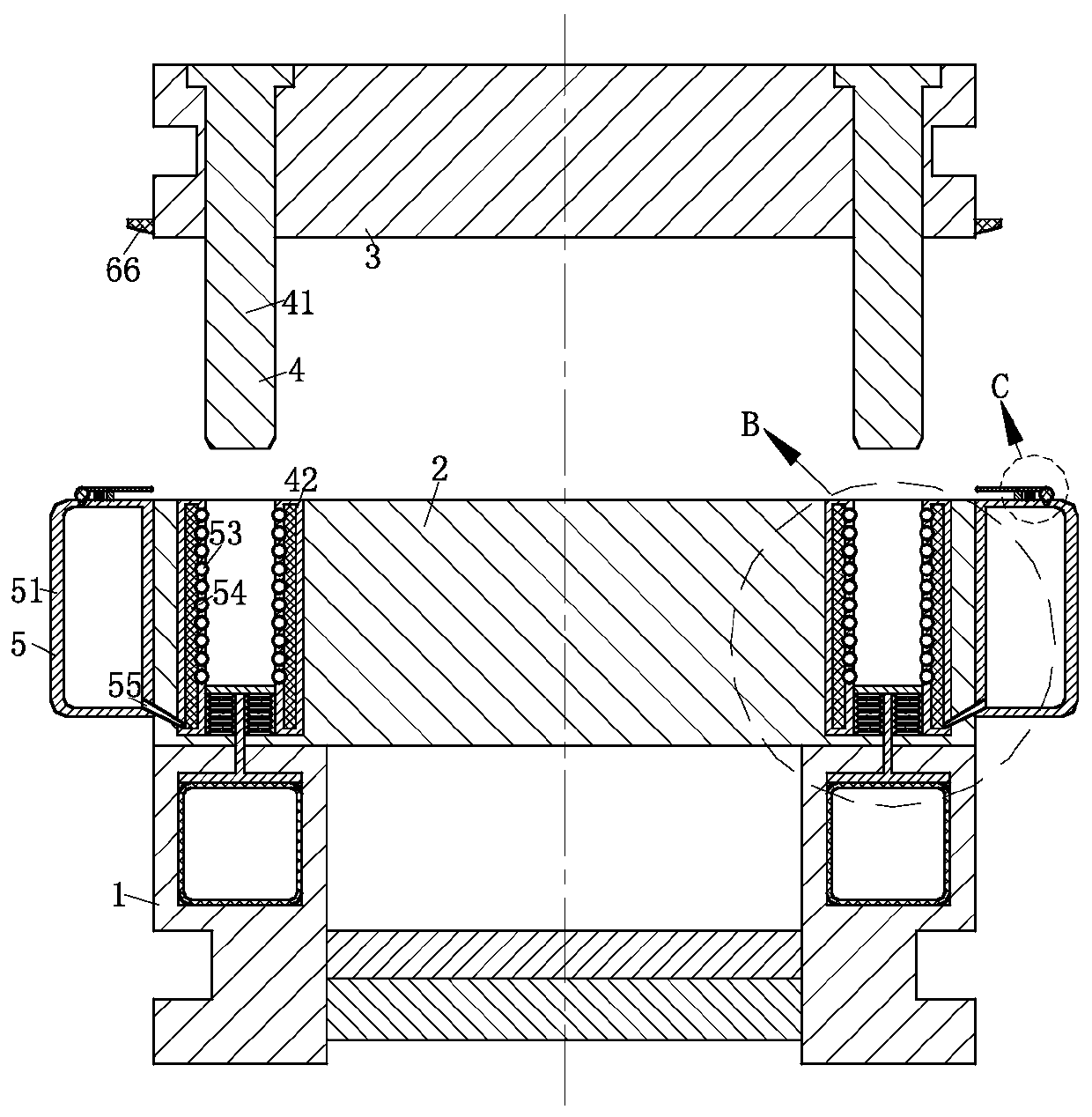

[0025] Such as Figure 1-Figure 7As shown, an aluminum alloy die-casting mold according to the present invention includes a mold foot 1, a rear mold frame 2, a front mold frame 3, a guide structure 4, a lubrication structure 5, an opening and closing structure 6, a discharge structure 7 and a cooling structure 8. The top ends of the two mold feet 1 used to support the entire mold are fixedly connected with the rear mold frame 2 used to fix the mold core, and the rear mold frame 2 is away from the two mold feet 1 One end is connected with the front mold frame 3 for die-casting; between the front mold frame 3 and the rear mold frame 2 is connected with the guide structure 4 for guiding, and in the rear mold frame 2 The lubricating structure 5 for l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap