A kind of h-shaped steel automatic cutting equipment

An H-shaped steel, fully automatic technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of impracticality, low efficiency of positioning cutting, miscutting, etc., and achieve the inconvenient use and disassembly, accurate and rapid control effect The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

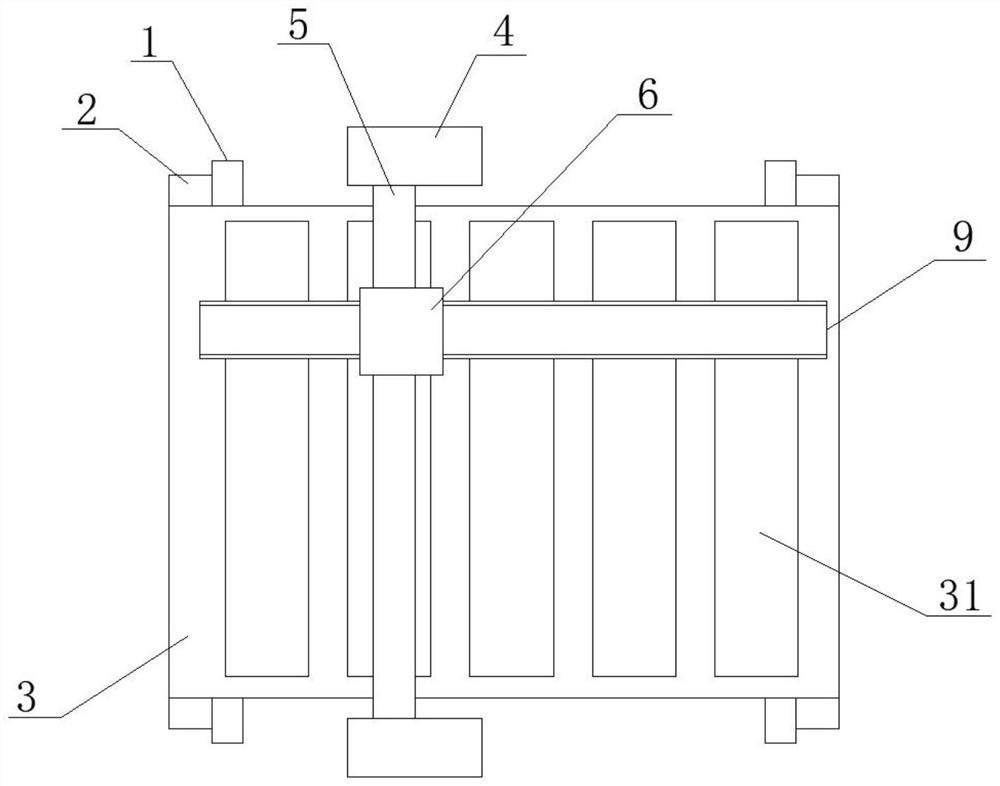

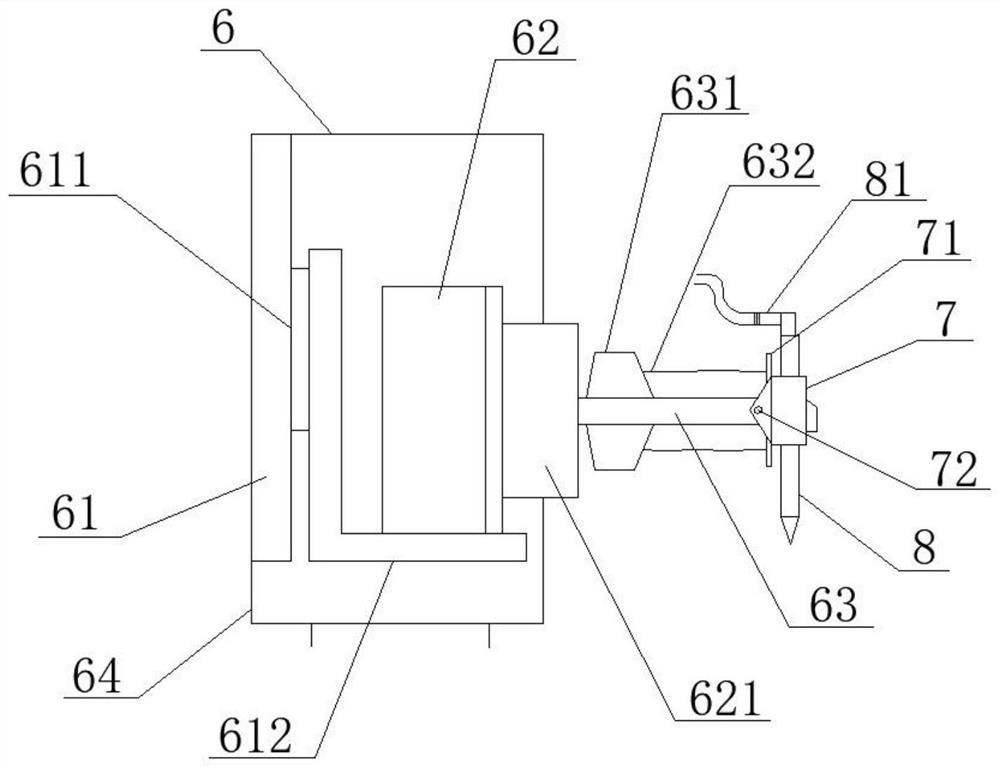

[0019] Such as Figure 1-2 As shown, the present invention discloses a fully automatic cutting equipment for H-shaped steel, including a support 1, a transmission driving device 2, a conveyor belt system 3, a pedestal 4, a sliding beam 5, a working slide 6, a holding frame 7 and a cutting gun 8. A conveyor belt system 3 is installed on the support 1, and H-shaped steel is placed on the conveyor belt system 3. The conveyor belt system 3 is driven and connected to the transmission drive device 2, and the two sides of the support 1 are provided with A pedestal 4, the upper part of the pedestal 4 is erected with a sliding beam 5 horizontally spanning the top of the conveyor belt system 3, a working slide 6 is installed on the sliding beam 5, and the working slide 6 includes a lifting drive device 61, a rotating Driving device 62, rotating rod 63 and housing 64, described lifting driving device 61 is fixedly installed on the inner wall of described housing 64, and the motion output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com