Automatic fixed-disassembly differential grinding machine and using method thereof

An automatic and grinding machine technology, applied in the direction of grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of affecting the grinding quality, material grinding deviation, and inability to fix materials, so as to improve quality, improve efficiency, and avoid The material has the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

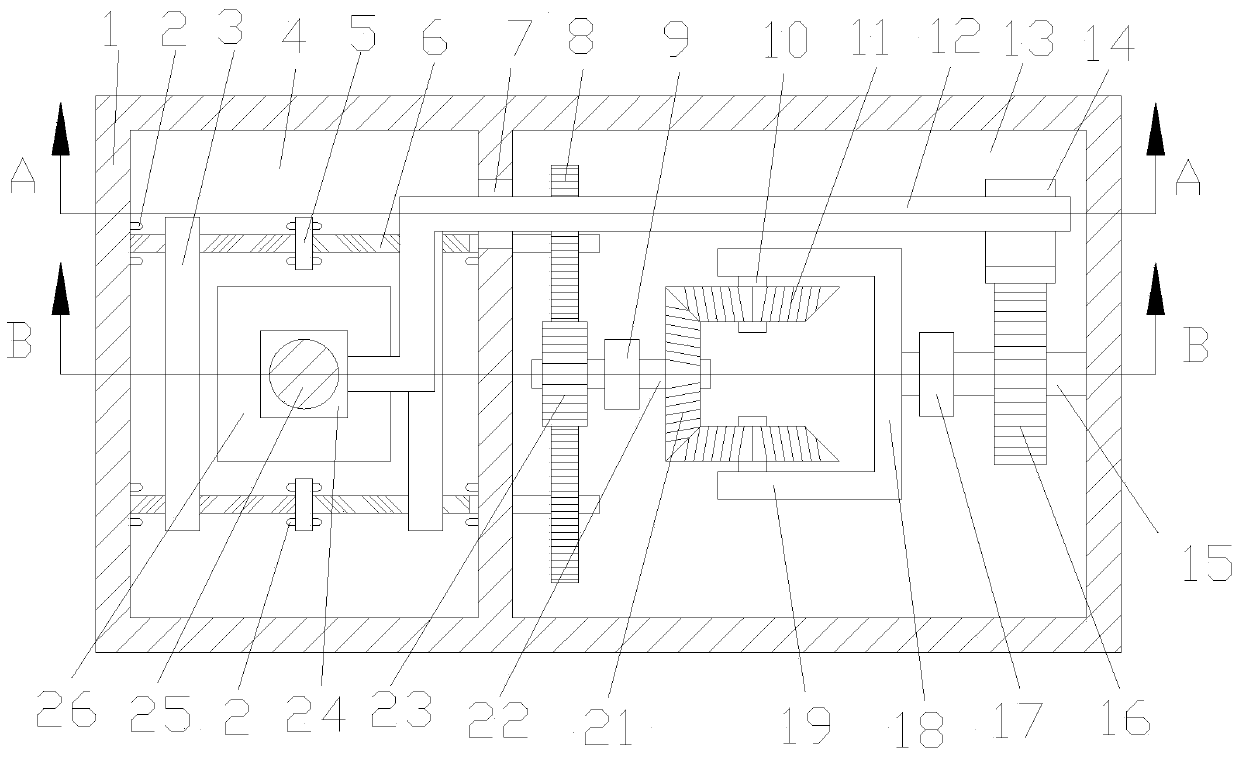

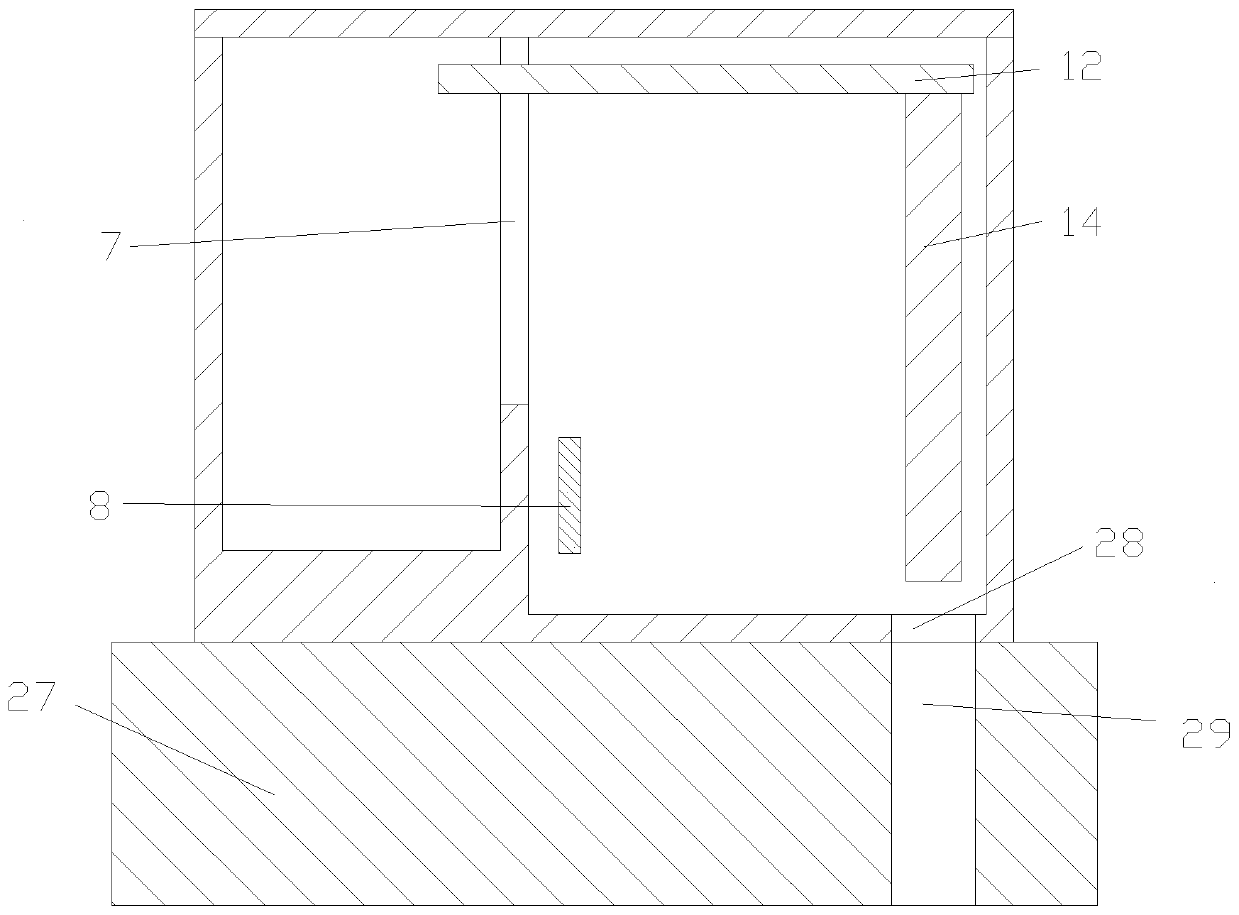

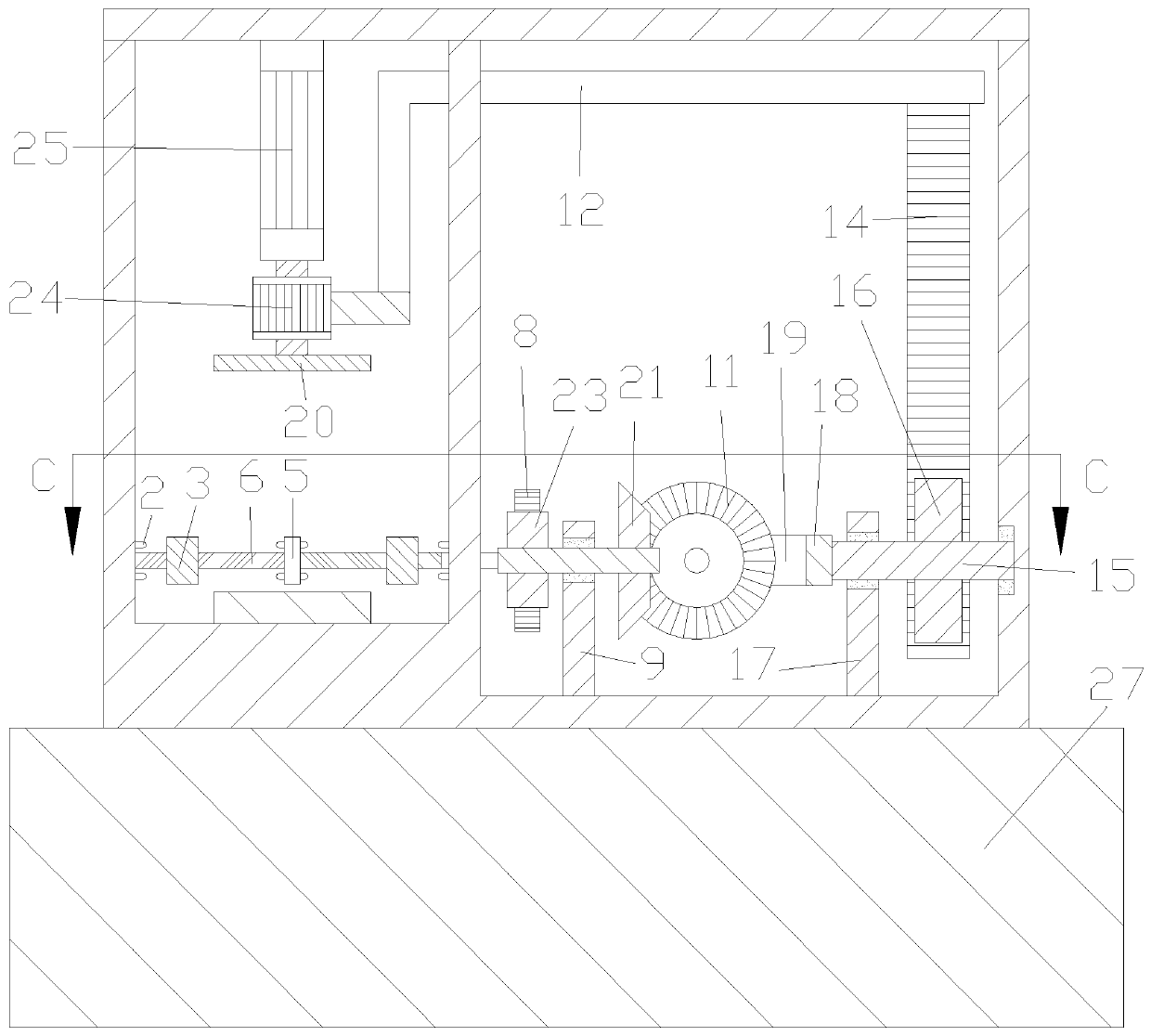

[0017] Refer to attached figure 1 , 2 , 3, 4: In the present embodiment, this automatic fixed disassembly differential speed grinding machine includes a casing 1, the bottom of the casing 1 is fixedly installed with a base 27, and the inside of the casing 1 is respectively provided with a grinding machine that is not connected to each other. Cavity 4 and clamping chamber 13, the bottom center of the inner wall of the grinding chamber 4 is fixedly installed with a bearing seat 26 for placing workpieces, and the front half and the rear half of the bearing seat 26 are respectively provided with a left end and a grinding chamber 4 The inner wall of the left end is movably connected, and the right end passes through the inner wall of the right end of the grinding chamber 4 and reaches the bidirectional screw 6 inside the clamping chamber 13. The distance between the bidirection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com