Test work pipe vice transferring device

A transfer device and work tube technology, applied in the directions of transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems of increased disassembly time and transportation costs, high labor intensity of hydraulic oil pipe clamps, low work efficiency, etc., and achieve convenient transportation. , The overall structure is reasonable, the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

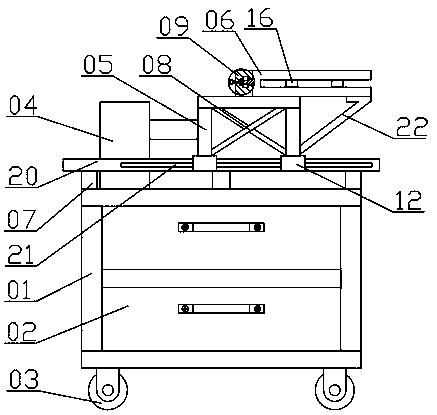

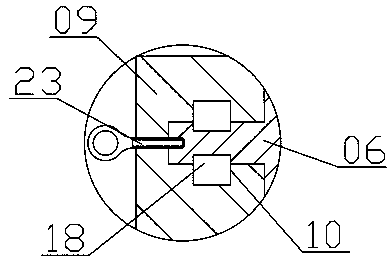

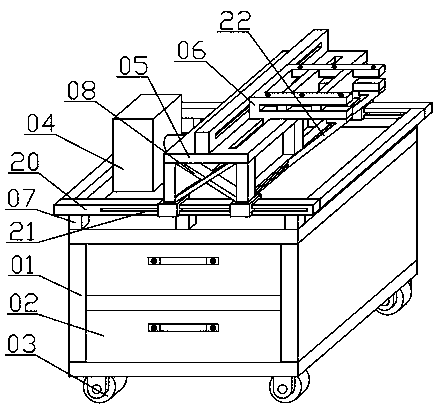

[0020] A pipe wrench transfer device for testing work, including a pipe wrench transfer car 01, a tool storage drawer 02, a universal wheel 03, a cylinder 04, a fixed support frame 05, a pipe wrench fixing frame 06, an X-shaped support frame 08, and an inclined support plate 22 The pipe wrench transfer vehicle 01 is internally connected with a plurality of tool storage drawers 02, the tool storage drawer 02 slides in the pipe wrench transfer vehicle 01, the bottom of the pipe wrench transfer vehicle 01 is connected with multiple universal wheels 03, and the pipe wrench transfer vehicle 01 The top of 01 is connected with a plurality of support columns 07, and the support columns 07 are evenly distributed on the top of the wrench transfer vehicle 01, and the top of the support column 07 is connected with a fixed support frame 20, and the fixed support frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com