Ball screw type electric cylinder

A ball screw and electric cylinder technology, applied in the field of electric lifting mechanism and ball screw electric cylinder, can solve the problems of poor positioning accuracy, easy dust accumulation and water leakage, poor rainproof and dustproof effect, etc., and achieves a simple and reliable structure. , Good dustproof and rainproof functions, high transmission efficiency and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual production structure of the present invention is not limited to the following embodiments.

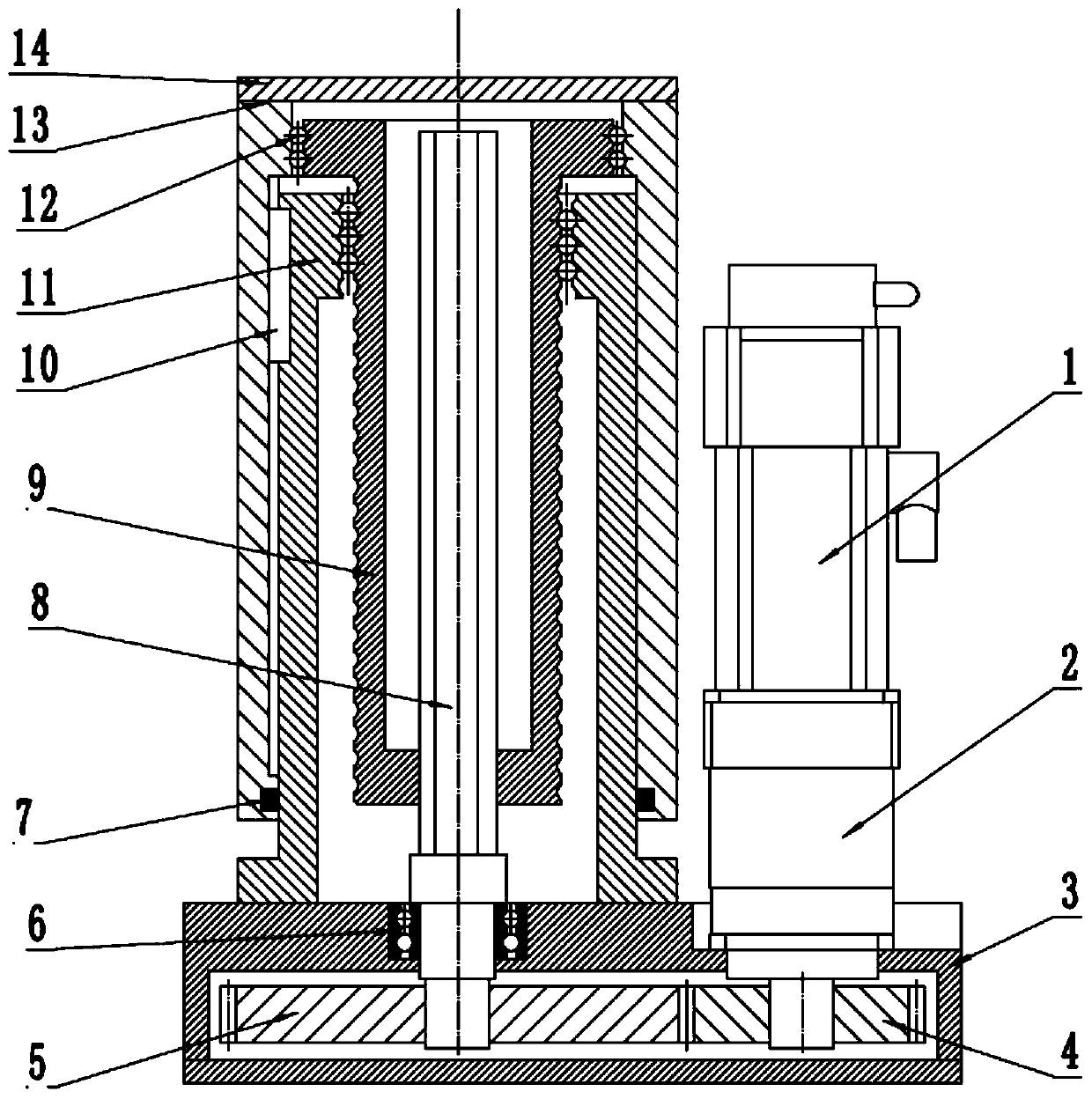

[0012] Referring to the accompanying drawings, the ball screw electric cylinder of the present invention consists of a power transmission box 3 and a motor 1, a reducer 2, a driving gear 4, a driven gear 5, a transmission shaft 8, and a ball screw arranged on the power transmission box 3. Members such as bar 9, sleeve nut 11, outer sliding sleeve 13 and upper top plate 14 are formed. The motor 1 and the reducer 2 form a power device, and the meshingly connected driving gear 4 and driven gear 5 form a gear pair transmission. The axle bar of transmission shaft 8 is a square rod, is installed on the power transmission case 3 by bearing 6, and the lower end of transmission shaft 8 is connected with the wheel center of moving gear 5, and bearing 6 plays a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com