Pressure-resistant polypropylene fiber concrete with mixed crude and fine fibers and preparation method of pressure-resistant polypropylene fiber concrete

A polypropylene fiber and concrete technology, applied in the field of civil engineering, can solve rare and other problems and achieve good practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

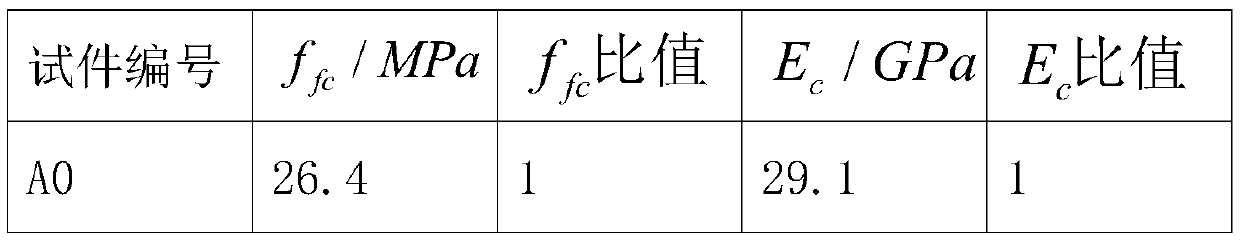

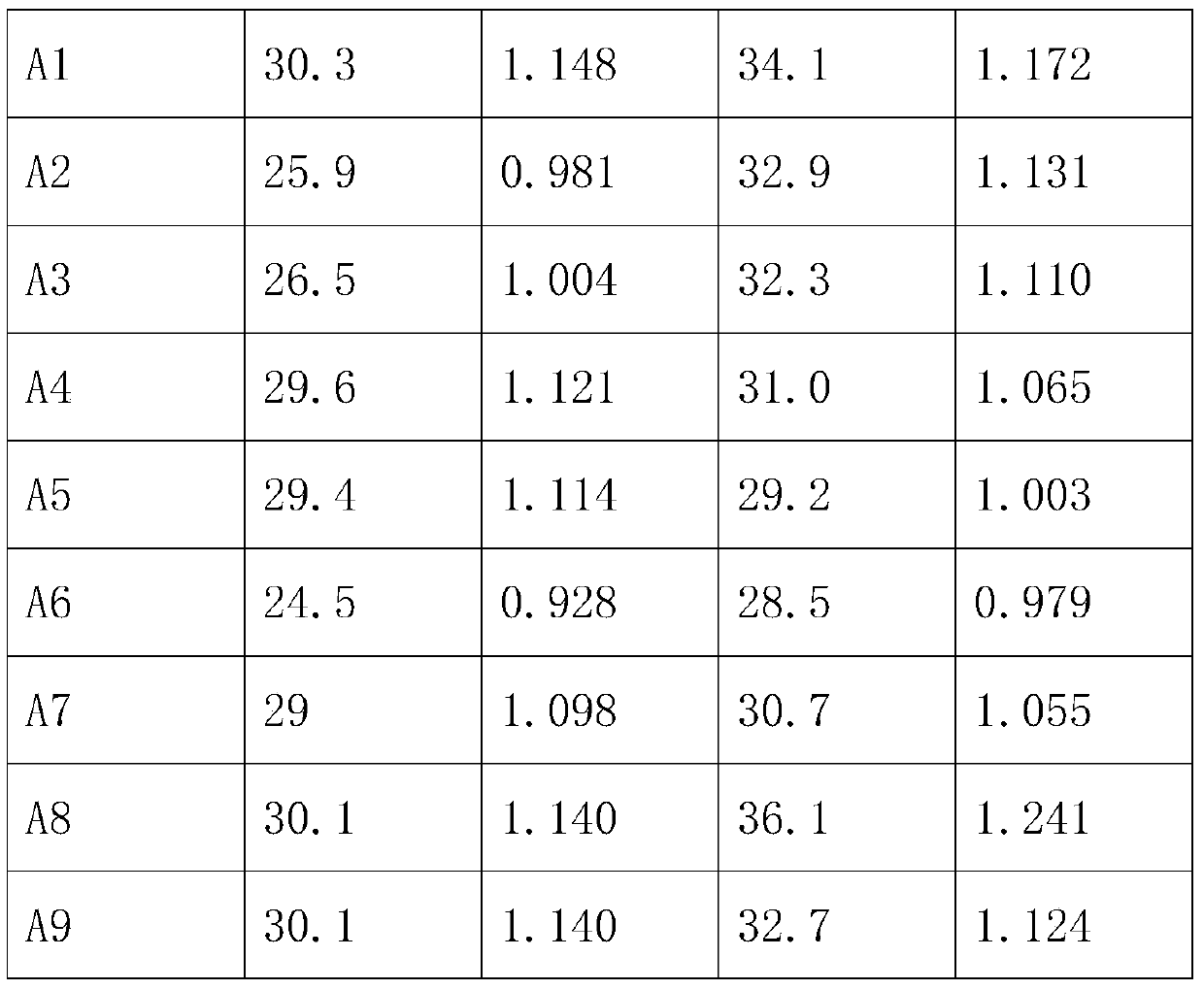

Embodiment 1

[0031] A compression-resistant polypropylene fiber concrete mixed with thick and thin fibers, consisting of the following mix ratio: cement 406kg / m 3 , sand 548kg / m 3 , Stone 1221kg / m 3 , water 207kg / m 3 .

Embodiment 2

[0033] A compressive polypropylene fiber concrete mixed with coarse and fine fibers, consisting of the following mix ratio: FF1 (0.9kg / m 3 ), cement 406kg / m 3 , sand 548kg / m 3 , Stone 1221kg / m 3 , water 207kg / m 3 .

Embodiment 3

[0035] A compression-resistant polypropylene fiber concrete mixed with thick and thin fibers, consisting of the following mix ratio: FF2 (0.9kg / m 3 ), cement 406kg / m 3 , sand 548kg / m 3 , Stone 1221kg / m3 , water 207kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com