On-line recovery method and device for silicon wafer cutting mortar

A technology of silicon wafer cutting and recycling methods, applied in the direction of lubricating compositions, etc., can solve the problems of unfavorable material consumption, material waste, and production cost reduction, and achieve the goal of minimizing material consumption, improving the total recovery rate, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

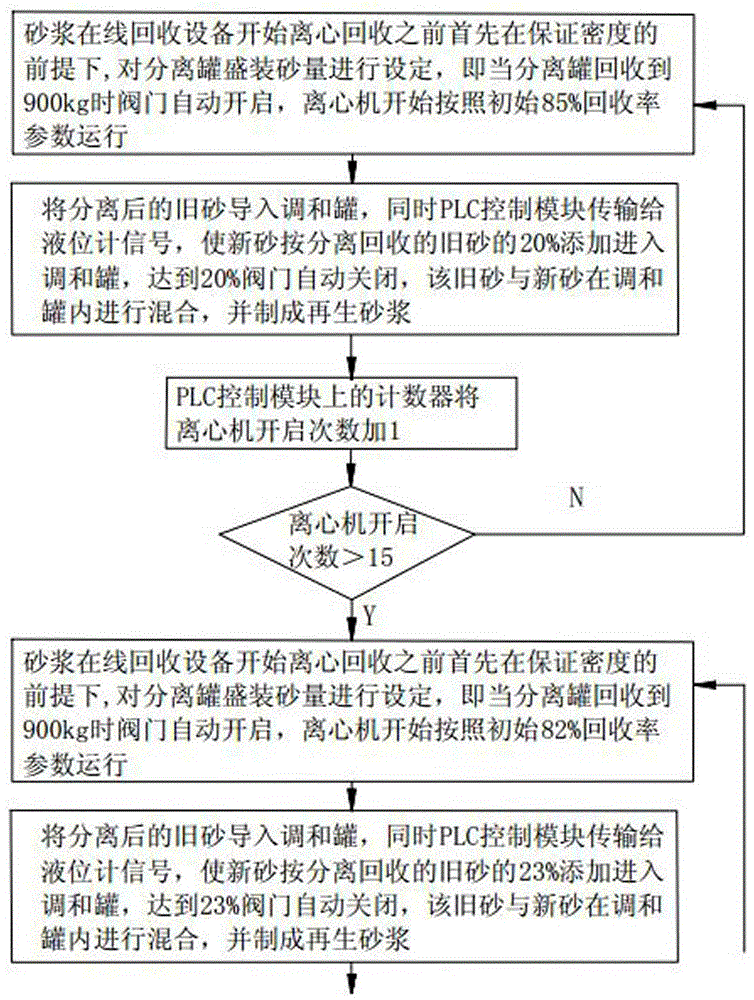

[0019] An online recovery method of silicon wafer cutting mortar, including the following steps:

[0020] (1) Centrifugal recovery of the old mortar stored after cutting according to the set ratio;

[0021] (2) Add new sand in a set proportion according to the recycled old sand;

[0022] (3) Fully mix the recycled old sand and added new sand and make recycled mortar;

[0023] (4) Send the recycled mortar to the cutting machine for silicon wafer cutting; the above cycle is one recovery;

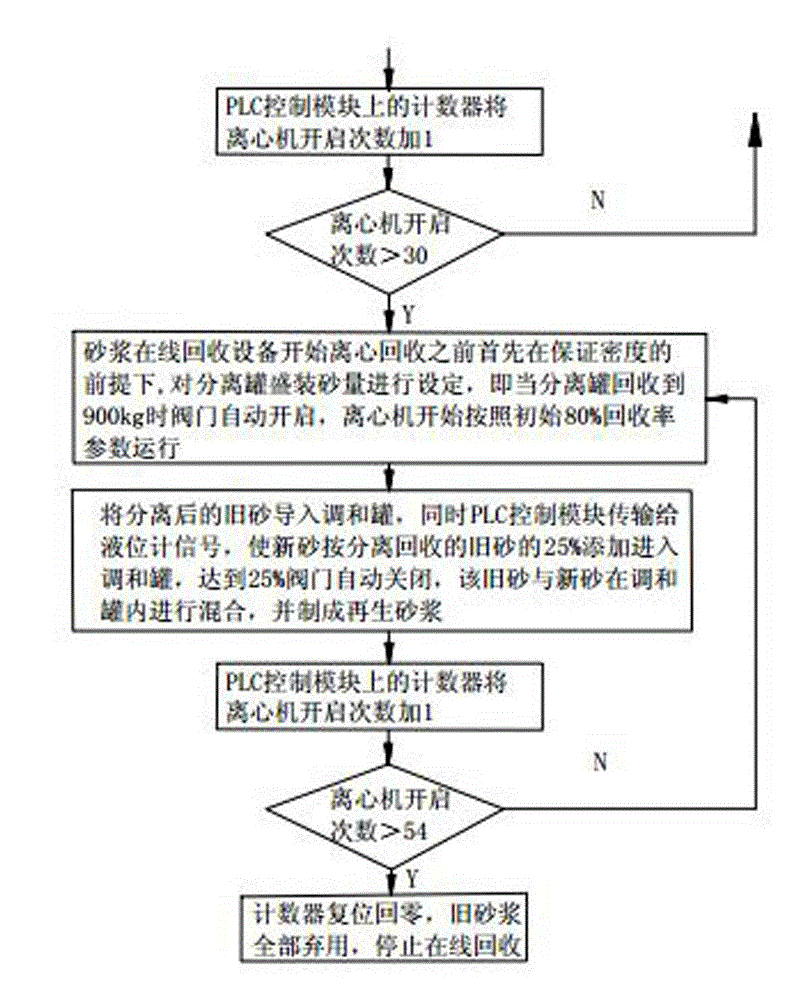

[0024] (5) Count the number of times of recycling of old mortar, after reaching the number of recycling specified in A, adjust the recycling ratio of old mortar and adjust the ratio of new sand to increase, and then repeat steps (1)~(4) ), to the number of times specified by B; after reaching the number of recycling specified by B, adjust the recycling ratio of old mortar and increase the ratio of new sand, and then continue to repeat steps (1) ~ (4) until the specified number of C After the number of...

Embodiment 2

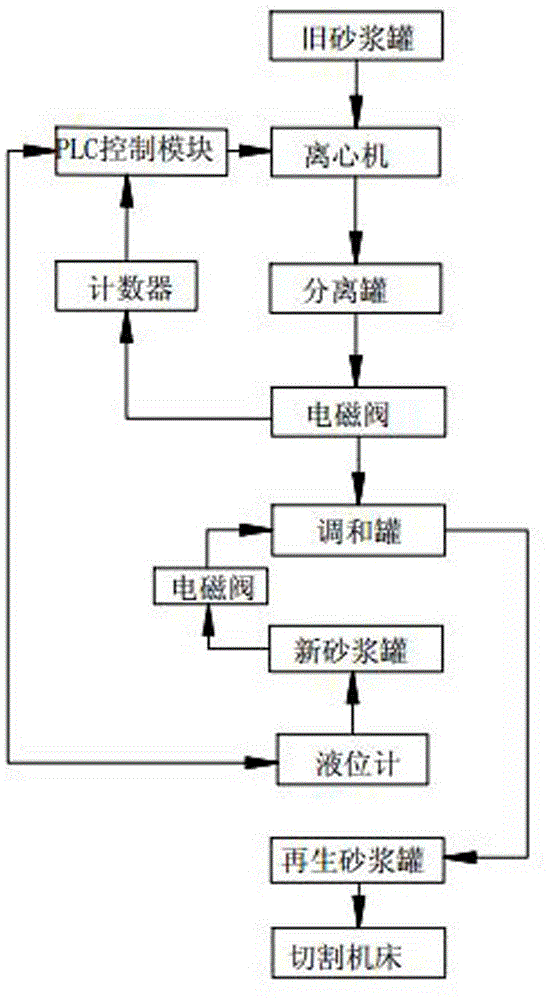

[0027] An online recovery device for silicon wafer cutting mortar, including old mortar tanks, centrifuges, separation tanks, blending tanks, new mortar tanks, and regenerated mortar tanks. The new mortar tank is equipped with a level gauge and the separation tank is equipped with an automatic weighing instrument. Solenoid valves are installed at the sand outlet of the separation tank and the new mortar tank. The old mortar tank is connected to the centrifuge, the centrifuge is connected to the separation tank, the separation tank is connected to the blending tank, and the new mortar tank is connected to the blending tank. The communication and blending tank is connected with the regenerated mortar tank, and is equipped with a pumping mechanism; the device also includes a PLC control module, which is connected to the centrifuge, the liquid level gauge, and the solenoid valve at the sand outlet of the separation tank through the data line. Counter connection.

[0028] Use steps of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com