Phase-change thermal-insulation cement mortar material

A technology of thermal insulation cement and mortar materials, applied in the field of building thermal insulation materials, can solve problems such as difficult process control conditions, and achieve the effects of excellent air permeability, strong adhesion, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a phase-change thermal insulation cement mortar material, which has a cement mortar layer as the main body, and a waterproof adhesive layer is coated on the outside of the cement mortar layer. The cement mortar layer is composed of a phase-change composite material with a mass fraction of 25%, a Fine aggregate and 30% cementitious materials are mixed and stirred.

[0056] Among them, the phase change composite material is paraffin / SiO 2 Phase change heat storage materials, among which paraffin and SiO 2 The mass ratio is in the range of 0.6-1.7.

[0057] Paraffin wax is mainly composed of straight-chain alkanes. The melting point increases gradually with the increase of the chain, and it shows a trend of fast first and then slow. But when the chain length increases to a certain extent, the melting point of paraffin will tend to a certain value; The heat of fusion of alkanes will also increase, but due to the influence of space, the change of h...

Embodiment 2

[0066] This embodiment discloses a phase-change thermal insulation cement mortar material, a phase-change thermal insulation cement mortar material, which has a cement mortar layer as the main body, and a waterproof adhesive layer is coated on the outside of the cement mortar layer. The cement mortar layer has a mass ratio of 4.5:5:4 phase change composite material, fine aggregate and cementitious material are mixed, and the thickness of the cement mortar layer is within 10-15cm.

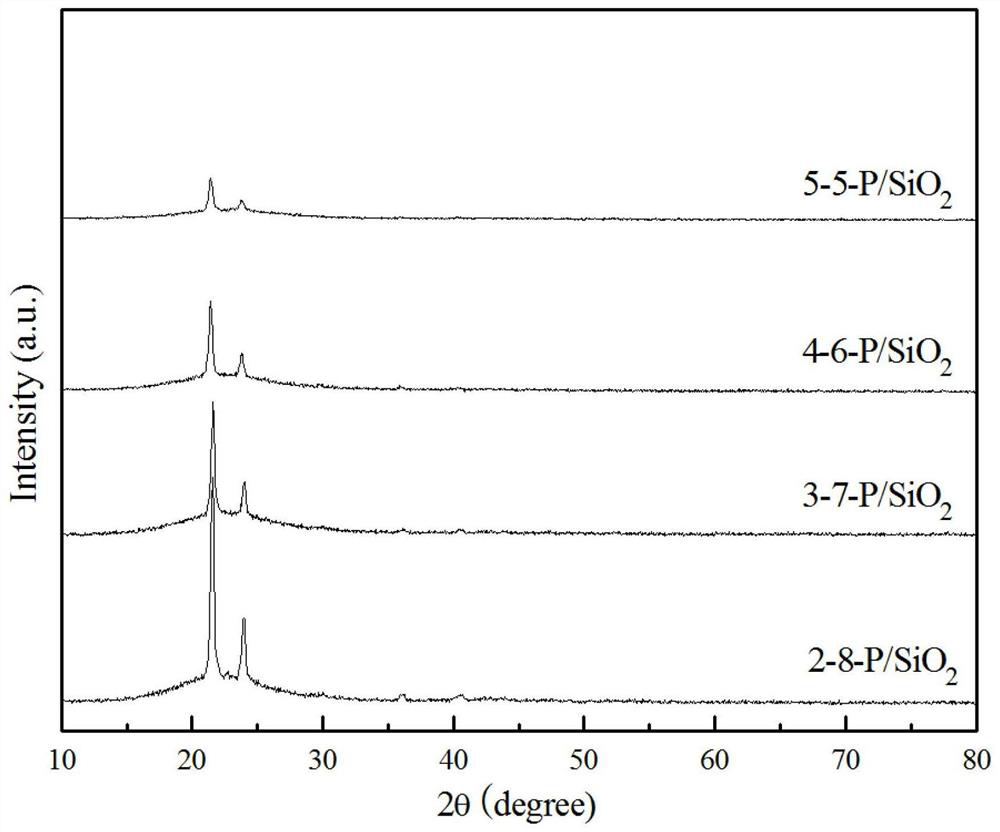

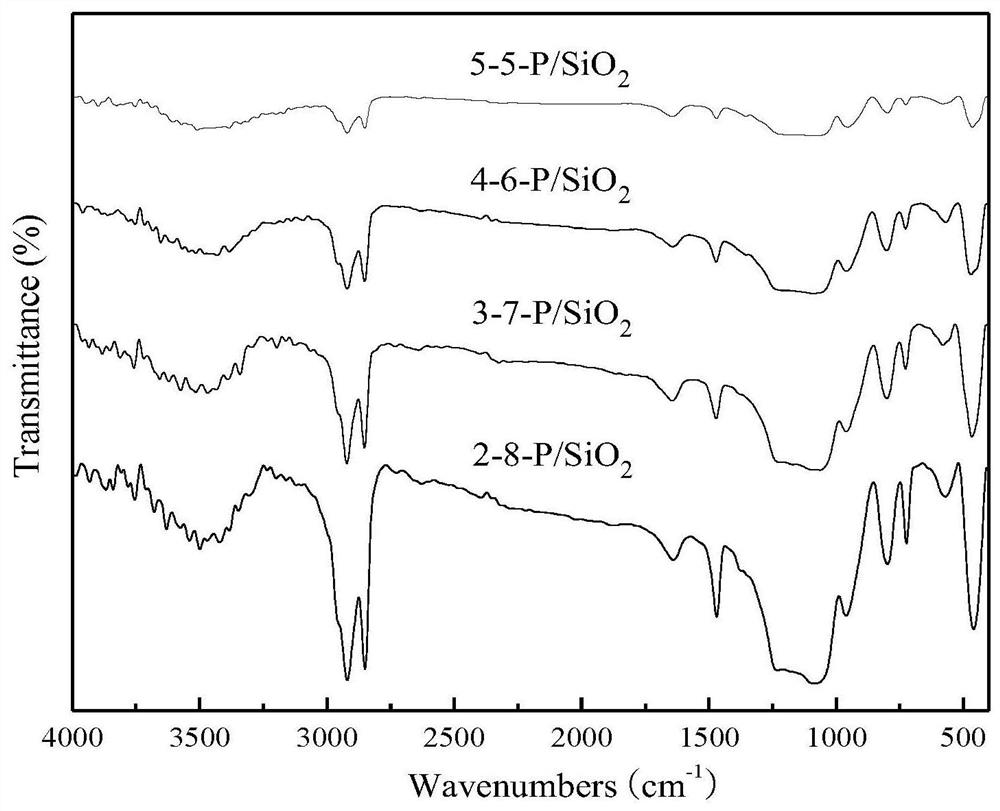

[0067] Among them, the phase change composite material is paraffin / SiO 2 Phase change heat storage materials, among which paraffin and SiO 2 The mass ratio is 5:5.

[0068] Paraffin and SiO in this embodiment 2 The mass ratio is defined in detail, and in order to study the performance advantages of its specific ratio, it is tested experimentally.

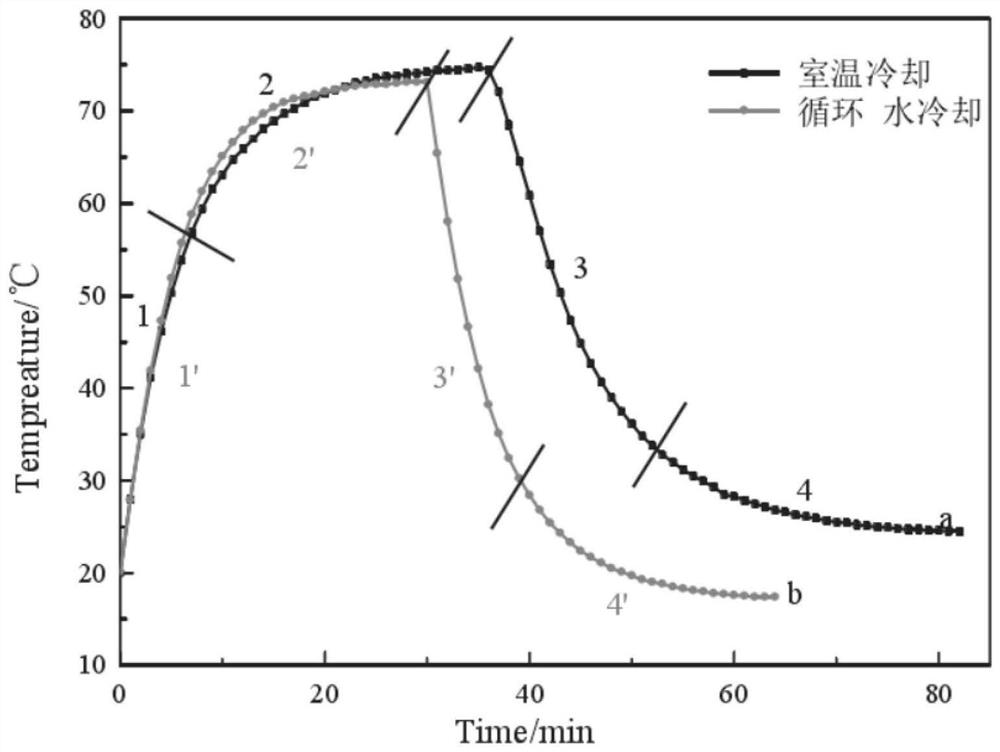

[0069] First make the phase change conforming material, weigh a certain quality of paraffin, 0.2g polyethylene glycol-20000 and 0.2g cetyltrimethylamm...

Embodiment 3

[0077] This embodiment discloses a phase-change thermal insulation cement mortar material. A phase-change thermal insulation cement mortar material has a cement mortar layer as the main body, and a waterproof adhesive layer is coated on the outside of the cement mortar layer. The mass ratio of the cement mortar layer is 4.5 : 5:4 phase change composite material, fine aggregate and cementitious material are mixed, and the thickness of the cement mortar layer is within 10-15cm.

[0078] Among them, the phase change composite material is paraffin / SiO 2 Phase change heat storage materials, among which paraffin and SiO 2 The mass ratio is 4:6.

[0079] Same as above-mentioned embodiment 2, in the present embodiment to paraffin and SiO 2 The mass ratio is defined in detail, and in order to study the performance advantages of its specific ratio, it is tested experimentally.

[0080] First make the phase change conforming material, weigh a certain quality of paraffin, 0.2g polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com