Mixed refrigerant

A technology of mixed refrigeration and working fluid, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem that the mixed refrigerant GWP cannot meet the requirements of automobile air-conditioning refrigerants, etc., and achieve the effect of weakening the flammability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

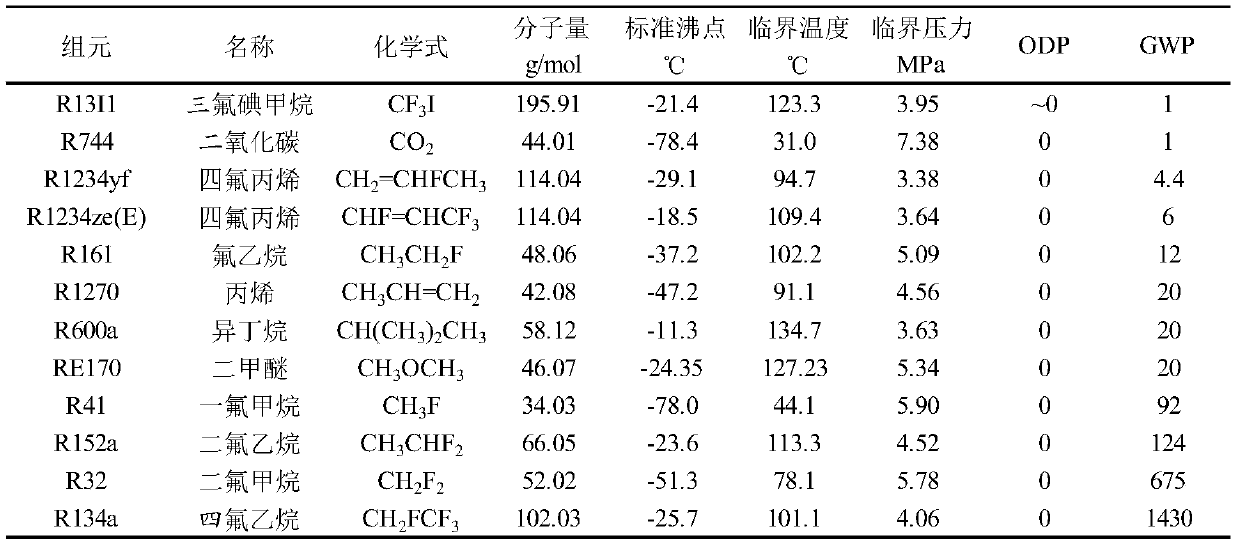

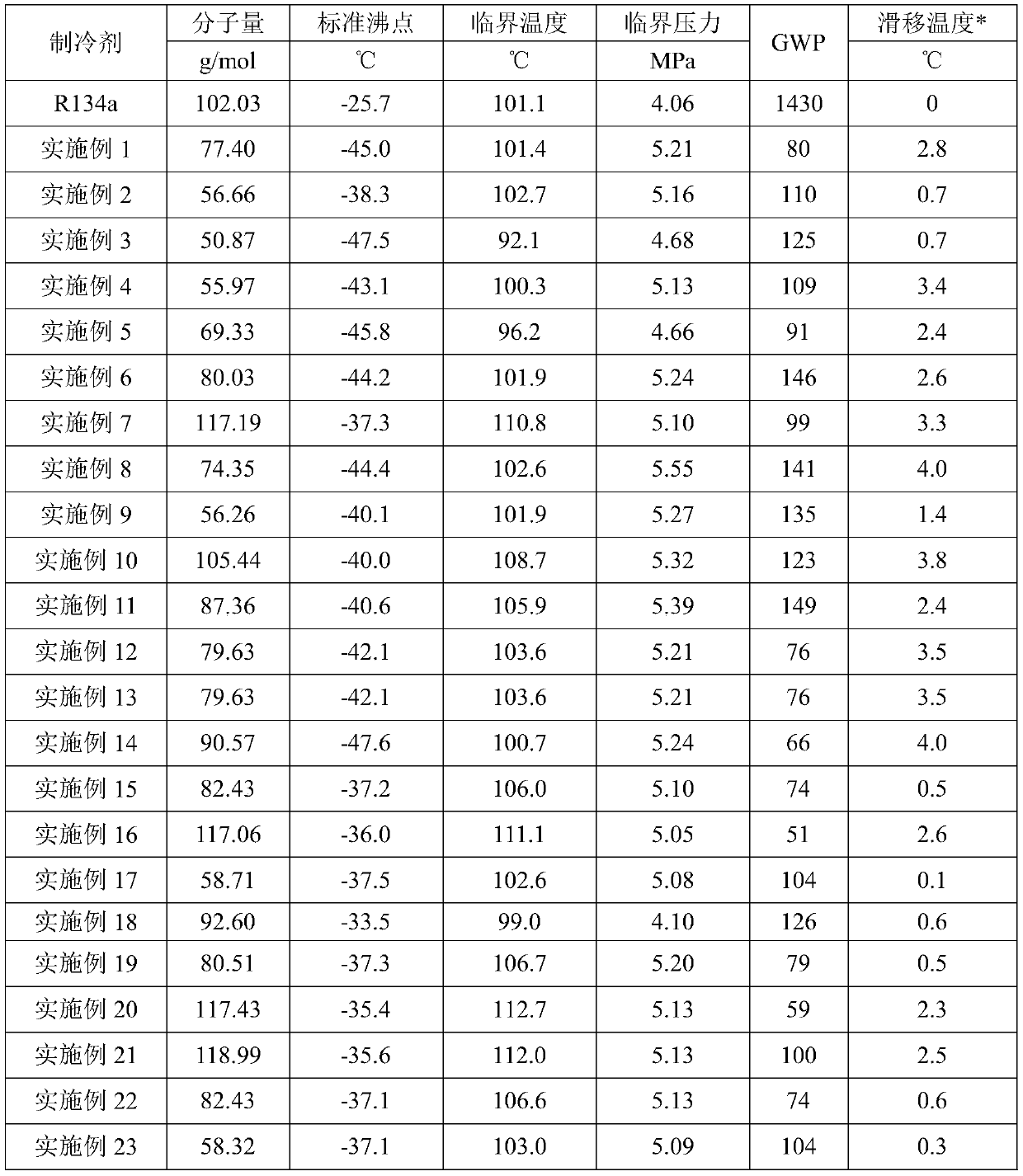

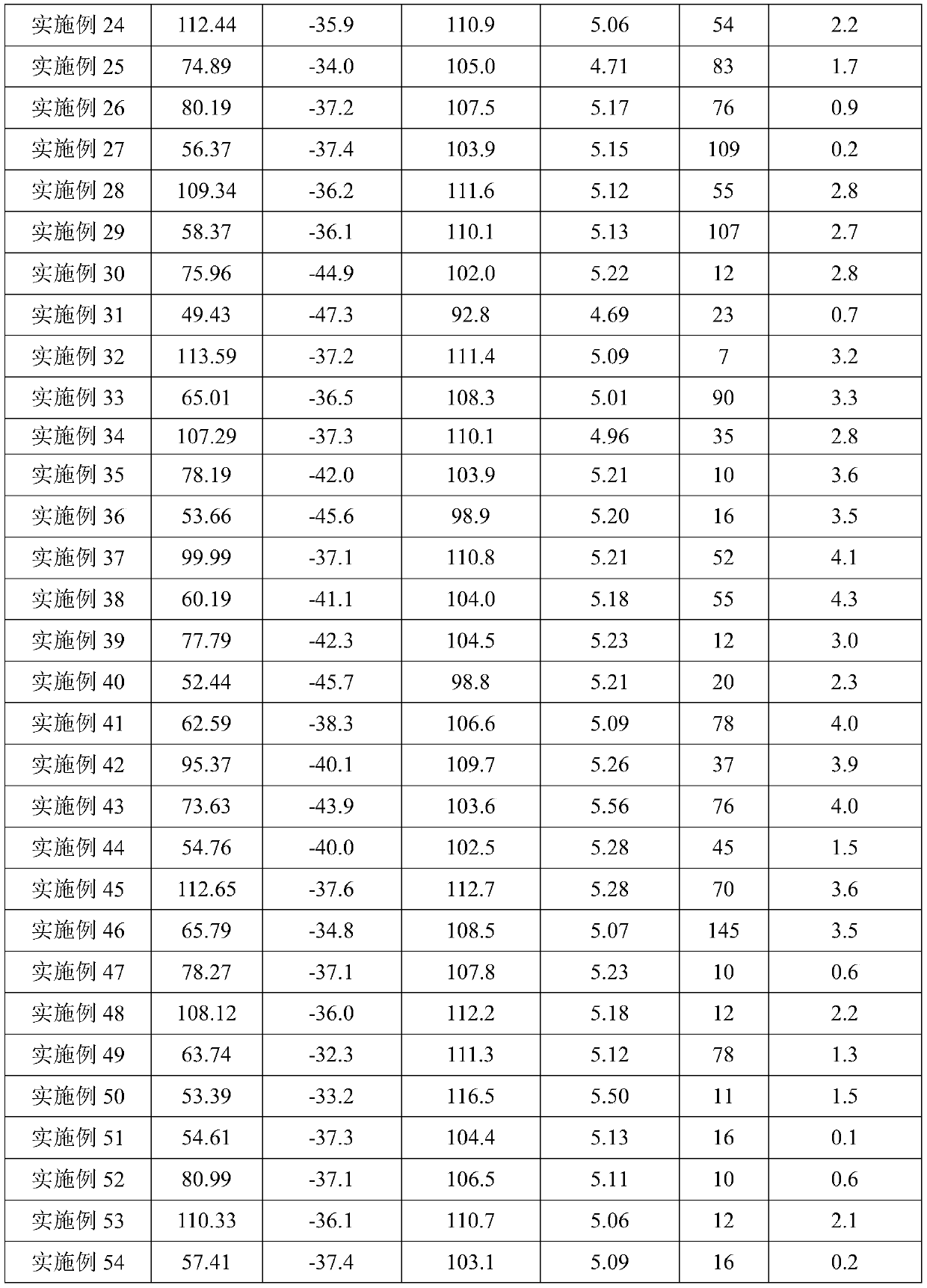

Method used

Image

Examples

Embodiment 1

[0030] The four components of trifluoroiodomethane (R13I1), fluoroethane (R161), tetrafluoroethane (R134a) and propylene (R1270) were subjected to a physical reaction in a liquid phase at room temperature at a mass percentage of 51:22:5:22. mixed as a refrigerant.

Embodiment 2

[0032] The four components of trifluoroiodomethane (R13I1), fluoroethane (R161), tetrafluoroethane (R134a) and propylene (R1270) were subjected to a physical reaction in a liquid phase at room temperature at a mass percentage of 14:76:9:1. mixed as a refrigerant.

Embodiment 3

[0034] The four components of trifluoroiodomethane (R13I1), fluoroethane (R161), tetrafluoroethane (R134a) and propylene (R1270) were subjected to a physical experiment in a liquid phase at room temperature at a mass percentage of 15:4:8:73. mixed as a refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com