Alloy steel fork center of asymmetrically welded three-throw turnout of I-shaped rail

A three-way switch and I-rail technology, applied in the track field, can solve the problems of poor integrity of asymmetric three-way turnout, heavy maintenance work, easy failure, etc., and achieve long service life, convenient surfacing and maintenance, and reduce wheel shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

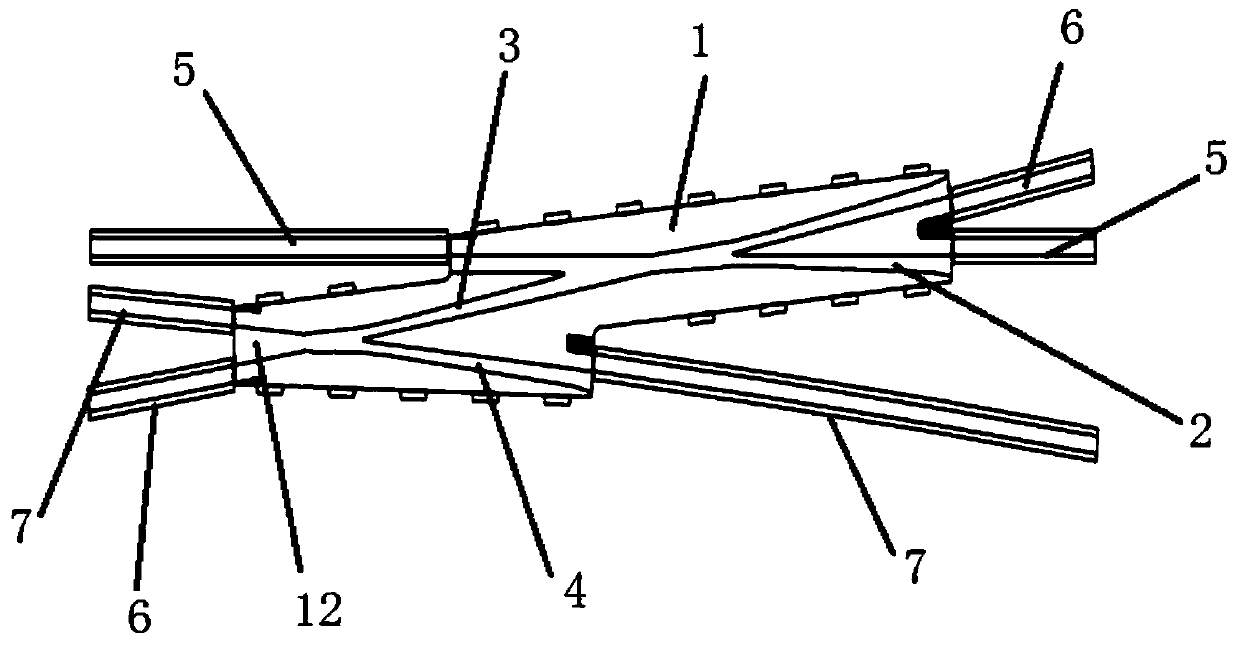

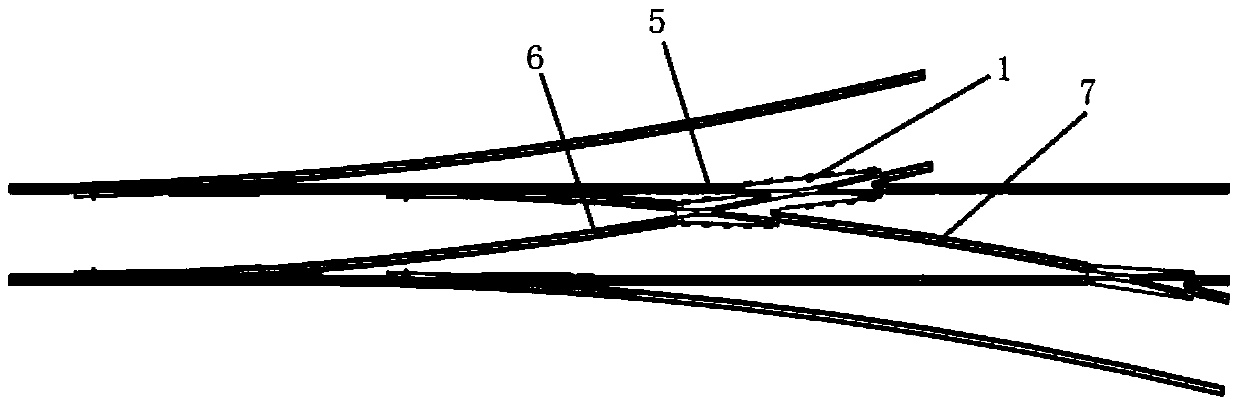

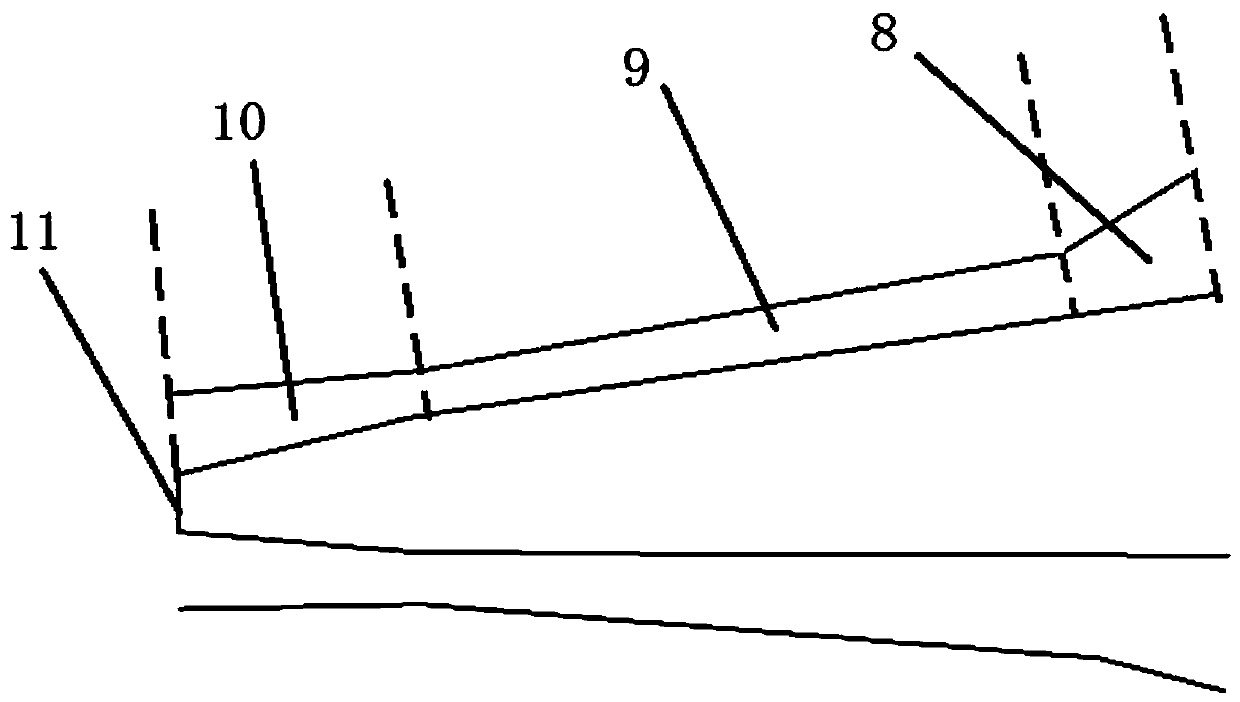

[0023] Such as Figure 1-3 As shown, the present invention provides an alloy steel fork center of an I-rail asymmetrically welded three-opening turnout, including a fork center block 1, and a fork center rim groove is opened on the fork center block 1, and the fork center track It includes straight rim groove 2, curved rim groove 1 3 and curved rim groove 2 4, the three-way turnout is an asymmetric structure, and the curved rim groove 2 4 is located at the front end of the curved rim groove 1 3 The straight rim groove 2 is on the same side, the curved rim groove 2 4 intersects with the curved rim groove 1 3 at the front of the fork block 1 to form the first fork center part, and the curved rim groove A 3 intersects with the straight rim groove 2 to form a second fork at the rear of the fork block 1 . This structure can be applied to the fork center of various asymmetric three-way turnouts. It has good integrity, and the number of components is only one fork center block. It h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap