Cross country vehicle and vehicle door hinge assembly thereof

A technology for door hinges and off-road vehicles, which is applied to door/window accessories, hinges with pins, wing leaf parts, etc. It can solve the problems of large door hinges, prone to fatigue fracture, and affecting the appearance quality of vehicles, etc., to achieve rapid assembly , Improve the effect of maintenance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

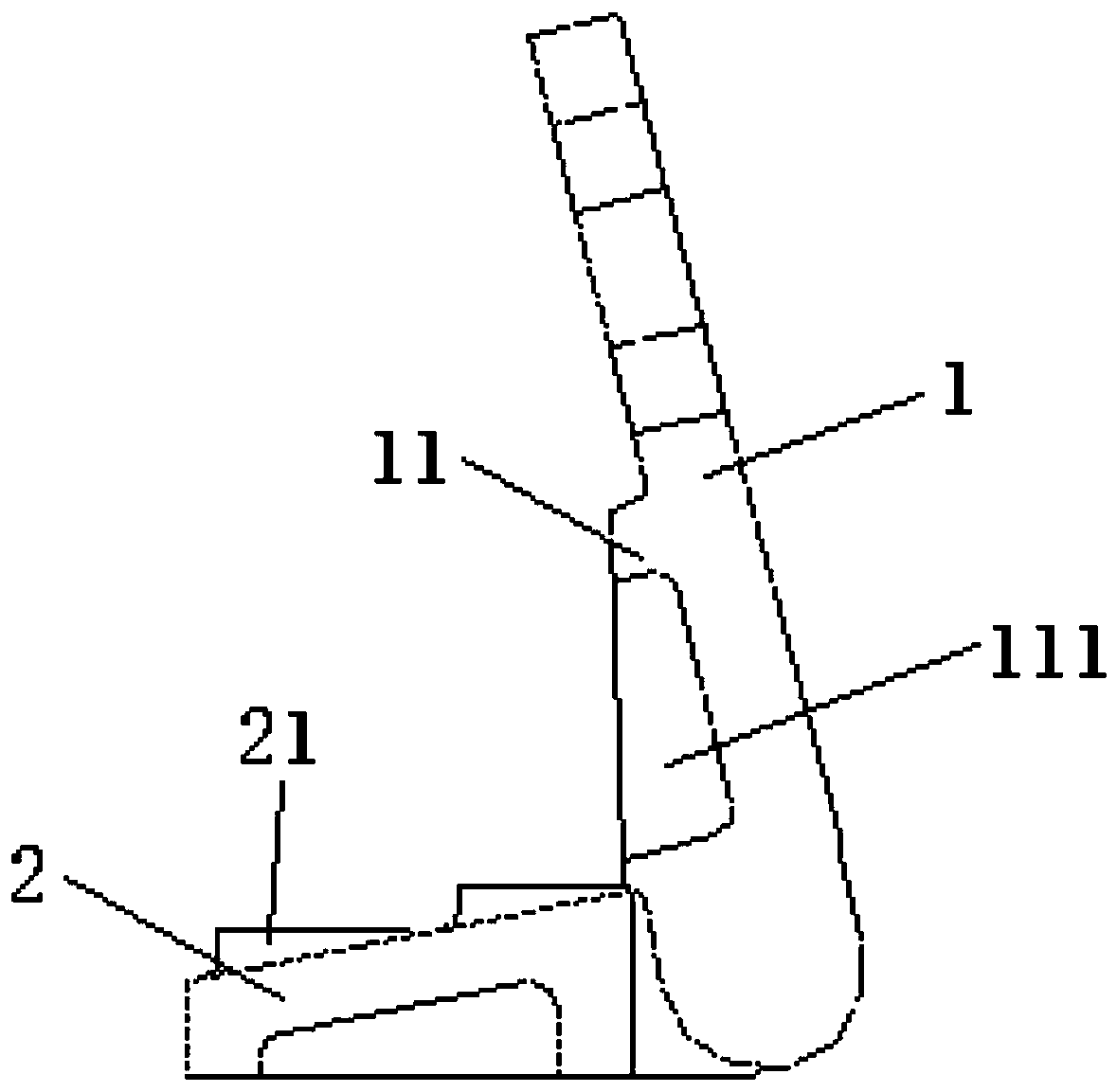

[0038] In a specific embodiment, the door hinge assembly 300 provided by the present invention is used in off-road vehicles, especially on special off-road vehicles with relatively harsh working environments, so as to realize quick disassembly and assembly of the vehicle door 200 and ensure that the vehicle door 200 has a high Strength and toughness, so that special off-road vehicles can be used in high-temperature, high-cold and high-impact environments.

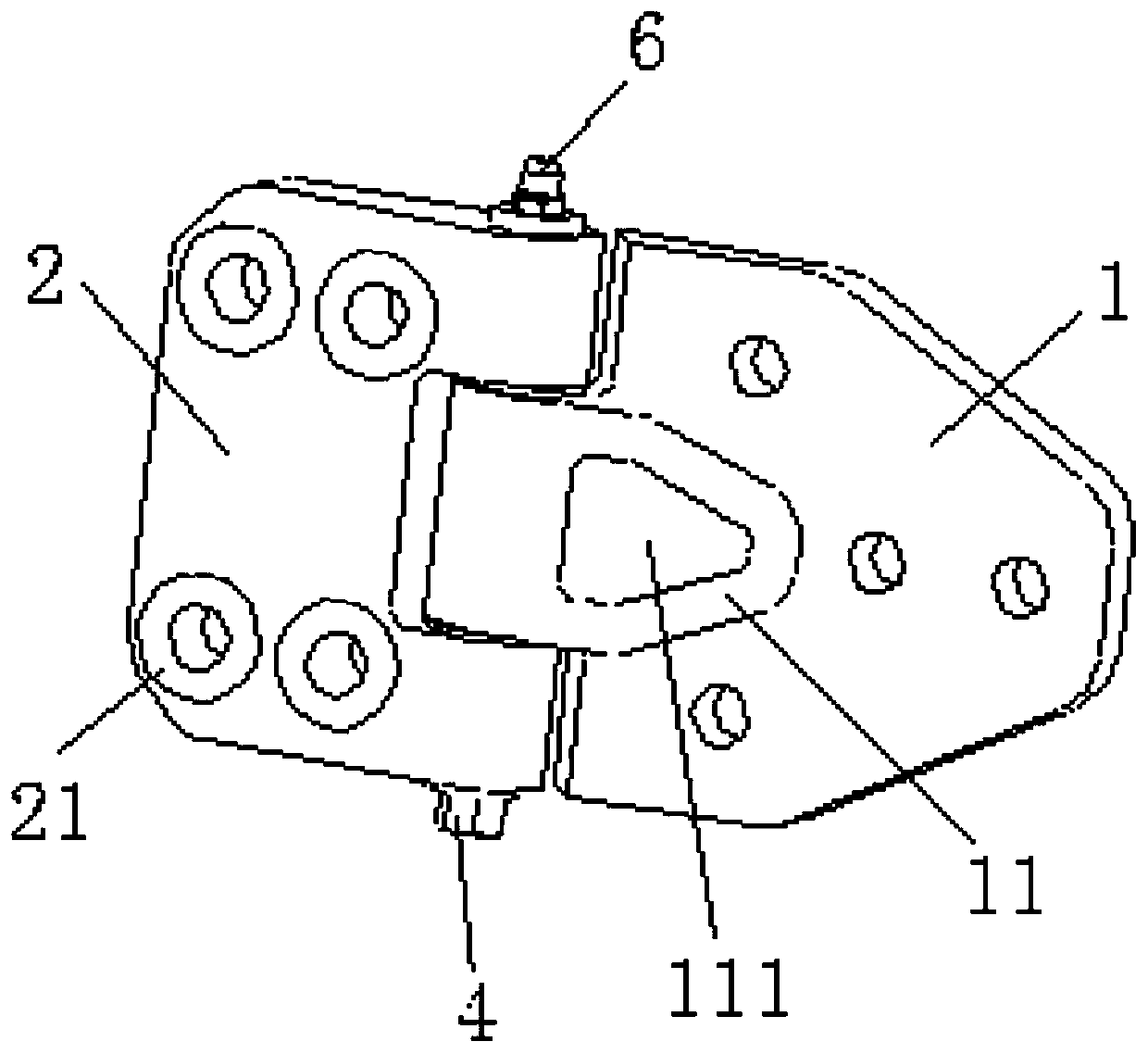

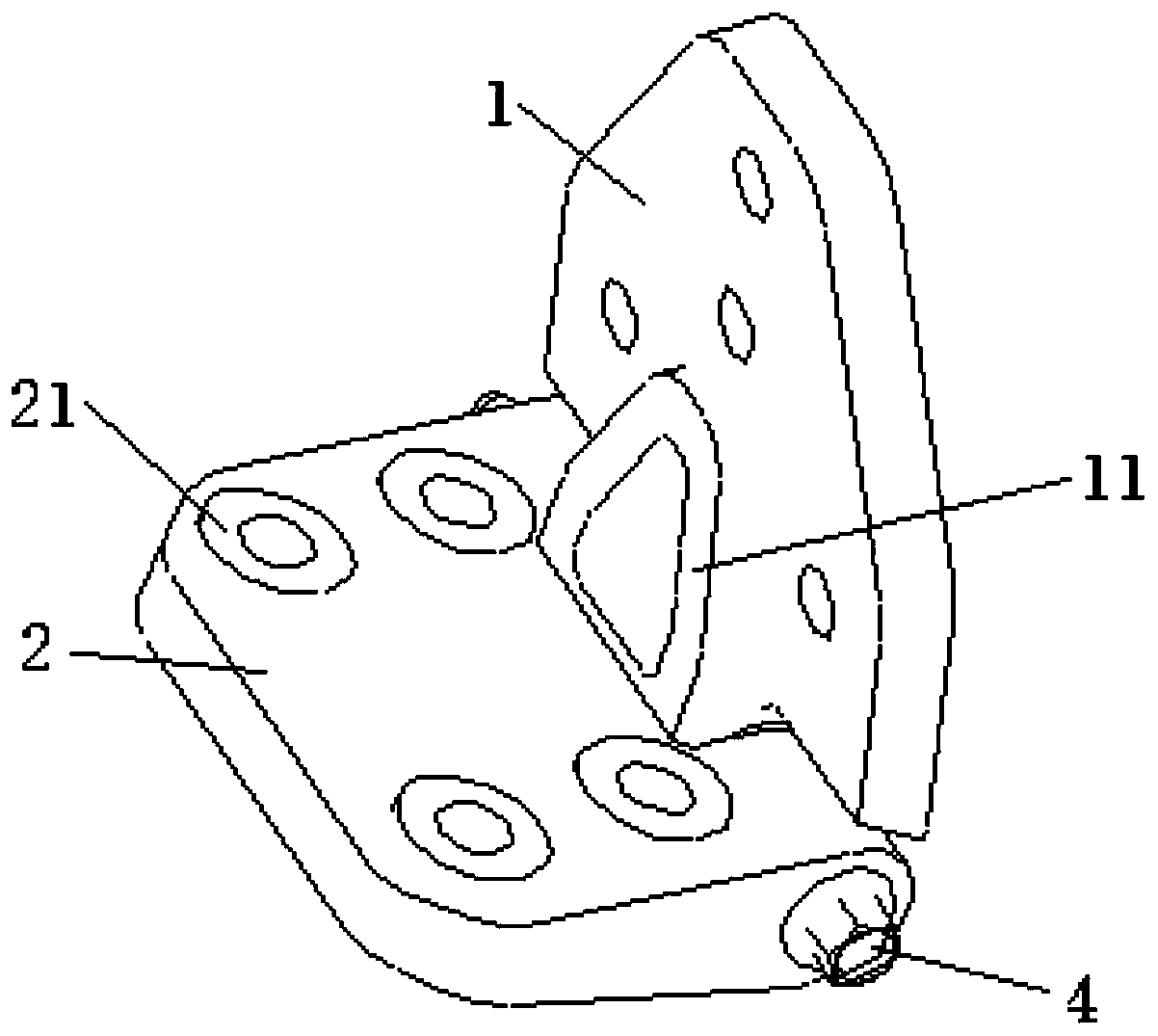

[0039] like Figure 1-9 As shown, the door hinge assembly 300 includes a first hinge 2, a second hinge 1 and a rotating connector; wherein, the first hinge 2 is fixedly mounted on the body 100 of the off-road vehicle, and the second A hinge plate 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com