Steel pipe piece for tunnel convenient to be spliced

A technology for steel pipes and tunnels, which is applied in the field of steel pipe sheets and steel pipe sheets for tunnels, and can solve problems such as loosening and falling off, rust on welds, and many steel pipe sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

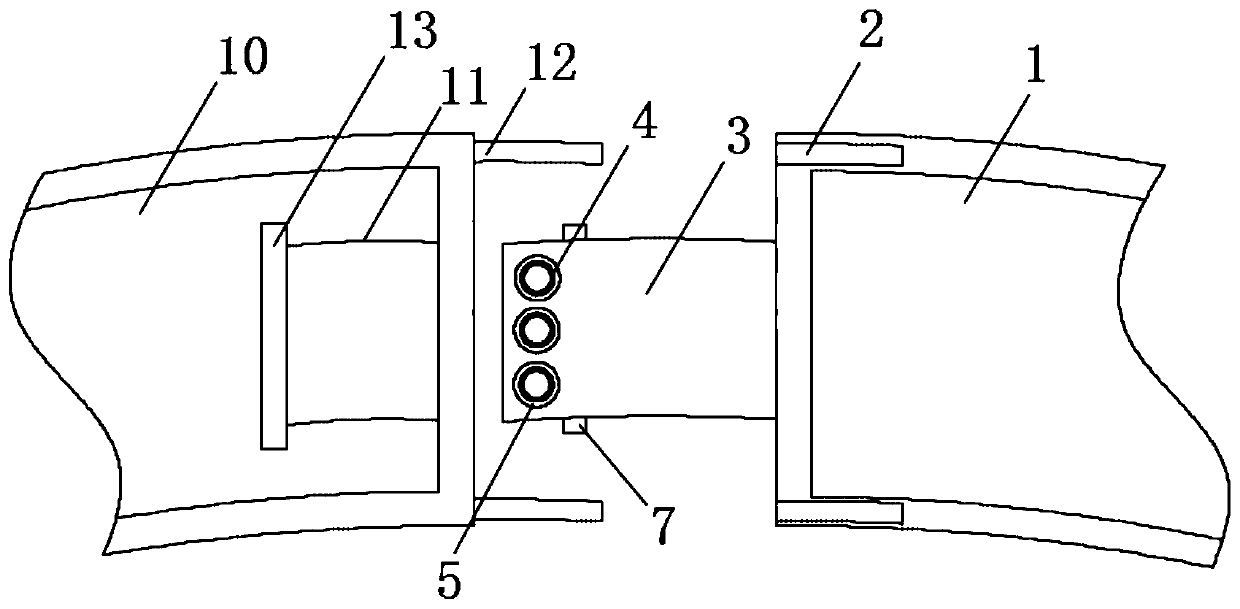

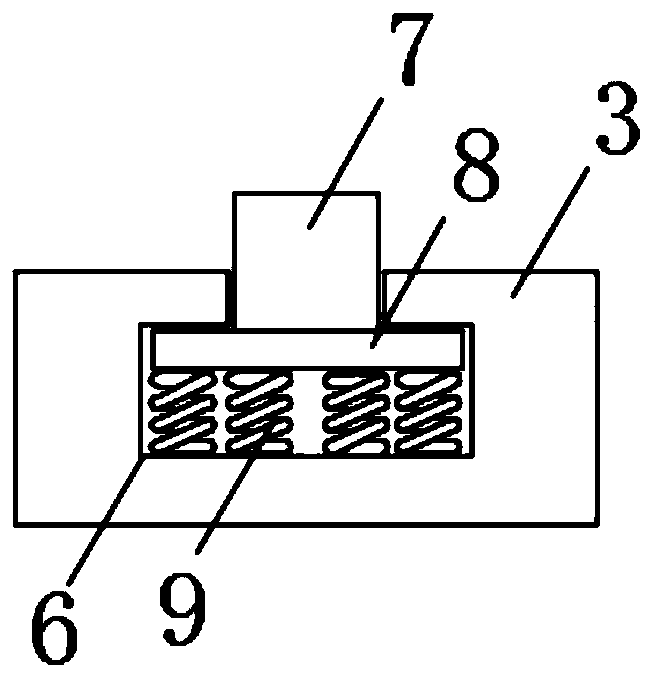

[0017] Such as Figure 1-2 As shown, a steel pipe sheet for tunnels that is convenient for splicing includes No. 1 steel pipe sheet 1, the top and bottom of the No. There is an interspersed block 3, which is located on the other side of the No. 1 steel pipe sheet 1, and a number of bolt connection grooves 4 are dug out. The top and bottom of the interspersed block 3 are provided with spring grooves 6 inside the two spring grooves 6. Both spring connecting blocks 7 are inserted, and one end of the two spring connecting blocks 7 located in the spring groove 6 is fixedly connected with a spring limiting plate 8, and there is a spring limiting plate 8 between the bottom of the spring limiting plate 8 and the bottom of the spring groove 6. A plurality of pressure springs 9, the No. 1 steel pipe piece 1 is interspersed and connected with the block limiting block 11 in the No. Bolts 5 are interspersed and connected, and the top and bottom ends of the clamping block limiting block 11...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap