Holding frame, bearing and assembling method

An assembly method and cage technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems affecting bearing cleanliness, plastic deformation, material loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

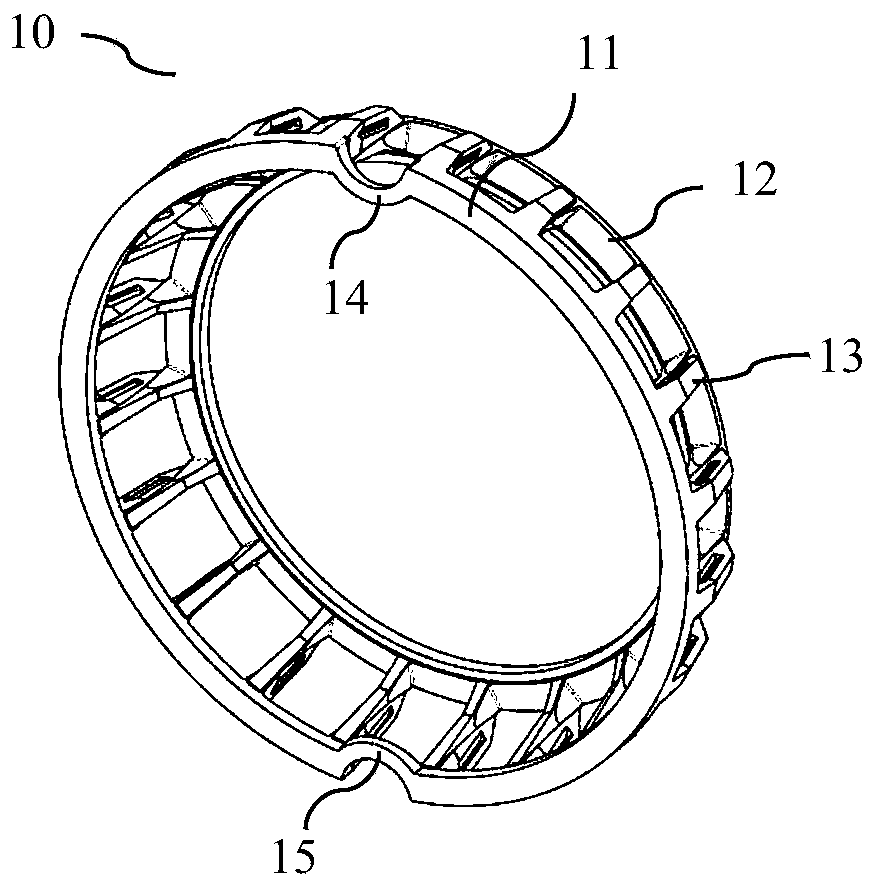

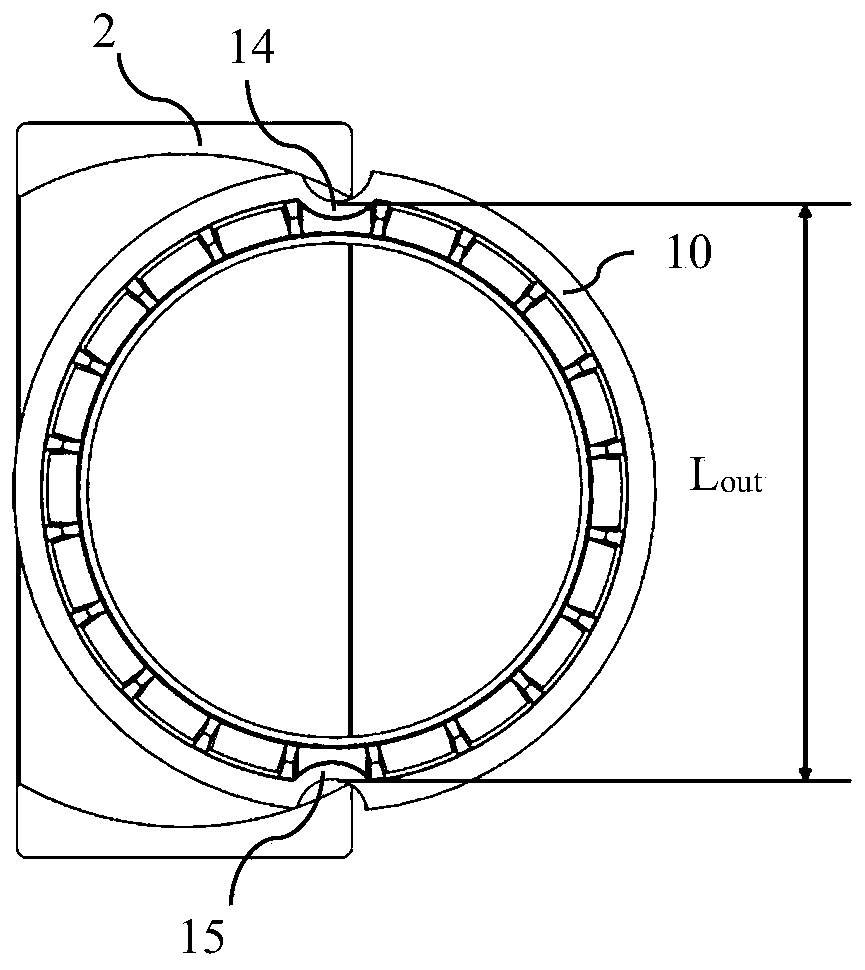

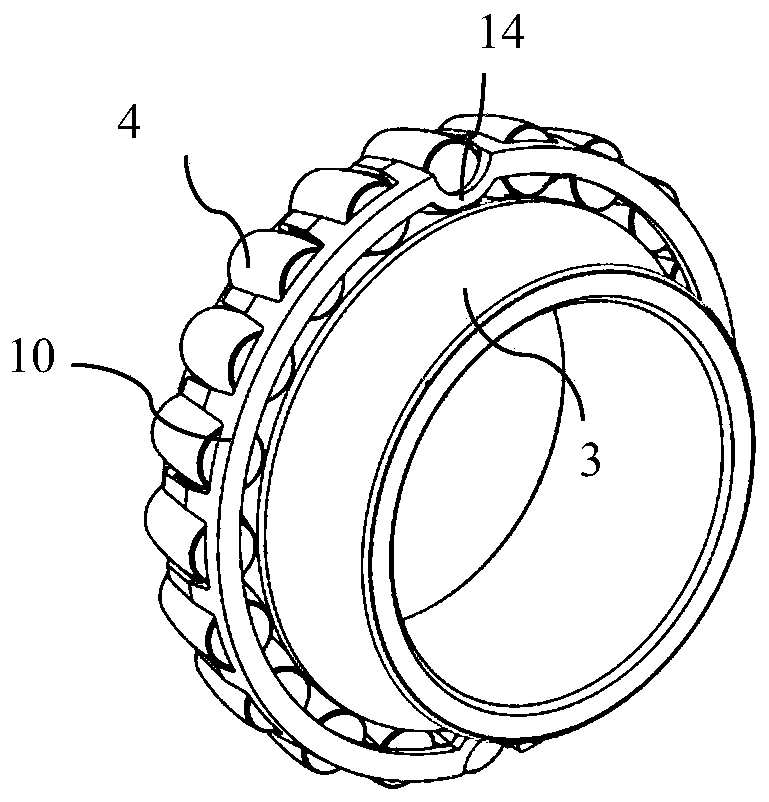

[0039] Figure 1 to Figure 4 A cage 10 according to a first embodiment of the invention is shown. In this embodiment, the cage 10 is used for a spherical roller bearing. The spherical roller bearing also includes at least an outer ring 2 , an inner ring 3 and rolling elements 4 .

[0040] figure 1 A perspective view of the cage 10 according to the first embodiment is shown. like figure 1 As shown, the cage 10 is designed as a window cage, which comprises two substantially ring-shaped and coaxially arranged ring parts, namely a large-diameter ring part 11 with a larger diameter and a small-diameter ring part with a smaller diameter. part 12, the cage 10 also includes a plurality of connecting parts 13 uniformly distributed in the circumferential direction, and the connecting part 13 connects the two annular parts 11, 12. The two ring parts 11 , 12 and the two adjacent connecting parts 13 enclose a pocket for guiding the rolling bodies. In this embodiment, the number of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com