Air cooling device with water cooling

An air-cooling device and water-cooling technology, which is used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of lack of rationality of cooling water, low cooling efficiency, low stability, etc. The effect of improving heat exchange efficiency and extending the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

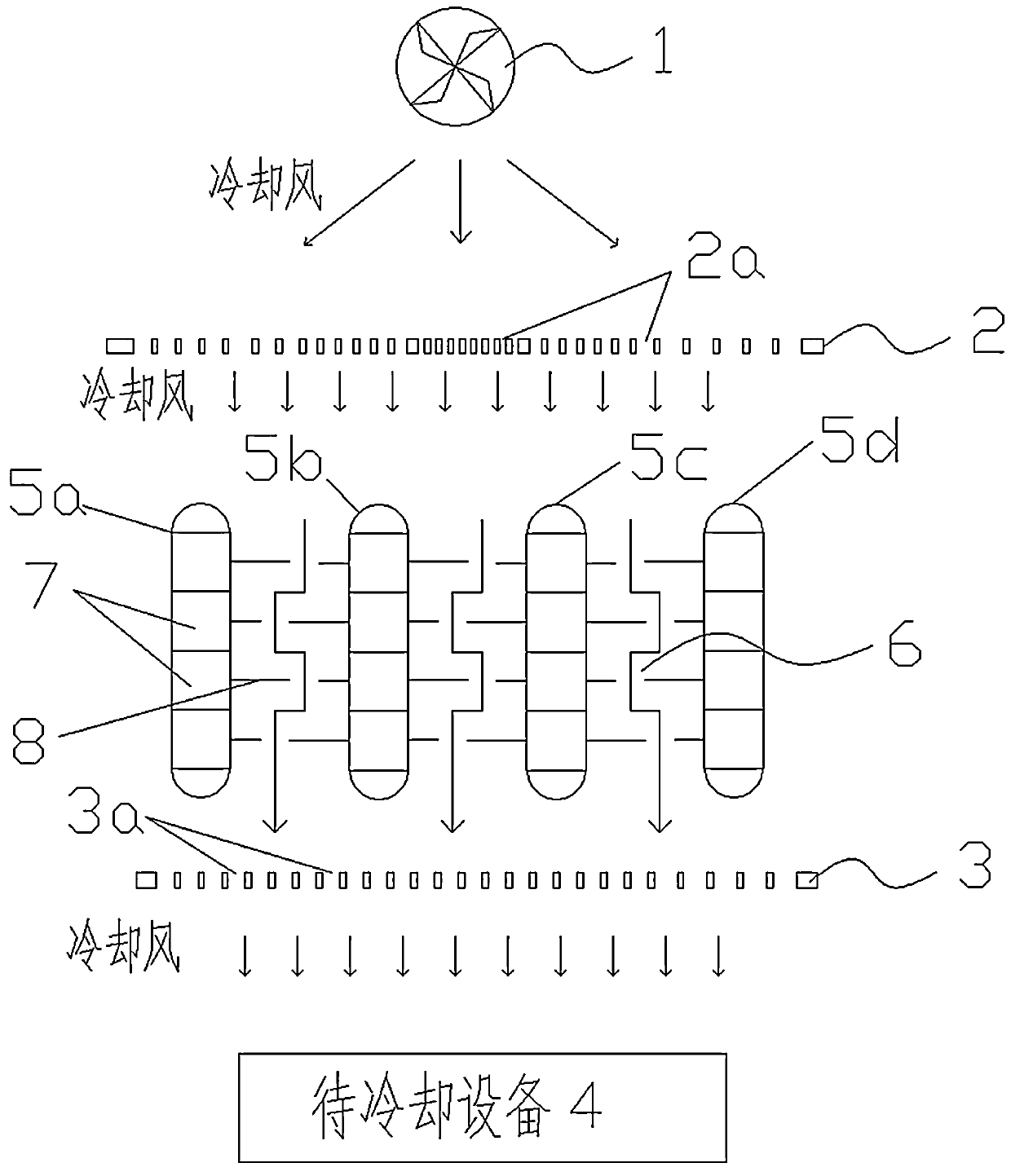

[0018] Such as figure 1 As shown, the present invention provides an air-cooled device with water cooling, including a cooling fan 1, an upper ventilation plate 2 and a lower ventilation panel 3 are arranged below the cooling fan 1 in turn, and the upper ventilation plate 2 is provided with a set of upper ventilation slots 2a , the lower ventilation plate 3 is provided with a set of lower ventilation grooves 3a, the width of each upper ventilation groove 2a gradually widens from the middle to both sides, and the width of each lower ventilation groove 3a is consistent with each other; the cooling equipment 4 is arranged at the outlet of the lower ventilation groove 3a below.

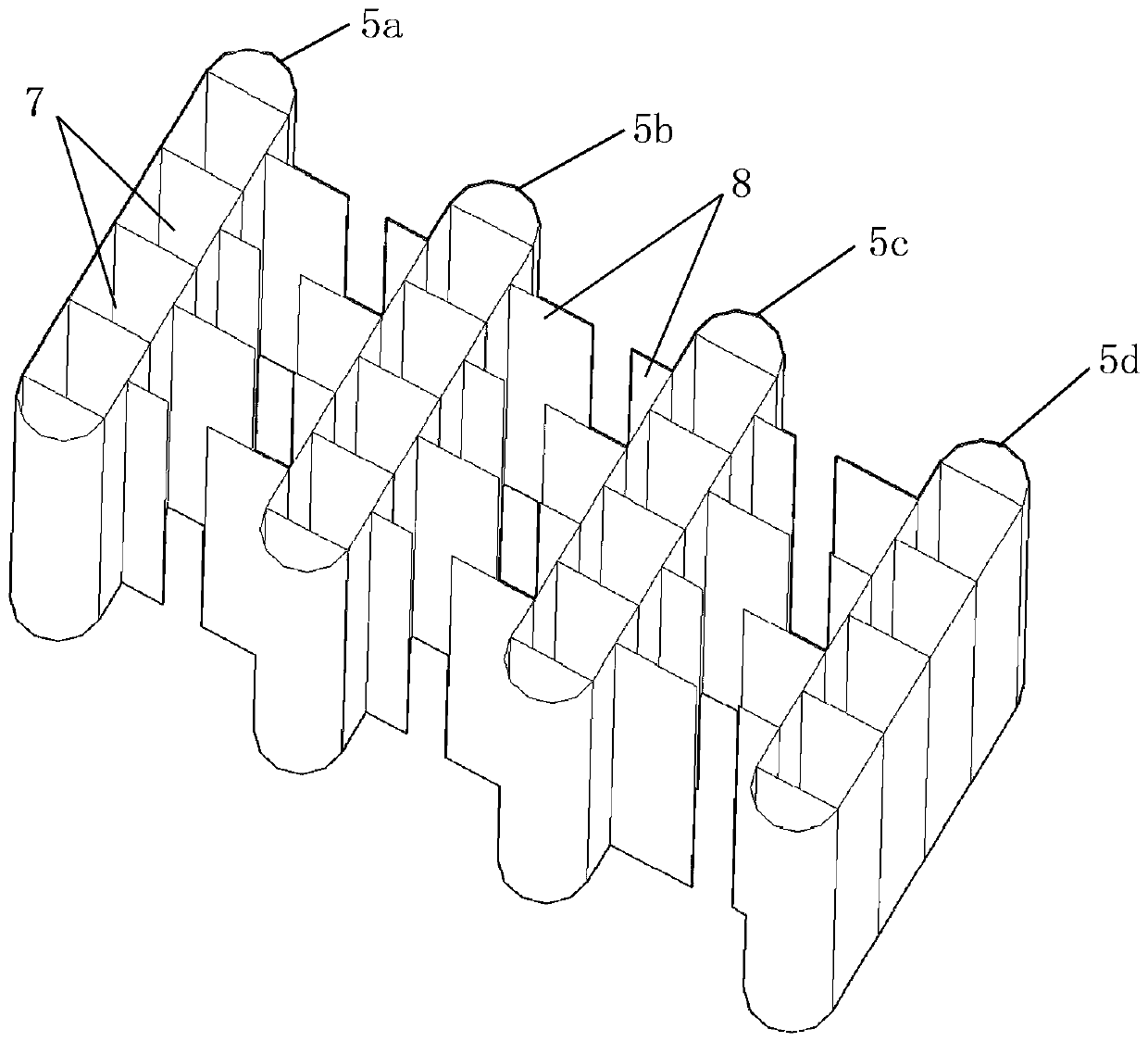

[0019] A group of vertical water-cooled heat exchangers are arranged in parallel between the upper ventilation plate 2 and the lower ventilation plate 3. In this embodiment, the first water-cooled heat exchanger 5a, the second water-cooled heat exchanger 5b, and the third water-cooled heat exchanger 5c an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap