Reversing brake device of DC electric tool switch and DC electric tool switch

A brake device and electric tool technology, which is applied in the field of electric switches, can solve problems such as arcing and sparking of reversing shrapnel, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

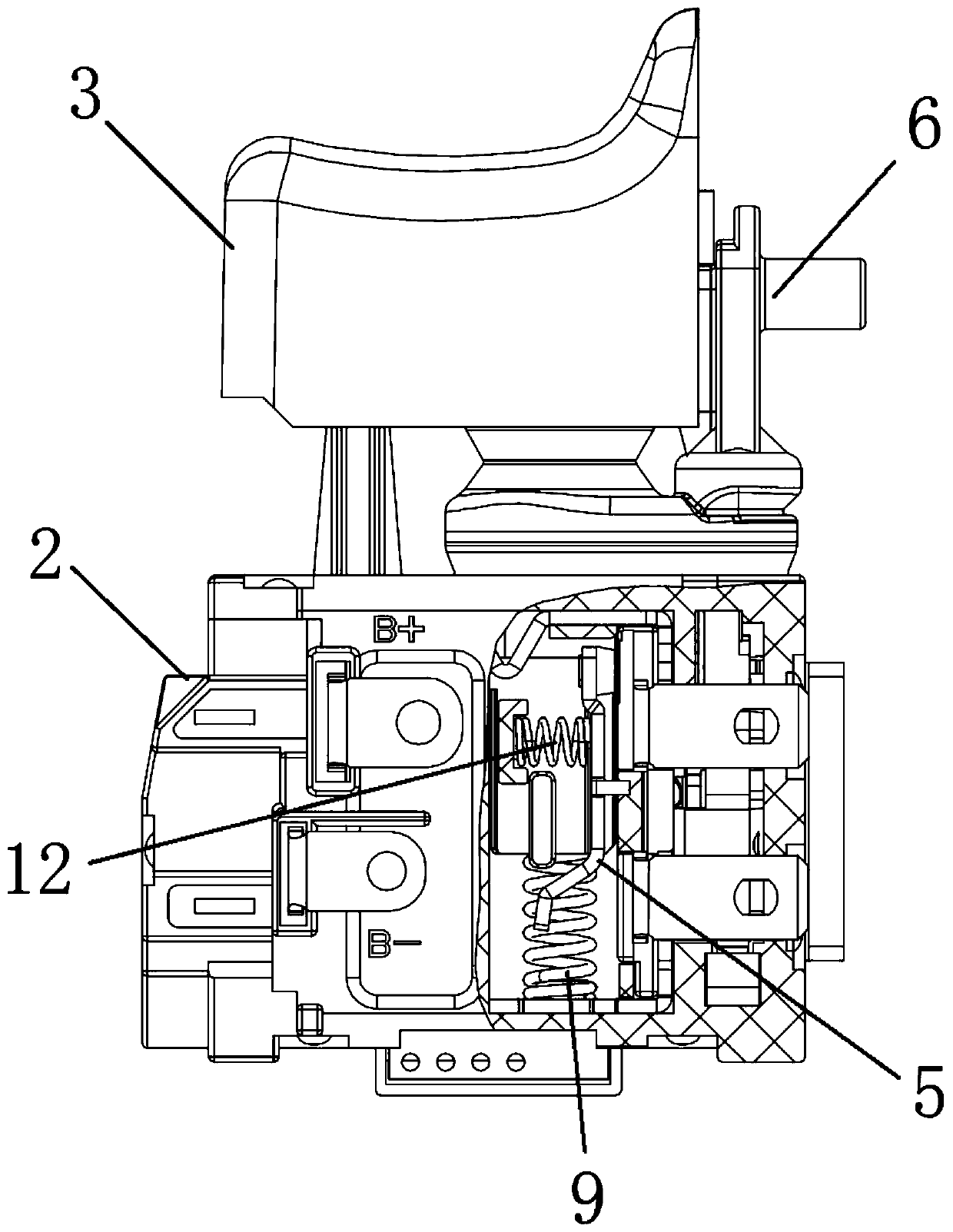

[0067] This embodiment provides a reversing braking device 1, such as image 3 As shown, it includes a housing 2 , a switch button 3 , a movable rod 24 , a reversing device 4 and a brake moving contact 5 . The reversing device 4 may have the same structure as the prior art, that is, by rotating the reversing rod 6, the direction in which the current enters the motor 7 is switched, so that the forward and reverse directions of the motor 7 are switched.

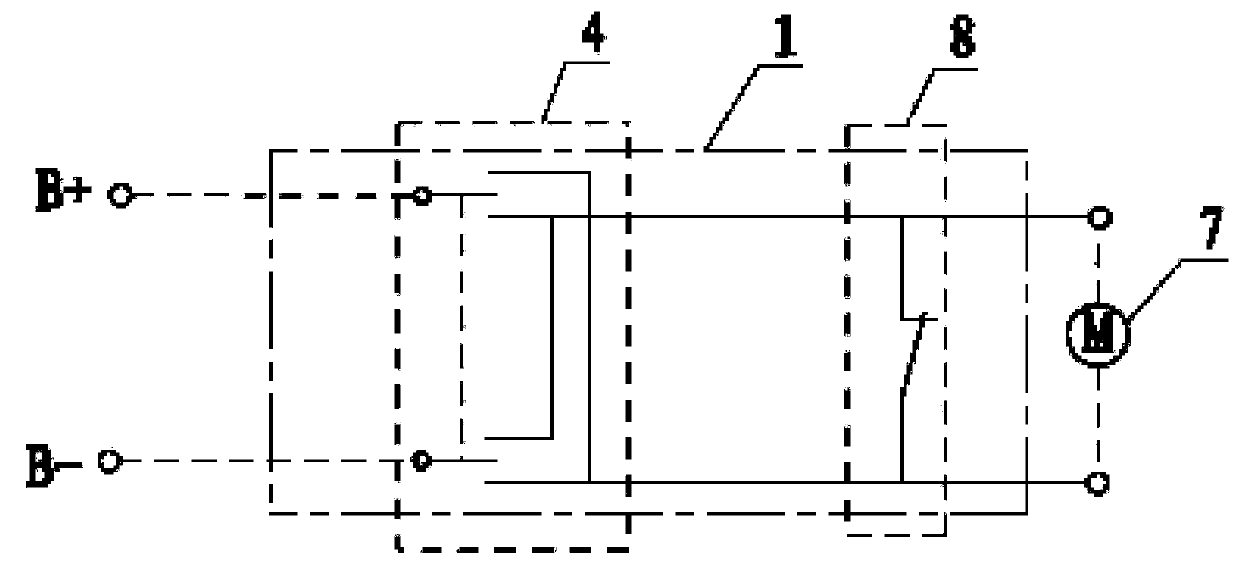

[0068] like figure 1 As shown, in the circuit schematic diagram of the reversing braking device, the reversing device 4 is connected between the motor 7 and the DC power supply, and the direction of the current entering the motor 7 is changed by switching. The two electrical connection ends of the braking device 8 are directly electrically connected to both ends of the motor 7 respectively, and the braking device 8 is in a closed state and forms a closed loop with the motor 7 .

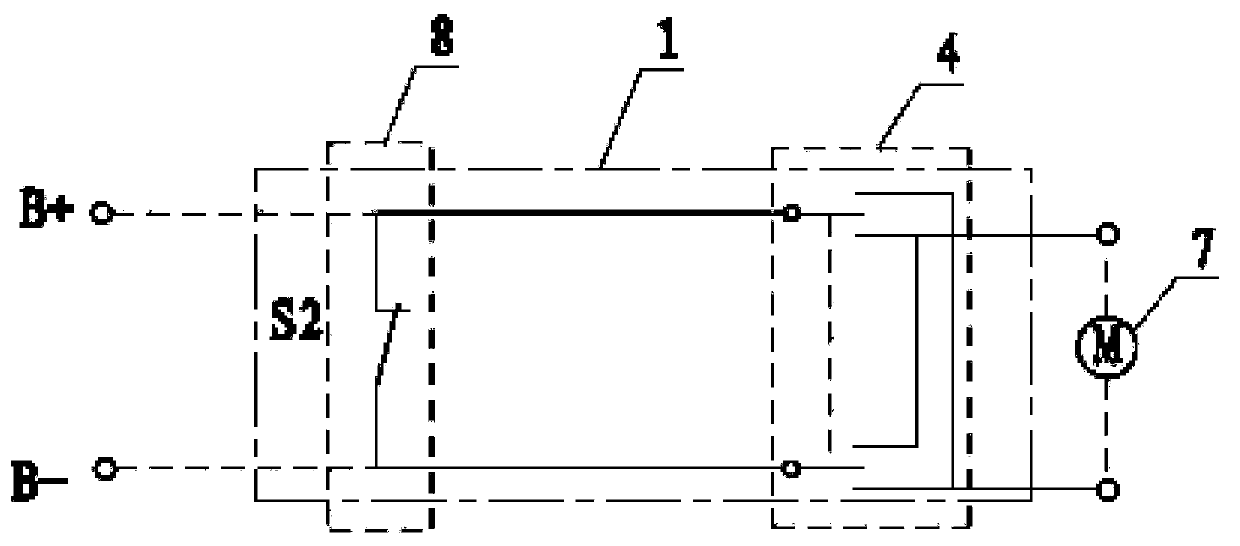

[0069] like figure 2 As shown, it is the cir...

Embodiment 2

[0079] This embodiment provides a reversing braking device 1, such as Figure 8 As shown, it includes a housing 2 , a switch button 3 , a movable rod 24 , a reversing device 4 and a brake moving contact 5 . Most of its structure is the same as that of the reversing brake device of the first embodiment, and the circuit principle of the reversing brake device is also the same as that of the first embodiment. The difference is that the brake moving contact 5 in this embodiment is slidably arranged in the switch housing 2 .

[0080] like Figure 9 As shown, the brake moving contact 5 of this embodiment includes: a first contact 13 , a second contact 21 and a connecting ring 22 . The first contact 13 is located on the top of the brake moving contact 5, and is used for electrical connection with the first contact point 10 when the brake device 8 is in the closed state; the second contact 21 is located on the brake moving contact The bottom of the head 5, when the brake device 8 i...

Embodiment 3

[0085] This embodiment provides a reversing braking device 1, such as Figure 15 As shown, it includes a casing 2 , a switch button 3 , a movable rod 24 , a reversing device 4 and a brake moving contact 5 . Most of its structure is the same as that of the reversing braking device of the first and second embodiments, and the circuit principle of the reversing braking device is also the same as that of the first and second embodiments. The braking contact 5 of this embodiment is also slidably arranged in the switch housing 2 as in the second embodiment, the difference lies in the shape of the braking contact 5 of this embodiment, and the matching with the braking contact 5 Other structures have been improved.

[0086] like Figure 16 As shown, the brake moving contact 5 of this embodiment includes: a first contact 13 , a second contact 21 and a connecting piece 25 . The first contact 13 is located on the top of the brake moving contact 5, and is used for electrical connection w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com