Conversion valve capable of achieving switching between cross and tee

A switching valve, three-way technology, applied in the field of switching valve, can solve the problems of high control time accuracy, increase system parts and costs, improve system uncertainty, etc., to achieve full market competitiveness, simple structure, simplification The effect of the control strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

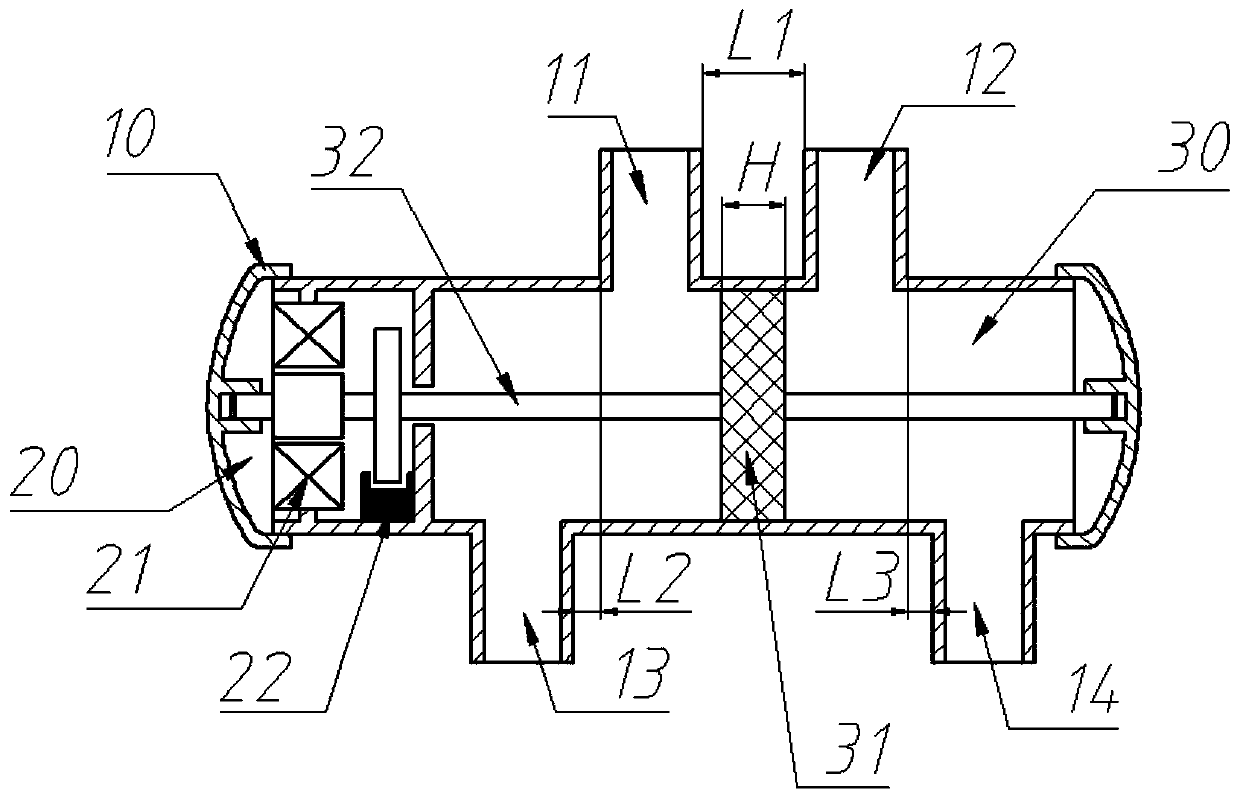

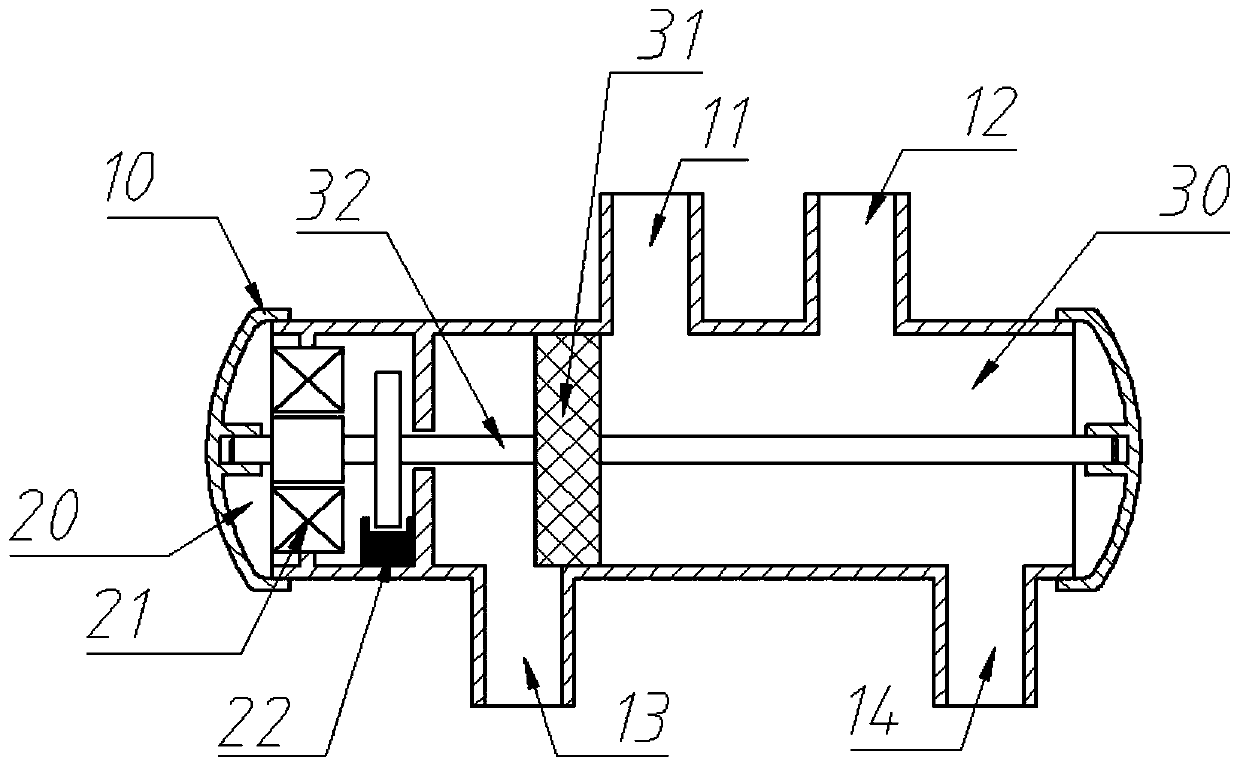

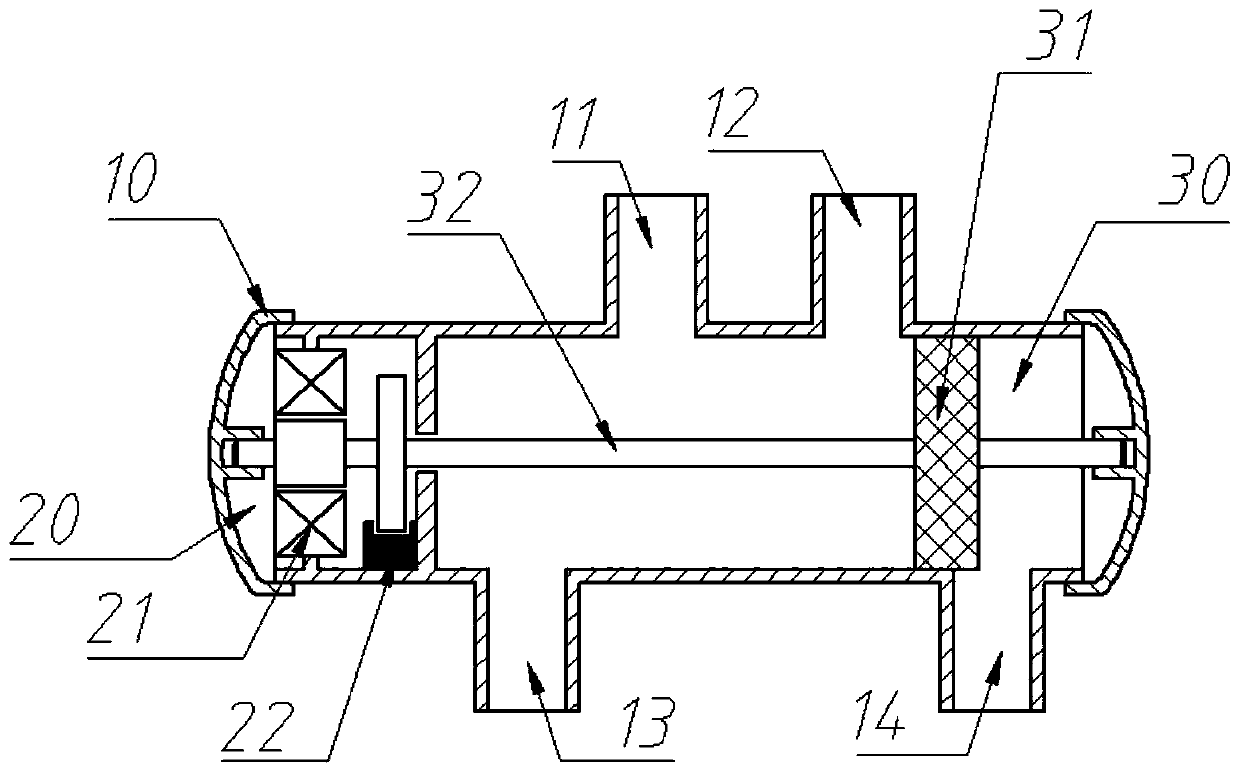

[0025] Such as figure 1 As shown, it is a cross-sectional view of a switching valve capable of switching between four-way and three-way according to the present invention.

[0026] The switching valve includes a cylinder body 10 , a slide valve 30 disposed in the cylinder body 10 and a control assembly 20 for controlling the slide valve 30 to move left and right or stop. The control part 20 includes a drive part 21 for controlling the left and right movement of the spool valve 30 and a stop part 22 for controlling the stop of the spool valve 30;

[0027] The driving part 21 is a stepping motor, and the slide valve 30 includes a spool 31 that can move left and right, and a screw rod 32 that controls the movement of the spool 31 . The screw 32 is controlled to rotate in different directions through the transmission of the stepping mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com