Conductive assembly structure of wire connecting device

A technology for connecting conductive components and wires, which is applied to the parts of connecting devices, contact parts, electrical components, etc. It can solve the problems of insufficient force to suppress the wires, affect the conductive contact area and conductive efficiency, and the pressing is not stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

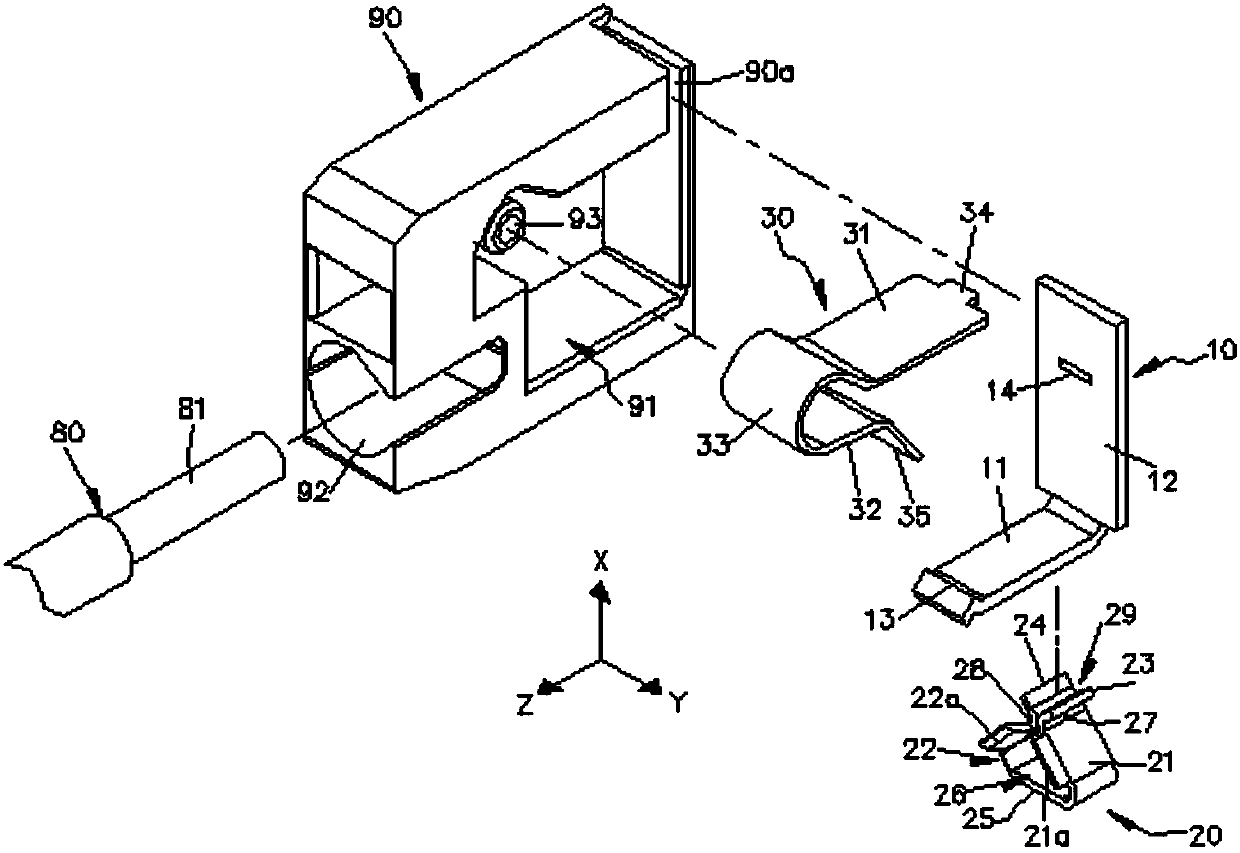

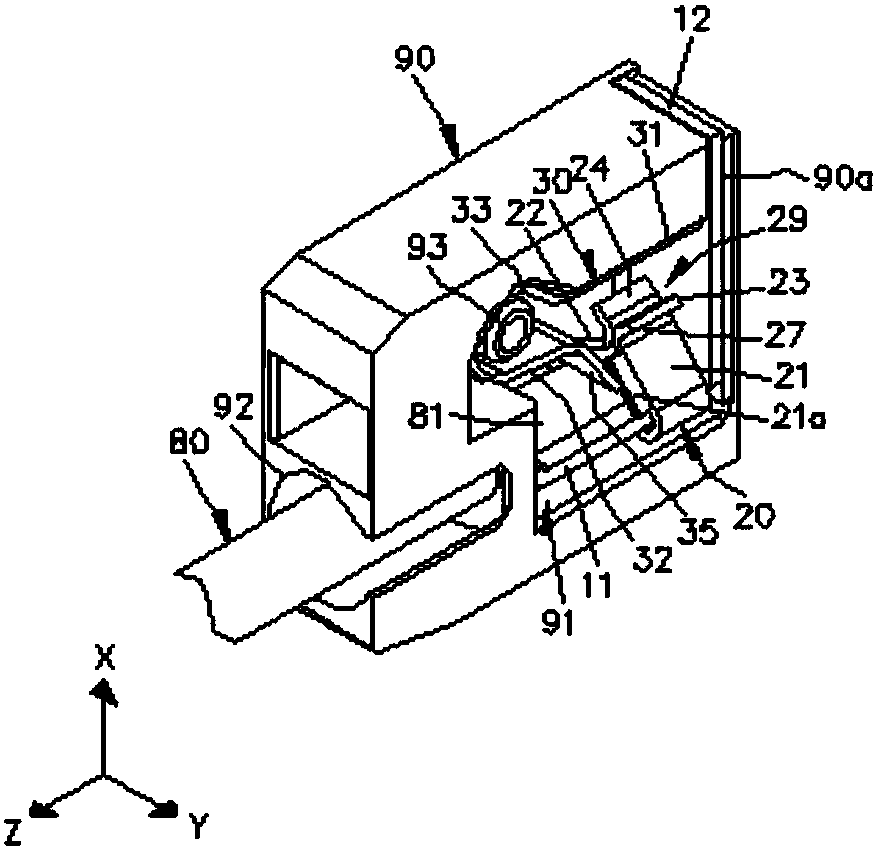

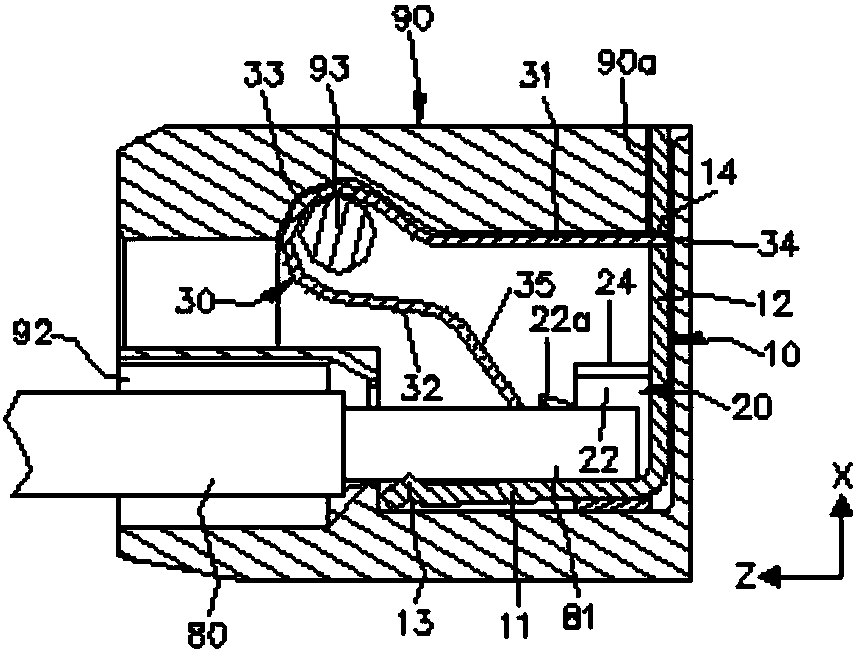

[0040] see figure 1 , figure 2 and image 3 , figure 1 It is an exploded perspective view of the three-dimensional structure of the conductive component according to an embodiment of the present invention; it shows the structural situation of the shell, the main body of the conductive component, the metal shrapnel, and the limiting body. figure 2 It is a schematic diagram of the three-dimensional structure combination of the present invention. image 3 for figure 2 A schematic diagram of a planar structure; showing the structural coordination of the body, metal shrapnel, limiting body and wires. Such as figure 1 , figure 2 and image 3As shown, the conductive assembly structure of the wire connection device of the present invention includes a combination of a body 10 and a limiting body 20 . Conductive components (or body 10, limiting body 20) are defined with X-direction reference axis, Y-direction reference axis and Z-direction reference axis which are perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com