Concrete pump pipe washing device and method

A technology for concrete pump pipes and cleaning devices, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., which can solve problems such as complicated and cumbersome cleaning procedures, pollution on the cleaning site, and long cleaning time, so as to prevent splashing Injury, short cleaning time, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

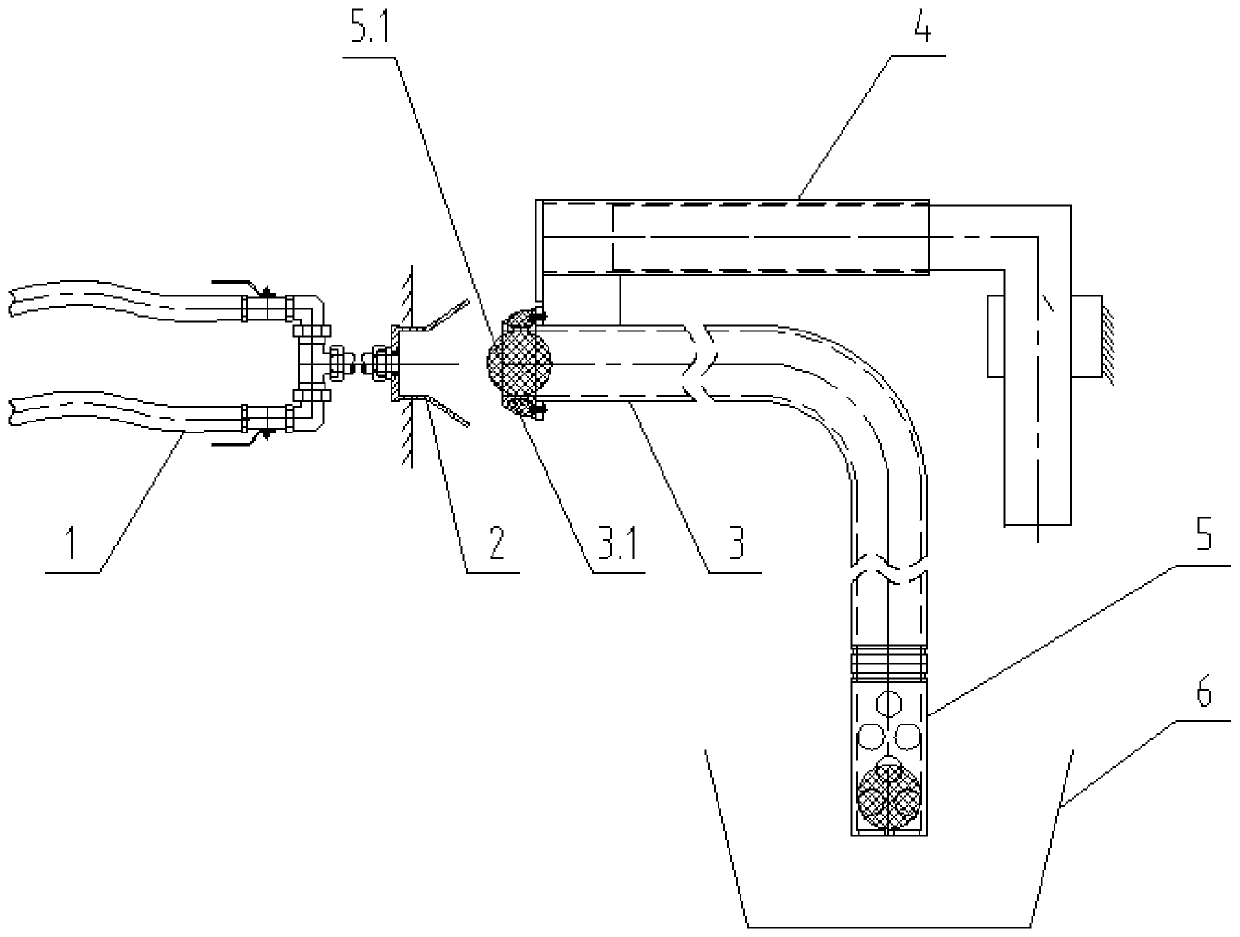

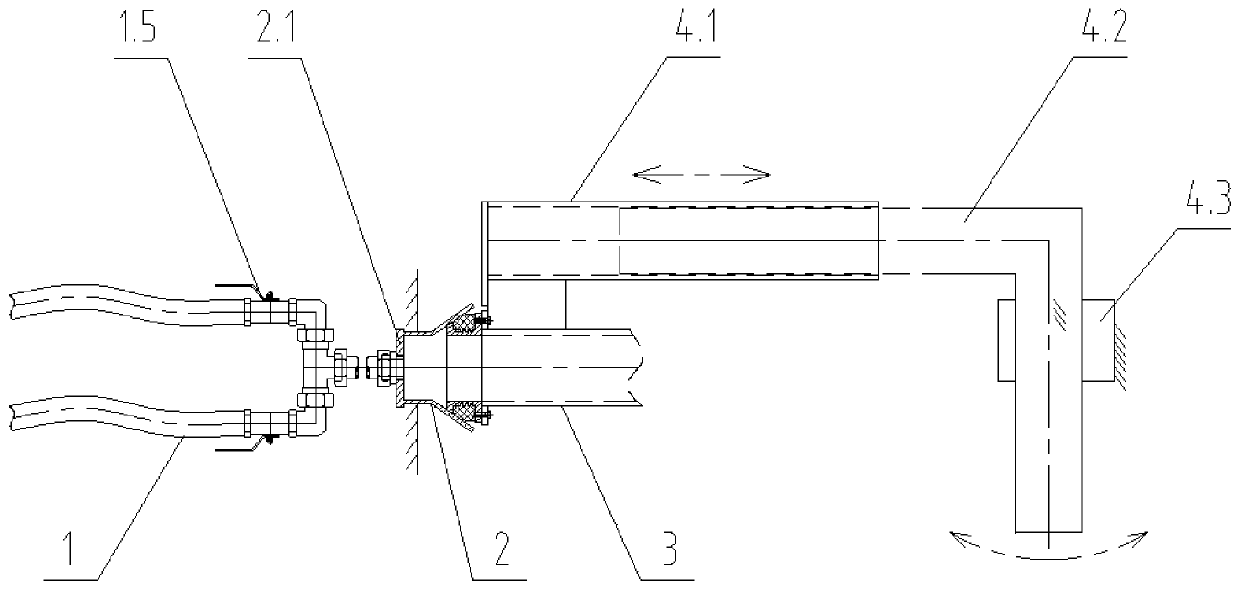

[0034] see Figure 1 to Figure 6 , a concrete pump pipe cleaning device includes a cleaning feed pipe group 1, a receiving end 2, a pump pipe 3, a movable arm 4, a cleaner recovery device 5 and a collection device 6; the cleaning feed pipe group 1 and the receiving end 2 The input end is connected; the output end of the receiving end 2 is sealed and connected with the output end of the pump tube 3; the pump tube 3 is installed on the movable arm 4, and the movable arm 4 is used to drive the pump tube 3 to move; the cleaner recovery device 5 is arranged on The input end of the pump pipe 3 is used to recover the cleaner coming out of the pump pipe; the collection device 6 is arranged at the input end of the pump pipe 3 to receive the concrete washed out of the pipeline.

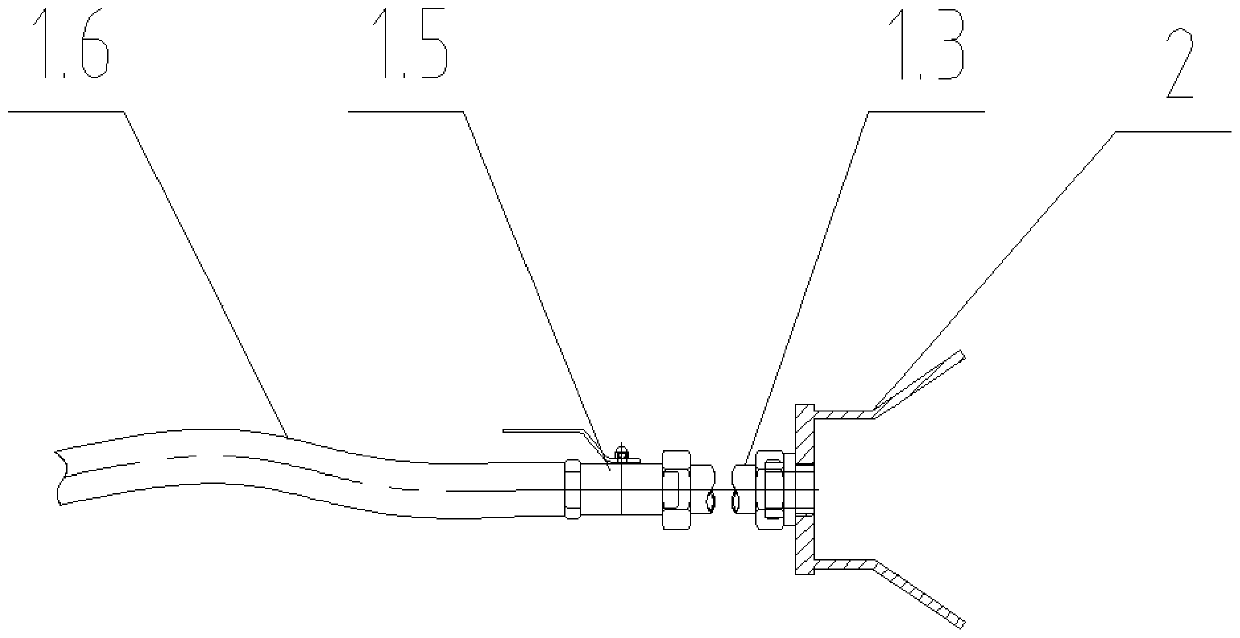

[0035] The cleaning feeding pipe group 1 includes a liquid inlet pipe 1.1 connected to a water tank or a cleaning liquid storage tank and an air inlet pipe 1.2 connected to a gas storage tank. The cleaning feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com