Photo-induction metal electrochemistry 3D printing device and method

A 3D printing and electrochemical technology, which is applied in the field of light-induced metal electrochemical 3D printing devices, can solve the problems of poor reconfigurability and cumbersome metal electrode production process, so as to reduce production costs, solve cumbersome production process and superior performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

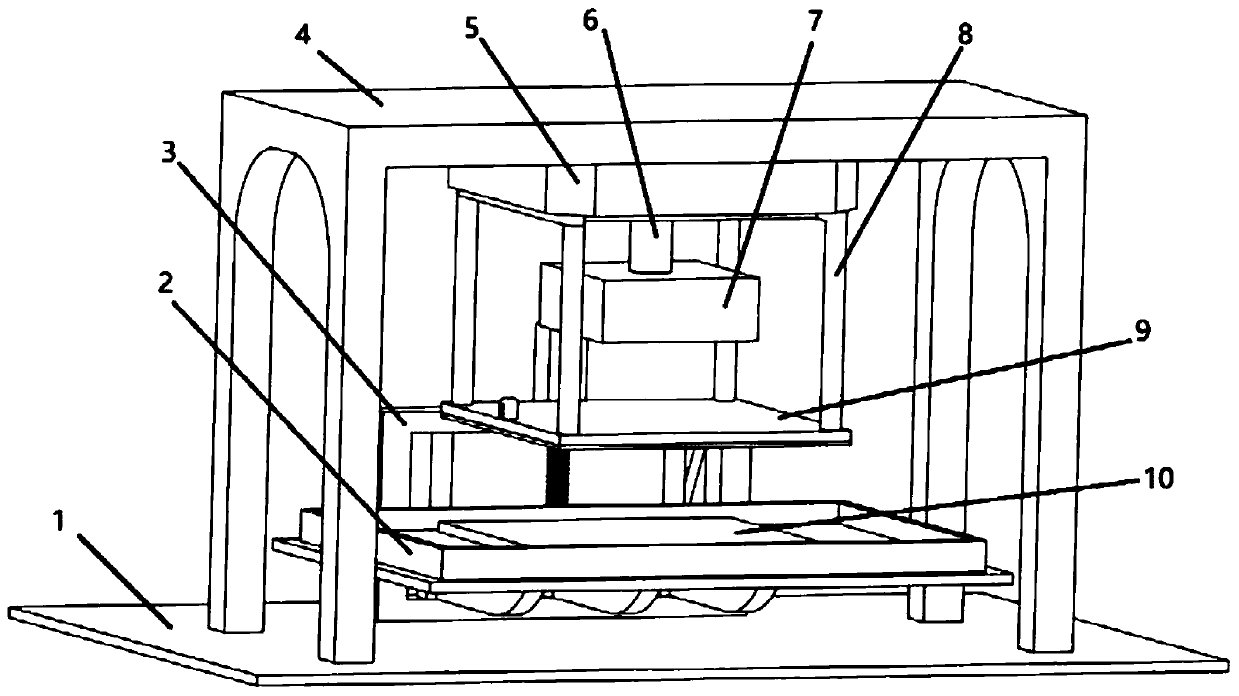

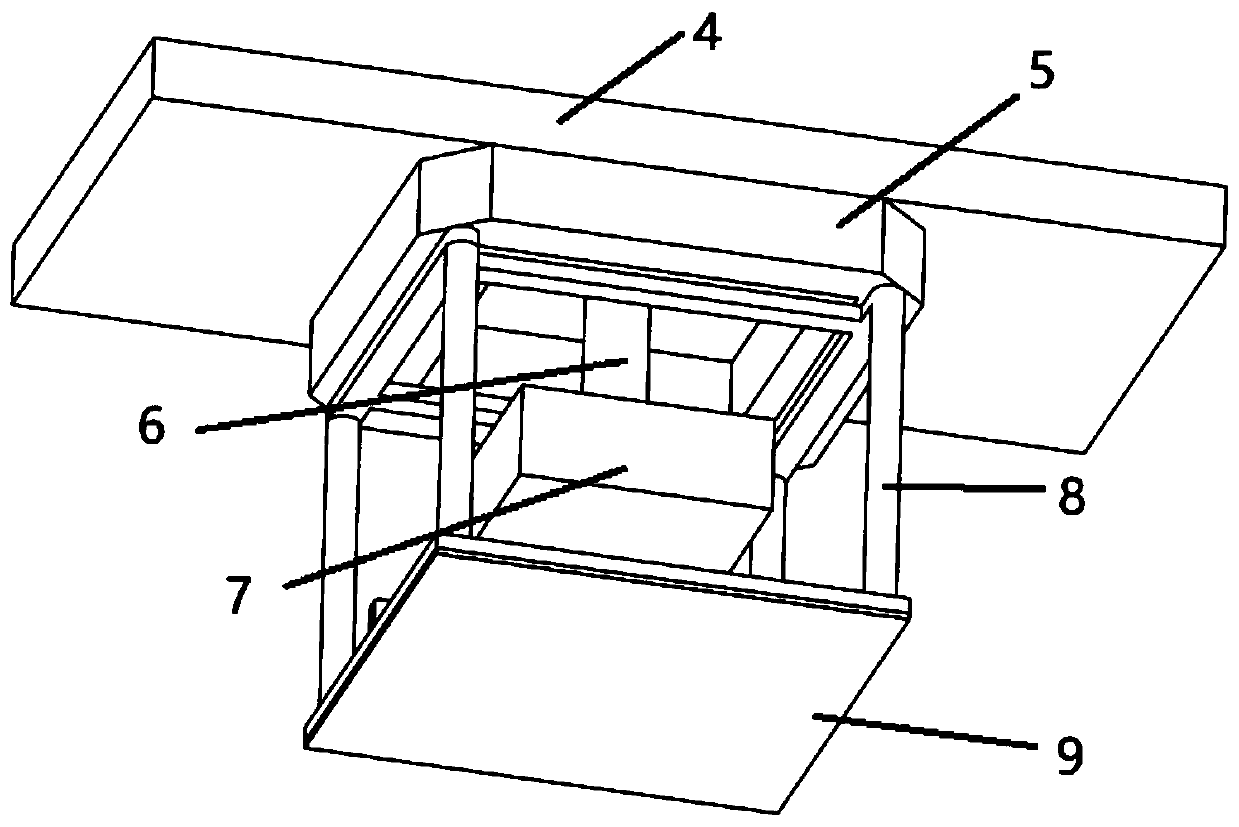

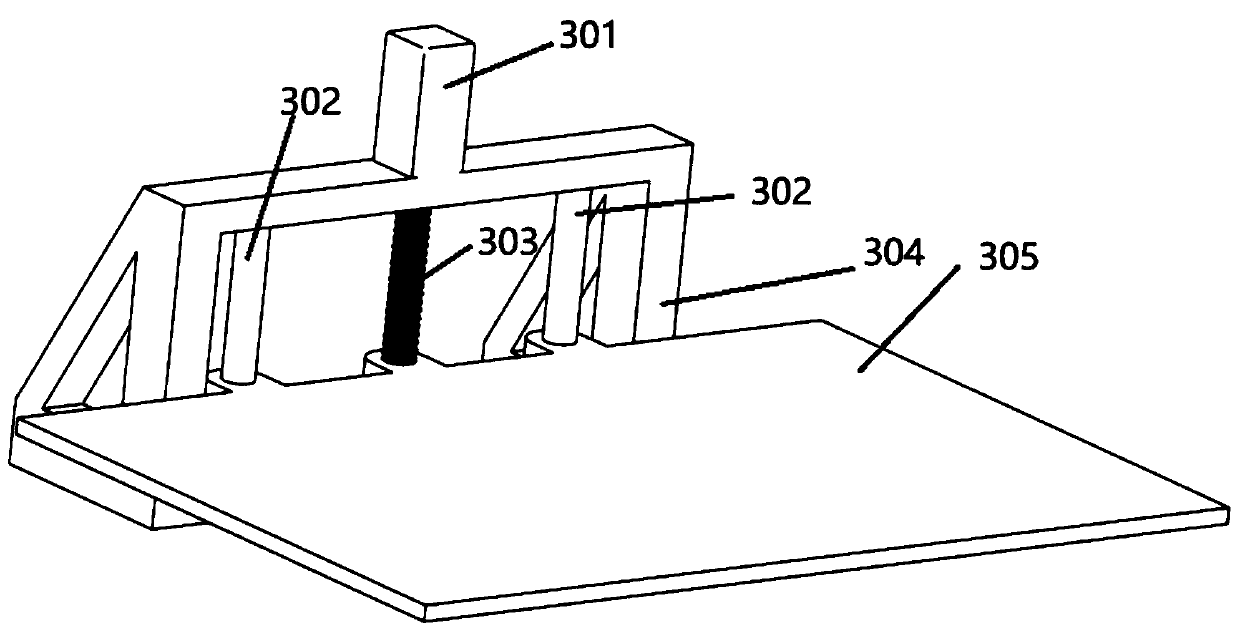

[0039] Such as figure 1 , figure 2 As shown, it includes a bottom plate 1, a liquid storage tank 2, a lifting device 3, a frame 4, a Z-axis moving device 5, a fixing device 6, a projection device 7, an installation frame 8, an anode plate 9, and a cathode plate 10, wherein the lifting device 3 and the frame 4 are installed on the bottom plate 1, the liquid storage tank 2 is fixedly installed on the lifting device 3, the cathode plate 10 is fixed at the center of the bottom of the liquid storage tank 2, and the Z-axis moving device 5 is installed on the platform installation hole 501 with bolts. Below the frame 4, the bottom surface of the Z-axis moving device 5 is in contact with the frame, the fixing device 6 is located in the center of the center hole of the Z-axis moving device 5 and connected to the frame 4, and the projection device 7 is suspended directly below the fixing device 6 connection, the mounting frame 8 is connected with the load mounting hole 502 of the Z-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com