Graphene-based gas diffusion electrode for proton exchange membrane fuel cell and preparation method of graphene-based gas diffusion electrode

A gas diffusion electrode and proton exchange membrane technology, which is applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of high consumption of noble metal catalysts, cumbersome manufacturing process, poor controllability, etc., and achieve low utilization rate of catalysts , The method is simple, and the effect of reduction is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

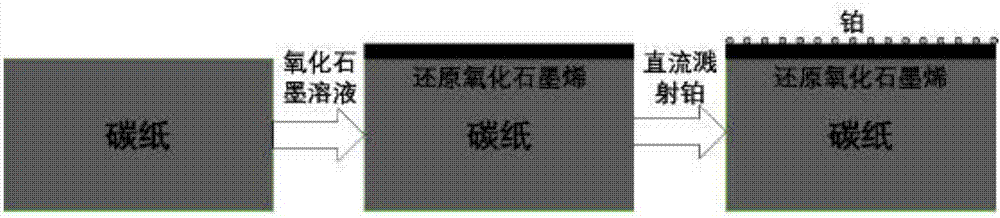

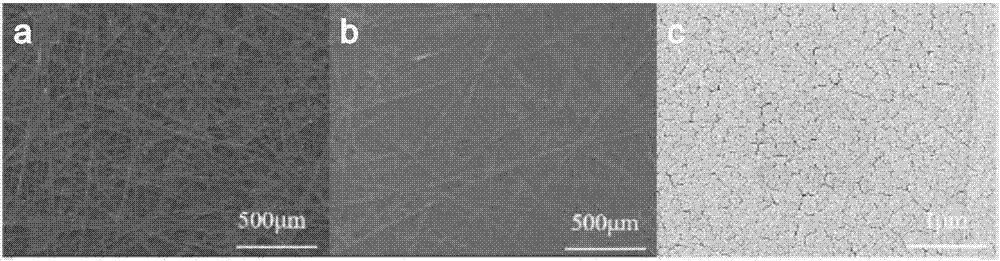

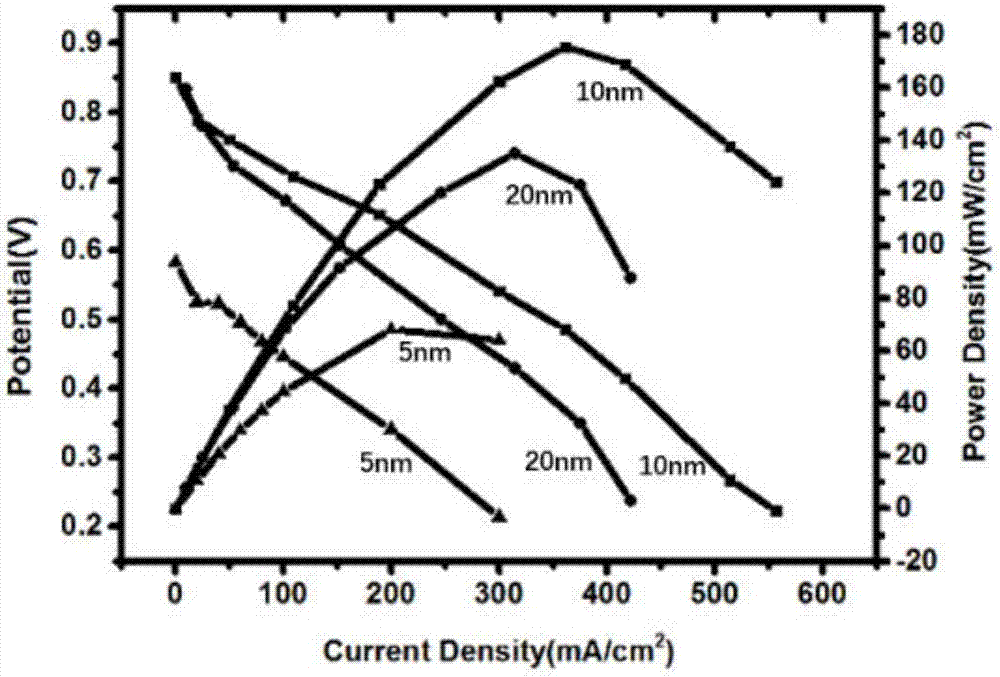

Embodiment 1

[0028] 400 ml of graphite oxide solution of 12.5 mg / ml was prepared by Hummers method. Take 6ml of graphite oxide solution, add 69ml of deionized water, stir until it is evenly mixed, and obtain 75ml of 1mg / ml graphite oxide solution. Cut 3×3cm 2 Carbon paper, put it into a watch glass, use a straw to absorb the graphite oxide solution, and evenly drop it on the carbon paper. Put the watch glass into an oven, set the temperature at 60°C, and dry it for 30 minutes, then transfer the sample to a tube furnace, feed a hydrogen-argon mixture with a hydrogen concentration of 5%, raise the temperature to 800°C, and keep it warm for 2 hours. After cooling, take it out to obtain a carbon paper covered with a reduced graphene oxide film. Use the sample as the substrate, fix it on the base of the magnetron sputtering instrument chamber, load the Pt target on the DC target position, adjust the distance between the target and the substrate to 15cm, and evacuate to 7×10 -4 Pa, set the sp...

Embodiment 2

[0033] 400 ml of graphite oxide solution of 12.5 mg / ml was prepared by Hummers method. Take 6ml of graphite oxide solution, add 69ml of deionized water, stir until it is evenly mixed, and obtain 75ml of 1mg / ml graphite oxide solution. Cut 3×3cm 2 Carbon paper, put it into a watch glass, use a straw to absorb the graphite oxide solution, and evenly drop it on the carbon paper. Put the watch glass into an oven, set the temperature at 60°C, and dry it for 30 minutes, then transfer the sample to a tube furnace, feed a hydrogen-argon mixture with a hydrogen concentration of 5%, raise the temperature to 800°C, and keep it warm for 2 hours. After cooling, take it out to obtain a carbon paper covered with a reduced graphene oxide film. Use the sample as the substrate, fix it on the base of the magnetron sputtering instrument chamber, load the Pt target on the DC target position, adjust the distance between the target and the substrate to 15cm, and evacuate to 7×10 -4 Pa, set the sp...

Embodiment 3

[0036] 400 ml of graphite oxide solution of 12.5 mg / ml was prepared by Hummers method. Take 6ml of graphite oxide solution, add 69ml of deionized water, stir until it is evenly mixed, and obtain 75ml of 1mg / ml graphite oxide solution. Cut 3×3cm 2 Carbon paper, put it into a watch glass, use a straw to absorb the graphite oxide solution, and evenly drop it on the carbon paper. Put the watch glass into an oven, set the temperature at 60°C, and dry it for 30 minutes, then transfer the sample to a tube furnace, feed a hydrogen-argon mixture with a hydrogen concentration of 5%, raise the temperature to 800°C, and keep it warm for 2 hours. After cooling, take it out to obtain a carbon paper covered with a reduced graphene oxide film. Use the sample as the substrate, fix it on the base of the magnetron sputtering instrument chamber, load the Pt target on the DC target position, adjust the distance between the target and the substrate to 15cm, and evacuate to 7×10 -4 Pa, set the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com