Customized partially-dismantled reinforced concrete structure and static crushing dismantling method thereof

A reinforced concrete, static crushing technology, applied in underwater structures, infrastructure engineering, building components, etc., can solve the problems of waste of resources, affect the safety of remaining structures, etc., and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

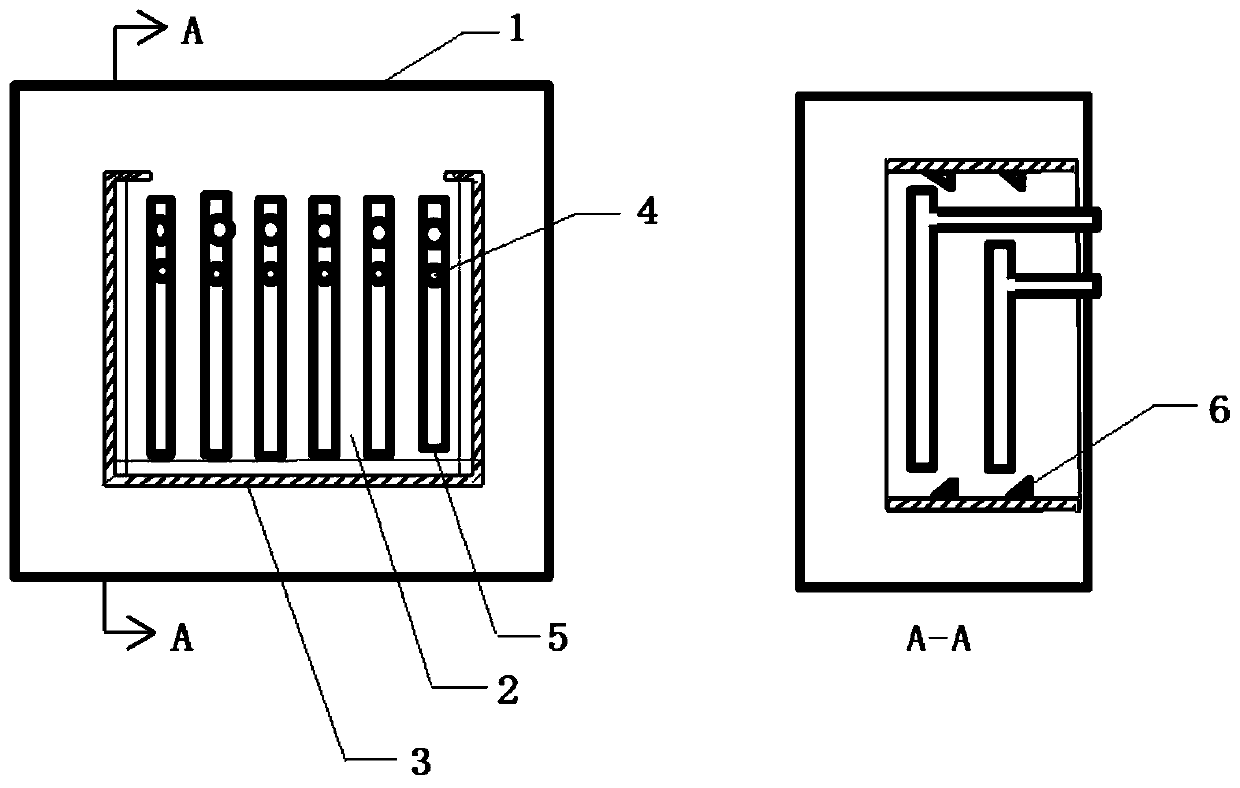

[0030] Take the subway shield ground connection wall as an example:

[0031] For the partly demolished ground connection wall of the entrance and exit of the subway shield section, its structure is divided into the part that needs to be demolished and the part that needs to be retained outside the boundary. Taking the ground connection wall with a thickness of 800mm and a height of 10000mm as an example, the specific implementation method is described.

[0032] The purpose of this project is to break a round hole with a diameter of 6700mm in the middle of the ground connection wall. At the same time, in order to ensure the safety of the tunnel door of the shield machine, when the ground connection wall is demolished, only the 600mm thick ground connection wall is removed, and the 200mm thick ground connection wall is retained. The wall serves as a temporary support structure, waiting for the shield cutterhead to break.

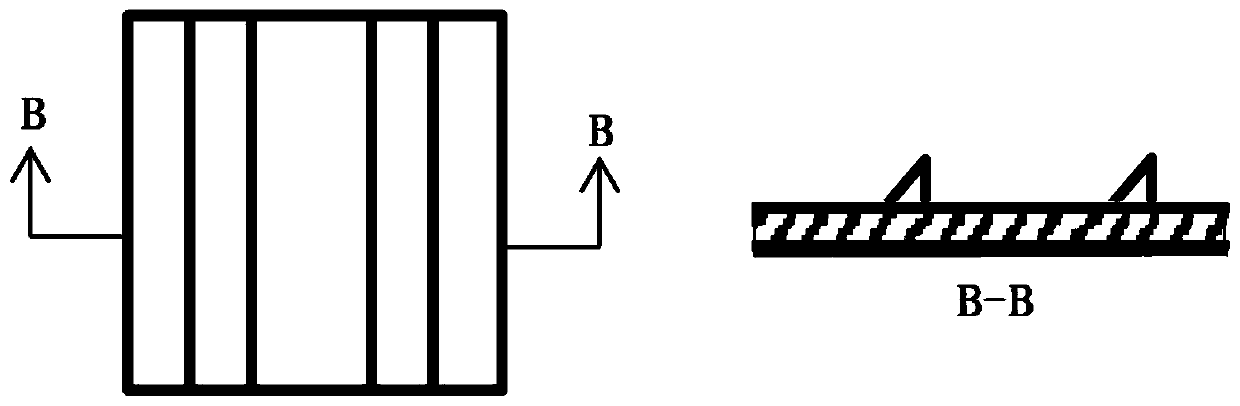

[0033] Before the ground wall concrete is poured, two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com